If you are facing roof leaks during heavy storms, worrying about wind damage during hurricane season, or dealing with constant roof repairs after harsh winter conditions, you are not alone. Many building owners struggle with traditional roofing materials that fail under extreme weather conditions, leading to expensive repairs and property damage. The good news is that 1 Inch Standing Seam Metal Roofing offers exceptional weather resistance that can protect your building for decades. This advanced roofing system features concealed fasteners and interlocking seams that create a weathertight barrier against rain, wind, snow, and hail, making it one of the most reliable roofing solutions available today.

Understanding the Weather-Resistant Design of 1 Inch Standing Seam Metal Roofing

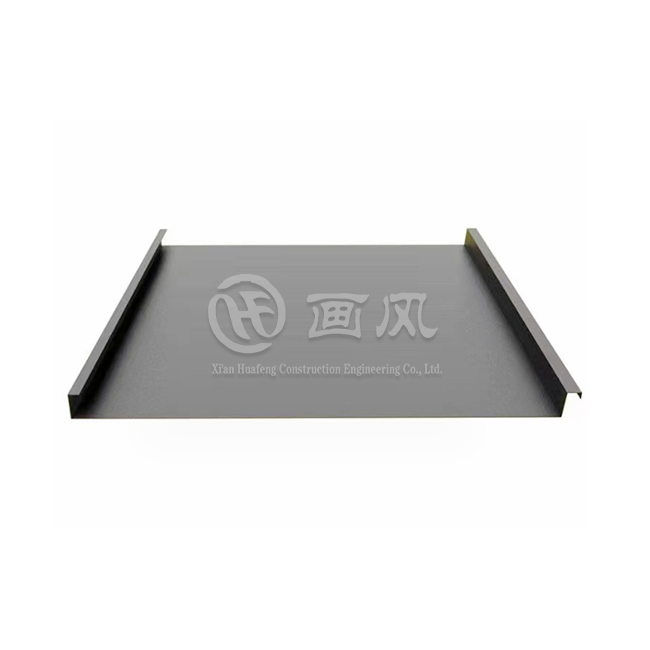

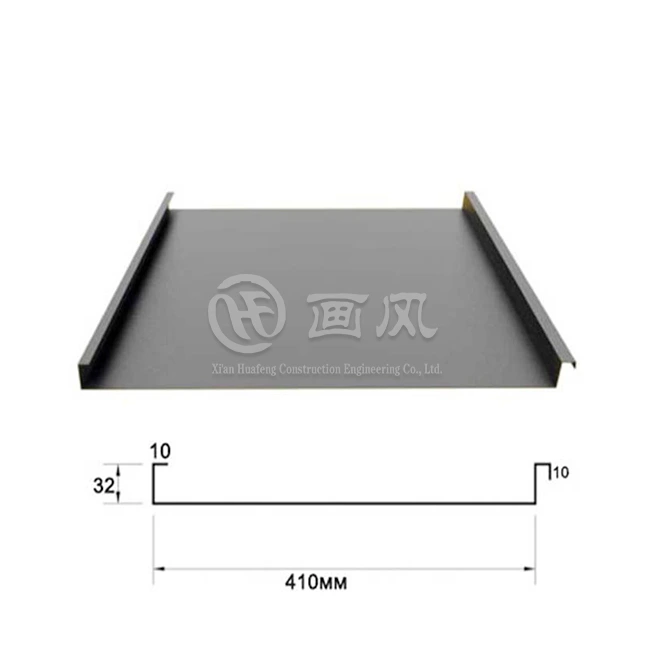

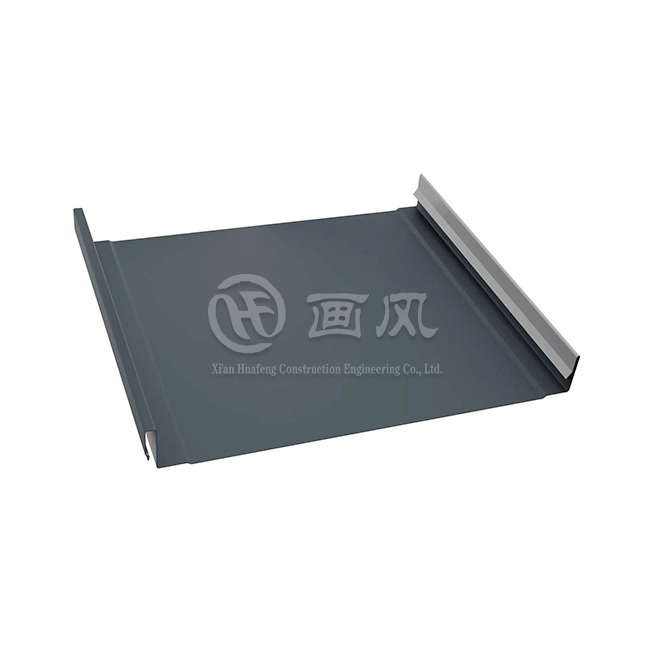

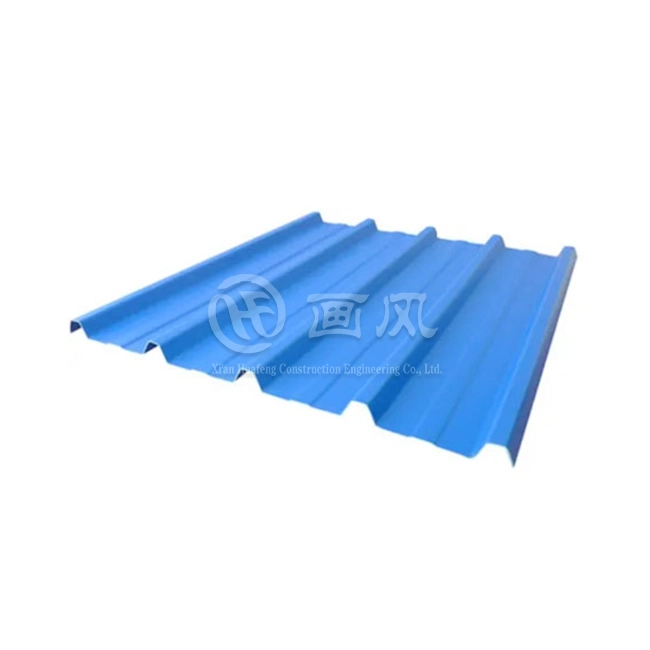

The superior weather resistance of 1 Inch Standing Seam Metal Roofing stems from its innovative design and engineering. Unlike traditional roofing systems with exposed fasteners that create potential leak points, standing seam metal roofing utilizes a concealed fastener system where metal panels interlock vertically along raised seams. The "1 inch" designation refers to the height of the standing seam protrusion, which measures approximately 25.4 millimeters and provides enhanced structural strength and water-shedding capabilities. The panel design creates a continuous waterproof surface that effectively channels water away from the building structure. Each metal panel connects to adjacent panels through mechanical seaming or snap-lock mechanisms, forming tight joints that prevent water infiltration even during driving rain or snow accumulation. The raised seam height ensures that water cannot pool on the roof surface and instead flows efficiently toward drainage systems. This design principle has been tested extensively and proven effective across various climate zones and weather conditions. Xi'an Huafeng Construction Engineering Co., Ltd. manufactures 1 Inch Standing Seam Metal Roofing panels with material thickness ranging from 0.5mm to 1.2mm, ensuring adequate strength