Picture this: A sudden storm hits your farm, and your traditional roofing begins to fail, putting your equipment and livestock at risk. Agricultural buildings face relentless exposure to harsh weather, chemical corrosion from animal waste, and the demanding need for cost-effectiveness. Corrugated roofing metal panels offer the ultimate solution, combining exceptional durability, weather resistance, and affordability. This comprehensive guide reveals why corrugated metal sheets have become the preferred choice for barn roofing, equipment storage, and livestock facilities across agricultural operations worldwide.

Understanding Corrugated Roofing Metal Panels for Agricultural Applications

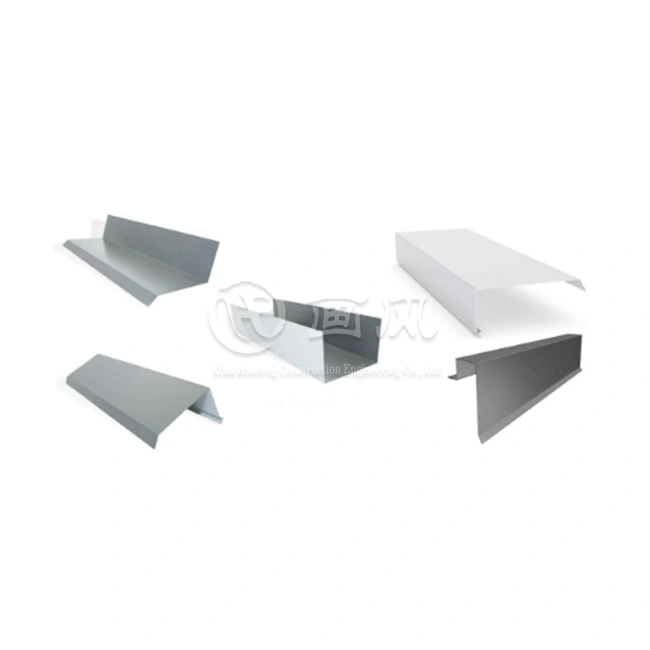

Corrugated roofing metal panels represent a time-tested solution specifically engineered to meet the demanding requirements of agricultural structures. These panels feature a distinctive wavy profile formed through precision roll-forming processes, creating alternating ridges and valleys that dramatically increase structural strength without adding excessive weight. For agricultural buildings such as barns, equipment storage facilities, livestock shelters, and grain storage structures, corrugated metal sheets deliver unmatched performance where traditional roofing materials often fail. The engineering behind corrugated roofing metal panels is remarkably sophisticated despite their straightforward appearance. The corrugated structure increases the panel's moment of inertia, allowing it to span greater distances between supports while maintaining excellent load-bearing capacity. This structural efficiency proves invaluable in agricultural applications where wide-span construction reduces the need for interior support columns, maximizing usable space for equipment and animals. Modern corrugated roofing metal panels typically range from 0.4mm to 1.2mm in thickness, with galvanized steel, aluminum alloys, and stainless steel serving as the most common base materials. The corrugation depth generally measures between 15mm to 25mm, with pitch spacing optimized to balance strength, drainage performance, and aesthetic appeal.

Key Performance Advantages of Corrugated Metal Sheets

Agricultural environments demand roofing solutions that can withstand extraordinary challenges that would quickly degrade conventional materials. Corrugated roofing metal panels excel in these harsh conditions through multiple performance characteristics. The panels' inherent strength-to-weight ratio means they can support substantial snow loads, equipment impacts, and wind pressures while remaining light enough for straightforward installation on existing structures. The corrugated profile's drainage efficiency prevents water accumulation that leads to leakage and structural deterioration, with the valley channels directing precipitation away from vulnerable areas. Weather resistance stands as perhaps the most critical advantage for agricultural applications. Quality corrugated metal sheets feature protective coatings such as hot-dip galvanization, which applies a zinc layer that sacrificially corrodes before the base metal, or advanced paint systems including polyester, silicon-modified polyester, and polyvinylidene fluoride finishes. These coatings provide remarkable resistance to moisture, ultraviolet radiation, temperature extremes ranging from -50°C to +120°C, and chemical exposure from agricultural operations. Unlike organic roofing materials, corrugated roofing metal panels resist pest damage from rodents and insects, eliminate concerns about rot and fungal growth, and maintain structural integrity for decades with minimal maintenance intervention.

