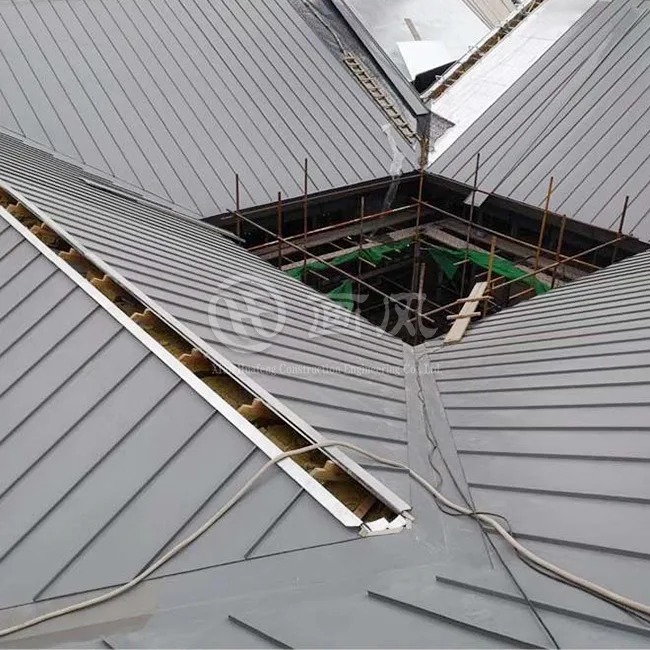

Are you struggling with finding the right roofing solution that not only protects your building but also maximizes your solar energy investment? Many industrial and commercial property owners face this challenge: traditional flat roofs waste valuable surface area, while inadequate structural support limits solar panel installation capacity. Deep Trapezoidal Roof Panels solve this critical problem by combining exceptional load-bearing capacity with optimal solar mounting compatibility, transforming your roof into a high-performance energy generation asset that delivers both protection and profitability for decades.

Why Deep Trapezoidal Roof Panels Are Ideal for Solar PV Systems?

Deep Trapezoidal Roof Panels have emerged as the preferred substrate for solar photovoltaic installations across industrial, commercial, and large-span structures. The unique geometry of these panels, characterized by their raised ribs and deep valleys, creates an inherently strong foundation that addresses multiple challenges simultaneously. Unlike conventional roofing materials, Deep Trapezoidal Roof Panels offer a distinctive combination of structural integrity and solar-ready design that dramatically simplifies the installation process while enhancing long-term system performance. The fundamental advantage lies in the panel's trapezoidal profile itself. This geometric design distributes loads efficiently across the surface, allowing for greater spans between structural supports compared to flat or corrugated alternatives. When solar arrays are mounted onto Deep Trapezoidal Roof Panels, the raised ribs serve as natural attachment points that eliminate the need for roof penetrations through the waterproof surface. Instead, mounting brackets secure directly to these elevated sections using specialized fastening systems that maintain weatherproofing integrity while providing exceptional pullout resistance. This design consideration becomes particularly valuable when considering the additional dead load and wind uplift forces that solar installations introduce to existing roof structures.

