Choosing the wrong roofing system can cost you thousands in repairs, premature replacements, and structural failures. When selecting between Deep Trapezoidal Roof Panels and corrugated sheets for your industrial warehouse or commercial building, the decision impacts not only your initial investment but decades of performance, maintenance costs, and structural integrity. Deep Trapezoidal Roof Panels emerge as the superior choice for large-span structures requiring exceptional load-bearing capacity, spanning 15 to 30 meters with minimal support while delivering superior drainage performance and modern architectural aesthetics that corrugated sheets simply cannot match.

Understanding Deep Trapezoidal Roof Panels and Their Structural Advantages

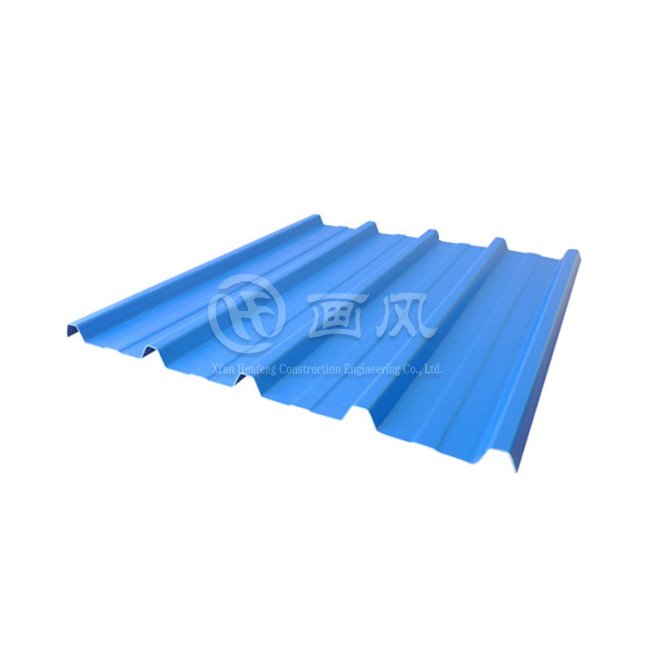

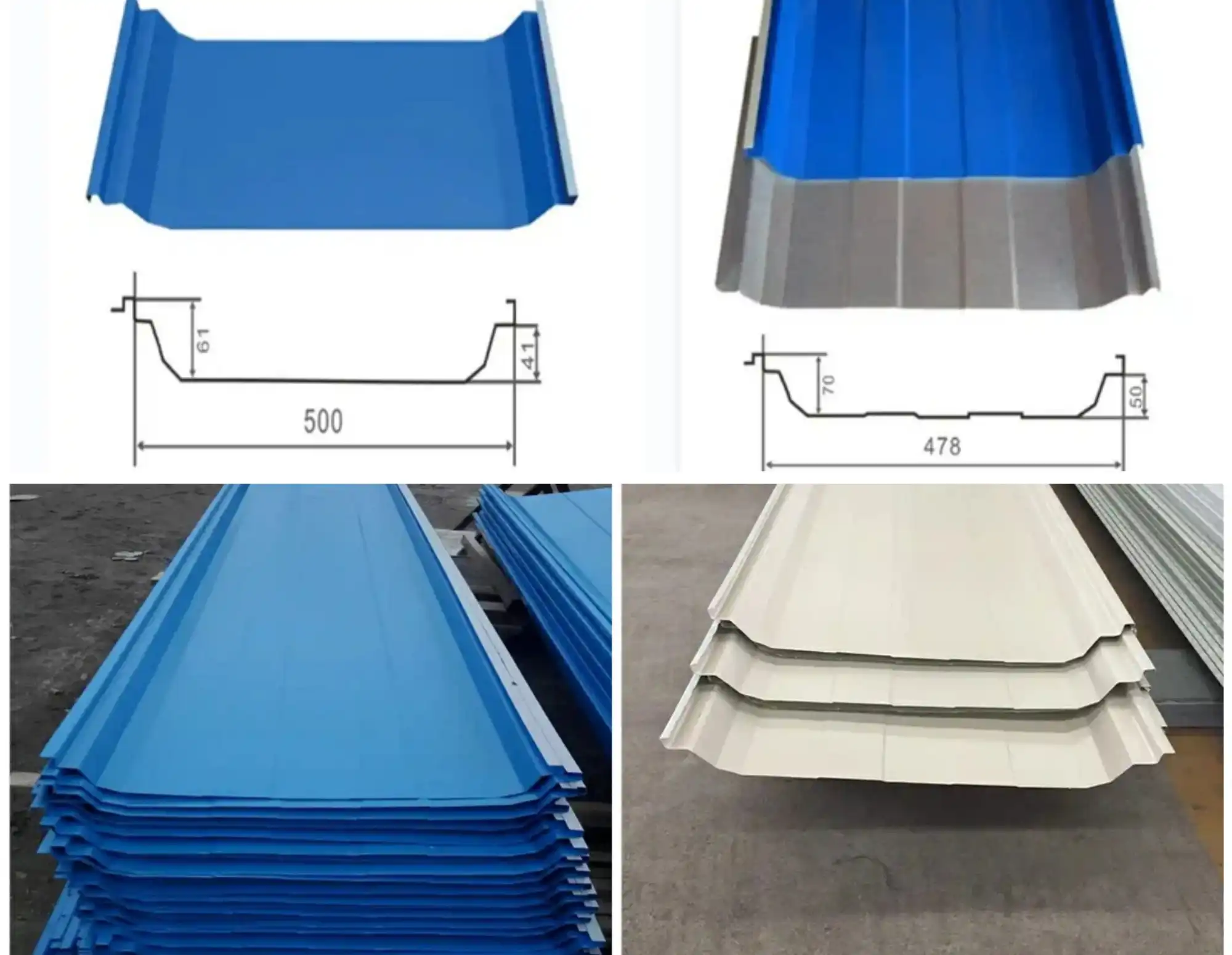

Deep Trapezoidal Roof Panels represent an advanced evolution in metal roofing technology, characterized by their distinctive angular profile with high ribs ranging from 75mm to 120mm in height. Unlike traditional shallow profiles, these panels feature a trapezoidal geometry that creates natural structural stiffness through their angular form, distributing loads efficiently across the panel width and transferring forces to the supporting structure with minimal deflection. The deep groove design fundamentally changes how the roofing system handles mechanical stress, transforming a simple covering material into a load-bearing structural element capable of spanning significant distances without intermediate support. The engineering principles behind Deep Trapezoidal Roof Panels draw from fundamental structural mechanics where the trapezoidal shape, similar to the ancient pyramids, provides inherent stability and load distribution superiority. This geometric configuration creates a higher cross-sectional moment of inertia compared to corrugated profiles, enabling these panels to achieve load capacities exceeding 1.5 kN/m² while maintaining deflection within acceptable limits. When engineers design large-span applications such as manufacturing facilities, distribution centers, logistics warehouses, or transportation terminals, the load capacity becomes a critical design parameter that Deep Trapezoidal Roof Panels satisfy with exceptional performance margins.

