Every builder faces the same frustrating dilemma when selecting roofing materials for commercial and industrial projects. Traditional roofing systems fail prematurely, require constant maintenance, and create costly callbacks that damage reputation and profit margins. Standing Seam Metal Roof Sheets eliminate these headaches by delivering a superior roofing solution that combines exceptional durability, weather resistance, and installation efficiency. This comprehensive guide reveals why professional builders worldwide are switching to Standing Seam Metal Roof Sheets for their most demanding construction projects.

Understanding Standing Seam Metal Roof Sheets Technology

Standing Seam Metal Roof Sheets represent an advanced roofing technology characterized by vertical panels featuring raised interlocking seams that run continuously from ridge to eave. Unlike traditional exposed fastener systems, Standing Seam Metal Roof Sheets utilize a concealed fastener mechanism where clips secure panels beneath the raised seams. This innovative design creates a weather-tight envelope that protects building structures for decades while maintaining a clean, modern aesthetic. The raised seams typically measure between twenty-five and sixty-five millimeters in height, providing superior water channeling capabilities that prevent moisture infiltration even during severe weather events. The manufacturing process for Standing Seam Metal Roof Sheets involves precision roll-forming of high-grade metal coils into custom panel profiles. Modern production facilities like Xi'an Huafeng's seven dedicated coating lines ensure consistent panel quality with thickness options ranging from half a millimeter to one-point-two millimeters. Premium surface treatments including PVDF and PE coatings enhance corrosion resistance and maintain color integrity for thirty years or longer. The interlocking seam design accommodates thermal expansion and contraction naturally, preventing panel buckling and fastener failure that plague conventional roofing systems.

Key Performance Characteristics of Professional-Grade Systems

Professional builders require roofing materials that deliver measurable performance advantages across multiple criteria. Standing Seam Metal Roof Sheets excel in structural integrity, providing Class A fire ratings and wind uplift resistance exceeding one hundred forty miles per hour in hurricane-prone regions. The concealed fastener system eliminates thousands of potential leak points, as traditional screw-down systems require approximately seventy fasteners per square, creating over two thousand penetrations on an average two-thousand-square-foot roof. Standing Seam Metal Roof Sheets reduce this vulnerability dramatically by securing panels with hidden clips that allow natural thermal movement without compromising weatherproofing. The material composition of Standing Seam Metal Roof Sheets significantly impacts long-term performance and project costs. Galvanized steel options with Galvalume coatings provide excellent corrosion resistance for inland applications, while aluminum-magnesium-manganese alloys deliver superior performance in coastal environments with salt air exposure. Copper and titanium-zinc options serve specialized architectural applications where aesthetic patina development enhances building character over time. Xi'an Huafeng sources premium materials from established suppliers including Baosteel, NedZink, and Chinalco, ensuring material certifications meet international standards including ASTM, DIN, JIS, and GB/T specifications.

Installation Efficiency Advantages for Construction Schedules

Construction timeline management directly impacts project profitability, making installation efficiency a critical consideration for professional builders. Standing Seam Metal Roof Sheets offer substantial time savings compared to traditional roofing systems through several mechanisms. The ability to manufacture panels in continuous lengths up to twelve meters eliminates horizontal seams that require additional labor and create potential leak points. Snap-lock profile options enable rapid installation on roof pitches of three-in-twelve or greater, reducing labor costs significantly compared to mechanically seamed systems. However, mechanically seamed Standing Seam Metal Roof Sheets remain essential for low-slope applications below three-in-twelve pitch, where superior weather-tightness justifies the additional installation time. Professional installation teams benefit from the systematic approach enabled by Standing Seam Metal Roof Sheets. Panels arrive at job sites pre-cut and numbered according to roof section plans, eliminating field measuring errors and material waste. Specialized tools including electric seaming machines, panel benders, and edge-forming equipment allow skilled crews to maintain consistent installation quality across large commercial projects. The clip fastening system permits panel removal and replacement without damaging adjacent sections, facilitating future maintenance access for rooftop equipment service or panel repairs if ever necessary.