Superior Load Distribution Characteristics

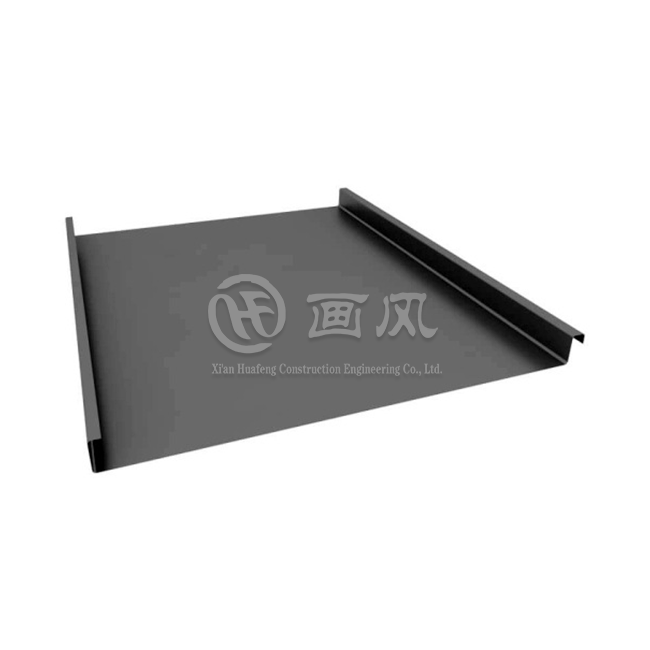

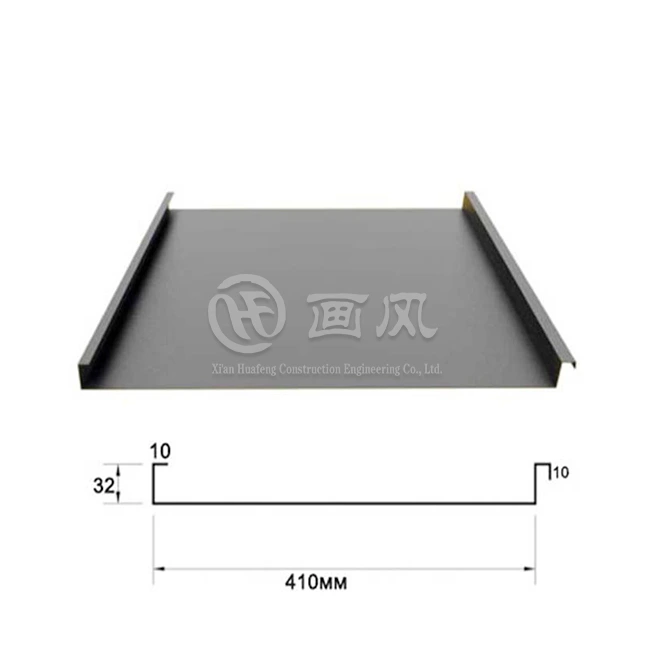

The engineering principles behind Deep Trapezoidal Roof Panels make them exceptionally well-suited for supporting photovoltaic systems. The high-rib profile, typically ranging from 75mm to 120mm in wave height, creates substantial cross-sectional moment of inertia that resists bending under concentrated loads. When solar mounting rails are attached to the panel crowns, the trapezoidal geometry naturally channels forces through the strongest portions of the profile, minimizing stress concentrations and potential failure points. This becomes critically important for large-scale commercial installations where dozens or hundreds of solar modules create cumulative loading that must be safely transferred to the building's primary structure. Deep Trapezoidal Roof Panels manufactured from high-strength materials such as G550 galvanized steel or AZ150 aluminum-zinc coated steel provide compressive strengths exceeding 300 MPa, delivering bearing capacities between 1.0 and 5.0 kN/m² depending on support spacing and panel thickness. These specifications align perfectly with the typical loading requirements of solar PV systems, which generally impose additional dead loads of 10-15 kg/m² for the modules themselves, plus mounting hardware and potential snow accumulation. The panels' ability to span 6 to 30 meters when properly supported by purlin systems means that solar installers can work with existing structural layouts without requiring costly reinforcements or modifications.

Streamlined Mounting System Integration

The compatibility between Deep Trapezoidal Roof Panels and modern solar mounting systems represents one of the most significant advantages for project developers and installers. Purpose-designed mounting brackets attach directly to the panel ribs using self-drilling screws or blind rivets that include integrated EPDM or neoprene washers, creating watertight seals at each penetration point. This direct-attachment method eliminates the need for bulky standoff systems or ballasted arrays that consume valuable roof space and add unnecessary weight to the structure. Short rail mounting systems, which have become the industry standard for trapezoidal roof applications, consist of aluminum profile sections typically 300-600mm in length that span between adjacent panel ribs. These rails accept standard mid-clamps and end-clamps that secure the solar module frames, creating a modular installation approach that significantly reduces labor time compared to traditional long-rail systems. Advanced insertion profile systems take this concept further by eliminating module clamps entirely, allowing panels to slide into pre-positioned channels for even faster deployment. Deep Trapezoidal Roof Panels with standardized rib spacing of 250-300mm work seamlessly with these mounting solutions, providing consistent attachment geometry across the entire roof surface.