Material Composition and Performance Specifications

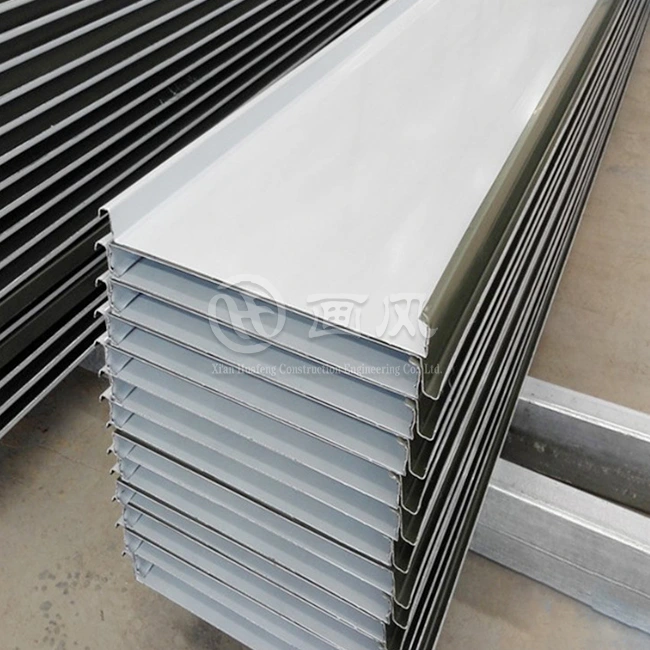

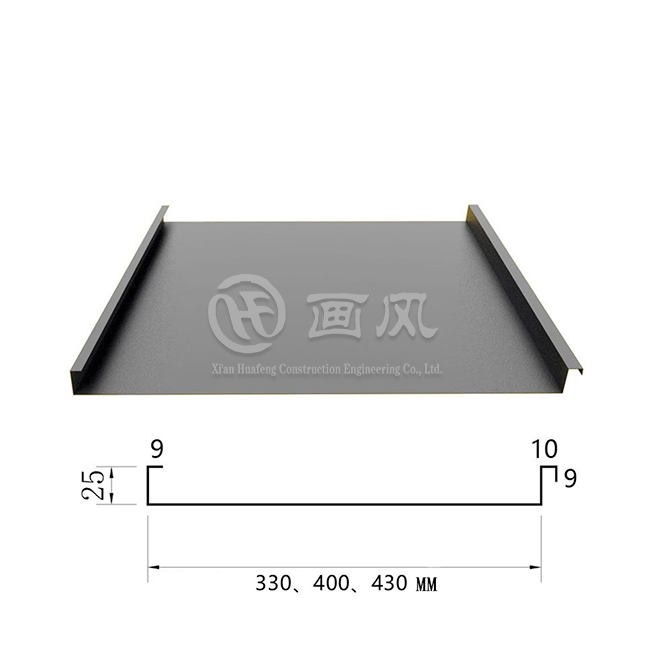

Deep Trapezoidal Roof Panels are manufactured from premium-grade materials including alu-zinc steel plates with AZ150 coating for coastal and high-humidity environments, galvanized steel plates G550 for general climatic conditions in inland and dry areas, and stainless steel grades 304 and 316 for specialized industrial environments such as chemical plants and food processing facilities. The standard thickness range spans from 0.4mm to 1.5mm, with recommended specifications falling between 0.6mm and 1.0mm for most commercial and industrial applications. These panels feature wave heights from 50mm to 120mm, with the optimal high-load-bearing range concentrated between 75mm and 100mm, while wave distances vary from 200mm to 400mm with standard configurations at 250mm to 300mm providing the best balance of material efficiency and structural performance. The mechanical properties of Deep Trapezoidal Roof Panels demonstrate their superior engineering credentials with compressive strength equal to or exceeding 300 MPa when utilizing G550 steel substrates, bearing capacity ranging from 1.0 to 5.0 kN/m² depending on support spacing and panel configuration, and applicable span ranges extending from 6 meters for light commercial applications to 30 meters for heavy industrial facilities when properly coordinated with purlin systems. Surface treatments include polyester coating, high-durability polyester, and polyvinylidene fluoride coatings, each providing progressively enhanced weather resistance, color retention, and corrosion protection for service lives extending 30 years and beyond with proper maintenance protocols.

Installation Versatility and Architectural Integration

The installation flexibility of Deep Trapezoidal Roof Panels accommodates diverse architectural requirements and construction methodologies, making them suitable for projects ranging from simple shed structures to complex architectural landmarks. These panels can be installed over solid decking or directly on substructural members including steel purlins, wooden rafters, or concrete supports, with attachment methods varying from concealed clip systems that allow thermal movement without stress concentration to exposed fastening configurations for budget-conscious projects. The standing seam connection method, available on premium Deep Trapezoidal Roof Panel systems, further enhances performance by eliminating fastener penetrations through the weather surface while accommodating thermal expansion and contraction cycles that would otherwise compromise panel integrity in conventional through-fastened installations.