Unmatched Weather Protection and Longevity

Water intrusion represents the most common and costly failure mode for commercial roofing systems, making weather resistance the paramount concern for professional builders. Standing Seam Metal Roof Sheets deliver superior moisture protection through their elevated seam design that positions panel joints well above the roof surface. This configuration prevents water accumulation at seams even during severe rainfall, driving rain, or snow melt conditions. The concealed fastener system eliminates weathering and UV degradation of exposed gaskets that compromise traditional screw-down systems within five to ten years. The thermal movement accommodation provided by Standing Seam Metal Roof Sheets prevents the stress-related failures that shorten conventional roofing lifespans. Metal roofing materials expand and contract significantly with temperature fluctuations, creating tremendous forces that can tear fasteners loose or buckle panels if not properly managed. Standing Seam Metal Roof Sheets address this challenge through clip systems that allow panels to slide freely during thermal cycling while maintaining weatherproof seam integrity. This engineering approach enables Standing Seam Metal Roof Sheets to achieve service lives of forty to seventy years, dramatically exceeding the twenty to thirty year lifespan of asphalt shingle systems or the fifteen to twenty year performance typical of exposed fastener metal roofing.

Superior Performance in Extreme Climate Conditions

Builders working in challenging climate zones require roofing systems proven to withstand environmental extremes without premature failure. Standing Seam Metal Roof Sheets excel across diverse conditions from arctic cold to tropical heat and humidity. The smooth panel surface combined with raised seams facilitates efficient snow and ice shedding, preventing dangerous accumulations that stress building structures and create liability concerns. Ice dam formation, a persistent problem with asphalt shingle roofs, becomes virtually eliminated as Standing Seam Metal Roof Sheets' thermal properties and surface characteristics prevent the freeze-thaw cycles that trap water behind ice barriers. Wind resistance testing demonstrates the structural superiority of Standing Seam Metal Roof Sheets for high-exposure applications including coastal construction and tornado-prone regions. The continuous clip attachment along panel edges creates a robust connection to the structural deck that resists uplift forces far exceeding building code minimums. Premium Standing Seam Metal Roof Sheets from manufacturers like Xi'an Huafeng undergo rigorous testing protocols confirming performance under simulated hurricane conditions. The interlocking seam design prevents wind-driven rain infiltration even at panel edges, protecting vulnerable building envelope transitions that defeat lesser roofing systems.

Fire Resistance and Insurance Cost Reduction

Fire safety requirements increasingly influence material selection decisions as building codes tighten and insurance underwriters scrutinize risk factors more carefully. Standing Seam Metal Roof Sheets manufactured from steel, aluminum, or other non-combustible metals achieve Class A fire ratings, the highest classification available for roofing materials. This superior fire resistance often qualifies building owners for reduced insurance premiums that offset material cost premiums over the building's lifecycle. The fire rating applies to the complete roofing assembly when Standing Seam Metal Roof Sheets are installed over appropriate underlayment materials and structural decking, protecting building occupants and contents from external fire exposure. Builders serving institutional clients including schools, hospitals, and government facilities particularly value the fire safety characteristics of Standing Seam Metal Roof Sheets. These buildings house vulnerable populations and critical functions where fire-related evacuation poses significant life-safety risks. Standing Seam Metal Roof Sheets will not ignite from external sources like windblown embers during wildfire events, making them the preferred choice for construction in wildland-urban interface zones. The same non-combustible properties prevent fire spread from neighboring structures, providing an additional layer of protection increasingly valued in high-density urban development projects.

Energy Efficiency and Environmental Sustainability

Operating cost reduction drives material selection decisions as building owners seek to minimize long-term expenses and meet sustainability goals. Standing Seam Metal Roof Sheets deliver measurable energy savings through solar reflectance properties that reduce cooling loads during hot weather. Premium coatings including PVDF finishes reflect substantial portions of solar radiation, preventing heat absorption that forces mechanical cooling systems to work harder. Studies document cooling cost reductions of ten to twenty-five percent when Standing Seam Metal Roof Sheets replace darker conventional roofing materials in warm climates. The same reflective properties benefit cold climate applications by facilitating rapid snow melt on south-facing roof sections, reducing structural loads and ice dam risks. The thermal performance advantages of Standing Seam Metal Roof Sheets extend beyond surface reflectivity to include compatibility with advanced insulation strategies. Builders can integrate continuous insulation layers above or below roof decking, creating highly efficient building envelopes that exceed energy code requirements. The concealed fastener system of Standing Seam Metal Roof Sheets eliminates thermal bridging through penetrations that compromise insulated assemblies. When combined with proper air sealing and vapor control strategies, Standing Seam Metal Roof Sheets contribute to ultra-efficient building designs including net-zero energy and Passive House certified projects.

