When your architectural project demands precision-engineered ventilation solutions but standard perforated materials fail to meet strict load-bearing requirements, selecting the right Aluminum Punch Plate supplier becomes critical. This comprehensive guide examines leading OEM manufacturers who deliver customized aluminium perforated sheet solutions backed by proven engineering expertise, helping you avoid costly installation delays and performance failures that plague inferior products.

Understanding Aluminum Punch Plate Manufacturing Excellence

The aluminum punch plate industry has evolved significantly over the past decade, with manufacturers now offering sophisticated solutions that extend far beyond basic perforated sheets. Modern Aluminum Punch Plate production requires advanced roll-forming systems, precision CNC punching equipment, and rigorous quality control protocols that ensure consistent hole patterns, accurate dimensions, and superior surface finishes. Leading suppliers maintain dedicated production facilities with multiple manufacturing lines capable of processing various aluminum alloys including 1050, 1060, 1100, 3003, 5052, and 6061 grades, each offering distinct mechanical properties suited to specific applications. The manufacturing process begins with premium-grade aluminum coil selection, where material traceability becomes paramount. Top-tier suppliers source aluminum from recognized brands and maintain comprehensive documentation including mill certificates and third-party testing reports. The punching operation itself demands specialized tooling designed to create clean holes without material distortion or edge burring, particularly crucial when working with thinner gauge materials. Advanced manufacturers employ real-time quality monitoring systems that track hole diameter consistency, pitch accuracy, and surface flatness throughout production runs, ensuring every aluminium perforated sheet meets exact specifications before proceeding to finishing operations.

Critical Factors in Supplier Selection

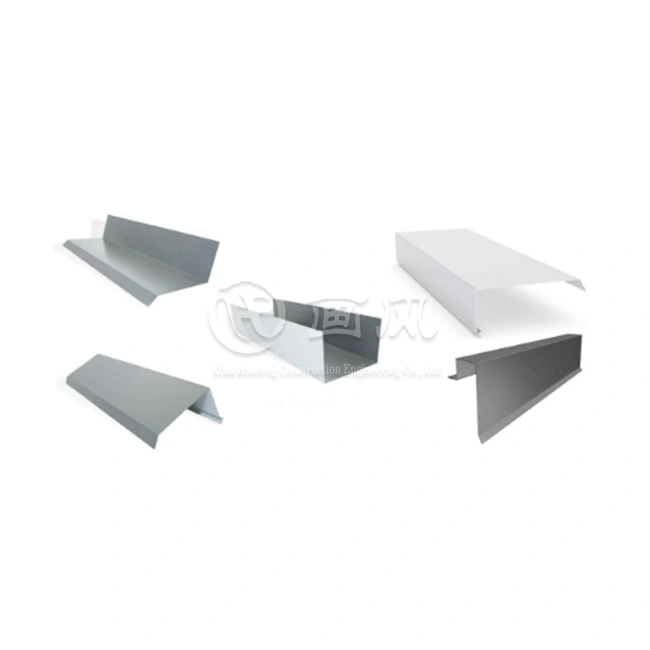

Evaluating potential Aluminum Punch Plate suppliers requires examining multiple performance indicators beyond basic pricing considerations. Production capacity stands as a fundamental criterion, with reliable suppliers demonstrating the ability to fulfill orders ranging from small custom batches to large-scale commercial projects exceeding 1000 tons monthly. Manufacturing infrastructure tells a compelling story about capability, where facilities equipped with seven or more color coating production lines, automated punching systems, and over forty precision machines signal serious industrial capacity rather than limited job-shop operations. Technical customization capabilities separate exceptional suppliers from commodity providers. The ability to produce diverse hole patterns including round, square, oblong, hexagonal, and custom-shaped perforations with apertures ranging from 1mm to 50mm demonstrates engineering flexibility essential for specialized architectural and industrial applications. Surface treatment options including anodizing, powder coating, electrophoresis, brushing, and polishing allow designers to achieve specific aesthetic and performance objectives. Furthermore, suppliers offering comprehensive design support services, including structural load analysis, drainage system simulation, and material specification advisory, add substantial value by helping clients optimize their Aluminum Punch Plate specifications before production begins.

