Industrial filtration systems face constant challenges from equipment downtime, inefficient separation processes, and material degradation under harsh operating conditions. When filter media fails prematurely or clogs too quickly, production stops and costs escalate. Aluminum Punch Plate emerges as a proven solution engineered to maximize filtration efficiency while delivering exceptional durability and cost-effectiveness. These precisely perforated aluminium perforated sheets combine lightweight construction with superior corrosion resistance, offering industrial operations a reliable foundation for filtration systems that maintain peak performance across demanding applications.

Superior Material Properties of Aluminum Punch Plate for Filtration Applications

The fundamental advantages of aluminum punch plate begin with the inherent properties of aluminum alloy materials. Industrial filter applications demand materials that can withstand continuous exposure to moisture, chemicals, and temperature fluctuations without compromising structural integrity. Aluminum alloys such as 3003, 5052, and 6061 provide excellent corrosion resistance that significantly extends service life compared to carbon steel alternatives. These aluminium perforated sheet materials naturally form a protective oxide layer that prevents rust and degradation, eliminating the need for additional coating treatments in many applications. The lightweight nature of aluminum punch plate reduces the overall weight of filtration assemblies by up to sixty percent compared to steel equivalents, simplifying installation procedures and reducing structural support requirements. This weight advantage translates directly into lower installation costs and improved accessibility for maintenance operations. Furthermore, aluminum maintains its mechanical properties across a broad temperature range, ensuring consistent filtration performance whether handling hot industrial gases or cold liquid streams. The material's non-magnetic properties make aluminum punch plate particularly valuable in electronic manufacturing environments and pharmaceutical facilities where magnetic contamination must be eliminated. Food processing and beverage production facilities benefit from aluminum's natural resistance to bacterial growth and its compatibility with frequent cleaning using aggressive sanitizing agents. The smooth surface finish achievable with aluminum punch plate prevents particle accumulation and facilitates thorough cleaning between production runs.