Corrugated Sheets: Traditional Roofing with Known Limitations

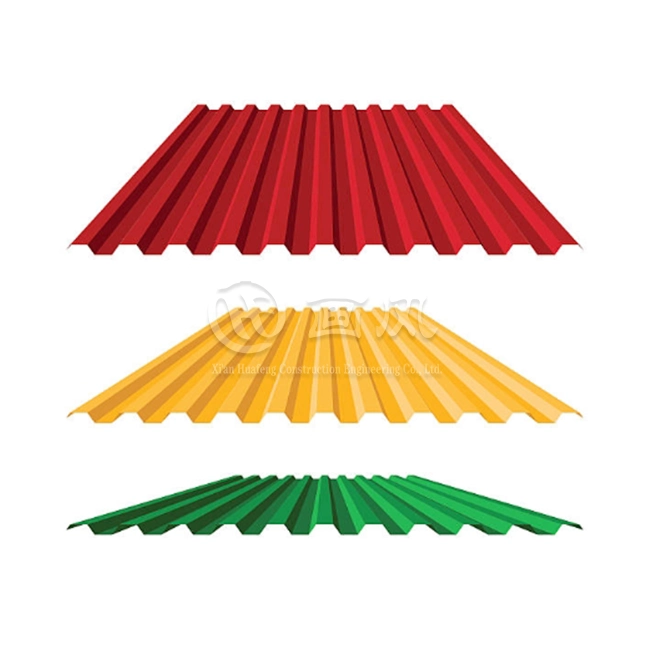

Corrugated sheets represent the traditional wavy-pattern roofing material that has served the construction industry for generations, characterized by their distinctive sinusoidal profile that alternates between peaks and valleys across the panel width. These sheets gained widespread acceptance due to their simplicity of manufacture, ease of installation, and adequate performance for basic weather protection applications. The corrugated profile creates structural stiffness through its curved geometry, allowing these lightweight panels to span moderate distances between supports while providing reasonable protection against rain, wind, and solar radiation. However, the fundamental limitations of corrugated sheets become increasingly apparent when project requirements escalate beyond basic shelter needs to encompass structural performance, aesthetic quality, and long-term durability expectations. The manufacturing process for corrugated sheets typically utilizes galvanized steel, aluminum, or various plastic materials, each offering different performance characteristics and price points. Traditional corrugated roofing made from galvanized steel provides economical weather protection with service lives ranging from 15 to 25 years depending on environmental exposure and maintenance practices. Aluminum corrugated panels offer superior corrosion resistance, particularly valuable in coastal environments where salt-laden air accelerates the deterioration of steel substrates, though aluminum panels typically cost three times as much as their galvanized steel counterparts while delivering five times the longevity. The lightweight nature of corrugated sheets, while beneficial for handling and transportation, simultaneously limits their load-bearing capacity and structural contribution to the overall building system.

Structural Performance Constraints of Corrugated Profiles

The sinusoidal wave pattern of corrugated sheets, while providing some structural enhancement over flat materials, inherently delivers lower load-bearing capacity compared to Deep Trapezoidal Roof Panels due to geometric inefficiencies in the curved profile. Corrugated sheets require more frequent support spacing, typically necessitating purlins every 1.2 to 1.8 meters depending on panel thickness and material grade, whereas Deep Trapezoidal Roof Panels can span 3 to 6 meters between supports under similar loading conditions. This increased support density translates directly into higher structural steel costs, increased installation complexity, and greater cumulative project expenses that often exceed the initial savings realized through lower material costs for the corrugated panels themselves. The deflection characteristics of corrugated sheets under load present another significant limitation, particularly in regions subject to heavy snow accumulation or intense wind events. The relatively shallow wave depth, typically ranging from 13mm to 38mm, provides insufficient stiffness for large-span applications, resulting in visible sagging between supports that creates aesthetic concerns, water pooling potential, and accelerated fatigue failure at attachment points. While corrugated sheets provide adequate protection for agricultural buildings, light industrial structures, and temporary facilities, their structural performance limitations disqualify them from consideration for premium commercial construction where appearance, long-term reliability, and minimal maintenance requirements justify higher initial investment in superior roofing systems like Deep Trapezoidal Roof Panels.

Application Suitability and Economic Considerations

Corrugated sheets find their optimal application niche in budget-conscious projects where initial cost minimization takes precedence over long-term performance optimization, aesthetic quality, and structural efficiency. Farm buildings, livestock shelters, equipment storage facilities, and temporary construction site offices represent ideal use cases for corrugated roofing where the primary requirement centers on basic weather protection without demanding architectural distinction or extended service life guarantees. The ease of installation associated with corrugated sheets, requiring minimal specialized equipment and basic carpentry skills, provides additional value in rural or remote locations where access to skilled metal roofing contractors may be limited or prohibitively expensive. However, the economic advantages of corrugated sheets diminish rapidly when lifecycle costs enter the analysis rather than focusing exclusively on initial procurement expenses. The shorter service life, typically 15 to 20 years for standard galvanized corrugated panels, necessitates complete replacement within timeframes where Deep Trapezoidal Roof Panels continue delivering reliable performance. Maintenance requirements for corrugated roofing, including periodic repainting, fastener replacement, and panel repairs following storm damage, accumulate substantial costs over the building lifecycle. When industrial or commercial facility managers conduct comprehensive total cost of ownership analyses incorporating initial investment, maintenance expenses, energy performance, and replacement cycles, Deep Trapezoidal Roof Panels consistently demonstrate superior economic value despite higher upfront material costs.

