Picture this scenario: Your construction project is halfway through, and you suddenly discover that the Pre Painted Corrugated Sheets you ordered in bulk don't meet specifications, forcing costly delays and emergency reordering. This nightmare situation affects countless procurement managers and contractors annually, resulting in budget overruns and project timeline disruptions. Understanding best practices for purchasing Pre Painted Corrugated Sheets in bulk isn't just about securing materials; it's about protecting your investment, ensuring quality consistency, and maintaining project schedules while maximizing cost efficiency through strategic supplier partnerships and rigorous quality verification protocols.

Understanding Pre Painted Corrugated Sheets Quality Standards

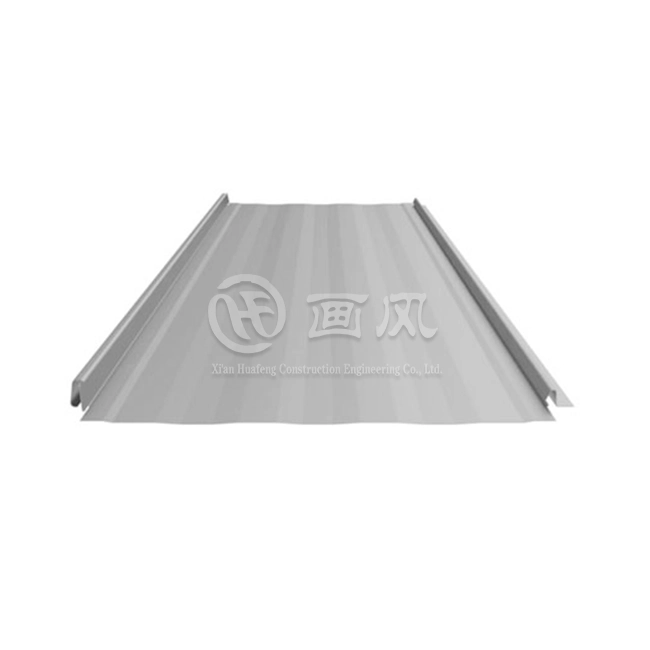

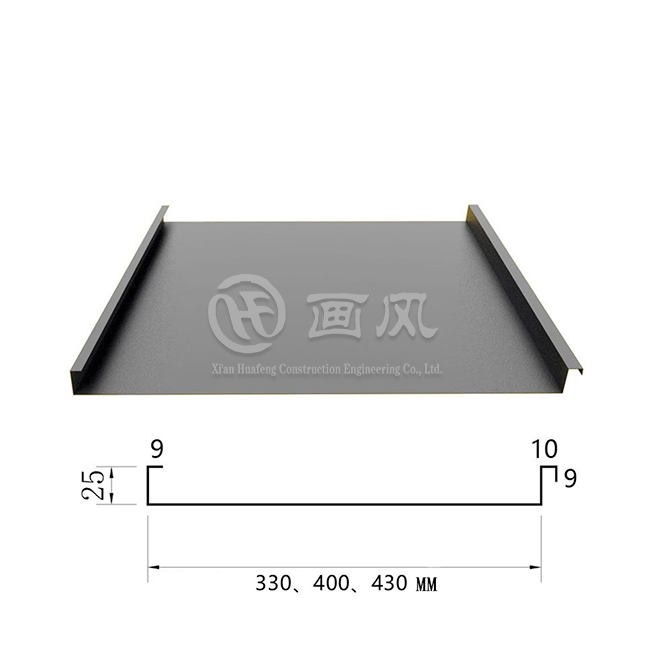

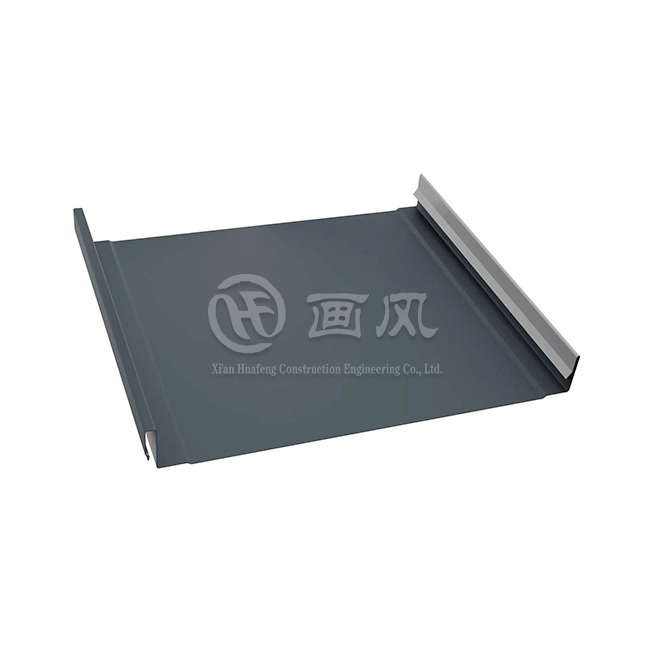

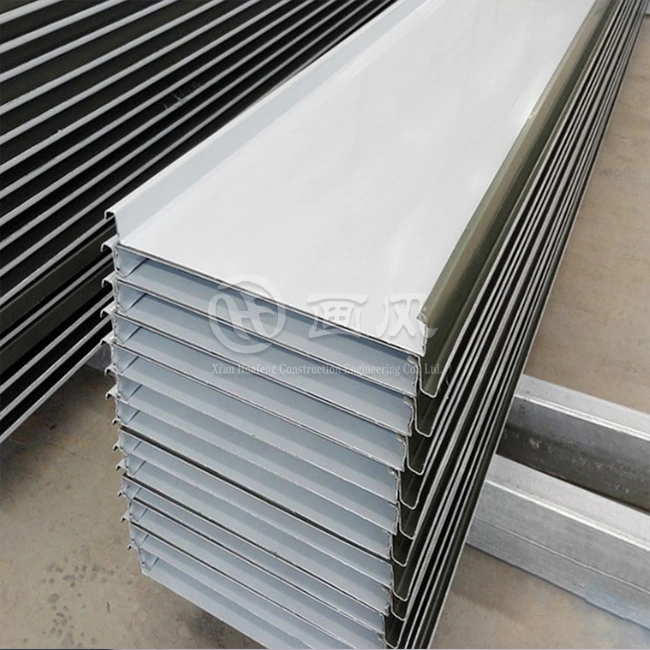

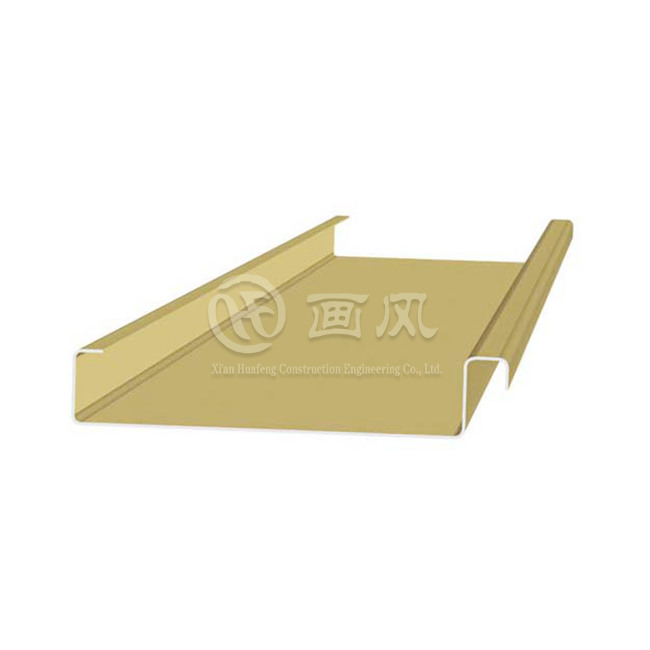

When sourcing Pre Painted Corrugated Sheets for large-scale projects, recognizing quality indicators becomes fundamental to avoiding expensive mistakes. Pre painted corrugated roofing sheet materials undergo specialized manufacturing processes that directly impact their long-term performance and durability. The quality foundation begins with substrate selection, where manufacturers utilize galvanized steel, galvalume steel, stainless steel, or aluminum alloy as base materials. Each substrate offers distinct advantages depending on environmental exposure conditions and structural requirements. For instance, galvalume substrates containing fifty-five percent aluminum-zinc alloy coating provide superior corrosion resistance compared to standard galvanized options, making them ideal for coastal or high-humidity environments where salt exposure accelerates material degradation. The coating application process represents another critical quality determinant. Premium Pre Painted Corrugated Sheets receive multiple coating layers applied through sophisticated processes involving two upper surface applications and one or two lower surface applications, followed by dual baking cycles that ensure optimal adhesion and durability. Coating thickness specifications vary according to finish type, with PVDF coatings requiring minimum twenty-five micrometers and polyester coatings needing at least eighteen micrometers to deliver promised weather resistance. Buyers should request detailed specifications including tensile strength ratings between 280 and 550 megapascals, yield strength exceeding 220 megapascals, and wind pressure resistance capable of withstanding twelve-level wind conditions at 1.5 kilopascals when properly installed with appropriate purlin spacing.

