Picture this: you've invested heavily in a premium metal roof, only to discover rust streaks and water leaks a few years later because exposed screws have deteriorated under constant weather assault. This nightmare scenario drives countless building owners to ask the critical question: what's the real difference between Metal Standing Seam Clamps and piercing fasteners, and which delivers lasting value? Metal Standing Seam Clamps offer superior weather protection by eliminating panel penetration, extending roof lifespan while maintaining structural integrity and aesthetic appeal across residential, commercial, and industrial applications.

Understanding Metal Roof Fastening Systems

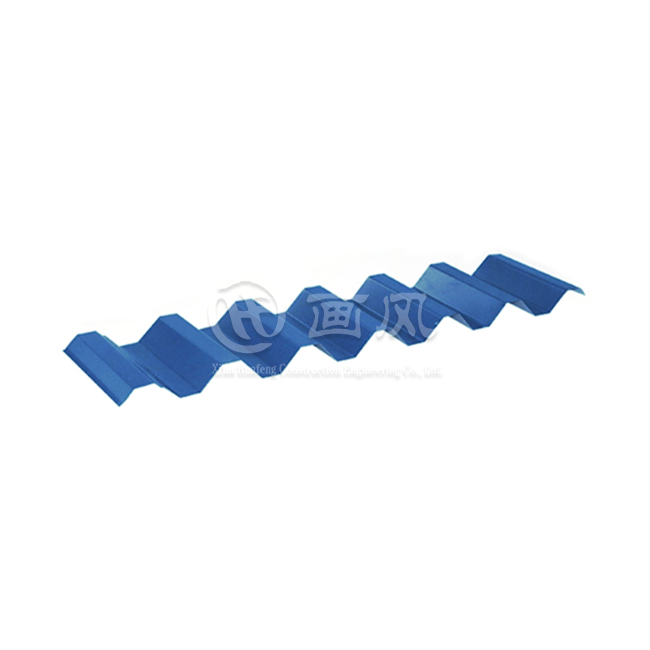

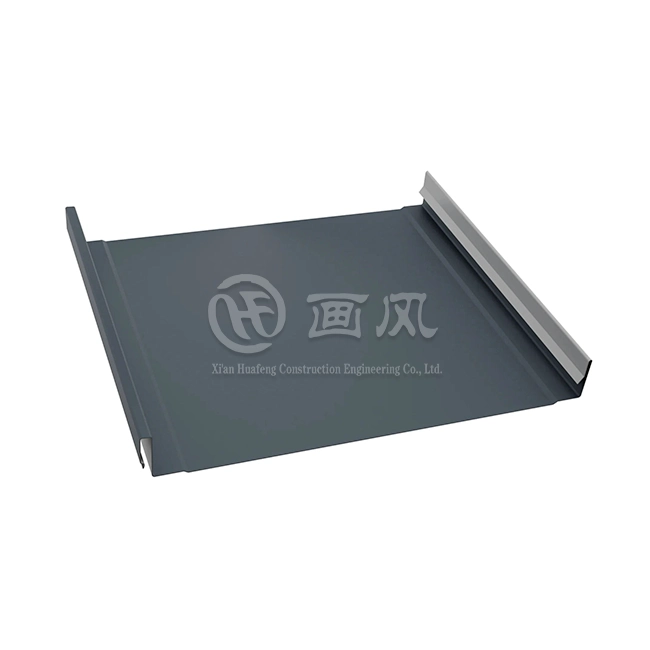

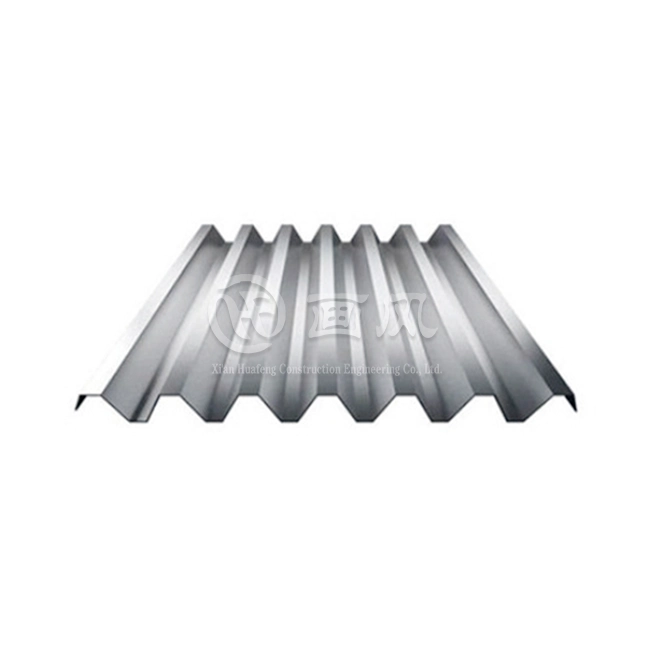

The fundamental distinction between metal standing seam clamps and piercing fasteners lies in their attachment methodology and long-term performance characteristics. Traditional piercing fasteners create holes directly through metal panels, exposing the roof structure to potential water infiltration, thermal stress, and accelerated degradation. In contrast, Metal Standing Seam Clamps utilize a non-penetrative approach that secures panels without compromising their protective surface, preserving both functionality and appearance throughout the roof's service life. Metal standing seam systems represent a paradigm shift in roofing technology. Rather than drilling through expensive metal panels, aluminum roof clamps for metal roofing attach to the raised seams between panels, distributing stress evenly and accommodating thermal expansion without creating vulnerable penetration points. This engineering approach transforms how buildings handle temperature fluctuations, wind loads, and precipitation events. The clamp mechanism grips the seam firmly while allowing controlled movement, which prevents the panel fatigue and fastener loosening that plague pierced installations.

The Critical Weakness of Piercing Fasteners