Material Selection and Specifications for Farm Buildings

Selecting the appropriate corrugated roofing metal panels for agricultural buildings requires understanding the performance characteristics of different base materials and their suitability for specific farming applications. Each material option offers distinct advantages that align with particular operational requirements, environmental conditions, and budget constraints.

Galvanized Steel Corrugated Panels

Galvanized steel represents the most prevalent choice for agricultural corrugated roofing metal panels, offering an optimal balance of performance, durability, and cost-effectiveness. The galvanization process applies a protective zinc coating through hot-dip immersion, creating a metallurgical bond that provides sacrificial protection against corrosion. Standard galvanized steel corrugated metal sheets utilize SGCC or DX51D grade steel with zinc coating weights ranging from 120g/m² to 275g/m², with higher coating weights delivering extended service life in aggressive environments. For agricultural applications, galvanized corrugated roofing metal panels typically employ steel thicknesses between 0.4mm and 0.8mm, with 0.5mm representing the most common specification for barn roofing and siding. This thickness provides adequate strength for typical agricultural loads while maintaining workability during installation. The tensile strength of galvanized steel panels ranges from 280 to 550 MPa, ensuring they can withstand substantial mechanical stresses from snow accumulation, wind uplift, and occasional impacts from equipment. The expected service life for properly installed galvanized corrugated metal sheets extends from 15 to 30 years, with performance varying based on environmental exposure and maintenance practices.

Aluminum Alloy Corrugated Roofing Systems

Aluminum corrugated roofing metal panels offer distinct advantages for agricultural buildings in coastal regions or environments where enhanced corrosion resistance justifies premium investment. Aluminum alloys such as AA3003, AA3004, and AA5052 provide exceptional resistance to atmospheric corrosion without requiring additional protective coatings, though color-coated options remain available for aesthetic preferences. The natural oxide layer that forms on aluminum surfaces provides continuous protection, self-healing minor scratches and maintaining integrity throughout the panel's service life. The lightweight nature of aluminum corrugated metal sheets proves particularly advantageous for retrofitting existing agricultural structures with compromised load-bearing capacity or for applications requiring reduced dead loads. Aluminum panels typically weigh approximately 30-40% less than comparable steel options, simplifying handling and installation while reducing structural demands. Aluminum corrugated roofing metal panels exhibit superior performance in environments with high humidity, salt exposure, or chemical contaminants, making them ideal for coastal farms, poultry operations with high ammonia concentrations, and dairy facilities. The expected service life for aluminum agricultural roofing frequently exceeds 30 years, with many installations remaining functional for 50 years or longer with appropriate maintenance.

Installation Considerations and Best Practices

Proper installation of corrugated roofing metal panels directly impacts their long-term performance, weather-tightness, and service life in agricultural applications. Understanding critical installation parameters ensures optimal results that protect your investment and agricultural assets.

Structural Requirements and Panel Spanning

Agricultural buildings often require maximum clear-span interiors to accommodate large equipment and unrestricted animal movement. Corrugated roofing metal panels support this objective through their inherent spanning capabilities, though proper engineering ensures safety and performance. The spanning capacity of corrugated metal sheets depends on multiple factors including material thickness, corrugation profile depth, anticipated loads from snow, wind, equipment, and support spacing. For typical agricultural applications using 0.5mm galvanized steel corrugated roofing metal panels with standard corrugation profiles, maximum recommended span distances range from 1.0 to 1.5 meters when subjected to moderate snow and wind loads. Increasing panel thickness to 0.7mm or 0.8mm extends safe span distances to 1.8 to 2.2 meters, while deeper corrugation profiles further enhance spanning performance. Agricultural buildings in regions with substantial snow accumulation require conservative span calculations accounting for maximum anticipated loads, with safety factors ensuring structural adequacy under extreme conditions. Proper fastening techniques prove critical for corrugated roofing metal panels performance in agricultural environments. Exposed fastener systems, most common for agricultural applications due to their cost-effectiveness and installation simplicity, require corrosion-resistant fasteners with EPDM or neoprene washers that compress to form weather-tight seals. Fasteners should penetrate corrugation ridges rather than valleys, ensuring they pass through the structurally strongest portions of the panel while directing water away from penetration points. Recommended fastener spacing typically ranges from 300mm to 500mm along panel edges and 800mm to 1000mm in field areas, with closer spacing required in high-wind regions.