Cost-Effectiveness and Installation Efficiency

The economic advantages of combining Deep Trapezoidal Roof Panels with solar PV systems extend well beyond initial material costs. When evaluated across the full project lifecycle, this roofing solution delivers measurable savings through reduced installation time, minimized labor requirements, and enhanced system longevity that protects the substantial investment in solar equipment. Property owners and developers increasingly recognize that the upfront cost differential between standard roofing and Deep Trapezoidal Roof Panels designed for solar integration becomes negligible when factoring in the avoided expenses of structural reinforcement and complex mounting solutions. Installation efficiency represents a critical cost driver in commercial solar projects where labor comprises 30-40% of total project expenses. Deep Trapezoidal Roof Panels enable installation teams to work at approximately 50% faster speeds compared to applications requiring custom mounting solutions or extensive roof modifications. The panels arrive at job sites with clearly defined attachment zones where mounting brackets can be positioned without complex calculations or field adjustments. Pre-drilling is typically unnecessary due to the availability of high-performance self-tapping fasteners designed specifically for metal roof applications. This streamlined approach reduces crew time on-site, minimizes equipment rental costs, and accelerates project timelines, allowing faster commissioning and earlier revenue generation from solar production.

Material Optimization and Customization Flexibility

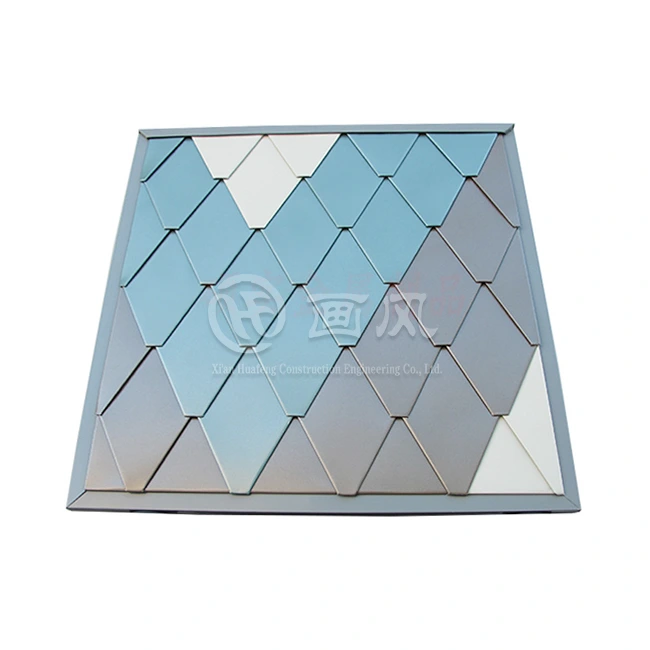

Xi'an Huafeng Construction Engineering Co., Ltd. manufactures Deep Trapezoidal Roof Panels with specifications precisely tailored to solar PV applications. The company's production capabilities include panel widths ranging from 750-1500mm and thicknesses from 0.4-1.2mm, with customization options that address specific project requirements. This flexibility allows structural engineers to specify the optimal balance between material cost and performance characteristics based on actual loading conditions, span requirements, and local climate factors. For solar installations, the recommended thickness range of 0.6-1.0mm provides sufficient fastener pullout strength while maintaining cost-effectiveness for large roof areas. The availability of multiple coating systems further enhances the value proposition. PE (polyester), HDP (high-durability polyester), and PVDF (polyvinylidene fluoride) finishes offer progressively enhanced UV resistance and color stability, with PVDF coatings providing 30-year warranties that match or exceed the operational lifespan of most photovoltaic systems. This synchronization of material durability ensures that the roof substrate maintains its protective and structural functions throughout the solar array's productive life, eliminating premature replacement costs and the need to remove and reinstall expensive solar equipment. Deep Trapezoidal Roof Panels with appropriate coatings resist chalking, fading, and corrosion even in aggressive coastal or industrial environments where salt spray and chemical exposure would rapidly degrade lesser materials.