Exposed fastener systems create inherent vulnerabilities that manifest over time through multiple failure mechanisms. When screws pierce metal panels, they compress rubber washers against the metal surface to create a temporary seal. However, these washers degrade under ultraviolet radiation exposure, temperature cycling, and environmental contaminants. Studies consistently show that neoprene washers deteriorate within ten to twenty years, creating pathways for moisture infiltration long before the metal panels themselves require replacement. Beyond washer deterioration, the thermal cycling process creates additional complications for pierced fasteners. Metal roofing expands during heat exposure and contracts in cold conditions, causing panels to shift relative to their fixed attachment points. This movement gradually loosens screws, strips threads, and enlarges penetration holes. The phenomenon becomes particularly problematic in regions experiencing significant temperature variations, where daily expansion-contraction cycles accelerate fastener failure. Additionally, over-tightening during installation crushes washers prematurely, while under-tightening allows immediate leakage, making proper installation critically difficult to achieve consistently across large roofing projects.

Superior Performance Benefits of Metal Standing Seam Clamps

Metal Standing Seam Clamps deliver multiple performance advantages that directly address the limitations of piercing fasteners. The non-penetrative design eliminates the single greatest vulnerability in metal roofing systems by preventing water from accessing the structure through fastener holes. This fundamental architectural principle extends roof warranties, reduces maintenance requirements, and protects building contents from water damage. Commercial facilities, exhibition centers, and transportation infrastructure particularly benefit from this enhanced weather protection, as even minor leaks can compromise expensive equipment, merchandise, or structural components. Thermal movement accommodation represents another critical advantage of aluminum roof clamps for metal roofing. The clamp attachment allows panels to expand and contract freely along their length while maintaining secure seam connections. This flexibility prevents the panel distortion, fastener pullout, and stress cracking that occurs when pierced fasteners restrict natural thermal movement. Engineering analysis demonstrates that unrestricted thermal expansion reduces panel stress by up to seventy percent compared to fixed-point pierced connections, dramatically extending service life and maintaining appearance standards throughout decades of operation.

