Picture this scenario: You're standing on a commercial roof during a critical installation deadline when you realize the mounting system you've specified doesn't match the standing seam profile. Panels are waiting, crews are on standby, and weather windows are closing fast. This nightmare situation happens more often than professionals care to admit, costing thousands in delays and rework. Metal Standing Seam Clamps installation requires precise technical knowledge, proper equipment selection, and adherence to manufacturer specifications to ensure watertight integrity and structural performance. This comprehensive guide delivers proven installation strategies from industry veterans who have completed thousands of successful projects across diverse roof profiles and challenging environmental conditions.

Understanding Metal Standing Seam Clamps and Their Critical Role

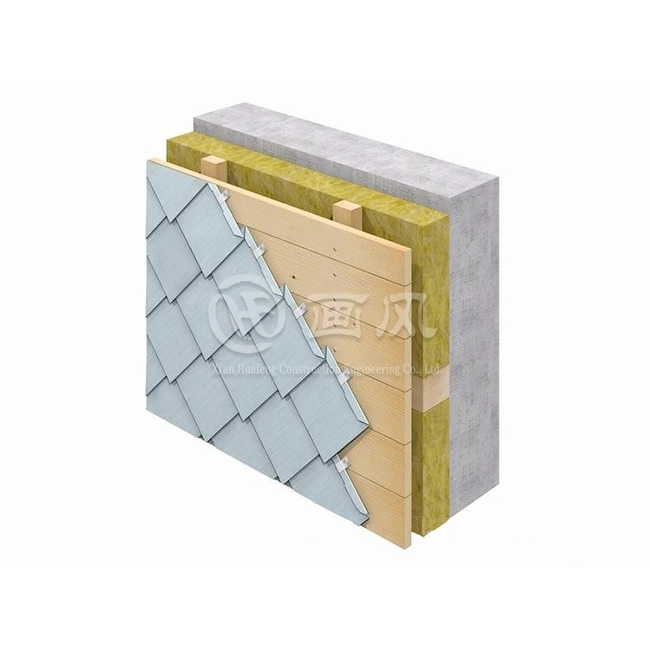

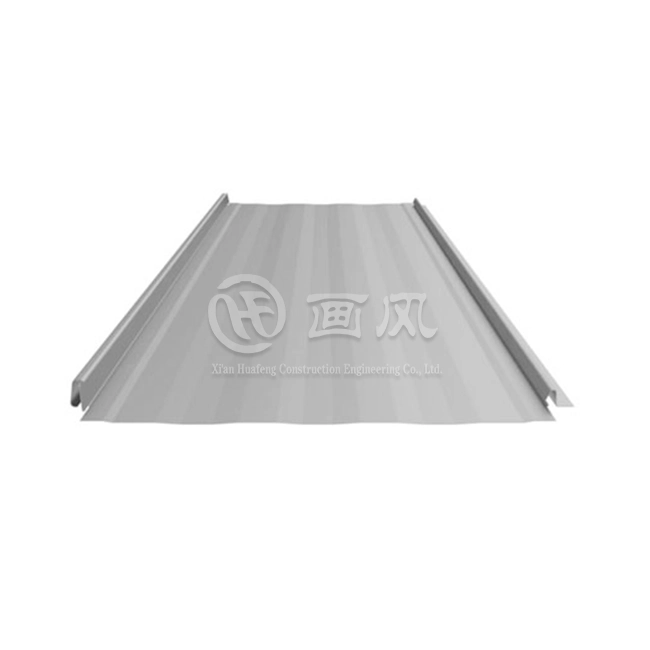

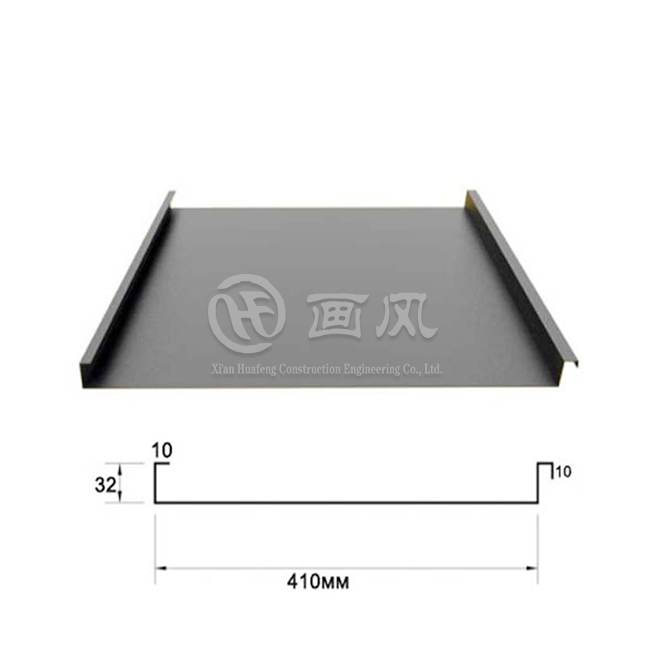

Metal Standing Seam Clamps represent a revolutionary advancement in non-penetrative roof attachment technology that fundamentally changed how professionals approach metal roofing installations. These precision-engineered devices grip standing seam profiles through mechanical compression rather than penetration, preserving the roof's weather barrier while providing secure mounting points for solar arrays, snow retention systems, HVAC equipment, walkways, signage, and various other roof-mounted accessories. The engineering behind modern aluminum roof clamps for metal roofing involves sophisticated load distribution mechanisms, corrosion-resistant materials, and profile-specific geometries that accommodate thermal movement while maintaining