Reduced Long-Term Maintenance Requirements

The inherent durability of Deep Trapezoidal Roof Panels translates directly into lower lifecycle maintenance costs for solar-equipped buildings. The elevated rib design naturally sheds water and debris, preventing pooling that could lead to accelerated corrosion or biological growth. When solar arrays are installed above these panels, the additional shading actually protects the roof surface from direct UV exposure, potentially extending service life beyond initial warranty periods. Fastening systems that utilize the panel ribs rather than penetrating the pan areas concentrate potential maintenance attention points in locations that are easily accessible and inspectable without disturbing the weatherproof envelope. For facility operators managing large building portfolios, the combination of Deep Trapezoidal Roof Panels and solar PV systems creates operational efficiencies that extend beyond energy cost savings. Routine solar array maintenance, which typically involves semi-annual inspections and occasional module cleaning, can be coordinated with roof condition assessments, consolidating contractor mobilization costs and minimizing disruption to building operations. The robust nature of properly installed Deep Trapezoidal Roof Panels means that technicians can safely access and work around solar equipment without concerns about damaging fragile roofing materials, reducing liability exposure and insurance costs associated with rooftop activities.

Technical Performance Advantages for Solar Applications

Deep Trapezoidal Roof Panels deliver specific technical benefits that directly enhance solar system performance and reliability. The three-dimensional geometry creates air circulation channels beneath mounted solar modules, providing passive convective cooling that improves photovoltaic efficiency. Solar panels generate maximum power at lower operating temperatures, with most crystalline silicon modules losing approximately 0.4-0.5% of rated capacity for each degree Celsius above their nominal operating cell temperature. The enhanced ventilation provided by Deep Trapezoidal Roof Panels can reduce module temperatures by 5-10°C compared to tight roof-parallel mounting on flat substrates, translating to 2-5% gains in annual energy production without any additional equipment cost. The structural rigidity of Deep Trapezoidal Roof Panels also minimizes dynamic movement and vibration that could compromise electrical connections or accelerate fatigue in solar mounting hardware. Wind-induced oscillations, which create cyclic loading on fasteners and module frames, are effectively damped by the panel's high stiffness-to-weight ratio. This becomes particularly important in regions subject to severe weather events where wind gusts can exceed 150 km/h. Properly engineered systems combining Deep Trapezoidal Roof Panels with appropriately rated mounting components routinely withstand wind speeds of 55 m/s (200 km/h) and snow loads of 1.4 kN/m², meeting the most stringent building code requirements for exposed locations while ensuring uninterrupted solar production and protecting substantial equipment investments.

Electrical System Integration Considerations

The metal composition of Deep Trapezoidal Roof Panels requires careful attention to electrical grounding and bonding when integrated with solar PV systems. Modern mounting brackets incorporate features that establish reliable electrical continuity between the solar array's grounding conductor and the roof structure, satisfying electrical code requirements for equipment grounding. The conductive path through Deep Trapezoidal Roof Panels to the building's grounding electrode system provides effective lightning protection and fault current dissipation, critical safety functions that protect both personnel and equipment. When properly implemented using fasteners with star washers or toothed interfaces that penetrate protective coatings, this integrated grounding approach eliminates the need for separate grounding conductors while providing superior performance compared to isolated mounting systems. The reflective properties of Deep Trapezoidal Roof Panels coated with light-colored finishes can contribute to enhanced solar production through albedo effects. Solar modules installed at appropriate heights above reflective roof surfaces receive additional irradiance from ground-reflected light, a phenomenon particularly beneficial for bifacial solar modules that can generate power from both front and rear surfaces. While the primary energy production comes from direct and diffuse sky radiation, the incremental gains from roof reflection can add 3-8% to overall system output, effectively increasing the return on investment without requiring additional module capacity. This synergy between Deep Trapezoidal Roof Panels and advanced solar technologies represents an emerging optimization strategy for maximizing energy yield from available roof areas.