Recyclability and Lifecycle Environmental Impact

Environmental responsibility influences material selection as builders respond to client sustainability requirements and green building certification programs including LEED and BREEAM. Standing Seam Metal Roof Sheets offer compelling environmental advantages throughout their lifecycle from manufacturing through end-of-service recycling. The aluminum, steel, and copper materials used in premium Standing Seam Metal Roof Sheets contain substantial recycled content, often exceeding seventy-five percent post-consumer material. At end of service life, Standing Seam Metal Roof Sheets are one hundred percent recyclable, avoiding landfill disposal and conserving natural resources. The extended service life of Standing Seam Metal Roof Sheets reduces environmental impact by minimizing replacement cycles that consume energy and generate construction waste. While asphalt shingle roofs require two or three replacements over a fifty-year period, Standing Seam Metal Roof Sheets typically provide service throughout this timeframe without major intervention. This longevity prevents disposal of thousands of pounds of waste materials while eliminating the energy consumption and emissions associated with multiple roof tear-offs and replacements. Xi'an Huafeng's commitment to green sustainable development aligns with these environmental priorities, integrating eco-friendly manufacturing processes across their production facilities.

Integration with Renewable Energy Systems

Renewable energy installations increasingly factor into roofing system selection as solar photovoltaic technology becomes economically attractive for commercial buildings. Standing Seam Metal Roof Sheets provide an ideal mounting platform for solar arrays through specialized non-penetrating clamp systems that attach directly to raised seams. This mounting approach preserves roof warranty and weatherproofing integrity while providing robust attachment points for panel racking systems. The long service life of Standing Seam Metal Roof Sheets matches the twenty-five to thirty-year lifespan of solar installations, avoiding the costly complication of removing and reinstalling arrays during roof replacement.

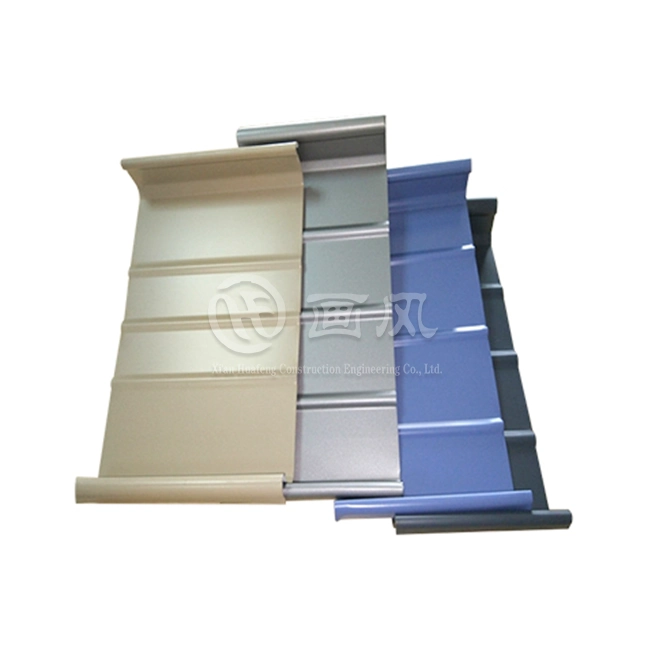

Aesthetic Versatility and Architectural Expression

Modern commercial architecture demands building envelope solutions that deliver technical performance without compromising design intent. Standing Seam Metal Roof Sheets offer exceptional aesthetic flexibility through numerous profile options, panel widths, seam heights, and finish selections. The clean, linear appearance of Standing Seam Metal Roof Sheets complements contemporary architectural styles while providing appropriate character for industrial and agricultural applications. Architects appreciate the crisp shadow lines created by raised seams and the sophisticated appearance of concealed fastener systems that eliminate the visual clutter of screw-down panels. Color selection significantly impacts building appearance and Standing Seam Metal Roof Sheets deliver extensive options through premium coating systems. Xi'an Huafeng offers a comprehensive palette of RAL and Pantone colors enabling precise coordination with exterior cladding, trim elements, and corporate branding requirements. Custom color matching accommodates specialty applications and ensures consistency across phased construction projects. The color retention properties of PVDF coatings maintain appearance for decades, preventing the fading and chalking that degrades lesser coating systems within ten to fifteen years.