holding strength across temperature extremes and dynamic loading conditions. Standing seam metal roofs feature raised vertical ribs that interlock to create continuous watertight seals running from ridge to eave. This architectural design eliminates exposed fasteners on the roof surface, significantly reducing leak potential while allowing for thermal expansion and contraction through floating clip systems. The seam profiles vary considerably across manufacturers and include snap-lock configurations, mechanical lock systems, batten seam designs, and architectural standing seams with heights ranging from 1 to 3 inches. Each profile type presents unique attachment challenges that Metal Standing Seam Clamps must address through specialized geometries, setscrew configurations, and clamping mechanisms designed to engage both male and female seam components without compromising panel integrity or voiding manufacturer warranties.

Professional installers recognize that aluminum roof clamps for metal roofing manufactured from 6063-T5 or T6 aluminum alloy with anodized surface treatments exceeding 40 micrometers provide optimal corrosion resistance and longevity matching the service life of premium metal roofing systems. Xi'an Huafeng Construction Engineering Co., Ltd. produces Metal Standing Seam Clamps with 3.00±0.15mm thickness specifications that deliver tensile strength exceeding 160 N/mm², ensuring reliable performance under extreme loading conditions encountered in high-wind coastal environments, heavy snow load regions, and seismic zones. The company's advanced manufacturing capabilities include surface sandblasting and fluorocarbon spray coating processes that enhance weathering resistance beyond standard anodizing treatments.