Key Selection Criteria for Aluminum Punch Plate Suppliers

Production Infrastructure and Technical Capabilities

World-class Aluminum Punch Plate manufacturers operate integrated production ecosystems that control quality from raw material procurement through final delivery. Comprehensive facilities typically encompass raw material production plants covering 200,000 square meters or more, multiple plate processing centers strategically located to serve regional markets, and extensive machinery inventories including longitudinal and transverse shearing lines, automated punching systems, and specialized forming equipment. This vertical integration enables suppliers to maintain consistent material quality, respond rapidly to design modifications, and guarantee delivery schedules critical to construction project timelines. Technical proficiency extends beyond equipment to encompass engineering expertise accumulated through decades of project execution. Leading suppliers employ design teams capable of conducting detailed 3D structural modeling, performing load-bearing calculations, and developing optimized drainage configurations specific to each project's requirements. They maintain extensive material selection libraries documenting performance characteristics of various aluminum alloys and can recommend optimal specifications based on environmental exposure conditions, structural loads, and aesthetic preferences. The capability to produce factory samples matching exact project specifications allows clients to verify material properties, hole patterns, surface finishes, and colors before committing to full-scale production.

Quality Assurance and Certification Standards

Rigorous quality control protocols distinguish premium Aluminum Punch Plate suppliers from marginal competitors. Comprehensive incoming material inspection programs verify aluminum alloy composition, temper designation, surface quality, and mechanical properties through both visual examination and laboratory testing. Raw material suppliers must provide complete material certification documentation and third-party test reports confirming conformance to specified standards. For critical applications, full inspection of small-quantity, high-value materials ensures zero defects enter the production stream, while statistical sampling methods efficiently monitor large-volume, frequently-purchased materials without compromising quality standards. Throughout production, quality checkpoints monitor critical parameters including hole diameter accuracy, pitch consistency, edge quality, surface flatness, and dimensional tolerances. Advanced suppliers conduct over a dozen specific inspections covering appearance characteristics, size verification, salt spray resistance, coating adhesion, hardness values, impact resistance, film thickness, acid resistance, weather resistance, and color consistency. Finished product inspection protocols verify that completed aluminium perforated sheets meet all specified requirements for appearance, dimensions, flatness, and curvature before packaging. This multi-stage quality verification process, when combined with international certifications including ISO9001 quality management, ISO14001 environmental standards, and SGS product testing, provides clients with confidence that delivered materials will perform as specified throughout their service life.

Comprehensive Service Capabilities Beyond Manufacturing

Design Engineering and Technical Support

Exceptional Aluminum Punch Plate suppliers function as engineering partners rather than mere material vendors, offering comprehensive design services that optimize project outcomes. The design process typically begins with detailed analysis of architectural drawings including floor plans, elevations, and node details, where experienced engineers identify potential challenges and develop feasible alternative solutions. Through collaborative consultation with clients, suppliers help determine optimal panel types, perforation patterns, and material specifications that balance aesthetic objectives with structural performance requirements and budget constraints. Advanced suppliers employ sophisticated design software for 1:1 scale drawing development of complex nodes and connection details throughout projects. This detailed engineering work identifies potential installation challenges before fabrication begins, allowing resolution during the design phase rather than discovering problems during expensive on-site construction. Multiple rounds of communication and refinement ensure that finalized drawings address all technical requirements and receive formal approval from both parties before production commences. For projects requiring sample verification, suppliers produce physical samples incorporating confirmed parameters including board type, material grade, thickness, surface treatment method, and color specification. These sealed samples establish definitive standards for subsequent production, quality inspection, and final acceptance procedures.

Installation Support and Project Management

Superior Aluminum Punch Plate suppliers extend their service commitment through the installation phase, recognizing that even perfectly manufactured materials require proper installation to achieve design performance. Experienced suppliers provide on-site construction guidance or complete installation services tailored to project requirements and client capabilities. Pre-installation site inspections allow technical teams to verify workspace conditions, confirm tool and equipment availability, and review safety protocols with installation crews. Detailed product organization systems, where packaging divides materials by roof sections and includes identification cards with sectional floor plans and component lists, streamline on-site material handling and minimize installation errors. Technical briefing meetings conducted before installation commencement thoroughly review work procedures, safety requirements, and quality standards with all personnel involved in the project. Throughout installation, experienced technicians monitor work progress, verify proper execution of critical connections, and address any field conditions requiring design adjustments. Upon completion, comprehensive testing protocols verify system performance, with particular attention to weatherproofing integrity ensuring zero-leakage performance. Final acceptance procedures include client walkthroughs of completed installations, documentation of all work performed, and establishment of maintenance protocols to preserve long-term system performance. This comprehensive approach to installation support distinguishes full-service suppliers from those offering only manufactured products.

