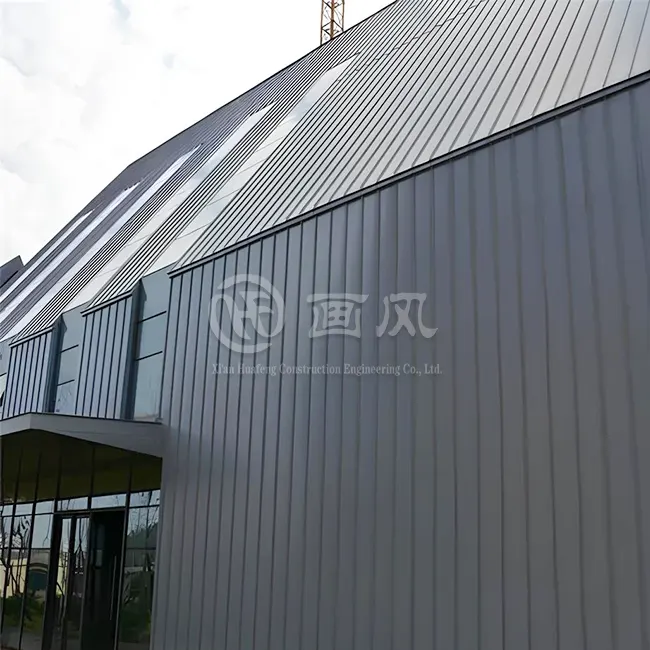

When facility managers and construction professionals face the challenge of roofing large-span structures that demand both exceptional load-bearing capacity and long-term durability, they often struggle to find a cost-effective solution that won't compromise on structural integrity or weather resistance. Deep Trapezoidal Roof Panels emerge as the answer to this critical roofing dilemma, offering high-strength performance specifically engineered for industrial plants, logistics warehouses, commercial complexes, and other demanding applications where conventional roofing systems fall short. This comprehensive guide explores the best applications for Deep Trapezoidal Roof Panels, revealing how their unique design characteristics, superior material specifications, and versatile installation capabilities make them the preferred choice for modern construction projects requiring reliable, long-lasting roofing solutions.

