Imagine discovering water damage after a severe storm because your traditional roofing system failed at the seams. Or picture struggling with endless maintenance costs and premature roof replacement due to corrosion and weathering. These challenges have pushed architects, builders, and property owners worldwide to seek advanced roofing solutions that deliver uncompromising protection while elevating architectural aesthetics. Aluminum Standing Seam Metal Roof Panels represent the evolution of modern roofing technology, combining exceptional durability, contemporary design, and sustainable performance. This comprehensive guide explores how these innovative roofing systems solve critical building challenges while creating striking architectural statements that stand the test of time.

Understanding Aluminum Standing Seam Metal Roof Panel Systems

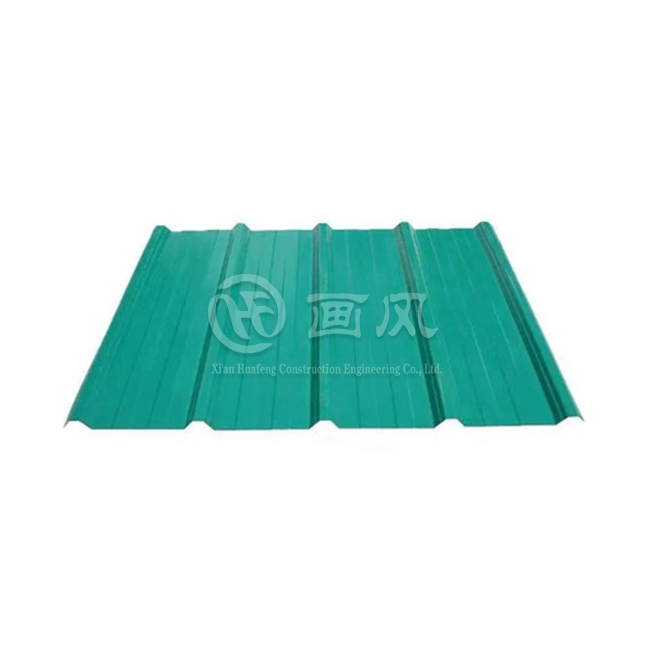

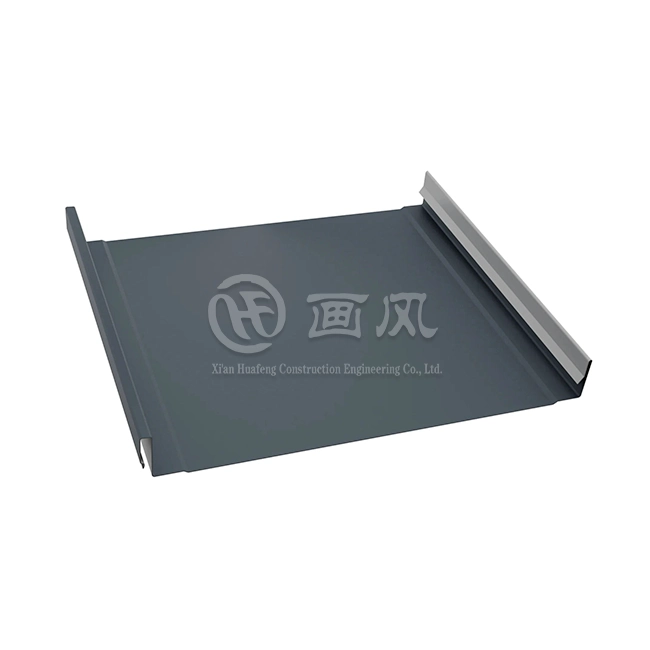

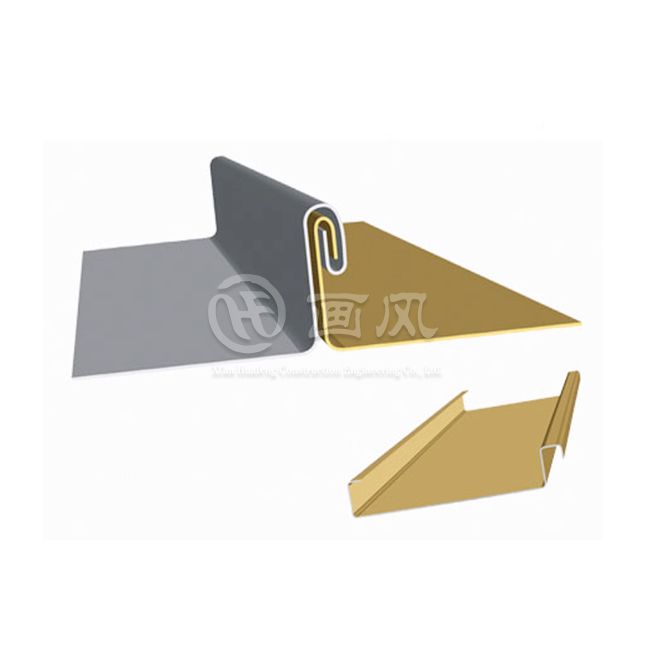

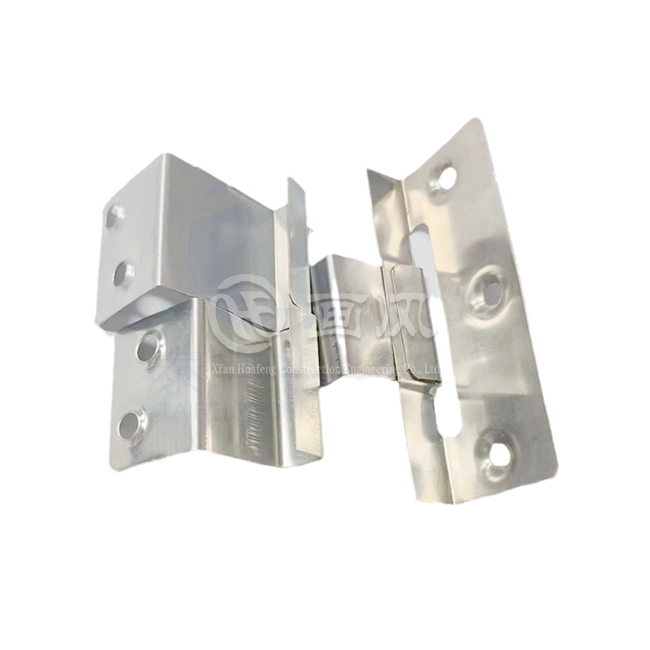

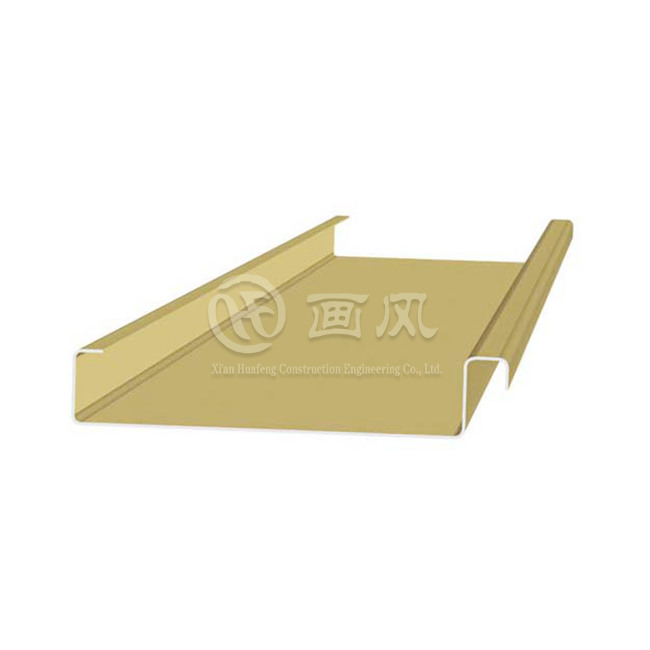

Aluminum Standing Seam Metal Roof Panels are premium roofing materials engineered from lightweight aluminum alloys, featuring raised interlocking seams with mechanical lock edges that eliminate exposed fasteners. This concealed fastener design creates a waterproof barrier while delivering a clean, modern aesthetic that complements contemporary architectural styles. The standing seam configuration allows panels to run continuously from ridge to eave, with vertical seams raised above the roof surface to channel water effectively and prevent leaks. The engineering behind Aluminum Standing Seam Metal Roof Panels focuses on thermal movement accommodation. Unlike traditional roofing materials, these systems feature floating clip mechanisms that allow panels to expand and contract naturally with temperature fluctuations without compromising structural integrity. This innovation eliminates common failure points associated with thermal stress, including