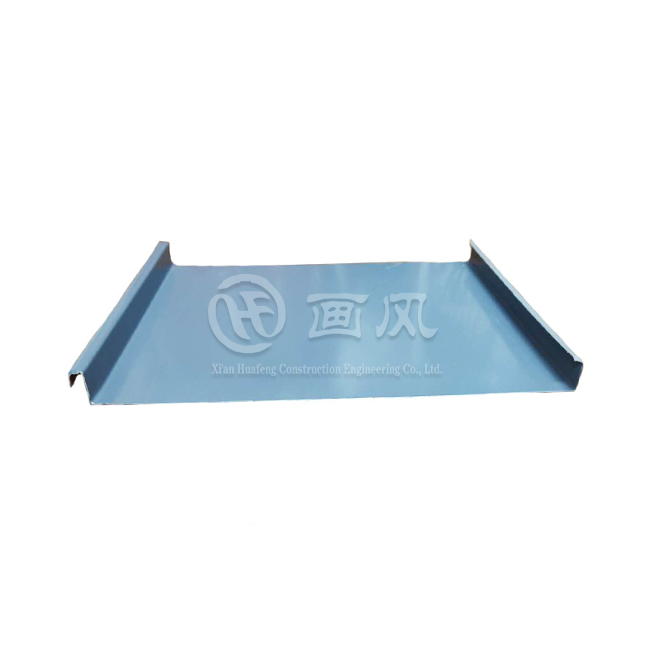

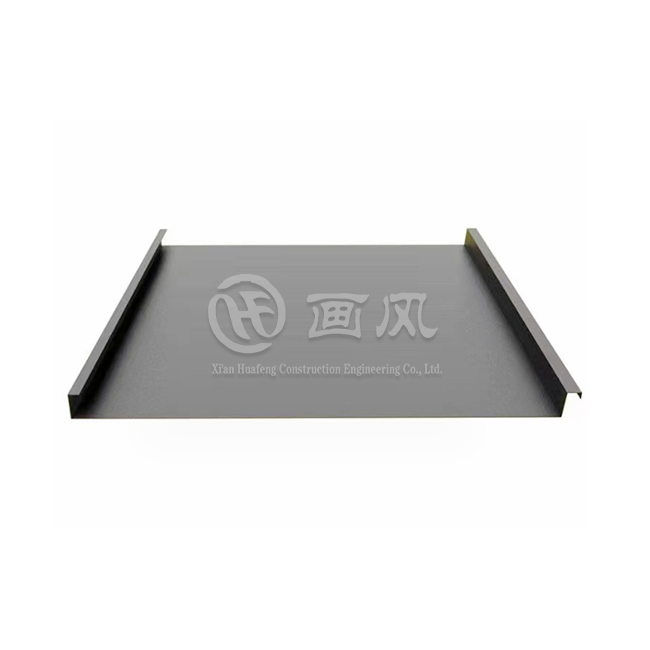

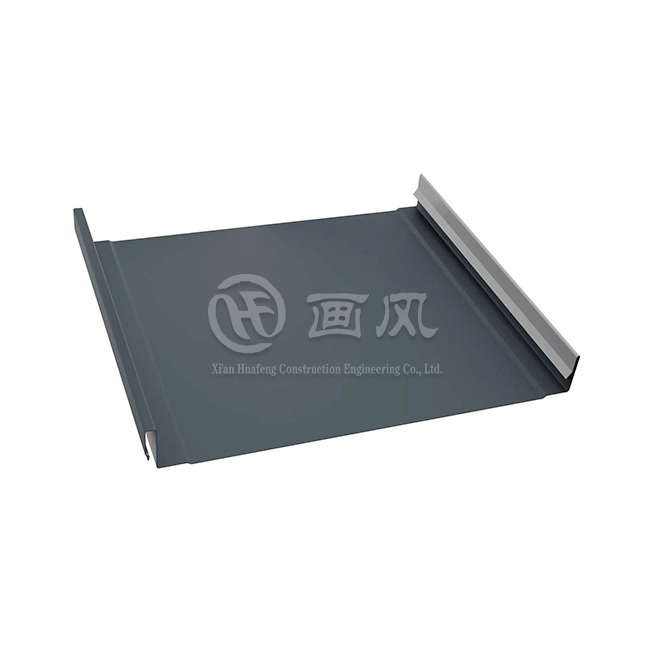

Leading Manufacturer Profile: Xi'an Huafeng Construction Engineering Co., Ltd.