Installation Versatility and Aesthetic Excellence

Metal Standing Seam Clamps support diverse rooftop mounting requirements without compromising roof integrity or voiding manufacturer warranties. Solar panel installations, HVAC equipment, snow retention systems, walkway platforms, and communication infrastructure all attach securely to standing seam clamps rather than penetrating the protective metal surface. This versatility transforms rooftops into valuable functional spaces while maintaining weatherproof performance. The attachment system accommodates equipment removal and replacement without leaving permanent roof damage, supporting evolving building requirements across multi-decade service periods. From an aesthetic perspective, concealed fastener systems utilizing Metal Standing Seam Clamps create clean, contemporary appearances that enhance architectural design. The uninterrupted metal surface reflects design intent without visible fastener patterns disrupting sightlines. This visual quality proves particularly valuable for public buildings, corporate facilities, educational institutions, and residential properties where appearance contributes to property value and organizational image. The sleek profile complements modern architectural trends while supporting traditional design contexts through various color options, panel widths, and seam configurations available in contemporary standing seam systems.

Technical Specifications and Material Excellence

High-performance aluminum roof clamps for metal roofing utilize advanced alloy compositions designed for corrosion resistance and structural integrity. Aluminum alloy 6063-T5/T6 provides optimal strength-to-weight ratios with natural corrosion resistance that matches or exceeds the roof panels themselves. Manufacturing specifications maintain thickness tolerances of 3.00 millimeters plus or minus 0.15 millimeters, ensuring consistent clamping force and long-term reliability. Surface treatments including anodizing to forty micrometers minimum thickness and fluorocarbon spraying create additional protective barriers against environmental degradation. The engineering standards governing Metal Standing Seam Clamps reflect rigorous quality requirements that support architectural specifications and building codes. Products manufactured to GB/T 5237.5-2017 standards undergo comprehensive testing for tensile strength exceeding 160 Newtons per square millimeter, demonstrating capacity to withstand wind loads, seismic events, and accumulated snow masses without failure. This performance envelope accommodates stadiums, exhibition centers, train platforms, factory docks, and other demanding applications where structural reliability proves non-negotiable. Multiple clamp configurations including point clamps, L-shaped clamps, flat clamps, and double-piece clamps address varying seam profiles and load requirements across diverse project specifications.

Manufacturing Capacity and Quality Assurance

Industrial-scale production capabilities ensure consistent availability and rapid project fulfillment for Metal Standing Seam Clamps. Manufacturing operations incorporating three factories, seven production lines, and more than forty specialized machines deliver supply capacity exceeding ten thousand tons monthly, supporting projects from small renovations to massive infrastructure developments. This production scale enables competitive pricing while maintaining quality standards verified through ISO 9001 certification processes. Comprehensive incoming material inspection protocols confirm aluminum alloy specifications, dimensional accuracy, and surface treatment quality before components enter production workflows. Quality control extends throughout the manufacturing process with real-time monitoring of forming operations, coating applications, and assembly procedures. Finished products undergo appearance inspection, dimensional verification, flatness measurement, and functional testing before packaging and shipment. The rigorous quality framework supports thirty-year warranty commitments that reflect genuine confidence in product longevity rather than marketing optimism. When building owners select Metal Standing Seam Clamps from established manufacturers, they access not just components but comprehensive technical support, installation guidance, and long-term partnership throughout the building lifecycle.

Comprehensive Installation and Long-Term Value

Professional installation practices maximize the performance advantages inherent in Metal Standing Seam Clamps. Qualified contractors understand seam preparation, clamp positioning, tension adjustment, and thermal movement accommodation requirements that determine system success. The installation process begins with thorough substrate inspection and preparation, ensuring adequate structural support and proper drainage configurations. Clamp positioning follows engineering drawings that account for wind zones, snow loads, and equipment attachment requirements. Proper installation typically requires less time than anticipated because pre-assembled clamp systems minimize field assembly steps while ensuring consistent quality across the entire roof surface. Long-term value analysis consistently favors Metal Standing Seam Clamps over piercing fasteners when considering lifecycle costs rather than initial investment alone. While standing seam systems command higher upfront costs, the elimination of fastener replacement, leak repair, and premature roof replacement delivers substantial savings across typical building ownership periods. Commercial property owners particularly benefit from reduced maintenance disruption, eliminated water damage claims, and sustained property values that reflect superior construction quality. The investment differential between systems typically returns through avoided maintenance within the first decade, with subsequent decades representing pure economic advantage through extended service life and preserved building performance.