Panel Profile Options for Diverse Applications

The Standing Seam Metal Roof Sheets category encompasses multiple panel profiles engineered for specific performance requirements and aesthetic preferences. Snap-lock profiles feature factory-formed seams that interlock during installation, enabling rapid panel attachment suitable for steep-slope residential and light commercial applications. Mechanically seamed profiles require field seaming using electric or manual crimping tools, creating a weathertight double-lock joint capable of withstanding low-slope conditions and extreme exposure. Batten seam systems incorporate raised caps covering panel seams, delivering enhanced visual impact appropriate for high-profile architectural projects. Panel width and seam height variations enable customization matching project requirements. Narrow panels with frequent seams create pronounced linear patterns suitable for vertical-emphasis designs, while wider panels with fewer seams provide a more subtle appearance and cost advantages through reduced material and labor requirements. Xi'an Huafeng manufactures Standing Seam Metal Roof Sheets in multiple profile configurations including twenty-five to sixty-five millimeter seam heights and panel widths accommodating various structural support spacing and aesthetic intentions.

Maintenance Efficiency and Lifecycle Cost Advantages

Total cost of ownership calculations increasingly influence roofing system selection as building owners recognize that initial material costs represent only a fraction of lifecycle expenses. Standing Seam Metal Roof Sheets deliver superior long-term value through minimal maintenance requirements that reduce ongoing service costs dramatically. The concealed fastener design eliminates the periodic screw replacement and regasketing that conventional exposed fastener systems require every five to ten years. Panel coating systems resist mold, mildew, and algae growth that degrades and stains other roofing materials, maintaining appearance without costly cleaning interventions. Routine maintenance for Standing Seam Metal Roof Sheets consists primarily of periodic inspections, debris removal from valleys and penetration areas, and verification of proper drainage function. These simple tasks typically consume only a few hours annually even on large commercial buildings, contrasting sharply with the intensive maintenance demands of built-up roofing, single-ply membranes, or tile systems. When repairs become necessary, the panel replacement capability of Standing Seam Metal Roof Sheets enables localized intervention without disrupting adjacent areas or compromising overall system integrity.

Warranty Coverage and Performance Assurance

Comprehensive warranty programs provide financial protection and performance confidence crucial for builders and building owners. Premium Standing Seam Metal Roof Sheets manufacturers including Xi'an Huafeng offer thirty-year warranties covering material performance, coating integrity, and weatherproofing function. These warranties demonstrate manufacturer confidence in product quality and provide recourse if unexpected failures occur. Warranty coverage extends beyond material defects to include paint finish guarantees protecting against excessive fading, chalking, or peeling that would compromise appearance and weather resistance.

Manufacturing Quality and Supply Chain Reliability

Professional builders require supply partners capable of delivering consistent quality and meeting demanding project schedules. Xi'an Huafeng Construction Engineering Company operates comprehensive manufacturing facilities including a two-hundred-thousand-square-meter raw material production plant and dedicated panel processing facilities in Hangzhou and Xi'an. This integrated production capability ensures material traceability and quality control throughout the manufacturing process. Seven color coating production lines and over forty specialized machines including shearing equipment, presses, and bending machines enable monthly production capacity exceeding one thousand tons of Standing Seam Metal Roof Sheets. Quality assurance protocols at Xi'an Huafeng encompass rigorous incoming material inspection, in-process verification, and finished product testing. Raw materials from approved suppliers undergo verification testing including salt spray exposure, adhesion measurement, hardness testing, and weather resistance evaluation before entering production. Finished Standing Seam Metal Roof Sheets receive dimensional inspection, flatness verification, and appearance grading ensuring compliance with project specifications. ISO 9001 and ISO 14001 certifications demonstrate commitment to systematic quality management and environmental responsibility.