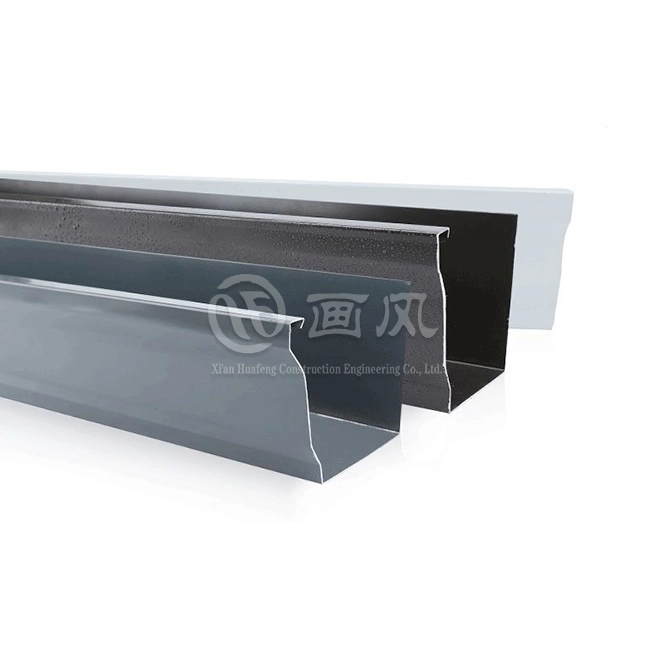

Types of Metal Standing Seam Clamps and Their Applications

Point clamps, L-shaped clamps, flat clamps, and double-piece clamps each serve specific installation requirements based on seam geometry, loading direction, and attachment objectives. Point clamps concentrate holding force at discrete locations ideal for distributed loading applications like snow guards, while L-shaped configurations provide offset mounting points for equipment positioning away from seam centerlines. Flat clamps deliver broad contact surfaces distributing loads across wider seam sections, making them suitable for heavy equipment installations requiring maximum pull-out resistance. Double-piece clamp assemblies feature adjustable components accommodating variable seam widths and irregular profiles common in retrofit applications where original panel specifications may be uncertain or inconsistent. Understanding load directionality proves critical when specifying Metal Standing Seam Clamps for professional installations. Normal-to-seam loads (pull-up forces) test clamp resistance to vertical separation from the roof surface, relevant for wind uplift, snow sliding forces, and equipment dead loads. Parallel-to-seam loads (drag forces) measure lateral resistance along the seam length, critical for seismic restraint, thermal movement accommodation, and distributed snow retention systems. Aluminum roof clamps for metal roofing must be engineered and tested for both load directions, with published load tables specific to panel manufacturer, profile nomenclature, material gauge, and coating systems. Xi'an Huafeng's clamps comply with GB/T 5237.5-2017 standards and undergo rigorous testing protocols validating performance across diverse roof profiles and environmental exposure conditions.

Pre-Installation Planning and Site Assessment

Successful Metal Standing Seam Clamps installation begins long before crews arrive on site with comprehensive planning that addresses panel identification, load calculation, spacing determination, tool preparation, and safety protocol establishment. Professional contractors recognize that inadequate planning causes the majority of installation delays, rework requirements, and performance failures in the field. Begin by obtaining complete roof panel specifications including manufacturer name, profile designation, material type, gauge thickness, coating system, and production year. This information determines compatible clamp models, allowable loading capacities, and installation torque specifications essential for warranty compliance and structural adequacy. Conduct thorough site surveys documenting seam spacing patterns, panel condition, existing penetrations, structural support locations, access constraints, fall protection requirements, and environmental hazards before mobilizing installation crews. Photograph representative seam cross-sections, measure actual seam heights and widths at multiple roof locations, and verify that panel conditions meet manufacturer specifications for clamp installation. Look for evidence of panel distortion, coating degradation, seam separation, previous repair attempts, or manufacturing defects that could compromise clamp performance or indicate underlying structural issues requiring remediation before proceeding with attachment installations.

Calculate required clamp quantities based on engineered spacing requirements derived from structural load analysis, building code compliance, and manufacturer installation guidelines. Aluminum roof clamps for metal roofing spacing typically ranges from 12 to 36 inches on center depending on loading intensity, wind exposure category, seismic design category, and panel spanning capabilities. Conservative spacing improves system redundancy and load distribution but increases material costs and installation labor, while excessive spacing may result in inadequate load transfer, panel deflection, or localized stress concentrations. Professional engineers should provide stamped calculations and installation drawings specifying clamp locations, quantities, and supplementary attachments required for code compliance.