fastener backup, panel buckling, and seal deterioration. Manufacturing processes utilize high-grade aluminum alloys including AA3003, AA3004, and AA5052, which offer superior corrosion resistance and moderate strength properties ideal for demanding environmental conditions. Surface treatment options significantly enhance the performance and longevity of Aluminum Standing Seam Metal Roof Panels. PVDF fluorocarbon coatings provide exceptional fade resistance and color retention for over twenty years, while anodizing treatments create durable oxide layers that protect against environmental degradation. Panel thickness ranges from 0.7mm to 1.2mm, with rib heights between 25mm and 65mm designed to maximize water shedding capacity and structural performance. The effective coverage width varies from 300mm to 600mm, allowing designers to achieve specific aesthetic effects while maintaining optimal installation efficiency.

Material Advantages for Modern Construction

Aluminum's inherent properties make it exceptionally suited for standing seam applications in modern architecture. With a density approximately one-third that of steel, Aluminum Standing Seam Metal Roof Panels dramatically reduce structural loads on buildings, enabling lighter framing systems and potentially lower foundation requirements. This weight advantage translates into reduced construction costs and expanded design possibilities for both new construction and retrofit applications. The material's natural oxide film provides continuous self-protection against atmospheric corrosion, eliminating rust concerns that plague steel roofing systems even in coastal and industrial environments. The longevity expectations for properly installed Aluminum Standing Seam Metal Roof Panels exceed fifty years, with PVDF-coated systems maintaining their appearance and protective qualities for decades with minimal maintenance intervention. This extended service life represents significant lifecycle cost savings compared to traditional roofing materials