to resist deformation under weather stress. The panels are available in widths from 300mm to 600mm and can be customized to lengths up to 12 meters, allowing for seamless installation that minimizes potential leak points. The company employs advanced roll-forming systems across seven production lines to maintain consistent quality and precise dimensional tolerances that are critical for weathertight performance.

Superior Wind Resistance Performance

Wind resistance represents one of the most critical weather-related performance factors for any roofing system, and 1 Inch Standing Seam Metal Roofing excels in this area. The interlocking panel design distributes wind loads evenly across the entire roof surface rather than concentrating stress at individual fastener points. When properly installed with appropriate clip systems, standing seam metal roofing can withstand wind speeds up to 140 miles per hour, making it suitable for hurricane-prone coastal areas and regions experiencing severe storm activity. The concealed fastening system plays a crucial role in wind resistance by protecting attachment points from direct wind exposure. Traditional roofing materials with exposed fasteners can experience fastener failure when wind forces directly impact these vulnerable connection points. In contrast, the hidden clip system used in 1 Inch Standing Seam Metal Roofing allows the panels to move slightly with thermal expansion while maintaining secure attachment to the roof structure. This flexibility prevents stress concentration that could lead to panel separation during high wind events. Xi'an Huafeng Construction Engineering Co., Ltd. conducts rigorous testing to ensure that their 1 Inch Standing Seam Metal Roofing products meet international standards including ASTM and FM Global certifications for wind uplift resistance. The company's engineering team provides load analysis and structural calculations for each project to optimize clip spacing and fastener selection based on specific wind zone requirements. With three manufacturing facilities equipped with more than 40 specialized machines, Huafeng ensures consistent production quality that meets the demanding performance requirements for wind-resistant roofing systems.