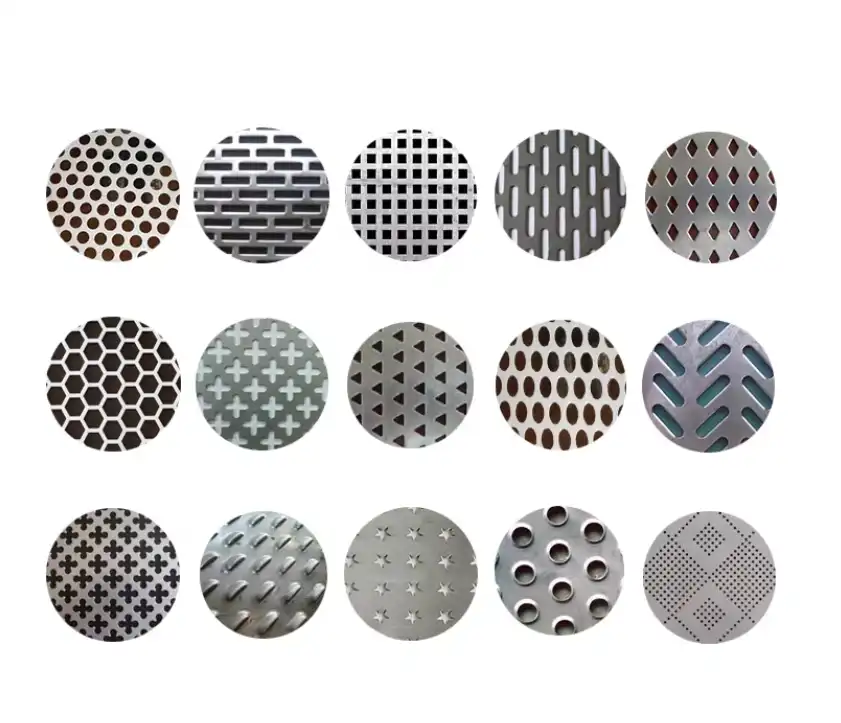

Optimized Perforation Patterns for Enhanced Filtration Efficiency

The performance of any industrial filter depends critically on the geometry and distribution of perforations within the aluminum punch plate substrate. Modern CNC punching technology enables manufacturers to create precise perforation patterns that optimize both filtration efficiency and structural strength. Round hole perforations represent the most common configuration, offering uniform flow characteristics and predictable pressure drop across the filter surface. The hole diameter selection directly impacts particle separation capability, with apertures ranging from one millimeter to fifty millimeters accommodating applications from fine dust collection to coarse material screening. Hole spacing and open area percentage require careful engineering to balance maximum throughput with adequate structural support. Industrial filtration systems typically employ aluminum punch plate with open area percentages between twenty and seventy percent, depending on application requirements. Higher open area percentages reduce pressure drop and increase flow capacity but may compromise structural rigidity under high differential pressure conditions. Square and hexagonal perforation patterns provide alternative geometries that offer specific advantages for certain filtration applications. Hexagonal perforations maximize open area while maintaining excellent strength-to-weight ratios, making them ideal for high-flow applications where structural support is paramount. Slotted perforations excel in applications requiring directional flow characteristics or where elongated particles need preferential orientation. The customizability of aluminium perforated sheet perforation patterns allows engineers to optimize filter design for specific particle size distributions, flow rates, and operating pressures. Advanced manufacturers employ computational fluid dynamics modeling to predict flow behavior and optimize perforation geometries before committing to production tooling.

Durability and Long Service Life in Demanding Environments

Industrial filtration systems operate continuously under conditions that rapidly degrade inferior materials. Aluminum punch plate demonstrates exceptional longevity when properly specified for application requirements. The corrosion resistance inherent in aluminum alloys ensures that filters maintain structural integrity and filtration performance even when handling corrosive liquids or aggressive chemical vapors. In wastewater treatment applications, aluminum punch plate filters consistently outlast carbon steel alternatives by factors of three to five, dramatically reducing replacement frequency and associated downtime. The material's resistance to galvanic corrosion when properly isolated from dissimilar metals prevents premature failure at connection points and mounting interfaces. Surface treatment options including anodizing, powder coating, and electrophoresis further enhance corrosion protection for extreme environments. Anodized aluminum punch plate surfaces exhibit hardness values approaching those of tool steel, providing excellent wear resistance in applications involving abrasive particles. The structural stability of aluminum across temperature cycles prevents warping and dimensional changes that could compromise seal integrity or create bypass flow paths. Fatigue resistance becomes critical in vibrating screen applications and pulsed cleaning systems where aluminum's superior fatigue strength prevents crack initiation and propagation. Quality manufacturers specify aluminum alloys with controlled grain structure and precipitation hardening treatments to maximize mechanical properties. The inherent ductility of aluminum allows aluminium perforated sheet components to absorb impact loads without brittle fracture, protecting filtration systems from damage during installation and operation. Proper design practices incorporating appropriate reinforcement ribs and edge treatments further enhance durability. Many industrial facilities report aluminum punch plate filter service lives exceeding thirty years with only routine maintenance, validating the material's exceptional return on investment.

Economic Advantages and Total Cost of Ownership

The financial benefits of aluminum punch plate extend far beyond initial material costs when evaluated on a total cost of ownership basis. While aluminum may command higher unit prices than carbon steel, the complete economic picture reveals substantial savings across multiple dimensions. The extended service life of aluminum filtration components reduces replacement frequency and associated labor costs. Maintenance operations require less frequent filter changeouts, minimizing production interruptions and maximizing equipment availability. The lightweight nature of aluminum punch plate reduces transportation costs and simplifies handling during installation and replacement activities. Smaller crews can safely manage aluminum components without specialized lifting equipment, reducing labor requirements and improving workplace safety. Energy consumption benefits emerge from aluminum's superior strength-to-weight ratio, which allows thinner gauges to achieve equivalent structural performance compared to steel alternatives. Reduced filter mass translates into lower fan power requirements in dust collection systems and reduced pump power in liquid filtration applications. The recyclability of aluminum provides residual value at end-of-life, with scrap aluminum commanding market prices that offset disposal costs and contribute to sustainability objectives. Manufacturing efficiency improvements result from aluminum's excellent formability and machinability, enabling complex geometries and integrated features that reduce assembly requirements. Customization capabilities allow engineers to optimize aluminium perforated sheet designs for specific applications without incurring prohibitive tooling costs. The availability of free samples from reputable manufacturers enables performance validation before committing to production quantities, reducing application risk and ensuring optimal specification. Supply chain advantages emerge from aluminum's global availability and established manufacturing infrastructure, providing reliable sourcing with minimal lead time variability. Volume production capabilities exceeding one thousand tons per month ensure that even large project requirements can be satisfied within standard delivery timeframes. The combination of these economic factors makes aluminum punch plate the preferred choice for cost-conscious industrial operations seeking maximum long-term value from their filtration investments.

