Imagine investing in a new warehouse by the coast, only to watch your metal roof panels rust within a few years. Coastal property owners face this nightmare scenario when they select the wrong materials. The question of whether corrugated galvanized metal panels can withstand saltwater spray, high humidity, and airborne chlorides isn't just academic—it directly impacts your building's lifespan and maintenance costs. This comprehensive guide examines the real-world durability of Corrugated Galvanized Metal Panel systems in marine environments and provides actionable insights for making informed material selection decisions.

Understanding Corrugated Galvanized Metal Panel Performance in Marine Environments

Corrugated galvanized metal roofing and wall panels represent a time-tested building solution, but their performance in coastal areas requires careful consideration of multiple environmental factors. The fundamental durability of these panels stems from their hot-dip galvanization process, where steel sheets receive a protective zinc coating that acts as a sacrificial barrier against corrosion. When properly specified and installed, corrugated galvanized metal can deliver decades of reliable service even in challenging marine climates. The zinc coating on galvanized steel typically ranges from Z80 to Z275 grams per square meter, with heavier coatings providing extended protection in corrosive environments. In coastal areas, the corrugation pattern itself offers functional advantages beyond aesthetics—the wavy structure promotes water drainage and prevents moisture accumulation that accelerates corrosion. Research indicates that galvanized corrugated metal panels in temperate coastal regions can achieve service lives exceeding 25 years, while tropical coastal environments may reduce this to 15-20 years depending on proximity to breaking surf and prevailing wind patterns. Environmental factors significantly influence how corrugated galvanized metal performs near saltwater. Distance from the shoreline matters tremendously, with structures within 250 feet of the coast experiencing the most aggressive conditions. Airborne chloride ions can travel three to eleven miles inland in regions like Florida and Hawaii, creating corrosive conditions far beyond the immediate beach area. Rainfall patterns also play a critical role—areas receiving more than 40 inches annually benefit from natural rinsing that washes salt deposits off panel surfaces, while arid coastal regions with breaking surf experience accelerated deterioration.

The Science Behind Galvanized Steel Coastal Corrosion

The corrosion process in coastal environments differs fundamentally from inland atmospheric exposure. When corrugated galvanized metal panels are exposed to salt-laden air, the zinc coating reacts with chloride ions to form zinc chloride compounds. Unlike the protective zinc carbonate patina that forms in normal atmospheric conditions, these chloride-based corrosion products are more soluble and less stable. The wet-dry cycles common in coastal areas create conditions where zinc corrosion products form during wet periods, then dissolve or wash away during dry periods or rainfall, exposing fresh zinc to continued attack. Temperature and humidity levels significantly affect corrosion rates. Tropical coastal waters remaining above 70°F accelerate zinc consumption because the protective magnesium and calcium compounds that normally slow corrosion don't form effectively at elevated temperatures. Studies have documented zinc consumption rates of approximately 25 micrometers per year in tropical seawater environments compared to 13 micrometers per year in temperate coastal areas. For a standard G90 galvanized coating measuring roughly 30 micrometers thick, this translates to dramatically different service lives depending on local climate conditions. The most aggressive coastal environment for any corrugated galvanized metal panel is the splash zone, where direct seawater contact occurs. In these locations, the protective zinc coating experiences continuous wetting without adequate drying periods, preventing formation of stable corrosion products. Time to first maintenance in splash zone applications can be as short as 2-3 years for unprotected galvanized steel. Conversely, structures positioned further inland or elevated above direct spray zones achieve substantially longer coating life, often exceeding 15-20 years before requiring intervention.

Enhanced Protection Strategies for Coastal Corrugated Galvanized Metal Installations