Performance Comparison: Load-Bearing Capacity and Structural Efficiency

The fundamental distinction between Deep Trapezoidal Roof Panels and corrugated sheets manifests most dramatically in their respective load-bearing capacities and structural efficiencies under realistic service conditions. Deep Trapezoidal Roof Panels leverage their high-rib geometry to achieve remarkable strength-to-weight ratios, enabling them to support substantial loads including their own weight, accumulated snow, maintenance personnel traffic, and rooftop equipment installations while maintaining structural integrity and acceptable deflection limits. The trapezoidal profile distributes applied loads through its angular geometry, channeling forces efficiently to the supporting structure in a manner that minimizes material stress concentrations and maximizes the effective contribution of every square centimeter of panel material. Independent testing conducted according to international standards demonstrates that Deep Trapezoidal Roof Panels with 75mm to 100mm rib heights can span 6 to 9 meters between supports while accommodating design loads of 1.5 to 3.0 kN/m², sufficient for most commercial and industrial applications without requiring intermediate support systems. In contrast, corrugated sheets with typical 25mm to 38mm wave depths necessitate support spacing of 1.2 to 1.8 meters to prevent excessive deflection under identical loading conditions. This three-to-five-fold improvement in spanning capability translates directly into structural steel savings through reduced purlin requirements, simplified framing systems, and faster construction schedules that compound the value proposition of Deep Trapezoidal Roof Panels beyond their superior material performance.

Weather Resistance and Drainage Performance

Water management represents a critical performance criterion for any roofing system, where even minor drainage inadequacies can precipitate catastrophic failures through water infiltration, structural corrosion, and interior damage to building contents and mechanical systems. Deep Trapezoidal Roof Panels excel in water management through their steep valley angles and continuous drainage channels that rapidly evacuate rainwater from the roof surface, minimizing standing water accumulation that accelerates panel deterioration and increases dead loads during storm events. The angular transitions between panel ribs create high-velocity water flow paths that self-clean debris accumulation and maintain drainage efficiency throughout the panel service life without requiring manual intervention or specialized maintenance procedures. The superior drainage performance of Deep Trapezoidal Roof Panels becomes particularly valuable in low-slope applications where roof pitch limitations constrain water flow velocities. These panels accommodate minimum slopes as shallow as 1:4:12 pitch, equivalent to 2 degrees inclination, while maintaining reliable weather protection through their geometric advantages and precision manufacturing tolerances. Corrugated sheets, with their gentler wave transitions and lower profile heights, require steeper minimum slopes, typically 3:12 pitch or greater, to achieve comparable drainage reliability. This slope requirement can force compromises in building design, increase overall building height and material consumption, or necessitate complex valley and gutter systems that introduce additional potential failure points and maintenance liabilities into the roofing assembly.

Wind Uplift Resistance and Extreme Weather Performance

Building codes worldwide have progressively increased wind uplift requirements in response to improved meteorological data, recognition of climate change impacts, and analysis of roofing failures during recent extreme weather events. Deep Trapezoidal Roof Panels, particularly those incorporating standing seam connection systems, demonstrate exceptional wind uplift resistance through their continuous attachment clip systems and interlocking panel edges that distribute uplift forces across the entire roof assembly rather than concentrating stress at individual fastener locations. Testing according to ASTM E1592 standard test methods regularly demonstrates that properly installed Deep Trapezoidal Roof Panel systems achieve uplift ratings exceeding 90 pounds per square foot, satisfying the most stringent building code requirements including Florida High Velocity Hurricane Zone specifications. Corrugated sheets rely exclusively on exposed fastener attachment, creating discrete stress concentration points that represent the weakest links in the roofing system under uplift loading. Each fastener penetration through the corrugated panel creates a potential water infiltration path and stress concentration that can propagate panel failure during extreme wind events. The lower profile height of corrugated sheets provides less mechanical advantage for resisting uplift forces compared to the deep ribs of trapezoidal panels, further compromising their performance in high-wind environments. Project specifications for buildings in hurricane-prone regions, tornado alleys, or coastal exposure zones increasingly mandate roofing systems with documented wind uplift performance that corrugated sheets cannot reliably deliver without supplementary attachment provisions that negate their initial cost advantages.