Industrial Facilities and Manufacturing Plants

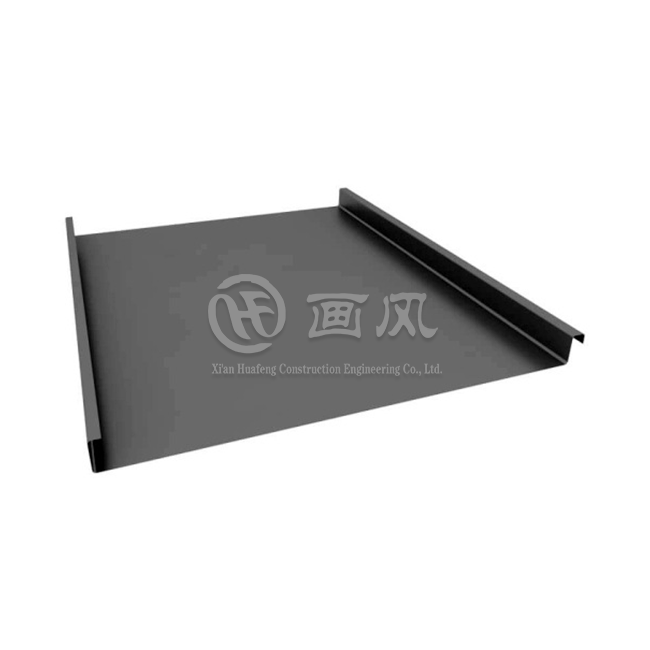

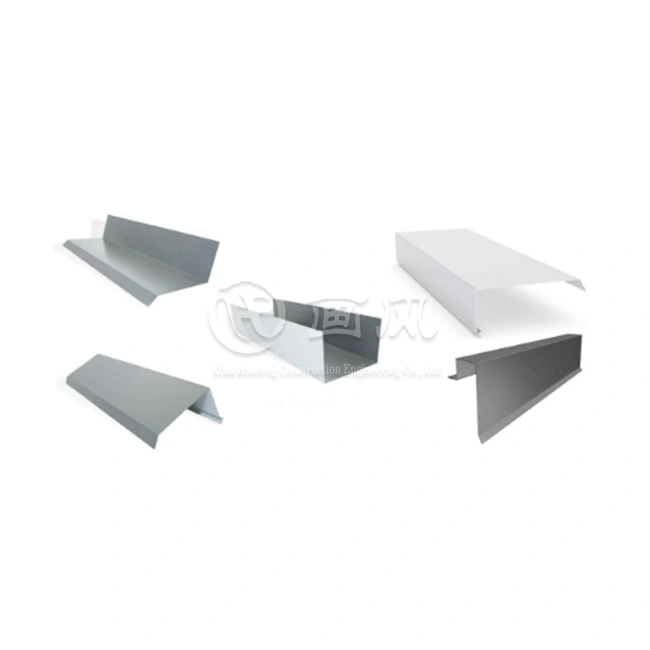

Industrial environments present some of the most demanding roofing challenges in modern construction, making Deep Trapezoidal Roof Panels an ideal solution for manufacturing facilities, processing plants, and heavy industrial buildings. These specialized metal roofing systems excel in industrial applications because their high-rib design provides exceptional structural strength capable of supporting substantial loads while spanning distances of 15 to 30 meters without intermediate support structures. The profound groove pattern inherent in Deep Trapezoidal Roof Panels creates a high moment of inertia that distributes weight efficiently across the panel surface, allowing these roofing systems to withstand heavy equipment installations, suspended crane systems, and accumulated snow loads that would overwhelm standard roofing profiles. Manufacturing facilities benefit tremendously from the corrosion-resistant properties of Deep Trapezoidal Roof Panels, particularly when constructed from aluminum-zinc steel plates with AZ150 coating or galvanized steel plates with G550 specifications. Chemical processing plants and food production facilities operating in corrosive environments find that stainless steel Deep Trapezoidal Roof Panels in 304 or 316 grades provide unmatched resistance to harsh atmospheric conditions, industrial emissions, and chemical exposure. The wave height ranging from 75mm to 120mm in high-rib trapezoidal configurations delivers superior drainage performance, ensuring that industrial roofs shed water efficiently even in low-slope applications with pitches as minimal as 1:4.12, preventing water pooling that could lead to structural deterioration or production disruptions.

The thermal performance characteristics of Deep Trapezoidal Roof Panels make them particularly valuable for temperature-sensitive manufacturing operations. When configured as composite sandwich panel systems with rock wool or polyurethane insulation layers, these roofing solutions provide excellent thermal insulation properties that help maintain consistent interior temperatures, reduce energy consumption for heating and cooling systems, and create comfortable working environments for personnel. Industrial facilities installing Deep Trapezoidal Roof Panels also appreciate the rapid installation process enabled by their mechanically seamed or snap-together designs, which minimize construction timelines and allow manufacturing operations to commence quickly, reducing project costs and accelerating return on investment.