requiring replacement every fifteen to twenty-five years. Environmental considerations further enhance aluminum's appeal, as the material maintains 100% recyclability without quality degradation, supporting sustainable building practices and LEED certification goals. Lower embodied energy requirements during production and the potential for cool roof performance through reflective coatings contribute to reduced building operational costs and environmental impact.

Design Flexibility and Architectural Integration

Aluminum Standing Seam Metal Roof Panels excel in accommodating complex architectural geometries that challenge conventional roofing materials. The material's formability allows for curved applications, radius work, and transitions between different roof planes without compromising weather protection. Architects can specify custom panel widths, rib heights, and seam configurations to achieve specific visual effects ranging from subtle sophistication to bold contemporary statements. Color customization through various RAL and Pantone selections enables precise matching to overall design schemes, while specialized finishes including metallic, matte, and high-gloss options expand creative possibilities. The compatibility of Aluminum Standing Seam Metal Roof Panels with modern building technologies supports integrated approaches to building performance. Solar panel mounting systems can be seamlessly incorporated into standing seam profiles, facilitating renewable energy generation without roof penetrations. Snow retention systems attach directly to seams, providing winter weather management without compromising roof integrity. These integration capabilities make standing seam aluminum an ideal choice for high-performance buildings pursuing net-zero energy goals and advanced sustainability certifications. The clean lines and concealed fastener approach inherent to standing seam design align perfectly with contemporary architectural aesthetics emphasizing minimalism and refined detailing.