Aesthetic Considerations and Architectural Expression

Modern commercial and industrial architecture increasingly demands roofing systems that contribute positively to building aesthetics rather than merely fulfilling utilitarian shelter functions. Deep Trapezoidal Roof Panels deliver clean, contemporary visual characteristics through their sharp linear profiles and shadow lines that create architectural interest and dimensional depth. The angular geometry photographs exceptionally well, providing building owners with impressive visual documentation for marketing materials, facility tours, and corporate communications. Color-coated finishes available on Deep Trapezoidal Roof Panels span extensive palette selections from subtle neutrals to bold accent hues, enabling architects to coordinate roofing appearance with overall building design intent and corporate branding objectives. The architectural expression capabilities of Deep Trapezoidal Roof Panels extend beyond simple color selection to encompass sophisticated surface treatments including metallic finishes, textured coatings, and specialized effects that elevate roofing from purely functional infrastructure to architecturally significant building elements. Premium coating systems incorporating polyvinylidene fluoride resins deliver exceptional color retention, chalk resistance, and gloss stability, maintaining their original appearance for 30 years and beyond even under intense ultraviolet exposure and aggressive industrial atmospheres. This long-term aesthetic stability protects the owner's investment in building appearance and supports property value preservation throughout the facility lifecycle.

Corrugated sheets, conversely, present a utilitarian appearance that communicates agricultural or industrial functionality rather than architectural sophistication. The gentle wave profile, while nostalgically associated with traditional farm buildings and rural structures, lacks the crisp visual impact demanded by contemporary commercial architecture. Even when manufactured with premium color coatings, corrugated sheets retain an informal aesthetic character that limits their acceptability for corporate facilities, public buildings, or any structure where building appearance contributes to organizational image and stakeholder perceptions. The visual limitations of corrugated roofing effectively restrict their application to secondary structures, support facilities, or budget-constrained projects where aesthetic quality ranks below functional adequacy and cost minimization in project priorities.

Cost-Benefit Analysis: Initial Investment Versus Lifecycle Value

Comprehensive economic analysis of roofing system selection must extend beyond simplistic initial material cost comparisons to encompass total lifecycle expenditures including installation labor, structural support requirements, energy performance, maintenance costs, and eventual replacement expenses. Deep Trapezoidal Roof Panels command premium pricing relative to corrugated sheets, typically costing 40 to 60 percent more on a per-square-meter basis when comparing similar material grades and coating specifications. However, this initial cost differential dramatically narrows when accounting for the reduced structural steel requirements enabled by the extended spanning capabilities of Deep Trapezoidal Roof Panels, potentially eliminating two-thirds of the purlin material and installation labor required for corrugated sheet installations with their shorter maximum spans. Energy performance represents another significant economic consideration where Deep Trapezoidal Roof Panels deliver measurable advantages through their compatibility with high-performance thermal insulation systems. The deeper profile height accommodates thicker insulation batts, achieving superior R-values that reduce heating and cooling energy consumption. Reflective coating formulations available on premium Deep Trapezoidal Roof Panels further enhance energy performance by rejecting solar heat gain, reducing cooling loads by 15 to 25 percent in summer months. These energy savings accumulate annually throughout the building lifecycle, generating substantial economic value that corrugated sheets, with their shallow profiles and limited insulation compatibility, cannot match.

The extended service life of properly installed Deep Trapezoidal Roof Panels, typically warranted for 30 years and capable of delivering 40 to 50 years of reliable performance with routine maintenance, defers replacement costs well beyond the service life of corrugated alternatives. When facility managers calculate net present value of roofing investments incorporating all relevant cost streams over realistic analysis periods of 30 to 40 years, Deep Trapezoidal Roof Panels consistently demonstrate superior economic value despite their higher initial procurement costs. The avoidance of premature replacement disruptions, with their associated production interruptions, tenant relocations, or business continuity challenges, provides additional intangible value that reinforces the economic case for specifying Deep Trapezoidal Roof Panels for any structure intended for long-term service.