Certification Requirements and Testing Protocols

Purchasing Pre Painted Corrugated Sheets in bulk demands verification of international standard compliance to ensure materials meet performance expectations throughout their service life. Reputable manufacturers maintain certifications including ISO9001 quality management systems, ISO14001 environmental management standards, and SGS inspection verification. These certifications demonstrate systematic quality control throughout production processes, from raw material procurement through finished product inspection. Beyond basic certifications, buyers should verify that suppliers conduct comprehensive testing protocols covering appearance inspection, dimensional accuracy, salt spray resistance, coating adhesion, hardness measurements, impact resistance, film thickness verification, acid resistance, weather resistance testing, and color consistency evaluation. Products meeting ASTM, DIN, JIS, BS, and GB/T standards provide assurance of manufacturing excellence and performance reliability. Thickness tolerance represents another crucial consideration when evaluating Pre painted corrugated roofing sheet quality. Standard thickness ranges from 0.4 to 1.2 millimeters, with custom specifications available for specialized applications requiring enhanced strength or unique aesthetic requirements. Thicker gauge materials naturally provide greater structural capacity and improved sound insulation properties, though they also increase material costs and structural loading considerations. Buyers must balance thickness selection against specific project requirements, considering factors such as span distances between supports, anticipated snow loads, wind exposure ratings, and acoustic performance objectives. Width dimensions typically range from 720 to 1500 millimeters, with custom widths available to minimize cutting waste and optimize installation efficiency for specific building geometries.

Supplier Evaluation and Selection Criteria

Selecting appropriate suppliers for bulk Pre Painted Corrugated Sheets purchases requires comprehensive evaluation beyond initial price comparisons. Manufacturing capacity directly influences delivery reliability and quality consistency. Suppliers operating multiple production facilities with diverse equipment configurations demonstrate greater flexibility and resilience against disruptions. For example, manufacturers maintaining separate raw material production plants, plate processing facilities, and accessories manufacturing operations can better coordinate complex orders and maintain inventory availability during peak demand periods. Production capacity metrics worth investigating include the number of color coating lines, laminating capabilities, longitudinal and transverse shearing equipment, automated punching systems, and complementary processing machinery such as shearing machines, presses, and bending equipment. Supply chain transparency provides essential insights into material sourcing and quality assurance practices. Leading manufacturers maintain documented supplier registration systems specifying approved brands for each material category. For aluminum substrates, established brands like Alucosuper, YATAI, and LIDAO offering 3003, 3004, and 5052 alloy specifications ensure consistent material properties. Steel substrate sourcing from recognized producers such as BAOSTEEL, GUANZHOU, or XINYU provides confidence in base material quality for cold rolled sheets, galvanized sheets, galvalume sheets, and color coated sheets. Stainless steel applications benefit from premium materials supplied by manufacturers like Baosteel and Tsingshan offering 316 and 304 grade specifications. This brand accountability allows buyers to trace material origins and verify conformance with project specifications throughout procurement processes.

Production Capability and Customization Flexibility

Bulk purchasing advantages extend beyond unit cost reductions to encompass customization opportunities that optimize material utilization and installation efficiency. Manufacturers offering comprehensive customization services can tailor Pre Painted Corrugated Sheets specifications including color matching to RAL standards or custom requirements, pattern variations, surface treatment modifications, and design adjustments accommodating unique architectural features. This customization flexibility proves particularly valuable for large commercial projects requiring distinctive aesthetic coordination or specialized performance characteristics. Minimum order quantities typically start around five hundred square meters, making bulk purchasing accessible for medium to large construction projects while enabling negotiation leverage for pricing, delivery scheduling, and technical support services. Production lead times significantly impact project planning and cash flow management. Standard delivery timelines ranging from fifteen to twenty days provide adequate planning windows for most construction schedules, though buyers should verify capacity availability during peak construction seasons when demand surges may extend standard lead times. Manufacturers maintaining monthly supply capacities exceeding one thousand tons demonstrate robust production capabilities that support reliable delivery commitments even during high-demand periods. Additionally, inquire about emergency expediting options, partial shipment capabilities, and inventory holding services that can accommodate project schedule fluctuations and phased construction approaches requiring staggered material deliveries coordinated with actual installation progress.