Exceptional Water Resistance and Leak Prevention

Water infiltration represents the primary cause of roof failure and building damage, making water resistance the most important performance characteristic for any roofing system. The 1 Inch Standing Seam Metal Roofing system provides exceptional protection against water penetration through multiple design features that work together to create a comprehensive waterproofing barrier. The raised seam design elevates panel connections above the flat walking surface, preventing water from reaching critical joint areas even during intense rainfall or rapid snowmelt conditions. The mechanical seaming process creates a continuous metal-to-metal connection along the entire panel length, eliminating gaps where water could potentially enter. Factory-applied sealants provide additional protection at endlap locations where panel ends meet on the roof surface. The concealed fastener design means that no screws or nails penetrate the visible panel surface, eliminating thousands of potential leak points that exist in exposed fastener roofing systems. This fundamental design advantage explains why standing seam metal roofing can be installed on roof slopes as low as 3:12 pitch while maintaining weathertight performance. The surface treatment applied to 1 Inch Standing Seam Metal Roofing panels further enhances water resistance by preventing corrosion that could compromise panel integrity over time. Xi'an Huafeng Construction Engineering Co., Ltd. offers PVDF and PE coating options that provide superior protection against moisture-related degradation. PVDF coatings, in particular, offer exceptional resistance to chalking and fading while maintaining a smooth surface that facilitates water runoff. The company's quality control processes include more than a dozen inspection steps covering adhesion, weather resistance, and color stability to ensure coating performance meets long-term durability requirements.

Material Composition and Coating Technology for Weather Protection

The material selection and surface treatment applied to 1 Inch Standing Seam Metal Roofing directly impact its weather resistance performance. Xi'an Huafeng Construction Engineering Co., Ltd. sources premium aluminum, steel, and stainless steel materials from reputable manufacturers including Baosteel, Alucosuper, and YATAI. The company maintains a comprehensive material selection brand library and conducts multiple inspections including material certification verification and third-party testing reports before accepting any incoming raw materials. Aluminum standing seam panels, typically manufactured in 0.7-0.8mm thickness with aluminum grades 3003, 3004, or 5052, provide excellent corrosion resistance naturally due to the formation of a protective oxide layer on the metal surface. These aluminum alloys contain magnesium and manganese elements that enhance strength and weather resistance while maintaining relatively lightweight properties compared to steel alternatives. Steel panels, generally produced in 0.6mm thickness as cold-rolled, galvanized, or galvalume sheet, offer higher strength characteristics suitable for structures requiring greater load-bearing capacity or resistance to impact damage from hail or debris.

Advanced Surface Treatment Systems

The surface coating applied to 1 Inch Standing Seam Metal Roofing panels serves as the first line of defense against environmental degradation including UV radiation, moisture exposure, temperature cycling, and chemical attack from atmospheric pollutants. Xi'an Huafeng Construction Engineering Co., Ltd. applies either PVDF (polyvinylidene fluoride) or PE (polyester) coating systems depending on project requirements and performance expectations. PVDF coatings, consisting of 70% PVDF resin combined with acrylic resins, represent the premium coating option offering superior color retention, chalk resistance, and chemical resistance compared to standard polyester formulations. The coating application process at Huafeng's seven color coating production lines ensures consistent film thickness and uniform coverage across the entire panel surface. The company conducts rigorous quality testing including film thickness measurement, adhesion testing, salt spray exposure, and accelerated weathering to verify coating performance before material enters production. These quality assurance measures ensure that 1 Inch Standing Seam Metal Roofing panels maintain their protective properties and aesthetic appearance throughout decades of service exposure to harsh weather conditions. Color selection also influences weather performance, with lighter colors reflecting more solar radiation and reducing heat buildup that can accelerate coating degradation. Xi'an Huafeng offers customized colors according to RAL standards and other international color systems, allowing project designers to balance aesthetic preferences with performance requirements. The company provides actual color samples for client approval before production to ensure accurate color matching and customer satisfaction.