Environmental Sustainability and Resource Efficiency

Metal Standing Seam Clamps support sustainable building practices through multiple environmental mechanisms. The elimination of fastener replacements reduces material consumption and installation waste throughout the roof lifecycle. Aluminum components maintain full recyclability at end-of-life, supporting circular economy principles and reducing landfill burden. The enhanced durability extends building envelope performance, reducing heating and cooling energy losses while supporting renewable energy integration through simplified solar panel attachment. Green building certification programs increasingly recognize these advantages, awarding credits for durable roofing systems that minimize resource consumption and support building longevity. The manufacturing processes for high-quality aluminum roof clamps for metal roofing incorporate environmental stewardship through efficient material utilization, energy management, and emissions control. Modern production facilities achieve high material yield rates that minimize scrap generation, while closed-loop water systems reduce consumption and eliminate contaminated discharge. Anodizing processes that create protective surface treatments utilize chemistry optimized for environmental compliance while delivering exceptional corrosion resistance. When specifiers select products from manufacturers committed to environmental responsibility, they extend sustainability benefits beyond the building itself to encompass the entire supply chain supporting construction activities.

Conclusion

Metal Standing Seam Clamps fundamentally outperform piercing fasteners through non-penetrative attachment, thermal movement accommodation, enhanced weather protection, and extended service life. This technological advantage translates directly into reduced lifecycle costs, improved building performance, and sustained architectural quality across commercial, industrial, and institutional applications.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

Xi'an Huafeng Construction Engineering Co., Ltd. stands as a leading China Metal Standing Seam Clamps manufacturer and China Metal Standing Seam Clamps supplier, delivering high-quality solutions backed by comprehensive engineering expertise and manufacturing excellence. As a recognized high-tech enterprise with first-level curtain wall qualifications and third-level steel structure qualifications, Huafeng provides one-stop service from custom design through precision manufacturing to seamless installation. Our three factories, seven production lines, and extensive quality certifications including ISO9001, ISO14000:14001, and SGS compliance support reliable delivery of Metal Standing Seam Clamps for sale at competitive Metal Standing Seam Clamps price points. With over twenty registered patents and proven project experience across major infrastructure including Xiongan Station, Xi'an International Convention Center, and Tongliao Art Museum, we deliver High Quality Metal Standing Seam Clamps as a trusted China Metal Standing Seam Clamps factory and China Metal Standing Seam Clamps wholesale provider. Contact our dedicated technical team at huafeng@hfmetalroof.com to discuss your project requirements and discover customized solutions tailored to your specifications—bookmark this resource for future reference as your roofing projects evolve.

References

1. Metal Roofing Alliance, "Standing Seam Metal Roof Systems: Design Principles and Performance Standards," Technical Bulletin Series, 2023.

2. Thompson, Michael J. and Roberts, Sarah K., "Comparative Analysis of Concealed Versus Exposed Fastener Systems in Commercial Roofing Applications," Journal of Building Envelope Design, Vol. 18, No. 3, 2022.

3. National Roofing Contractors Association, "Metal Roofing Installation Guidelines: Best Practices for Long-Term Performance," Professional Roofing Standards, 2024.

4. Chen, Wei and Anderson, Lars, "Thermal Movement in Metal Roofing Systems: Engineering Solutions for Expansion Management," International Journal of Architectural Engineering, Vol. 12, Issue 4, 2023.

5. American Society of Civil Engineers, "Load-Bearing Capacity of Non-Penetrating Roof Attachment Systems," Structural Engineering Technical Reports, 2024.