Technical Specifications and Performance Requirements

Detailed technical specifications form the foundation of successful bulk Pre Painted Corrugated Sheets procurement by establishing clear performance expectations and acceptance criteria. Material composition specifications should comprehensively define substrate type, base material thickness, coating system type distinguishing between polyester, high-durability polyester, and PVDF formulations, coating thickness measurements for both exterior and interior surfaces, and surface preparation methods employed before coating application. These specifications directly influence material lifespan expectations, with properly specified and manufactured Pre painted corrugated roofing sheet systems delivering service lives exceeding twenty to thirty years under normal environmental exposure conditions. Structural performance requirements must align with building code obligations and site-specific environmental challenges. Thermal expansion coefficients around 11.5 times ten to the negative sixth power per degree Celsius match steel substrate properties, requiring proper fastening system design that accommodates dimensional changes throughout seasonal temperature cycles. Fire rating requirements vary according to building occupancy classifications and local code enforcement standards, with materials achieving B1 ratings under GB 8624 standards or A-level classifications when combined with flame retardant coating treatments. Sound insulation performance ranges from twenty-five decibels for single sheet installations to forty decibels or greater when combined with rockwool or similar acoustic insulation materials, addressing noise control requirements for industrial facilities, commercial buildings near transportation corridors, or residential applications prioritizing acoustic comfort.

Weather Resistance and Environmental Durability

Geographic location dramatically influences appropriate Pre Painted Corrugated Sheets specifications due to varying environmental exposure challenges. Coastal installations require enhanced corrosion resistance achieved through galvalume or stainless steel substrates combined with premium PVDF coating systems that resist salt spray degradation. Industrial environments with chemical exposure necessitate acid-resistant coating formulations verified through specific testing protocols. High-temperature climates benefit from reflective coating technologies and enhanced heat insulation properties that reduce cooling energy consumption and extend coating service life by minimizing thermal stress cycles. Cold climate applications must accommodate snow loading requirements through appropriate thickness selection and purlin spacing while considering potential ice formation patterns that could create localized stress concentrations. UV resistance represents another critical performance parameter affecting color retention and coating integrity throughout the material service life. Premium Pre painted corrugated roofing sheet products incorporate UV stabilizers within coating formulations that maintain color consistency and prevent chalking or fading even after decades of continuous sunlight exposure. Manufacturers should provide accelerated weathering test results demonstrating coating performance under simulated long-term exposure conditions. Additionally, evaluate warranty coverage specifically addressing color fade limits, coating adhesion maintenance, and corrosion perforation protection. Standard warranties typically extend fifteen to thirty years depending on coating system selection and environmental exposure classification, with premium products offering extended coverage reflecting superior material quality and manufacturing confidence.

Cost Analysis and Budget Optimization

Bulk purchasing Pre Painted Corrugated Sheets requires sophisticated cost analysis extending beyond simple unit price comparisons to encompass total ownership economics. Initial material costs represent only one component of overall project economics, with installation labor, transportation logistics, waste factors, maintenance requirements, and expected service life contributing to true cost performance. Buyers should develop comprehensive cost models comparing alternative material specifications, supplier options, and procurement strategies to identify optimal value propositions. For example, premium PVDF coatings commanding higher initial costs frequently deliver superior lifecycle value through extended service life, reduced maintenance requirements, and sustained aesthetic appearance that defers costly replacement cycles compared to economy polyester coating alternatives requiring earlier replacement. Transportation costs significantly impact bulk order economics, particularly for large projects requiring substantial material volumes. Buyers should evaluate supplier proximity to project sites, transportation mode options, freight consolidation opportunities, and delivery coordination flexibility. Direct manufacturer sourcing eliminates distributor markups while enabling negotiation of favorable freight terms, though buyers must ensure adequate lead time for production scheduling and transportation logistics. Container shipping offers cost advantages for large volume purchases, with proper packaging preventing edge damage, moisture exposure, and surface scratching during transit. Verify packaging specifications including protective films, intermediate separation materials, sectional bundling corresponding to roof plan layouts, and exterior identification labeling facilitating efficient site organization and installation sequencing.

Negotiation Strategies and Contract Considerations

Effective negotiation maximizes bulk purchasing advantages while establishing clear performance obligations and risk allocation between buyers and suppliers. Volume commitments provide leverage for pricing concessions, extended payment terms, dedicated technical support, priority production scheduling, and customization services. However, buyers should structure agreements incorporating flexibility mechanisms addressing potential scope changes, schedule adjustments, and quality acceptance procedures. Staged delivery schedules aligned with construction progress minimize site storage requirements and material exposure risks while maintaining cash flow flexibility. Payment term negotiations should balance supplier cash flow needs against buyer financial management preferences, with milestone-based payments providing appropriate incentive structures and risk sharing arrangements. Quality acceptance provisions represent critical contract elements protecting buyer interests throughout procurement and installation phases. Specifications should reference industry standards, establish sampling and testing protocols, define acceptance criteria for dimensional tolerances and visual appearance standards, outline dispute resolution procedures, and specify remedy options for non-conforming materials including replacement obligations, price adjustments, or schedule impact compensation. Factory inspection opportunities allow buyers to verify manufacturing processes, review quality control systems, and examine representative product samples before shipment authorization. Some suppliers offer sealed sample procedures where customer-approved samples serve as baseline standards for subsequent production batches, ensuring consistency throughout large orders requiring multiple production runs over extended timeframes.