Thermal Management and Building Energy Performance

Beyond supporting solar equipment, Deep Trapezoidal Roof Panels contribute to overall building energy efficiency through their thermal characteristics. When specified with composite sandwich construction incorporating rock wool or polyurethane foam insulation, these panels provide R-values sufficient to meet modern energy codes while supporting solar arrays on their exterior surface. This integrated approach delivers both renewable energy generation and reduced HVAC energy consumption, addressing building energy performance from multiple directions simultaneously. The solar array itself acts as additional shading, reducing solar heat gain through the roof assembly during summer months and providing a modest insulating effect during winter periods when air gaps beneath modules trap still air. For industrial facilities and warehouses where internal climate control represents significant operating costs, the combination of insulated Deep Trapezoidal Roof Panels and roof-mounted solar generation can reduce total energy consumption by 40-60% compared to buildings with conventional roofing and grid-supplied electricity. The solar production directly offsets electrical demand during peak daytime hours when both cooling loads and electricity rates reach maximum levels, while the enhanced roof insulation reduces baseline heating and cooling requirements around the clock. This multiplicative effect on energy performance makes Deep Trapezoidal Roof Panels an essential component of comprehensive building sustainability strategies that target net-zero or near-net-zero energy consumption.

Project Planning and Specification Guidance

Successful integration of Deep Trapezoidal Roof Panels with solar PV systems requires careful planning during the design phase to optimize both structural performance and energy production. Structural engineers must evaluate the cumulative effects of roof self-weight, solar equipment, environmental loads, and construction live loads to properly size the panel gauge, purlin spacing, and primary structural members. Deep Trapezoidal Roof Panels with wave heights of 75-100mm typically prove optimal for commercial solar applications, providing the necessary strength for 6-15 meter purlin spans while maintaining cost-effectiveness for large roof areas. Projects requiring longer spans or heavier snow loading conditions may specify T-100 or higher profiles with wave heights up to 120mm and thicker base material. Panel orientation decisions significantly impact both structural economy and solar system layout. When Deep Trapezoidal Roof Panels are installed with ribs running perpendicular to the building's long axis, solar modules oriented in landscape format allow mounting rails to follow the rib lines, minimizing rail lengths and associated costs. Conversely, portrait-oriented modules require rails to span between ribs, necessitating slightly longer rail segments but potentially optimizing electrical string layouts for inverter compatibility. Coordination between the roofing contractor, structural engineer, and solar designer during early project phases prevents costly modifications and ensures that the as-built roof configuration supports efficient solar installation.

Material Selection and Environmental Durability

The choice of base material and coating system for Deep Trapezoidal Roof Panels should align with the project's service life expectations and environmental exposure conditions. For solar applications where 25-30 year operational lifespans are standard, specifying panels with AZ150 aluminum-zinc coatings or higher provides superior corrosion resistance compared to standard galvanized steel, particularly in coastal regions or areas with significant industrial pollution. The zinc-aluminum-magnesium coating technology employed in AZ150 substrates forms a protective barrier that self-heals minor scratches and resists red rust formation even when exposed to salt spray or acidic precipitation, ensuring that the roof maintains its structural integrity and watertight performance throughout the solar system's productive life. PVDF coating systems, while commanding premium pricing, deliver unmatched color stability and gloss retention over multi-decade exposure periods. For building owners prioritizing aesthetic appearance or operating facilities where corporate branding and visual presentation carry significant value, the additional investment in PVDF-coated Deep Trapezoidal Roof Panels proves justified through eliminated repainting costs and sustained curb appeal. These coatings also provide superior resistance to mildew and algae growth, maintaining clean surfaces that reflect rather than absorb solar radiation, contributing to both building energy efficiency and solar module cooling through reduced infrared reradiation from the roof surface.