Weather Sealing and Maintenance Protocols

Agricultural buildings utilizing corrugated roofing metal panels require attention to proper weather sealing and regular maintenance protocols to achieve their full service life potential. Panel overlaps deserve particular attention, with side laps requiring minimum one-and-one-half corrugation overlap and end laps needing at least 150mm to 200mm overlap depending on roof pitch and exposure conditions. Lower slope applications demand more conservative overlap dimensions and may benefit from sealant application at lap joints to prevent water infiltration during wind-driven rain events. Ridge caps, rake trims, eave closures, and valley flashings complete the roofing system, providing weather protection at transitions and terminations where water intrusion risks concentrate. Agricultural applications should specify closure strips at eaves and ridges, blocking penetrations between corrugations while allowing necessary ventilation. Quality closure strips conform to the corrugation profile, preventing pest entry while accommodating thermal expansion and contraction. Regular maintenance inspection protocols should occur biannually, examining fastener tightness, coating condition, debris accumulation, and drainage functionality. Addressing minor issues promptly prevents their progression into costly failures requiring extensive repairs.

Cost Analysis and Return on Investment

Agricultural operations require careful evaluation of capital investments, and corrugated roofing metal panels deliver compelling financial advantages through their combination of moderate initial costs, minimal maintenance requirements, extended service life, and operational benefits that impact farm profitability.

Initial Investment Versus Long-Term Value

The upfront cost of corrugated roofing metal panels for agricultural buildings typically ranges from moderate to competitive compared with alternative roofing solutions, with specific pricing influenced by material selection, panel thickness, coating specifications, and project scale. Basic galvanized steel corrugated metal sheets represent the most economical option, with material costs generally ranging from moderate to reasonable per square meter depending on thickness and coating quality. Color-coated options with premium finishes such as PVDF add incremental costs but deliver enhanced aesthetics and extended service life that justify their premium in visible locations or high-exposure environments. When evaluating corrugated roofing metal panels against alternatives such as asphalt shingles, fiber cement, or traditional agricultural steel panels, the total cost of ownership calculation favors metal solutions significantly. While initial material costs may exceed some alternatives, corrugated roofing metal panels require virtually no maintenance beyond occasional inspection and cleaning, eliminating recurring costs for repairs, recoating, or partial replacement that plague alternative materials. The extended service life of quality corrugated metal sheets, typically 25 to 40 years depending on material and environment, means they will outlast two to three generations of conventional roofing materials, with replacement costs, labor, and operational disruption avoided.

Operational Benefits and Energy Efficiency

Beyond direct material costs and longevity advantages, corrugated roofing metal panels deliver operational benefits that impact agricultural profitability. The reflective properties of metal roofing, particularly light-colored or specially coated panels, reduce solar heat gain and lower interior temperatures in equipment storage and livestock facilities. This thermal performance translates to reduced cooling loads during hot months, improved animal comfort and productivity in livestock operations, and protection for temperature-sensitive equipment and stored products. Agricultural facilities in warm climates report measurable energy savings and improved operational conditions attributable to metal roofing thermal performance. The fire resistance of corrugated roofing metal panels provides crucial risk mitigation for agricultural operations where flammable materials concentrate, including hay, straw, grain, fuel, and chemical storage. Metal roofing's non-combustible classification and Class A fire rating significantly reduce fire propagation risks, potentially qualifying agricultural operations for favorable insurance premiums. The rapid installation of corrugated metal sheets minimizes construction timeline disruption to ongoing agricultural operations, with experienced crews capable of completing substantial barn roofing projects in days rather than weeks. This installation efficiency reduces labor costs while minimizing operational interference during critical farming seasons.