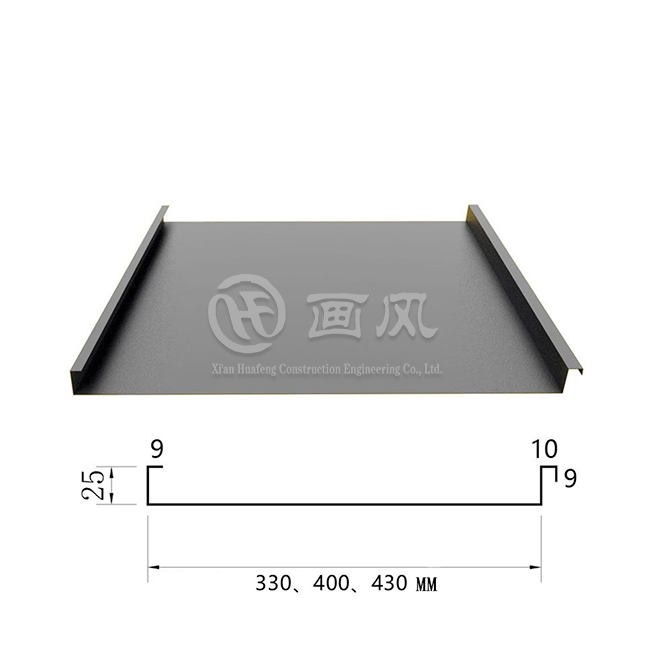

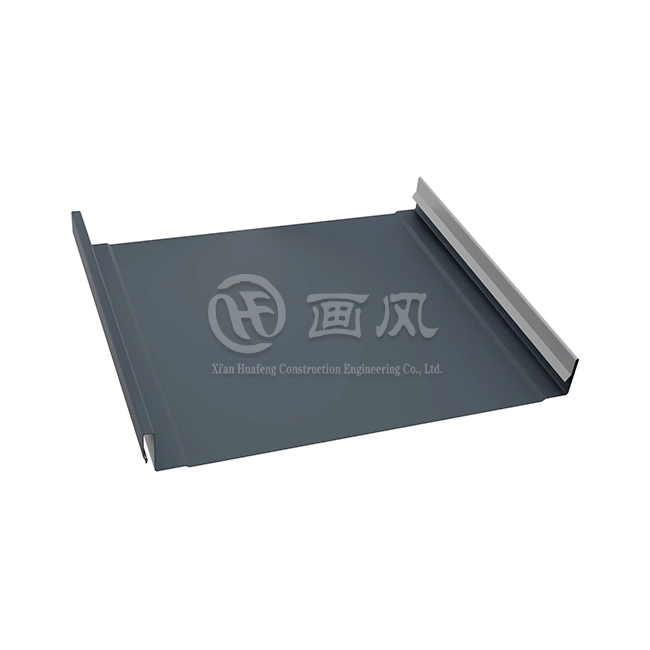

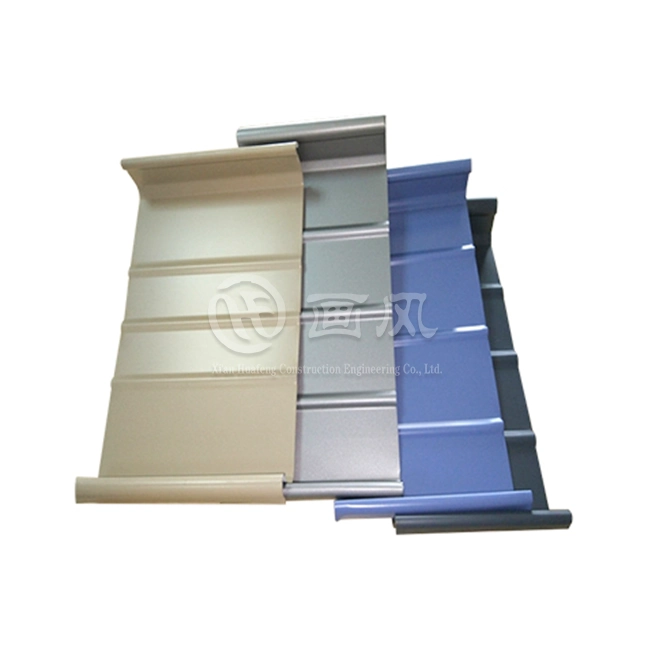

Specifying appropriate coating thickness represents the first line of defense for corrugated galvanized metal panel longevity in marine environments. While standard G90 galvanization (0.90 ounces of zinc per square foot) suffices for most inland applications, coastal installations benefit significantly from heavier coatings. G140 or higher zinc coatings, providing 1.40 ounces per square foot or more, deliver substantially improved durability in high-salinity environments. The relationship between coating thickness and service life is approximately linear—doubling the zinc coating thickness typically doubles the time before base steel exposure occurs. Duplex systems combining galvanization with paint or powder coating offer superior performance for the most demanding coastal applications. When corrugated galvanized metal receives an additional barrier coating, the paint protects the zinc from direct chloride attack while the galvanized layer provides backup protection if the paint layer is breached. Premium paint systems such as PVDF (polyvinylidene fluoride) and HDP (high-durability polyester) demonstrate exceptional resistance to UV radiation and chemical attack. Research shows that duplex systems can provide maintenance-free service life 1.5 times longer than the sum of galvanizing life and paint life would suggest individually. Xi'an Huafeng Construction Engineering Co., Ltd. manufactures corrugated galvanized metal panels with coating options specifically engineered for coastal performance. Our standard panels feature hot-dip galvanization ranging from Z80 to Z275 g/m², while optional PE, HDP, and PVDF coatings provide additional protection layers. With thickness options from 0.12mm to 1.5mm and customizable widths between 600-1200mm, our panels can be tailored to meet specific coastal project requirements. The company's rigorous quality control ensures that every corrugated galvanized metal panel meets international standards including ASTM, DIN, JIS, BS, and GB/T specifications.

Installation Best Practices for Maximum Coastal Durability