Installation Quality Assurance and Best Practices

Achieving optimal performance from Deep Trapezoidal Roof Panels supporting solar PV systems demands strict adherence to installation best practices and manufacturer specifications. Fastener selection represents a critical decision point where using inappropriate or substandard hardware can compromise both structural performance and waterproofing. Self-drilling screws specifically engineered for solar mounting applications incorporate features such as bi-metal construction (hardened point with ductile shank), integrated EPDM washers, and hex-washer heads that provide consistent clamping force without overtightening. These fasteners must achieve minimum pullout values appropriate for the panel gauge and expected loading, typically requiring 1.5-2.5 kN withdrawal resistance for standard residential systems and higher values for commercial installations subject to extreme wind exposure. Xi'an Huafeng Construction Engineering Co., Ltd. provides comprehensive installation documentation and on-site technical support to ensure that Deep Trapezoidal Roof Panels are properly integrated with solar mounting systems. The company's experienced installation teams conduct pre-construction site surveys to verify substrate conditions, confirm structural adequacy, and identify any potential complications before materials are delivered. During installation, quality control inspections verify proper fastener engagement, adequate sealing at all penetrations, correct module alignment and spacing, and electrical bonding continuity. This attention to installation detail prevents common failure modes such as water infiltration, inadequate load transfer, or electrical code violations that could compromise system performance or create long-term liability issues.

Conclusion

Deep Trapezoidal Roof Panels deliver unmatched benefits for solar PV mounting through superior load capacity, streamlined installation, and long-term durability that protects your energy investment while maximizing production efficiency and minimizing lifecycle costs.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

Xi'an Huafeng Construction Engineering Co., Ltd. stands as a recognized high-tech enterprise specializing in metal roofing systems, building curtain walls, and steel structure enclosures since 2018. With first-level qualification for building curtain walls and third-level qualification for building steel structures, Huafeng operates three advanced manufacturing facilities: a 200,000-square-meter raw material production plant in Anhui, plus specialized plate and accessories processing plants in Hangzhou and Xi'an. Our seven color coating production lines and more than 40 precision machines enable production capacity exceeding 1,000 tons monthly.

As a leading China Deep Trapezoidal Roof Panels factory and China Deep Trapezoidal Roof Panels supplier, we provide High Quality Deep Trapezoidal Roof Panels at competitive Deep Trapezoidal Roof Panels price points for both China Deep Trapezoidal Roof Panels wholesale and Deep Trapezoidal Roof Panels for sale to global markets. Our position as a premier China Deep Trapezoidal Roof Panels manufacturer is reinforced by more than 20 registered patents, comprehensive CE, ISO9001, ISO14001, and SGS certifications, plus successful collaborations with Fortune 500 companies on landmark projects including Xiongan Station, Xi'an International Convention Center, and Inner Mongolia Tongliao Art Museum.

We deliver one-stop solutions encompassing structural 3D modeling, custom manufacturing with 15-20 day delivery, on-site installation guidance, and ongoing maintenance support. Our commitment to green sustainable development and architectural aesthetics ensures your Deep Trapezoidal Roof Panels meet the highest international standards including ASTM, DIN, JIS, BS, and GB/T specifications. Contact our technical team at huafeng@hfmetalroof.com to discuss your solar PV mounting requirements and receive expert specification guidance that maximizes both structural performance and energy production for your project.

References

1. Solar Mounting Systems for Trapezoidal Metal Roofs: Design Considerations and Installation Guidelines - National Renewable Energy Laboratory (NREL), 2023

2. Structural Load Analysis for Photovoltaic Systems on Industrial Metal Roofing - American Society of Civil Engineers (ASCE), Journal of Structural Engineering, Volume 149, 2024

3. Corrosion Resistance of Metallic Roof Coatings in Solar PV Applications - International Organization for Standardization (ISO), Technical Committee 156, 2023

4. Wind Load Effects on Solar Arrays Mounted to Trapezoidal Roof Profiles - European Committee for Standardization (CEN), EN 1991-1-4 Commentary, 2024

5. Thermal Performance of Building-Integrated Photovoltaic Systems with Metal Roof Substrates - Building Research Establishment (BRE), Solar Energy Materials and Solar Cells, Volume 245, 2024