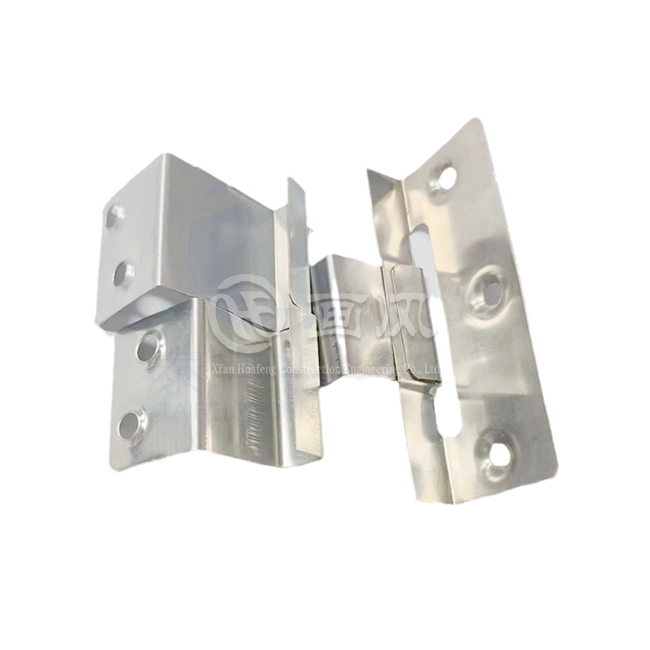

Xi'an Huafeng Construction Engineering Co., Ltd. exemplifies the comprehensive capabilities that define top-tier Aluminum Punch Plate suppliers in the global market. Established in 2018 and recognized as a Shaanxi Province high-tech enterprise in 2020, Huafeng has rapidly developed into a vertically integrated manufacturer with extensive production infrastructure spanning raw material production through finished product delivery. The company maintains a 200,000 square meter raw material production plant in Anhui Province along with two specialized plate and accessories processing facilities located in Hangzhou and Xi'an, strategically positioned to serve major construction markets throughout China and international export destinations. Huafeng's manufacturing capabilities include seven color coating production lines, one laminating line, ten longitudinal and transverse shearing production lines, fully automated punching systems, and over forty specialized machines including shearing equipment, presses, and precision bending machines. This extensive equipment inventory enables production of diverse aluminium perforated sheet specifications with hole patterns ranging from standard round and square configurations to custom-designed shapes meeting unique project requirements. The company's product portfolio extends beyond Aluminum Punch Plate to encompass standing seam metal roofing panels, aluminum-magnesium-manganese plates, titanium-zinc plates, corrugated roofing and wall sheets, flat lock panels, and comprehensive roofing system accessories, positioning Huafeng as a single-source supplier for complete metal building envelope systems.

The company's commitment to innovation is evidenced by over twenty registered patents for roofing systems along with multiple trademarks and software certifications. Huafeng maintains rigorous quality standards complying with ISO9001 quality management, ISO14001 environmental management, and SGS testing protocols. The company's engineering capabilities encompass complete project lifecycle support from initial design consultation through final installation and maintenance, with proven experience executing major commercial and institutional projects including the Xiongan Station Commercial Body, Xi'an International Convention and Exhibition Center, Jinghe New City International Culture and Art Center, and Inner Mongolia Tongliao Art Museum, among numerous other high-profile installations.

Conclusion

Selecting the right Aluminum Punch Plate supplier requires evaluating production capacity, technical capabilities, quality certifications, and comprehensive service offerings that extend beyond basic manufacturing to encompass design engineering, customization flexibility, and installation support throughout project execution.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

As a China Aluminum Punch Plate factory with over three decades of engineering experience, Xi'an Huafeng Construction Engineering Co., Ltd. stands ready to serve as your trusted China Aluminum Punch Plate supplier and China Aluminum Punch Plate manufacturer. Our integrated facilities deliver High Quality Aluminum Punch Plate with competitive Aluminum Punch Plate price points, offering Aluminum Punch Plate for sale through flexible China Aluminum Punch Plate wholesale arrangements. With seven production lines, twenty-plus machines, international certifications including CE, ISO, and SGS, plus proven collaboration with Fortune 500 companies, we provide customized solutions backed by one-stop service from raw materials through accessories. Our 30-year warranty, 15-20 day delivery, free samples, and comprehensive design optimization distinguish us in the market. Contact our team at huafeng@hfmetalroof.com today to discuss your project requirements and discover how our expertise transforms architectural visions into reality.

References

1. "Metal Roofing Systems: Design and Installation Best Practices" - American Institute of Steel Construction, Technical Committee on Metal Building Systems

2. "Aluminum Alloy Selection Guide for Architectural Applications" - The Aluminum Association, Standards and Data Division

3. "Perforated Metal Products: Manufacturing Processes and Quality Standards" - International Organization for Standardization, ISO/TC 164 Mechanical Testing Committee

4. "Building Envelope Systems: Material Selection and Performance Criteria" - National Institute of Building Sciences, Building Enclosure Technology and Environment Council

5. "Quality Management Systems for Metal Fabrication Industries" - American Society for Quality, Construction Division Standards Board