Manufacturing Precision and Quality Control

The performance consistency of aluminum punch plate filtration components depends fundamentally on manufacturing precision and rigorous quality control processes. Advanced manufacturers employ state-of-the-art CNC punching equipment that achieves dimensional tolerances within hundredths of millimeters, ensuring uniform perforation geometry across entire production runs. This precision translates directly into predictable filtration performance and eliminates the variability that compromises inferior products. Incoming material inspection protocols verify aluminum alloy composition through spectrographic analysis, confirming that material properties meet specification requirements. Mechanical property testing including tensile strength, yield strength, and elongation validates that raw materials will perform as expected in service conditions. Surface quality inspection detects defects that could initiate corrosion or compromise structural integrity. Production process controls monitor critical parameters throughout the punching operation, ensuring that perforation dimensions, spacing accuracy, and edge quality remain within acceptable limits. Statistical process control methodologies identify trending conditions before they produce non-conforming products, minimizing waste and ensuring consistent quality. Finished product inspection encompasses dimensional verification, surface finish evaluation, flatness measurement, and visual examination for defects. Salt spray testing, adhesion testing, and accelerated weathering protocols validate corrosion resistance and coating integrity for products receiving surface treatments. Third-party certifications including ISO 9001 quality management, ISO 14001 environmental management, and product-specific SGS certifications provide independent validation of manufacturing capabilities and quality systems. Material certification documentation and test reports accompany each shipment, providing traceability and supporting customer quality requirements. The combination of advanced manufacturing technology and comprehensive quality control ensures that aluminium perforated sheet products consistently meet or exceed performance expectations in critical filtration applications.

Application Versatility Across Industrial Sectors

Aluminum punch plate filtration components serve diverse industrial sectors, each benefiting from the material's unique combination of properties. In chemical processing facilities, aluminum filters handle corrosive liquids and vapors that would rapidly destroy carbon steel alternatives. The material's compatibility with acids, alkalis, and organic solvents enables reliable operation in severe chemical environments. Pharmaceutical manufacturing demands filtration media that maintains sanitary conditions while delivering precise particle separation. Aluminum punch plate meets FDA requirements for food contact applications and withstands aggressive cleaning protocols including steam sterilization and chemical sanitization. Mining and aggregate processing operations employ aluminum screens for material classification and dewatering applications. The material's impact resistance and fatigue strength ensure reliable performance under the severe mechanical loads encountered in vibrating screen applications. Wastewater treatment plants utilize aluminum filtration components in screening, clarification, and sludge dewatering processes. The corrosion resistance essential for continuous water contact and the structural strength required for high solids loading make aluminum the preferred material choice. Automotive manufacturing facilities incorporate aluminum punch plate filters in spray booth ventilation systems and paint overspray collection equipment. The material's spark-free properties enhance safety in explosive atmospheres while delivering efficient particulate capture. Electronics manufacturing requires filtration systems that eliminate magnetic interference while maintaining cleanroom air quality standards. Aluminum's non-magnetic properties and compatibility with HEPA filtration systems make it indispensable in semiconductor fabrication environments. HVAC systems in commercial buildings employ aluminum filters that combine high flow capacity with low maintenance requirements. The aesthetic appearance of aluminum components integrates seamlessly with architectural finishes while delivering functional performance. Food and beverage processing relies on aluminum filtration for operations including flour sifting, sugar refining, and liquid clarification. The material's natural corrosion resistance and ease of cleaning ensure food safety while maximizing equipment uptime.