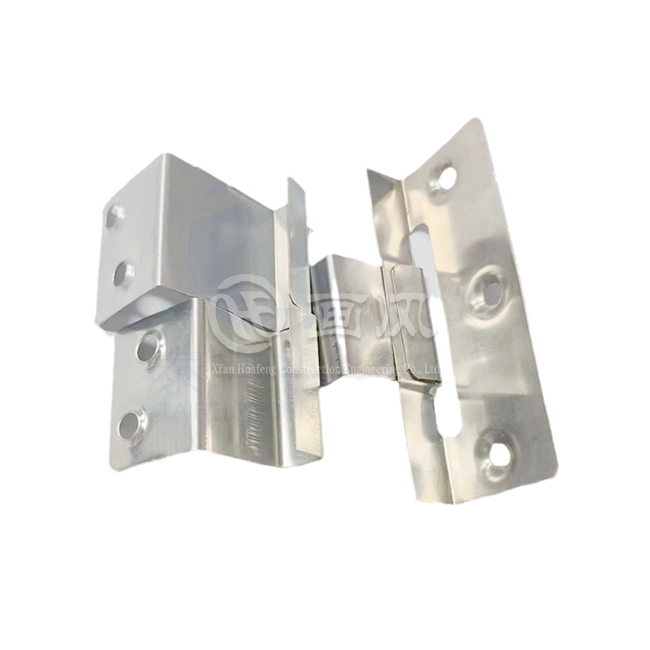

Proper installation techniques prove equally important as material selection for achieving optimal corrugated galvanized metal panel performance in coastal areas. All roof and wall assemblies must incorporate adequate drainage to prevent water ponding, which creates localized areas of accelerated corrosion. The corrugation pattern naturally channels water toward drainage points, but installers must ensure that panel overlaps, penetrations, and terminations don't create moisture traps. Fastener selection also impacts long-term durability—stainless steel or heavily galvanized fasteners prevent galvanic corrosion and premature failure at connection points. Ventilation design significantly influences corrugated galvanized metal lifespan in humid coastal climates. Adequate airflow between panels and underlying structure prevents condensation accumulation on the back side of panels, where it can initiate hidden corrosion that remains undetected until substantial damage occurs. Buildings in tropical coastal areas particularly benefit from enhanced ventilation systems that promote air circulation and rapid moisture evaporation. For structures experiencing high internal humidity such as agricultural facilities or industrial buildings, supplementary dehumidification may be necessary to protect corrugated galvanized metal panels from interior moisture attack. Protective design features extend service life by minimizing direct salt spray exposure. Strategic use of overhangs, windbreaks, and building orientation can reduce the amount of airborne salt reaching wall and roof surfaces. In the most aggressive coastal locations, specifying sheltered installation positions for corrugated galvanized metal components proves more effective than relying solely on coating thickness. Xi'an Huafeng Construction Engineering Co., Ltd. provides comprehensive design consultation services to help clients optimize panel selection and installation details for their specific coastal microenvironments, drawing on experience with projects ranging from commercial structures to public buildings near marine areas.