Installation Excellence and Performance Optimization

Professional installation represents a critical factor in maximizing the performance potential of Aluminum Standing Seam Metal Roof Panels. The concealed fastener clip system requires precise alignment and proper engagement to ensure panels float correctly during thermal expansion cycles. Installation technicians must understand substrate preparation requirements, including proper ventilation, underlayment selection, and deck flatness tolerances that directly impact final appearance and long-term performance. Mechanical seaming operations demand specialized equipment including hand seamers or motorized seaming tools that create consistent 90-degree or 180-degree locks between adjacent panels. Quality control throughout the installation process prevents common failure modes and ensures warranty compliance. Panel layout planning must account for thermal movement allowances, expansion joint locations, and proper clip spacing based on wind load calculations and structural requirements. Transition details at roof penetrations, ridges, valleys, and eaves require careful execution using compatible trim accessories manufactured to precise tolerances. Proper sequencing of operations, from substrate inspection through final trim installation, maintains construction schedule efficiency while delivering superior results. Post-installation testing including water testing at critical details verifies complete weather protection before project acceptance.

Manufacturing Quality and Material Specifications

Manufacturing excellence begins with material selection and quality verification procedures. Premium Aluminum Standing Seam Metal Roof Panels utilize aluminum alloys meeting ASTM B209 specifications, with chemical composition and mechanical properties certified through mill test reports. Coil coating operations apply PVDF fluoropolymer finishes meeting AAMA 2605 standards for superior weather resistance, with minimum dry film thickness specifications ensuring long-term color stability. Roll-forming processes maintain tight dimensional tolerances across panel length, with sophisticated quality control systems monitoring profile geometry, seam alignment, and surface condition. Advanced production facilities incorporate multiple quality checkpoints throughout the manufacturing sequence. Incoming material inspection verifies aluminum substrate thickness, surface preparation, and coating adhesion through standardized testing protocols including salt spray exposure, impact resistance, and cross-hatch adhesion tests. In-process quality measures monitor roll-former setup parameters, panel straightness, and mechanical properties to ensure consistent output. Finished product inspection examines appearance characteristics including color uniformity, surface defects, and dimensional accuracy before packaging. These comprehensive quality systems ensure that Aluminum Standing Seam Metal Roof Panels leaving the factory meet exacting specifications for critical architectural applications.

Application Scenarios and Project Types

Aluminum Standing Seam Metal Roof Panels serve diverse building types across commercial, industrial, and residential sectors. Commercial applications including shopping malls, office buildings, and airport terminals benefit from the material's ability to span long distances while maintaining weather integrity and aesthetic appeal. The low maintenance requirements and extended service life align with commercial property management goals focused on lifecycle cost optimization. High-profile visibility in these applications demands superior appearance retention, which PVDF-coated aluminum consistently delivers across decades of service. Public facilities including gymnasiums, museums, educational institutions, and cultural centers increasingly specify Aluminum Standing Seam Metal Roof Panels for their combination of performance and architectural expression. These buildings often feature complex geometries and large uninterrupted roof planes where standing seam systems excel in providing reliable weather protection while creating distinctive visual character. The material's fire resistance properties and compliance with stringent building codes make it particularly suitable for assembly occupancies and historic renovation projects requiring non-combustible roofing solutions. Industrial applications present demanding service environments where Aluminum Standing Seam Metal Roof Panels demonstrate exceptional value. Chemical processing facilities, food production plants, and manufacturing operations benefit from aluminum's inherent corrosion resistance against industrial atmospheres and process emissions. The material's immunity to rust eliminates contamination concerns critical in food-grade and pharmaceutical facilities. Coastal industrial sites particularly value aluminum's performance in salt-laden environments where steel-based systems suffer accelerated deterioration.

Residential and High-End Applications

High-end residential construction increasingly embraces Aluminum Standing Seam Metal Roof Panels as discerning homeowners seek permanent roofing solutions combining beauty with minimal maintenance demands. Contemporary villa designs and architectural statement homes utilize standing seam profiles to reinforce modern design vocabularies emphasizing clean lines and material authenticity. The ability to accommodate complex residential roof forms including multiple valleys, dormers, and architectural features makes aluminum standing seam practical beyond simple shed or gable configurations. Special environmental applications showcase aluminum's superior performance characteristics. Beachfront properties face constant salt spray exposure that rapidly degrades conventional roofing materials, while Aluminum Standing Seam Metal Roof Panels provide decades of reliable service without corrosion or deterioration. Tropical climate installations benefit from aluminum's reflective properties and cooling roof effects that reduce heat gain and lower air conditioning costs. High-altitude applications subject to intense UV exposure and extreme temperature swings rely on aluminum's dimensional stability and PVDF coating durability to maintain both protection and appearance through harsh seasonal cycles.