Installation Factors That Enhance Weather Resistance

Proper installation represents a critical factor in achieving the full weather resistance potential of 1 Inch Standing Seam Metal Roofing systems. Even the highest quality panels and materials cannot provide adequate protection if installation procedures fail to follow manufacturer specifications and industry best practices. Xi'an Huafeng Construction Engineering Co., Ltd. provides comprehensive installation guidance and can deploy experienced technicians to construction sites for installation oversight or direct installation services as part of their one-stop solution approach. The substrate preparation and underlayment installation establish the foundation for weathertight roof performance. Proper drainage slope must be verified to ensure water flows toward designated drainage points rather than ponding on the roof surface. Ice and water shield underlayment should be installed in critical areas including eaves, valleys, and penetrations to provide secondary water protection. The roof deck must provide adequate structural support to prevent panel deflection that could compromise seam integrity during wind events or snow loading conditions.

Panel Seaming and Fastening Techniques

The mechanical seaming process for 1 Inch Standing Seam Metal Roofing creates the critical weather barrier that distinguishes this system from other metal roofing options. Proper seaming requires specialized equipment and trained operators to ensure consistent seam formation along the entire panel run. The seaming machine progressively folds and compresses the panel edges together, creating a double-lock joint that provides superior resistance to water infiltration and wind uplift compared to snap-together connections. Xi'an Huafeng's installation teams utilize factory-calibrated seaming equipment and follow systematic quality verification procedures to ensure every seam meets performance standards. The concealed clip fastening system allows for thermal movement of the metal panels while maintaining secure attachment to the roof structure. Clips are positioned at specified intervals along each panel seam and fastened directly to the structural deck or purlins. The next panel locks into the clip system, concealing all fasteners beneath the standing seam. This installation method eliminates exposed fastener penetrations through the panel face while accommodating the natural expansion and contraction of metal materials as temperatures fluctuate throughout daily and seasonal cycles. Xi'an Huafeng provides detailed processing drawings that specify exact panel dimensions, clip spacing, fastener types, and seaming requirements for each project. The company's design department conducts 1:1 drawing deepening of nodes in different roof areas to address transitions, penetrations, and termination details that require special attention to maintain weather integrity. Each panel component is numbered sequentially according to project specifications, ensuring that installation proceeds systematically according to the engineered design.

Long-Term Weather Performance and Durability

The true measure of weather resistance extends beyond initial installation performance to encompass decades of exposure to environmental conditions including temperature extremes, moisture cycling, UV radiation, and atmospheric pollutants. The 1 Inch Standing Seam Metal Roofing systems manufactured by Xi'an Huafeng Construction Engineering Co., Ltd. carry a 30-year warranty that demonstrates confidence in long-term durability and weather protection capabilities. This warranty coverage reflects the inherent material stability and proven performance history of properly installed standing seam metal roofing systems. Metal roofing materials do not experience the degradation mechanisms that limit the lifespan of organic roofing materials such as asphalt shingles or wooden shakes. Metal panels will not rot, crack, warp, or become brittle with age. The PVDF and PE coating systems protect the underlying metal substrate from corrosion while maintaining color stability and surface integrity. Regular maintenance inspections can identify and address minor issues such as damaged sealant or loose flashings before they develop into significant problems that compromise weather protection.