Essential Tools and Equipment for Professional Installation

Assemble complete tool kits before commencing Metal Standing Seam Clamps installation to avoid productivity losses from missing equipment or improper tool selection. Required tools include calibrated torque-limiting screw guns or cordless drills with adjustable clutch settings, T30 Torx driver bits specifically designed for clamp setscrews, dial-indicating torque wrenches for tool calibration verification, measuring tapes and marking tools for layout documentation, and personal fall protection equipment certified for metal roof applications. Xi'an Huafeng recommends using professional-grade electric or pneumatic screw guns with digital torque displays providing real-time feedback during setscrew tightening to ensure consistent installation quality across large-scale projects. Verify all tools function properly and meet manufacturer specifications before beginning installations. Calibrate screw gun torque settings using precision torque wrenches set to specified values, typically 90 inch-pounds for cupped-tip setscrews on aluminum roof clamps for metal roofing, though exact requirements vary by clamp model and panel material. Test calibration on sample panels or sacrificial seam sections before proceeding to final installations, adjusting clutch settings until consistent torque achievement occurs without over-torquing that causes excessive seam distortion or under-torquing that fails to adequately secure clamps. Document calibration results and recheck torque settings periodically throughout extended installation periods to account for tool wear, battery voltage fluctuations, or environmental temperature effects on torque delivery.

Step-by-Step Metal Standing Seam Clamps Installation Process

Begin installation by thoroughly cleaning seam surfaces where Metal Standing Seam Clamps will be positioned, removing all dust, debris, oxidation, or contaminants that could interfere with proper clamp seating or setscrew engagement. Use clean rags or compressed air to clear seam channels without damaging panel coatings or introducing abrasive materials that accelerate corrosion. Inspect cleaned seams for coating integrity, verifying no bare metal exposure, coating delamination, or surface defects exist at planned clamp locations. Address any coating damage through touch-up procedures specified by the panel manufacturer before proceeding with clamp installation to maintain corrosion protection and warranty coverage. Position the first clamp at the designated location according to installation drawings, ensuring proper orientation with setscrew access facing the correct direction for tool engagement. Top-loading clamp designs allow placement anywhere along seam length without feeding from panel ends, significantly reducing installation time and minimizing finish damage risks compared to non-top-loading configurations. Slide the clamp over the seam until it fully seats against the seam base with the clamp body horizontal throat properly engaging the batten cap or seam fold. Verify complete seam engagement before tightening setscrews, as partial seating reduces holding capacity and may cause progressive loosening under dynamic loading conditions.

Thread setscrews into the clamp body by hand until finger-tight resistance indicates engagement with the seam surface. This preliminary positioning prevents cross-threading and ensures proper alignment before applying torque. Insert the T30 Torx driver bit into the screw gun, verify torque setting accuracy, and begin systematic tightening following the alternating sequence specified by the clamp manufacturer. For two-setscrew designs typical of aluminum roof clamps for metal roofing, partially tighten the first setscrew to approximately fifty percent of final torque, then partially tighten the second setscrew to the same level. Return to the first setscrew and advance to final torque specification, then complete final torquing on the second setscrew. This alternating tightening pattern ensures uniform compression distribution across the seam width, preventing asymmetric loading that causes panel distortion or premature clamp failure.

Critical Installation Details and Common Mistakes to Avoid

Achieving proper setscrew torque represents the most critical factor determining Metal Standing Seam Clamps installation success or failure. Insufficient torque allows clamps to slip under load, progressively loosening until complete detachment occurs, while excessive torque causes seam crushing, coating penetration, or panel deformation that compromises both structural performance and weather resistance. Modern cupped-tip setscrews used on quality aluminum roof clamps for metal roofing require only 90 inch-pounds torque compared to 150 inch-pounds or higher for round-tip designs, significantly reducing panel distortion while improving corrosion resistance by minimizing coating disruption. Xi'an Huafeng's clamps feature anti-seizing coarse thread setscrews with cupped tips that dimple rather than penetrate panel surfaces, allowing unlimited re-torquing and re-attachment cycles without progressive coating damage or thread galling issues common with inferior setscrew designs.

Never attempt to compensate for undersized or incorrectly specified clamps by over-torquing setscrews beyond manufacturer recommendations. This dangerous practice causes immediate panel damage and frequently results in catastrophic clamp failure under loading conditions well below published capacities. If clamps fail to adequately grip seams at specified torque settings, immediately stop installation and verify correct clamp model selection for the actual roof profile. Panel profile misidentification represents a frequent cause of field installation problems, particularly on retrofit projects where original construction documentation may be incomplete or inaccurate. Consult panel cross-section measurements, contact the building owner for original specifications, or submit profile samples to clamp manufacturers for positive identification before proceeding. Maintain consistent installation quality across all clamp locations through systematic inspection protocols and quality control documentation. Photograph completed installations at representative locations, record actual torque values achieved, document any anomalies or deviations from standard procedures, and verify that all clamps are fully seated and properly oriented before releasing installation crews from the roof. Professional contractors implementing formal quality assurance programs experience significantly lower callback rates, warranty claims, and performance issues compared to those relying on informal inspection approaches or installer self-certification without independent verification.