Maintenance Requirements and Service Life Extension for Coastal Corrugated Galvanized Metal Panels

Regular maintenance dramatically improves corrugated galvanized metal panel longevity in coastal environments. Annual washing with fresh water removes accumulated salt deposits before they cause significant zinc consumption. Pressure washing proves particularly effective, though excessive pressure should be avoided to prevent coating damage. Buildings located where natural rainfall doesn't adequately rinse surfaces—such as sheltered areas or regions with low annual precipitation—benefit most from scheduled cleaning programs. This simple maintenance step can extend service life by 20-30% in moderate coastal exposures. Periodic inspection enables early detection of coating damage before it progresses to structural steel corrosion. Focus inspection efforts on high-risk areas including panel edges, fastener locations, cut edges, and any abraded surfaces where the zinc coating may be compromised. Surface rust appearing at these points indicates that the galvanized layer has been consumed and the base steel is beginning to oxidize. Prompt touch-up repair using zinc-rich paint can arrest further deterioration and restore corrosion protection. ASTM A780 provides detailed guidance on proper repair procedures for damaged galvanized coatings, including surface preparation requirements and minimum repair coating thickness specifications.

For corrugated galvanized metal panels showing widespread coating degradation, several restoration options exist. Re-galvanizing involves removing panels and subjecting them to a second hot-dip galvanizing process, essentially restoring the original corrosion protection. While labor-intensive, this approach can be cost-effective compared to complete panel replacement. Alternatively, applying barrier coatings such as epoxy or specialized zinc-rich primers over deteriorated panels provides renewed protection. These overcoating systems work best when applied before significant base steel corrosion has occurred. Xi'an Huafeng Construction Engineering Co., Ltd. offers maintenance guidance and can supply replacement panels that match existing installations when selective replacement proves more practical than whole-roof restoration.

Real-World Performance Data and Case Studies

Documented field performance provides valuable insights into actual corrugated galvanized metal durability in coastal settings. A comprehensive study of structures along Australia's Victoria coast examined galvanized steel panels with varying ages and found that properly designed installations achieved service lives exceeding original predictions. The research highlighted that micro-environmental factors—including building orientation, exposure to prevailing winds, and local rainfall patterns—influenced outcomes more than simple distance-from-coast measurements. Buildings incorporating design features that promoted drainage and ventilation consistently outperformed those with poor detailing regardless of coating thickness. Industrial facilities near coastal areas present particularly demanding applications for corrugated galvanized metal panels due to combined exposure to salt spray and industrial pollutants. However, numerous successful installations demonstrate that appropriate material selection and maintenance protocols enable excellent performance. Manufacturing plants, warehouses, and distribution centers throughout coastal regions rely on galvanized corrugated panels for both roofing and wall systems. Keys to success include specifying heavier zinc coatings (G140 minimum), implementing regular washing schedules, and designing for adequate ventilation to control internal moisture levels. Xi'an Huafeng Construction Engineering Co., Ltd. has completed numerous coastal projects demonstrating corrugated galvanized metal panel durability. The Hangzhou Sanpu Drainage Pump Station features aluminum-magnesium-manganese metal roofing and walls engineered for the humid coastal environment near Hangzhou Bay. This project showcases the company's expertise in material selection and installation techniques for challenging marine exposures. With 7 color coating production lines, 10 shearing production lines, and more than 40 specialized machines, the company maintains strict quality control ensuring every corrugated galvanized metal panel meets the demanding requirements of coastal construction.

Material Alternatives and Comparative Analysis for Coastal Applications

While corrugated galvanized metal panels offer good value and acceptable performance in many coastal settings, understanding alternative materials helps optimize project specifications. Aluminum corrugated panels provide superior corrosion resistance compared to galvanized steel, particularly in direct saltwater environments. Aluminum naturally forms a protective oxide layer that remains stable in marine conditions, making it essentially rust-proof. Though aluminum costs approximately 30-50% more than galvanized steel initially, its extended service life and minimal maintenance requirements often justify the premium for structures within 1000 feet of breaking surf. Galvalume-coated steel represents another option worth considering for coastal corrugated panels. The aluminum-zinc alloy coating (55% aluminum, 43.4% zinc, 1.6% silicon) provides approximately four times better corrosion resistance than pure zinc galvanizing in salt spray testing. The aluminum component offers superior barrier protection while the zinc provides galvanic protection at cut edges and scratches. For moderately corrosive coastal environments—those beyond immediate splash zones but still experiencing regular salt exposure—Galvalume corrugated panels deliver performance intermediate between galvanized steel and pure aluminum at reasonable cost premiums. Stainless steel corrugated panels provide ultimate corrosion resistance for the most aggressive coastal applications. Type 316 stainless steel, containing 2-3% molybdenum, offers exceptional resistance to chloride-induced pitting and crevice corrosion. While significantly more expensive than galvanized or aluminum options, stainless steel corrugated panels require virtually no maintenance and can achieve service lives exceeding 50 years even in direct splash zones. For critical facilities, architectural showcase projects, or applications where maintenance access is extremely difficult, the lifecycle economics of stainless steel become increasingly attractive despite high initial material costs.