Proven Performance in Diverse Climate Conditions

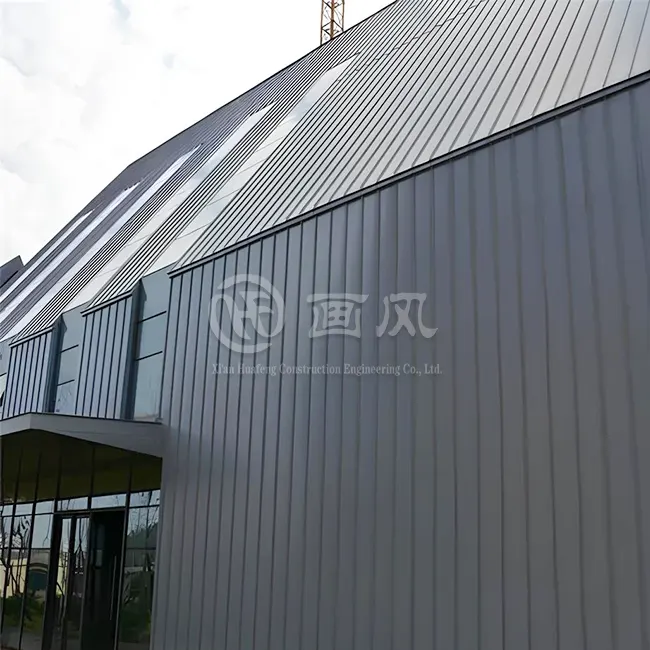

Xi'an Huafeng Construction Engineering Co., Ltd. has successfully supplied 1 Inch Standing Seam Metal Roofing for major projects including Xiongan Station Commercial Body, Xi'an International Convention and Exhibition Center, Xi'an Station East Auxiliary Building, Jinghe New City International Culture and Art Center, and Inner Mongolia Tongliao Art Museum. These diverse project locations expose the roofing systems to varied climate conditions ranging from cold northern winters with heavy snow loads to hot humid summers with intense solar radiation and severe thunderstorms. The company's comprehensive approach encompasses custom engineering design services including structural 3D modeling, load analysis, and drainage system simulation to optimize roof performance for specific site conditions. This engineering expertise ensures that each installation achieves maximum weather resistance by properly accounting for local wind speeds, snow loads, rainfall intensity, and temperature ranges. The integration of architecture, technology, and aesthetics represents Huafeng's corporate goal, producing roofing solutions that provide reliable weather protection while enhancing building appearance and functionality.

Conclusion

The 1 Inch Standing Seam Metal Roofing offers exceptional weather resistance through its concealed fastener design, interlocking panel system, premium materials, and advanced coating technology. This roofing solution provides long-lasting protection against wind, rain, snow, and hail while requiring minimal maintenance throughout its extended service life, making it an excellent investment for building owners seeking reliable weather protection.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

Xi'an Huafeng Construction Engineering Co., Ltd., established in Shaanxi Province, China in 2018, stands as a high-tech enterprise recognized by Shaanxi Province with first-level qualifications for building curtain walls and third-level qualifications for building steel structures. As a leading China 1 Inch Standing Seam Metal Roofing manufacturer, China 1 Inch Standing Seam Metal Roofing supplier, and China 1 Inch Standing Seam Metal Roofing factory, Huafeng integrates green sustainable development concepts throughout operations while specializing in design, production, sales, and construction of metal roofing systems, building curtain wall systems, and building steel structure enclosure systems.

Our comprehensive manufacturing capabilities include a raw material production plant covering 200,000 square meters in Anhui Province, plus two plate and accessories processing plants located in Hangzhou and Xi'an. We operate seven color coating production lines, one laminating production line, ten longitudinal and transverse shearing production lines, fully automatic punching production lines, and more than forty shearing machines, presses, bending machines and other specialized equipment. This advanced infrastructure enables us to provide High Quality 1 Inch Standing Seam Metal Roofing with supply capacity reaching 1000 tons per month, competitive 1 Inch Standing Seam Metal Roofing price, and reliable delivery within 15-20 days for orders meeting our 500 square meters/1 ton minimum order quantity.

Our one-stop service approach encompasses custom engineering design including structural 3D modeling and load analysis, precision manufacturing with real-time quality control and raw material traceability, and seamless installation with on-site project management and safety compliance documentation. We maintain more than 20 registered patents for roofing systems along with various trademarks and computer software certificates, while our products comply with ISO9001, ISO14000:14001, and SGS quality requirements as well as ASTM, DIN, JIS, BS, and GB/T international standards. When you need reliable 1 Inch Standing Seam Metal Roofing for sale backed by engineering expertise, manufacturing excellence, and comprehensive service support, contact Xi'an Huafeng Construction Engineering Co., Ltd. at huafeng@hfmetalroof.com to discuss your project requirements and receive a detailed quotation. Save this article for future reference when planning your next roofing project.

References

1. Sheffield Metals International. "Standing Seam Metal Roofing: Comprehensive Guide to Types, Benefits, and Applications." Technical publication on metal roofing systems and performance characteristics.

2. American Society for Testing and Materials (ASTM International). "Standard Specifications for Metal Roofing Materials and Installation Methods." Industry standards for metal roofing performance testing and qualification.

3. Metal Construction Association. "Weather Resistance of Standing Seam Metal Roofing Systems: Engineering Analysis and Performance Data." Technical research on weather resistance mechanisms in metal roofing.

4. National Roofing Contractors Association. "Metal Roofing Systems Design and Installation Manual." Professional guidance on standing seam metal roofing installation practices and quality assurance.

5. FM Global. "Property Loss Prevention Data Sheets: Metal Roof Systems." Engineering standards and testing protocols for weather resistance and wind uplift performance of metal roofing systems.