Advanced Installation Techniques for Challenging Conditions

Complex roof geometries, unusual panel profiles, retrofit applications, and extreme environmental conditions frequently require advanced installation techniques beyond standard procedures. Hip and valley conditions where panel directions change demand careful attention to clamp orientation, load distribution, and thermal movement accommodation to prevent binding or stress concentration at transitional roof areas. Consider installing supplementary structural reinforcement or using specialized clamp configurations designed for multi-directional loading when attaching equipment or snow retention systems near roof geometry transitions. Consult with structural engineers and Metal Standing Seam Clamps manufacturers to develop project-specific installation details addressing unique site conditions. Retrofit installations on aged roof systems require additional precautions and assessment procedures compared to new construction applications. Older panels may exhibit coating degradation, seam loosening, fastener corrosion, or structural fatigue that compromises clamp holding capacity below published values derived from testing on new material samples. Conduct comprehensive roof condition surveys including representative panel removal and laboratory testing when planning major retrofit installations on systems exceeding twenty years service age. Consider panel replacement, structural reinforcement, or alternative attachment strategies if existing conditions cannot reliably support planned loading intensities. Never assume that published clamp capacities apply to deteriorated roof systems without engineering evaluation and load testing validation on actual project conditions.

Cold weather installation presents specific challenges related to material brittleness, coating flexibility, and tool performance that require procedural modifications for successful outcomes. Aluminum roof clamps for metal roofing and panel materials become more brittle at temperatures below freezing, increasing risk of coating cracking, seam fracture, or clamp body damage during installation. Warm clamps and panels to ambient temperatures before installation when possible, use temperature-compensated torque specifications accounting for material property changes, and avoid impacting or shocking cold materials that may fracture under conditions tolerated during warmer weather. Battery-powered tools experience capacity reduction in cold conditions, requiring more frequent recharging and performance monitoring to maintain consistent torque delivery throughout installation activities.

Quality Assurance Testing and Performance Verification

Implement systematic quality assurance testing procedures validating Metal Standing Seam Clamps installation integrity and load-carrying performance before accepting completed work and releasing final payments. Non-destructive testing methods include visual inspection for proper seam engagement and orientation, torque verification using calibrated wrenches on random clamp samples, and proof loading selected installations to percentages of design loads through controlled pull testing equipment. Destructive testing on designated sacrificial installations provides definitive performance validation by loading clamps to failure, documenting actual capacity achieved compared to published values, and verifying installation procedures produced outcomes consistent with engineering design assumptions. Document all testing results through comprehensive reports including photographic evidence, data tables, comparison to acceptance criteria, and corrective action documentation for any deficiencies identified during testing programs. Professional installations should achieve load-carrying capacities within ten percent of published values when testing accounts for actual panel conditions, gauge thicknesses, and material properties. Significant deviations below published capacities indicate installation defects, panel degradation, or profile incompatibilities requiring investigation and remediation before system acceptance. Xi'an Huafeng Construction Engineering Co., Ltd. provides technical support for installation verification testing, including recommended protocols, acceptance criteria, and interpretation of test results for projects using their aluminum roof clamps for metal roofing systems.