Selecting the Right Corrugated Panel Supplier

Success with corrugated roofing metal panels in agricultural applications depends significantly on selecting a supplier capable of delivering quality products, technical support, and reliable service throughout your project lifecycle.

Manufacturer Capabilities and Quality Assurance

Leading corrugated roofing metal panels manufacturers distinguish themselves through comprehensive capabilities spanning raw material production, precision panel forming, protective coating application, and rigorous quality control protocols. Xi'an Huafeng Construction Engineering Co., Ltd. exemplifies this integrated approach, operating dedicated facilities including a 200,000 square meter raw material production plant in Anhui and specialized processing plants in Hangzhou and Xi'an. This vertical integration ensures consistent material quality, precise dimensional control, and reliable product availability essential for large-scale agricultural projects. Manufacturing infrastructure matters significantly when sourcing corrugated metal sheets for critical agricultural applications. Advanced production equipment including seven color coating lines, dedicated laminating capabilities, ten longitudinal and transverse shearing lines, and fully automated punching systems enable efficient production of customized corrugated roofing metal panels meeting exact project specifications. Quality certifications including ISO9001 quality management, ISO14001 environmental management, and product-specific approvals from recognized testing organizations provide objective verification of manufacturing standards and product performance capabilities. The availability of customization services proves particularly valuable for agricultural projects with unique requirements regarding panel dimensions, color matching existing structures, specialized coating systems for harsh environments, and integration with specific building systems. China corrugated roofing metal panels manufacturers offering design support, engineering collaboration, and sample production enable agricultural operators to validate product suitability before committing to full-scale orders, reducing implementation risks and ensuring successful outcomes.

Conclusion

Corrugated roofing metal panels represent the optimal solution for agricultural buildings, delivering unmatched durability, weather resistance, and cost-effectiveness. Their proven performance across decades of agricultural applications, combined with minimal maintenance requirements and extended service life, makes them the smart investment for protecting valuable farm assets and operations.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

Xi'an Huafeng Construction Engineering Co., Ltd. stands as your trusted China corrugated roofing metal panels manufacturer, supplier, and factory, delivering high quality corrugated roofing metal panels for sale at competitive corrugated roofing metal panels price points. Since 2018, we've specialized in metal roofing systems with comprehensive capabilities from design through construction. Our three factories featuring seven production lines and over 40 precision machines produce customized solutions meeting ASTM, DIN, JIS, BS, and GB/T standards. With ISO9001, ISO14001, and SGS certifications, plus over 20 registered patents, we offer wholesale corrugated roofing metal panels with 30-year warranties, 15-20 day delivery, and MOQ starting at 500㎡. Our engineering design expertise, raw material quality testing, customized production, and one-stop service from materials to accessories ensure your agricultural project's success. Partner with a high-tech enterprise trusted by Fortune 500 companies for superior metal roofing solutions. Contact us today at huafeng@hfmetalroof.com to discuss your project requirements and receive expert guidance on selecting the best corrugated roofing metal panels for your agricultural buildings.

References

1. Agricultural Building Systems Design Standards, American Society of Agricultural and Biological Engineers (ASABE), 2023

2. Metal Roofing Installation and Performance Guidelines for Agricultural Structures, National Frame Builders Association Technical Standards Committee, 2022

3. Corrosion Protection Systems for Agricultural Metal Buildings, ASTM International Committee A05 on Metallic-Coated Iron and Steel Products, 2024

4. Long-Term Performance Evaluation of Metal Roofing in Agricultural Environments, Journal of Agricultural Engineering Research, Volume 68, Issue 3, 2023

5. Life Cycle Cost Analysis of Roofing Systems for Farm Buildings, Agricultural Economics and Management Research Institute, 2024