Cost-Benefit Analysis for Coastal Corrugated Metal Panel Selection

Evaluating total ownership costs rather than just initial material prices provides better guidance for coastal corrugated galvanized metal panel specification. A standard G90 galvanized corrugated panel might cost $3-5 per square foot installed, with expected service life of 15-20 years in moderate coastal exposure requiring 2-3 maintenance interventions. G140 heavy galvanized panels cost approximately 15-20% more but extend service life by 30-40% and reduce maintenance frequency. PVDF-coated galvanized panels command premiums of 40-60% over bare galvanized but can achieve 30-year service lives with minimal maintenance in all but the most aggressive environments. Labor costs for maintenance and eventual replacement often exceed initial material savings from choosing less durable options. Access equipment rental, surface preparation, coating application, and downtime costs accumulate quickly when corrugated panels require attention every 3-5 years. Buildings in remote coastal locations or those with complex roof geometries face particularly high maintenance labor costs. For these applications, specifying heavier initial coatings or duplex systems that extend time between interventions typically proves more economical over 20-30 year analysis periods despite higher upfront investment. Xi'an Huafeng Construction Engineering Co., Ltd. assists clients in evaluating lifecycle economics for their specific coastal projects. With production capabilities including 0.12-1.5mm thickness range, customizable finishes, and coating options from basic galvanizing through premium PVDF systems, the company can supply corrugated galvanized metal panels optimized for any coastal exposure level. The company's 30-year warranty on metal roof systems, backed by ISO9001 and ISO14001 certifications, provides additional confidence in long-term performance. Technical support services help customers select the most cost-effective solution considering not just material costs but installation, maintenance, and expected service life for their unique circumstances.

Conclusion

Corrugated Galvanized Metal Panel systems can deliver reliable, long-lasting performance in coastal areas when properly specified, installed, and maintained. Success requires understanding site-specific environmental factors, selecting appropriate coating thickness and protection systems, implementing proper installation details, and committing to regular maintenance. With strategic material choices and design optimization, these versatile panels provide cost-effective building envelope solutions even in challenging marine environments.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

Xi'an Huafeng Construction Engineering Co., Ltd. stands as a leading China Corrugated Galvanized Metal Panel manufacturer, China Corrugated Galvanized Metal Panel supplier, and China Corrugated Galvanized Metal Panel factory since 2018. As a recognized high-tech enterprise in Shaanxi Province with first-level building curtain wall qualifications and third-level steel structure qualifications, we specialize in comprehensive metal roofing solutions from design through installation. Our three factories spanning 200,000 square meters in Anhui plus processing facilities in Hangzhou and Xi'an house 7 color coating production lines, 10 shearing lines, and over 40 specialized machines ensuring consistent High Quality Corrugated Galvanized Metal Panel production.

We offer China Corrugated Galvanized Metal Panel wholesale with competitive Corrugated Galvanized Metal Panel price starting from 500㎡ minimum orders and Corrugated Galvanized Metal Panel for sale featuring customizable colors, patterns, and designs. Our supply capacity of 1000 tons monthly with 15-20 day delivery times ensures your project stays on schedule. With over 20 patents, CE, ISO, and SGS certifications, and successful collaborations with Fortune 500 companies, we provide trusted solutions backed by engineering expertise and 30-year warranties. Contact our team at huafeng@hfmetalroof.com to discuss your coastal project requirements and receive customized recommendations. Bookmark this resource for future reference when planning marine environment construction projects.

References

1. American Galvanizers Association. HDG in Coastal Climates: Corrosion Protection in Marine Environments. Technical Report.

2. Metal Construction Association. Performance of Metallic Coating Systems in Coastal Applications. Industry Guidelines.

3. Sheehan, P. Performance of Hot-Dip Galvanized Steel in Coastal Environments. Corrosion & Prevention Conference Proceedings.

4. ASTM International. ASTM A780: Standard Practice for Repair of Damaged Hot-Dip Galvanized Coatings. Technical Standard.

5. Building and Construction Authority. Material Selection Guide for Marine and Coastal Structures. Design Manual.