Maintenance and Long-Term Performance Monitoring

Professional Metal Standing Seam Clamps installations require ongoing maintenance and monitoring programs ensuring continued performance throughout the building service life. Establish inspection schedules conducting visual surveys annually or following significant weather events like hurricanes, heavy snow loads, or hailstorms that may impact roof system integrity. Document clamp conditions including corrosion evidence, coating degradation, setscrew loosening, panel distortion, or attached equipment movement indicating potential installation issues requiring corrective action. Address identified deficiencies promptly through re-torquing procedures, clamp replacement, or supplementary reinforcement before progressive deterioration leads to catastrophic failures. Aluminum roof clamps for metal roofing manufactured with proper materials and surface treatments should exhibit minimal corrosion or degradation throughout thirty-year warranty periods when installed on compatible roof systems in appropriate environmental exposures. However, dissimilar metal contact, electrolytic corrosion from improper material selection, coating damage during installation, or environmental factors like industrial pollution or coastal salt exposure may accelerate deterioration beyond normal weathering expectations. Monitor high-risk installations more frequently, implement corrosion mitigation strategies like supplementary coatings or cathodic protection systems, and maintain detailed condition documentation supporting warranty claims or insurance requirements if premature failures occur.

Train facility maintenance personnel in proper inspection techniques, documentation requirements, and corrective action procedures ensuring that building owners can effectively manage roof clamp systems without requiring continuous professional contractor involvement. Provide comprehensive maintenance manuals including clamp specifications, installation drawings, recommended inspection intervals, torque specifications for re-tightening procedures, and manufacturer contact information for technical support or replacement component procurement. Xi'an Huafeng offers maintenance guidance and technical assistance for systems using their Metal Standing Seam Clamps, helping building owners maximize investment returns through extended service life and optimal performance.

Conclusion

Metal Standing Seam Clamps installation demands technical expertise, quality materials, proper equipment, and systematic procedures ensuring reliable performance protecting building investments and occupant safety. Professional contractors who master these installation principles deliver superior outcomes reducing callbacks, warranty claims, and long-term maintenance costs while building reputations for excellence that generate repeat business and referrals.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

Xi'an Huafeng Construction Engineering Co., Ltd. stands as a China Metal Standing Seam Clamps factory, China Metal Standing Seam Clamps supplier, and China Metal Standing Seam Clamps manufacturer delivering exceptional quality products since 2018. Our comprehensive manufacturing capabilities include three factories with seven production lines and more than forty machines producing Metal Standing Seam Clamps for sale meeting the highest international standards. As a recognized high-tech enterprise in Shaanxi Province holding first-level building curtain wall qualifications and third-level steel structure qualifications, we provide one-stop solutions from design through construction for metal roofing systems, wall systems, and building envelope applications. Our High Quality Metal Standing Seam Clamps feature aluminum alloy 6063-T6 construction, anodizing exceeding 40 micrometers, and surface treatments including sandblasting and fluorocarbon spraying ensuring thirty-year warranty performance. With over twenty registered patents, ISO9001 and ISO14001 certifications, and proven experience on major projects including Xiongan Station, Xi'an International Convention Center, and numerous other high-profile installations worldwide, we deliver the expertise and capacity your project demands. Our China Metal Standing Seam Clamps wholesale pricing, customization capabilities, and dedicated technical support team provide competitive advantages for contractors and developers seeking reliable partners. Contact us today at huafeng@hfmetalroof.com to discuss your project requirements and discover how our engineering design experience, quality certifications, and customized solutions deliver superior Metal Standing Seam Clamps price value and performance. Save this resource and contact us whenever questions arise during your metal roofing projects!

References

1. Metal Roofing Alliance. "Standing Seam Metal Roof Systems: Installation and Performance Guidelines." Technical Manual Series, 2023.

2. Thompson, Robert J., and Sarah Mitchell. "Non-Penetrative Attachment Systems for Metal Roofing: Engineering Analysis and Field Performance Data." Journal of Architectural Engineering, Vol. 28, No. 4, 2022.

3. American Society of Civil Engineers. "Standard Practice for Roof Clamp Load Testing on Standing Seam Metal Roof Systems." ASCE Technical Committee Report, 2021.

4. National Roofing Contractors Association. "Metal Roof Attachment Guidelines: Best Practices for Contractors and Installers." Professional Roofing Magazine Technical Supplement, 2023.

5. Zhang, Wei, and David Peterson. "Corrosion Resistance and Long-Term Performance of Aluminum Roof Clamps in Coastal Environments." Corrosion Engineering International Quarterly, Vol. 45, No. 2, 2022.