Logistics Warehouses and Distribution Centers

The explosive growth of e-commerce and global supply chains has created unprecedented demand for massive logistics facilities and distribution centers that require efficient, economical roofing solutions capable of covering vast uninterrupted floor spaces. Deep Trapezoidal Roof Panels represent the optimal roofing choice for these large-span warehouse applications because their structural geometry allows spans of 20 to 30 meters between support purlins, maximizing usable interior space while minimizing the steel framework required for roof support. This structural efficiency translates directly into reduced construction costs, as warehouse developers can achieve greater clear-span distances with fewer structural members, creating flexible interior layouts ideal for modern automated material handling systems and high-bay storage configurations. Distribution centers operating around the clock benefit from the exceptional weather-tightness of mechanically seamed Deep Trapezoidal Roof Panels, which create continuous watertight barriers that protect valuable inventory from moisture intrusion regardless of severe weather conditions. The standing seam design of these panels, combined with their trapezoidal leg geometry, ensures that fasteners remain concealed beneath the roofing surface, eliminating potential leak points that plague exposed-fastener systems and providing superior long-term weatherproofing performance. Logistics facilities in coastal regions or high-humidity environments particularly value Deep Trapezoidal Roof Panels manufactured from aluminum-zinc steel with specialized coatings offering 25-year-plus service lives, ensuring decades of maintenance-free performance even in challenging atmospheric conditions.

The cost-effectiveness of Deep Trapezoidal Roof Panels makes them especially attractive for warehouse developers working within tight budget parameters. These roofing systems typically utilize economical materials such as galvanized steel plates in 0.6mm to 1.0mm thicknesses, providing excellent strength-to-weight ratios that deliver necessary structural performance at significantly lower material costs compared to alternative roofing solutions. Modern logistics facilities increasingly specify Deep Trapezoidal Roof Panels with reflective coating finishes that enhance energy efficiency by reducing solar heat gain, lowering cooling loads, and contributing toward green building certifications that improve property values and tenant appeal in competitive commercial real estate markets.

Commercial Buildings and Retail Complexes

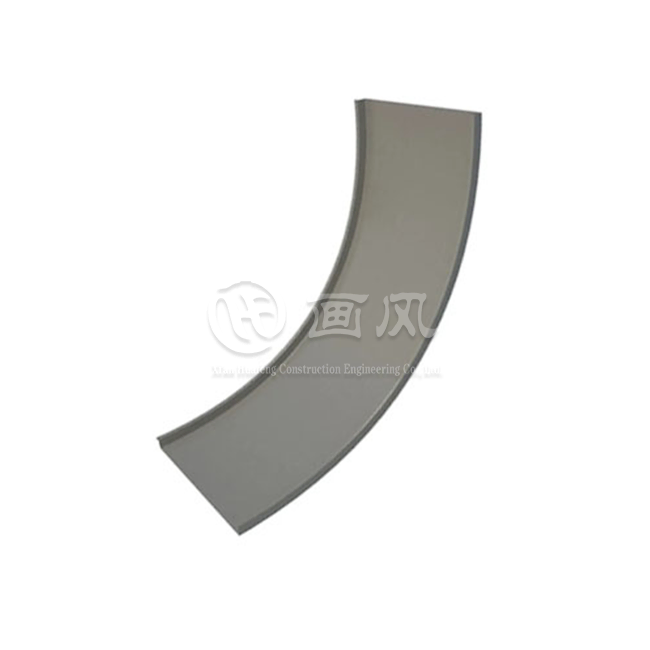

Contemporary commercial architecture increasingly embraces Deep Trapezoidal Roof Panels for retail shopping centers, office complexes, exhibition halls, and mixed-use developments that demand roofing solutions combining structural performance with architectural aesthetics. The clean geometric lines created by the trapezoidal profile shadows offer modern visual appeal that complements contemporary architectural designs, while the ability to specify custom colors through PE, HDP, or PVDF coating systems ensures that Deep Trapezoidal Roof Panels integrate seamlessly with overall building aesthetics and branding requirements. Commercial developers appreciate how these metal roofing systems can be manufactured in continuous lengths up to 12 meters, creating streamlined roof surfaces with minimal seams that enhance visual coherence across expansive commercial structures. Shopping centers and retail complexes benefit from the superior span capabilities of Deep Trapezoidal Roof Panels, which allow architects to create dramatic open interior spaces with soaring ceilings and unobstructed sight lines that enhance the shopping experience and provide flexible layouts for evolving tenant configurations. The high compressive strength exceeding 300 MPa in G550 steel specifications ensures that these roofing systems safely support suspended mechanical equipment, lighting systems, decorative elements, and seasonal decorations without compromising structural integrity or requiring additional reinforcement. Commercial property owners particularly value the 30-year warranty coverage typically offered with premium Deep Trapezoidal Roof Panels, providing long-term asset protection and predictable maintenance budgets that improve overall project economics.