Installation Planning and Technical Support

Successful bulk Pre Painted Corrugated Sheets procurement extends beyond material acquisition to encompass comprehensive installation planning and supplier technical support coordination. Design optimization services provided by experienced manufacturers can significantly enhance project outcomes through structural modeling, load analysis, drainage system simulation, and material specification advisory services. These technical services help buyers avoid common specification errors, optimize material utilization, and ensure compliance with building codes and performance objectives. Detailed shop drawing development breaking down architectural concepts into precise installation drawings facilitates accurate material fabrication, systematic site organization, and efficient installation sequencing that minimizes labor costs and schedule duration. On-site technical support represents valuable service differentiation among competing suppliers. Experienced manufacturers assign installation technicians who visit construction sites before material delivery to assess site conditions, verify preparation adequacy, review storage arrangements, and confirm tool availability for proper installation execution. Pre-installation meetings review detailed drawings, clarify work sequencing, address safety protocols, and establish communication procedures resolving field questions efficiently without disrupting installation progress. During installation phases, technical guidance ensures proper fastening techniques, appropriate sealant application, correct panel overlap configurations, and systematic quality verification preventing water infiltration and ensuring structural adequacy. Post-installation acceptance procedures typically include zero-leakage testing, dimensional verification, visual appearance inspection, and customer training covering maintenance requirements and warranty claim procedures.

Conclusion

Successful bulk purchasing of Pre Painted Corrugated Sheets demands comprehensive evaluation of quality standards, supplier capabilities, technical specifications, cost economics, and installation support services to achieve optimal project outcomes and long-term performance satisfaction.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

Xi'an Huafeng Construction Engineering Co., Ltd. stands as a leading China Pre Painted Corrugated Sheets manufacturer and China Pre Painted Corrugated Sheets supplier, offering exceptional quality and comprehensive services since our establishment in 2018. As a recognized high-tech enterprise in Shaanxi Province holding first-level building curtain wall qualifications and third-level steel structure qualifications, we operate three advanced factories with seven color coating production lines and over forty specialized machines across our 200,000 square meter Anhui production facility and processing plants in Hangzhou and Xi'an. Our China Pre Painted Corrugated Sheets factory delivers monthly supply capacity exceeding 1,000 tons with standard delivery timelines of fifteen to twenty days, offering Pre Painted Corrugated Sheets for sale with competitive Pre Painted Corrugated Sheets price structures reflecting our direct manufacturer advantages.

We provide High Quality Pre Painted Corrugated Sheets meeting international ASTM, DIN, JIS, BS, and GB/T standards, with ISO9001, ISO14000, and SGS certifications ensuring manufacturing excellence throughout our one-stop solution encompassing custom design services, precision manufacturing with real-time quality control, and seamless installation support. Our extensive experience includes landmark projects such as Xiongan Station Commercial Body, Xi'an International Convention and Exhibition Center, and Inner Mongolia Tongliao Art Museum, demonstrating our capability to deliver complex large-scale installations. As a trusted China Pre Painted Corrugated Sheets wholesale partner, we offer customizable solutions with thirty-year warranties, flexible MOQ starting at 500 square meters, and comprehensive technical support from initial design through post-installation maintenance. Contact our team at huafeng@hfmetalroof.com to discuss your project requirements and discover how our proven expertise can optimize your bulk procurement outcomes while ensuring exceptional quality and reliable delivery performance.

References

1. Thompson, Richard & Martinez, Elena. "Material Selection and Quality Assurance in Metal Roofing Systems." Construction Materials and Technology Journal, Volume 28, Number 4.

2. Anderson, David. "Bulk Procurement Strategies for Commercial Construction Materials." Industrial Purchasing and Supply Chain Management Quarterly.

3. Williams, Sarah & Chen, Michael. "Coating Technologies and Performance Standards for Pre-Painted Metal Building Products." International Journal of Building Science and Technology.

4. Roberts, James. "Lifecycle Cost Analysis of Metal Roofing Systems in Commercial Applications." Journal of Construction Economics and Management, Volume 17.

5. Peterson, Laura & Singh, Rajesh. "Quality Control and Testing Protocols for Architectural Metal Products." Building Materials Testing and Certification Standards Manual.