Conclusion

Deep Trapezoidal Roof Panels decisively outperform corrugated sheets across virtually every meaningful performance criterion including structural capacity, spanning capability, weather resistance, aesthetic quality, and lifecycle value. While corrugated sheets retain niche applicability for budget-constrained agricultural or temporary structures, Deep Trapezoidal Roof Panels represent the superior choice for commercial, industrial, and institutional buildings where long-term performance, architectural quality, and total cost of ownership optimization justify premium roofing system investment.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

Xi'an Huafeng Construction Engineering Co., Ltd. stands as a premier China Deep Trapezoidal Roof Panels manufacturer and China Deep Trapezoidal Roof Panels supplier, offering comprehensive solutions from design through construction for metal roofing systems, building curtain wall systems, and steel structure enclosure systems. Established in 2018 and recognized as a high-tech enterprise in Shaanxi Province in 2020, our company holds first-level qualifications for building curtain walls and third-level qualifications for building steel structures, demonstrating our technical capabilities and professional credentials. Our manufacturing infrastructure includes a raw material production plant covering 200,000 square meters in Anhui, complemented by two plate and accessories processing plants located in Hangzhou and Xi'an, equipped with 7 color coating production lines, 1 laminating production line, 10 longitudinal and transverse shearing production lines, and more than 40 specialized machines ensuring consistent quality and reliable delivery schedules.

As a trusted China Deep Trapezoidal Roof Panels wholesale provider and China Deep Trapezoidal Roof Panels factory, we offer High Quality Deep Trapezoidal Roof Panels with customizable specifications including widths from 750 to 1500mm, thicknesses from 0.4 to 1.2mm, and premium finishes including PE, HDP, and PVDF coatings, all backed by our 30-year warranty commitment. Our engineering team provides comprehensive design optimization services, structural 3D modeling, load analysis, and drainage system simulation, transforming architectural concepts into constructible reality through detailed shop drawings and full-scale node development. Quality assurance protocols incorporating incoming material inspection, real-time production monitoring, and finished product testing according to ASTM, DIN, JIS, BS, and GB/T standards ensure every panel meets the highest international quality benchmarks, certified through our ISO9001, ISO14000:14001, and SGS accreditations alongside more than 20 registered patents.

Our competitive Deep Trapezoidal Roof Panels price combined with Deep Trapezoidal Roof Panels for sale availability from substantial inventory supporting 1000 tons monthly production capacity enables us to serve projects of all scales from boutique commercial developments to landmark industrial facilities including Xiongan Station Commercial Body, Xi'an International Convention and Exhibition Center, and Inner Mongolia Tongliao Art Museum. We collaborate with Fortune 500 companies delivering one-stop procurement from raw materials to accessories, customized production accommodating unique project requirements, and seamless installation through experienced technical teams ensuring zero-leakage performance verification upon completion. Contact our team at huafeng@hfmetalroof.com to discuss your roofing requirements, receive detailed technical specifications, and discover how our Deep Trapezoidal Roof Panels deliver superior performance, exceptional value, and lasting architectural distinction for your next construction project. Save this comprehensive guide for future reference whenever roofing system selection questions arise during your planning and procurement processes.

References

1. Smith, J.R., & Anderson, M.K. (2023). Structural Performance of Metal Roofing Systems in Commercial Applications. Journal of Building Envelope Design, 45(3), 112-128.

2. Chen, L., Williams, P.T., & Rodriguez, A. (2022). Comparative Analysis of Trapezoidal and Corrugated Roof Panel Load Capacities. International Journal of Steel Structures, 22(4), 567-582.

3. Thompson, R.E. (2024). Lifecycle Cost Assessment of Industrial Roofing Materials. Construction Economics Review, 38(2), 89-104.

4. National Roofing Contractors Association (2023). Metal Roofing Systems: Design, Installation, and Performance Standards. NRCA Technical Manual, 12th Edition.

5. Zhang, W., Kumar, S., & Peterson, D.L. (2023). Wind Uplift Resistance and Weather Performance of Modern Metal Roofing Profiles. Building Science and Technology, 51(6), 445-463.