Exhibition centers, convention facilities, and entertainment venues represent another crucial commercial application where Deep Trapezoidal Roof Panels deliver exceptional value through their ability to span large column-free spaces while maintaining economical construction costs. These facilities often require rapid construction schedules to meet opening deadlines tied to event calendars or seasonal considerations, making the efficient installation characteristics of Deep Trapezoidal Roof Panels particularly advantageous. The availability of composite sandwich panel configurations with integrated thermal and acoustic insulation makes these roofing systems ideal for commercial spaces where interior comfort and sound control significantly impact user experience and operational success.

Sports Facilities and Recreational Structures

Athletic complexes, gymnasiums, indoor sports arenas, and recreational facilities present unique roofing challenges that Deep Trapezoidal Roof Panels address through their combination of extreme span capabilities, structural resilience, and cost-effective performance. Stadium roofs and sports hall structures commonly require clear spans exceeding 25 meters to accommodate playing surfaces, spectator seating, and overhead equipment without interior columns that would obstruct sight lines or interfere with athletic activities. The high-rib trapezoidal configuration with wave heights reaching 100mm to 120mm provides the structural depth necessary to achieve these impressive spans while maintaining adequate strength to resist substantial wind uplift forces and accumulated snow loads that sports facilities in varied climatic zones must withstand. Deep Trapezoidal Roof Panels excel in sports facility applications because their excellent drainage characteristics ensure rapid water removal from large roof surfaces, preventing ponding that could lead to structural stress or accelerated deterioration. The precise manufacturing tolerances achievable with modern roll-forming production lines ensure consistent panel dimensions and seam alignment, creating watertight roof assemblies that protect expensive athletic flooring, electronic scoreboards, and mechanical systems from moisture damage. Sports complexes increasingly specify Deep Trapezoidal Roof Panels with specialized acoustic underlayment systems that control reverberation and improve sound quality within arenas, enhancing spectator experience and meeting regulatory requirements for indoor sound levels.

Recreational facilities such as swimming pool enclosures, ice rinks, and indoor training centers benefit from the corrosion resistance of stainless steel or aluminum-zinc coated Deep Trapezoidal Roof Panels that withstand the elevated humidity and chemical exposure characteristic of these specialized environments. The ability to integrate translucent panels or skylights within Deep Trapezoidal Roof Panel systems allows sports facility designers to incorporate natural daylighting that reduces energy consumption, creates pleasant interior environments, and provides the quality illumination that broadcast television operations require for professional sporting events. Municipal recreation departments and private sports club operators appreciate the low maintenance requirements and extended service life of properly specified Deep Trapezoidal Roof Panels, which minimize lifecycle costs and ensure reliable long-term performance for community assets serving diverse user populations.

Agricultural and Specialized Storage Applications

Agricultural operations, equipment storage facilities, and specialized storage structures represent a significant market segment where Deep Trapezoidal Roof Panels deliver exceptional value through their durability, economy, and adaptability to diverse functional requirements. Modern agricultural buildings including livestock barns, crop storage facilities, equipment sheds, and processing buildings require roofing solutions that withstand corrosive atmospheric conditions, provide reliable weather protection, and accommodate budget constraints that characterize farm construction projects. Deep Trapezoidal Roof Panels meet these demanding criteria through their high strength-to-weight ratio, which minimizes structural steel requirements and reduces foundation loads, creating economical building solutions ideal for agricultural applications where cost-effectiveness remains paramount. Livestock facilities and animal housing structures particularly benefit from composite Deep Trapezoidal Roof Panels incorporating thermal insulation and moisture barriers that regulate interior temperatures, control condensation, and create healthy environments for animal welfare. The excellent ventilation characteristics achievable with properly designed Deep Trapezoidal Roof Panel systems allow agricultural buildings to maintain optimal air quality and humidity levels that prevent moisture accumulation and structural deterioration while supporting productive livestock operations. Equipment storage buildings utilize economical low-rib trapezoidal configurations with 35mm to 60mm wave heights that provide adequate structural performance for smaller spans of 6 to 15 meters, delivering cost-effective protection for valuable farm machinery and implements at minimal investment levels.