Technical Performance and Environmental Benefits

The thermal performance characteristics of Aluminum Standing Seam Metal Roof Panels contribute significantly to building energy efficiency. High solar reflectance values, particularly with light-colored PVDF coatings, reduce absorbed heat and lower cooling loads during warm weather. Thermal emittance properties allow absorbed heat to radiate away quickly, further enhancing energy performance. These cool roof attributes can qualify projects for energy code credits and utility incentive programs while providing measurable operational cost reductions. The air space created beneath raised seams enhances ventilation potential, supporting moisture management and additional thermal benefits. Structural performance capabilities enable Aluminum Standing Seam Metal Roof Panels to withstand severe weather events including high winds, heavy snow loads, and hail impact. Properly engineered systems tested to Miami-Dade protocols demonstrate wind resistance exceeding 200 mph, providing confidence in hurricane-prone regions. The interlocking seam configuration distributes wind uplift forces across the entire roof assembly rather than concentrating stress at individual fastener points. Impact resistance testing demonstrates Class 4 hail ratings, the highest classification available, protecting building contents and minimizing insurance claims from severe weather damage. Environmental sustainability considerations position Aluminum Standing Seam Metal Roof Panels as responsible choices for green building initiatives. The material's complete recyclability at end of service life supports circular economy principles, with recycled aluminum requiring only five percent of the energy needed for primary production. Low maintenance requirements eliminate the environmental burden of frequent repairs and premature replacement cycles common with traditional roofing materials. Potential for integration with solar power generation and rainwater harvesting systems enhances overall building sustainability performance while contributing toward certification under LEED, BREEAM, and other green building rating systems.

Maintenance Requirements and Lifecycle Considerations

Proper maintenance ensures Aluminum Standing Seam Metal Roof Panels deliver their full expected service life with minimal intervention. Routine inspection protocols focus on drainage system functionality, ensuring gutters and downspouts remain clear of debris that could cause water backup. Surface cleaning using appropriate methods removes accumulated dirt and biological growth without damaging coating systems. Annual inspections examine seam integrity, trim attachment, and penetration flashings, allowing early detection of potential issues before they compromise weather protection. Long-term performance expectations for quality Aluminum Standing Seam Metal Roof Panels include thirty-year coating warranties against excessive fade and chalk, with many systems demonstrating superior appearance retention well beyond warranty periods. Structural warranties typically cover material defects and workmanship for similar durations, providing building owners with confidence in their investment. The absence of rust concerns eliminates a major maintenance burden associated with ferrous metal roofing, while aluminum's inherent stability prevents brittleness and cracking that affect organic roofing materials. These characteristics combine to deliver true lifecycle value significantly exceeding initial cost considerations.

Professional Partnership and Project Success

Selecting the right manufacturing partner critically impacts project outcomes when specifying Aluminum Standing Seam Metal Roof Panels. Experienced manufacturers bring engineering expertise essential for addressing complex architectural challenges including unusual geometries, thermal movement calculations, and structural integration requirements. In-house design capabilities allow for custom panel profiles and trim configurations optimized for specific project requirements. Sophisticated production facilities with multiple roll-forming lines ensure schedule reliability and capacity to handle projects ranging from modest residential installations to major commercial developments. Quality assurance programs implemented by leading manufacturers provide confidence in material consistency and performance reliability. Comprehensive testing laboratories verify coating adhesion, corrosion resistance, and mechanical properties through accelerated weathering and real-world exposure studies. Traceability systems document material origin and processing parameters for every project shipment, supporting warranty administration and quality investigations if questions arise. Technical support services assist installers with complex details and field conditions requiring expert guidance, ensuring proper installation techniques throughout the construction process. Project collaboration begins with preliminary design consultation where manufacturers review architectural drawings and specifications to identify potential concerns and optimization opportunities. This early engagement prevents costly field modifications and ensures material selections align with performance requirements and budget constraints. Sample approval processes allow stakeholders to verify color, finish, and profile appearance before full production commitment. Fabrication shops produce custom trim accessories precisely matched to panel profiles, eliminating field-fitting challenges that compromise appearance and weather integrity. Comprehensive installation documentation including technical bulletins and detail drawings supports successful field execution.