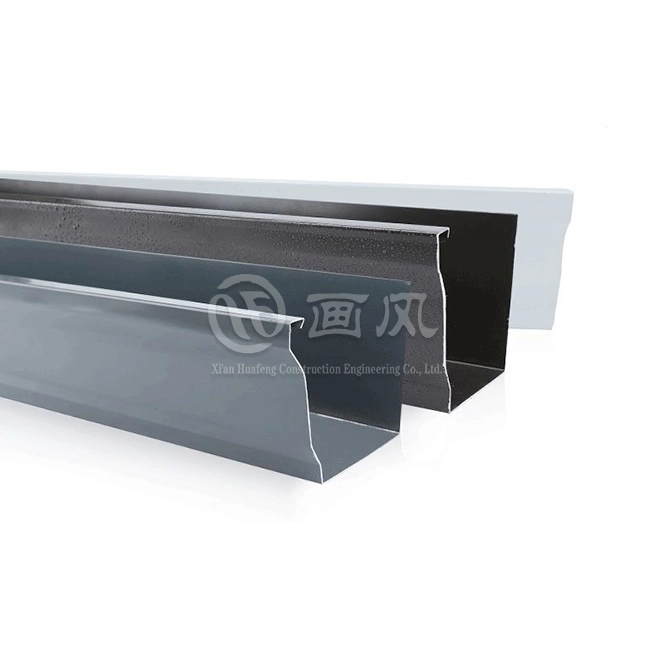

Project Support and Technical Resources

Successful Standing Seam Metal Roof Sheets installations require comprehensive technical support throughout the project lifecycle from design development through construction completion. Xi'an Huafeng provides engineering services including structural analysis, drainage system design, and material specification assistance that optimize system performance and cost-effectiveness. The company's design department performs detailed drawing development, translating architectural concepts into manufacturable panel configurations with properly coordinated trim and accessory components. Installation guidance ensures field crews execute proper techniques that realize the performance potential of Standing Seam Metal Roof Sheets. Xi'an Huafeng's technical specialists provide on-site construction support, verifying substrate conditions, supervising critical installation phases, and conducting final system testing. This comprehensive approach prevents common installation errors that compromise even premium materials, protecting builder reputations and ensuring client satisfaction.

Conclusion

Standing Seam Metal Roof Sheets represent the optimal roofing solution for professional builders seeking superior performance, longevity, and value across commercial, industrial, and institutional projects. The combination of weather-tight concealed fastener design, exceptional material quality, and comprehensive manufacturing support delivers measurable advantages that justify material premiums through reduced lifecycle costs and enhanced building performance.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

Xi'an Huafeng Construction Engineering Company has established industry leadership through comprehensive capabilities spanning design, manufacturing, and construction. Established in Shaanxi Province in 2018, the company achieved recognition as a high-tech enterprise in 2020, supported by first-level qualification for building curtain walls and third-level qualification for building steel structures. The company's integrated approach provides clients with one-stop solutions encompassing custom engineering design, precision manufacturing, and seamless installation services.

As a China Standing Seam Metal Roof Sheets factory and China Standing Seam Metal Roof Sheets manufacturer, Xi'an Huafeng delivers competitive Standing Seam Metal Roof Sheets price through efficient production operations and strategic material sourcing. The company serves as a trusted China Standing Seam Metal Roof Sheets supplier offering China Standing Seam Metal Roof Sheets wholesale for projects requiring volume quantities. High Quality Standing Seam Metal Roof Sheets for sale include multiple specifications from twenty-five-three-thirty through sixty-five-four-thirty profiles with PVDF and PE surface treatments. Minimum order quantities of five hundred square meters and delivery within fifteen to twenty days accommodate diverse project requirements.

Xi'an Huafeng's extensive project portfolio demonstrates proven capability across high-profile applications including Xiongan Station Commercial Complex, Xi'an International Convention and Exhibition Center, and Inner Mongolia Tongliao Art Museum. The company holds over twenty registered patents protecting innovative roofing system designs and maintains comprehensive certifications including CE, ISO, and SGS qualifications. Engineering design expertise, advanced production equipment featuring seven dedicated lines and forty specialized machines, and complete quality management systems position Xi'an Huafeng as your premier partner for demanding Standing Seam Metal Roof Sheets applications. Contact our team today at huafeng@hfmetalroof.com to discuss your project requirements and discover how our customized solutions deliver superior value.

References

1. American Iron and Steel Institute. "Standing Seam Metal Roofing Systems: Design and Installation Guide." Technical Publication Series.

2. Metal Construction Association. "Architectural Metal Roofing: Design Standards and Performance Testing." Industry Standards Documentation.

3. National Roofing Contractors Association. "The NRCA Metal Panel and SPF Roof Systems Manual." Professional Installation Guidelines.

4. Sheffield Metals International. "Metal Roofing Engineering Handbook: Technical Specifications for Standing Seam Systems." Manufacturing Reference.

5. Western States Metal Roofing Technical Staff. "Understanding Metal Roofing Panel Profiles: A Comprehensive Guide for Builders." Construction Industry Publication.

_1757558889992.webp)