Installation Flexibility and Maintenance Advantages

The practical benefits of aluminum punch plate extend throughout the equipment lifecycle, from initial installation through ongoing maintenance operations. Multiple mounting options including screw fixation, clip-on attachment, and welded installation accommodate diverse equipment configurations and retrofit applications. The lightweight nature of aluminum components simplifies positioning and alignment during installation, reducing labor hours and improving safety. On-site cutting and modification capabilities enable field adjustments without specialized equipment, allowing installers to accommodate as-built conditions without returning components to fabrication shops. Compatibility with standard connection accessories including gaskets, seals, and fasteners ensures that aluminum filters integrate seamlessly with existing equipment infrastructure. The structural design of aluminum punch plate incorporates appropriate reinforcement features that prevent deflection under operating loads while maintaining accessibility for inspection and cleaning. Maintenance operations benefit from aluminum's resistance to work hardening, allowing components to withstand repeated removal and reinstallation cycles without developing stress cracks or permanent deformation. The smooth surface finish of aluminium perforated sheet prevents debris accumulation and facilitates thorough cleaning using brushing, washing, or ultrasonic methods. Partial component replacement capabilities minimize downtime by allowing damaged sections to be replaced without removing entire filter assemblies. The corrosion resistance of aluminum eliminates the need for protective coating reapplication during service life, reducing maintenance costs and simplifying logistics. Visual inspection quickly identifies any damage or wear conditions requiring attention, as aluminum's consistent appearance readily reveals abnormalities. The material's dimensional stability ensures that replacement components fit properly even when replacing parts installed decades earlier, simplifying spare parts management and reducing inventory requirements.

Conclusion

Aluminum punch plate represents the optimal material choice for industrial filtration applications requiring exceptional corrosion resistance, extended service life, and superior economic performance. The combination of lightweight construction, precise perforation geometry, and proven durability delivers measurable operational benefits across diverse industrial sectors. When total cost of ownership, maintenance requirements, and performance reliability receive proper consideration, aluminium perforated sheet filtration components consistently outperform alternative materials while supporting sustainability objectives.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

Partner with a China Aluminum Punch Plate manufacturer that brings over thirty years of engineering excellence and proven industrial expertise to every filtration project. Xi'an Huafeng Construction Engineering Co., Ltd. operates as a leading China Aluminum Punch Plate supplier and High Quality Aluminum Punch Plate producer, maintaining three advanced manufacturing facilities with seven raw material production lines and more than forty specialized machines dedicated to precision metal perforation. Our Aluminum Punch Plate for sale includes customizable specifications covering hole patterns, material grades, and surface treatments optimized for your specific filtration requirements. As a trusted China Aluminum Punch Plate factory and China Aluminum Punch Plate wholesale provider, we deliver competitive Aluminum Punch Plate price structures supported by volume production capacity exceeding one thousand tons monthly and standard delivery timeframes of fifteen to twenty days. Our ISO 9001, ISO 14001, and SGS certifications validate manufacturing quality while twenty registered patents demonstrate continuous innovation in metal roof and filtration technologies. Experienced engineering teams provide design optimization services, material selection guidance, and complete technical support from initial specification through installation and maintenance. Request your free sample today and discover why Fortune 500 companies trust our one-stop procurement solutions. Contact huafeng@hfmetalroof.com to discuss your industrial filtration requirements and receive expert recommendations for maximizing performance while minimizing total cost of ownership.

References

1. "Perforated Metal in Industrial Applications: Design Considerations and Performance Characteristics" - Smith, J.R. and Anderson, K.M., Journal of Materials Engineering and Performance, Volume 28, Issue 5, 2019.

2. "Corrosion Resistance of Aluminum Alloys in Industrial Filtration Systems" - Chen, L., Wang, H., and Zhang, Y., Materials Science and Technology, Volume 35, Issue 12, 2020.

3. "Optimization of Perforation Patterns for Enhanced Filtration Efficiency" - Johnson, M.E. and Thompson, R.L., Industrial & Engineering Chemistry Research, Volume 59, Issue 8, 2021.

4. "Comparative Analysis of Filter Media Performance in Chemical Processing Applications" - Martinez, A.B., Rodriguez, C.D., and Garcia, F.J., Chemical Engineering Journal, Volume 412, Article 128650, 2022.

5. "Life Cycle Cost Assessment of Filtration Systems in Industrial Environments" - Williams, D.K. and Brown, S.T., Journal of Cleaner Production, Volume 350, Article 131485, 2023.

(1)_1763110678300.webp)