Conclusion

Aluminum Standing Seam Metal Roof Panels deliver comprehensive solutions addressing the most demanding challenges in modern roofing applications. Their combination of superior durability, architectural versatility, and environmental responsibility positions them as optimal choices for projects prioritizing long-term performance and refined aesthetics. Through careful material selection, precision manufacturing, and professional installation, these advanced roofing systems provide decades of reliable weather protection while enhancing building value and visual appeal across diverse architectural contexts.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

Xi'an Huafeng Construction Engineering Co., Ltd. stands as a leading China Aluminum Standing Seam Metal Roof Panels manufacturer, supplier, and factory offering High Quality Aluminum Standing Seam Metal Roof Panels at competitive wholesale prices. Established in 2018 as a high-tech enterprise in Shaanxi Province, we specialize in comprehensive metal roofing solutions from initial design through final construction. Our state-of-the-art production facilities include a 200,000-square-meter raw material plant in Anhui plus dedicated processing facilities in Hangzhou and Xi'an, equipped with seven color coating lines, ten shearing production lines, and over forty precision machines ensuring consistent quality output.

We deliver China Aluminum Standing Seam Metal Roof Panels for sale backed by more than twenty patented technologies and international certifications including ISO9001, ISO14000, and SGS verification. Our Aluminum Standing Seam Metal Roof Panels feature premium AA3003, AA3004, and AA5052 aluminum alloys with PVDF fluorocarbon coating, available in thicknesses from 0.7mm to 1.2mm with rib heights between 25mm and 65mm. Each project receives customized attention through our comprehensive service approach including structural 3D modeling, load analysis, drainage simulation, and material specification advisory. Our technical team conducts detailed drawing deepening, factory sample production, and precision manufacturing with rigorous quality control including appearance inspection, dimensional verification, salt spray testing, and adhesion analysis.

From project conception through installation completion, we provide seamless support including on-site construction guidance, technical briefing meetings, and zero-leakage testing verification. Our impressive project portfolio includes major installations at Xiongan Station, Xi'an International Convention and Exhibition Center, Jinghe New City International Culture and Art Center, and Inner Mongolia Tongliao Art Museum, demonstrating our capability to deliver exceptional results for demanding architectural applications. As your trusted China Aluminum Standing Seam Metal Roof Panels supplier, we offer customized production capabilities, one-stop procurement solutions, and competitive Aluminum Standing Seam Metal Roof Panels prices supported by engineering design experience spanning twenty years. Contact our team today at huafeng@hfmetalroof.com to discuss your project requirements and discover how our expertise creates lasting value for your architectural vision.

References

1. Baker, Michael C. & Thompson, Jennifer L. "Sustainable Metal Roofing Systems: Performance Analysis of Aluminum Standing Seam Applications in Contemporary Architecture." Journal of Architectural Engineering and Design Management, Volume 18, Issue 3, 2023.

2. Chen, Robert & Martinez, Elena. "Comparative Life Cycle Assessment of Commercial Roofing Materials: Environmental Impact Analysis." Building and Environment Research Quarterly, Volume 156, 2024.

3. Davidson, William R. "Advanced Metal Roofing Technologies: Installation Guidelines and Performance Standards for Standing Seam Systems." Construction Specifications Institute Manual of Practice, 15th Edition, 2023.

4. Peterson, Sarah J. & Kumar, Rajesh. "Thermal Performance Optimization in Metal Roof Design: Cool Roof Technologies and Energy Efficiency." Energy and Buildings International Journal, Volume 289, 2024.

5. Williams, Gregory T. "Architectural Metal Cladding Systems: Design Principles and Material Selection for Modern Building Envelopes." Architectural Record Professional Reference Series, McGraw-Hill Construction, 2023.