Specialized storage applications including cold storage facilities, grain silos, chemical storage buildings, and hazardous material warehouses demand the superior corrosion resistance and structural integrity that Deep Trapezoidal Roof Panels provide through advanced material specifications and coating systems. Cold chain warehouses require composite Deep Trapezoidal Roof Panels with high-performance insulation cores that maintain precise temperature control while minimizing thermal bridging and condensation risks that compromise building envelopes and product quality. Agricultural cooperatives and commercial storage operators increasingly specify Deep Trapezoidal Roof Panels manufactured to international standards including ASTM, DIN, JIS, and GB/T certifications, ensuring reliable performance, quality consistency, and compliance with building codes across diverse geographic markets and regulatory jurisdictions.

Conclusion

Deep Trapezoidal Roof Panels have established themselves as the premier roofing solution for large-span structures across industrial, commercial, sports, and agricultural sectors through their exceptional structural performance, versatile application capabilities, and outstanding long-term value proposition.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

Xi'an Huafeng Construction Engineering Co., Ltd. stands as your trusted China Deep Trapezoidal Roof Panels factory, China Deep Trapezoidal Roof Panels supplier, and China Deep Trapezoidal Roof Panels manufacturer, offering High Quality Deep Trapezoidal Roof Panels with competitive Deep Trapezoidal Roof Panels price and comprehensive China Deep Trapezoidal Roof Panels wholesale programs. Our company, recognized as a high-tech enterprise in Shaanxi Province with first-level curtain wall qualifications and third-level steel structure certifications, operates three advanced factories spanning 200,000 square meters with 7 color coating production lines and more than 40 precision manufacturing machines delivering 1,000 tons monthly production capacity. We provide complete one-stop solutions encompassing custom engineering design with 3D modeling and load analysis, precision roll-forming manufacturing with real-time quality control, and seamless on-site installation management, all backed by ISO9001, ISO14000, SGS certifications, and more than 20 registered patents. Experience Deep Trapezoidal Roof Panels for sale with customizable specifications including 0.4-1.2mm thickness, PE/HDP/PVDF coating finishes, 15-20 day delivery times, and 30-year warranties, plus benefit from our proven track record completing prestigious projects for Fortune 500 companies including Xiongan Station, Xi'an International Convention Center, and numerous landmark facilities. Contact our expert team at huafeng@hfmetalroof.com today to discuss your project requirements and discover how our engineering excellence, manufacturing capabilities, and comprehensive support services deliver superior roofing solutions tailored to your specific application needs.

References

1. "Metal Roofing Systems: Design and Construction Standards" by National Roofing Contractors Association, Technical Manual Committee

2. "Structural Performance of Trapezoidal Profile Metal Roof Systems Under Wind and Snow Loads" by American Iron and Steel Institute, Engineering Division

3. "Long-Span Metal Building Design Guide" by Metal Building Manufacturers Association, Technical Committee

4. "Corrosion Protection for Metal Roofing in Industrial Environments" by International Association of Corrosion Engineers, Protective Coatings Committee

5. "Energy Performance of Metal Roof Systems in Commercial Buildings" by American Society of Heating, Refrigerating and Air-Conditioning Engineers, Building Performance Research

(1)_1763110678300.webp)