When extreme weather conditions threaten your building's integrity, selecting the right roofing material becomes critical. Standing Seam Metal Roof Sheets offer superior protection against hurricanes, torrential rains, heavy snowfall, and intense UV exposure, making them the preferred choice for projects in demanding environments. This comprehensive guide explores the top five standing seam metal roofing options engineered specifically to withstand nature's harshest challenges while delivering decades of reliable performance.

Understanding Standing Seam Metal Roof Sheets for Extreme Weather Conditions

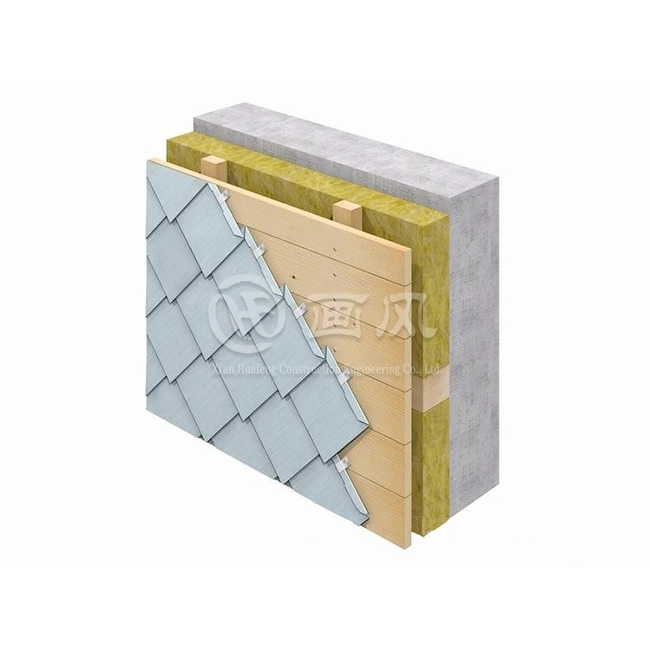

Standing Seam Metal Roof Sheets represent an advanced roofing technology designed specifically for buildings exposed to severe climatic conditions. These high-performance panels feature raised interlocking seams that create a continuous weathertight barrier from ridge to eave, eliminating potential water entry points that plague traditional roofing systems. The concealed fastener design ensures that no screws or nails penetrate the roofing surface, which dramatically reduces the risk of leaks, wind uplift damage, and thermal bridging that can compromise structural integrity during extreme weather events. The engineering behind Standing Seam Metal Roof Sheets addresses multiple environmental stressors simultaneously. Their vertical panel orientation promotes rapid water drainage, preventing the pooling that leads to ice dam formation in cold climates or accelerated degradation in tropical environments. The raised seam heights ranging from twenty-five to sixty-five millimeters provide exceptional resistance to wind-driven rain and snow infiltration, while the interlocking mechanism distributes wind loads across the entire roof assembly rather than concentrating stress on individual fasteners. This holistic design approach explains why these systems consistently outperform alternatives in regions experiencing hurricanes, cyclones, blizzards, or extreme temperature fluctuations. Material selection plays an equally critical role in harsh climate performance. Premium Standing Seam Metal Roof Sheets utilize galvanized steel, aluminum-magnesium-manganese alloys, or specialized coatings like PVDF that resist corrosion, UV degradation, and thermal cycling. These materials maintain their structural properties across temperature ranges from negative forty to positive eighty degrees Celsius, ensuring consistent performance whether installed in arctic conditions or desert environments. The combination of intelligent design and advanced materials creates a roofing solution capable of protecting critical infrastructure for thirty to fifty years with minimal maintenance requirements.

Why Concealed Fastener Systems Excel in Harsh Climates?

The concealed fastener approach employed in Standing Seam Metal Roof Sheets provides substantial advantages over exposed fastener systems when confronting challenging weather patterns. Traditional roofing methods rely on screws driven through the panel face, creating thousands of potential water entry points that require ongoing inspection and maintenance as rubber washers deteriorate under UV exposure and thermal cycling. In coastal regions where salt spray accelerates corrosion, exposed fasteners can fail within five to ten years, necessitating expensive restoration work or premature replacement. Concealed fastener Standing Seam Metal Roof Sheets eliminate this vulnerability entirely by positioning all attachment points beneath the panel surface where they remain protected from direct weather exposure. Specialized clips engage with the vertical seam legs and transfer wind loads directly to the structural deck without penetrating the waterproofing membrane. This configuration allows the metal panels to expand and contract freely in response to temperature changes without creating stress concentrations around fixed points. During hurricane-force winds, the continuous seam engagement distributes uplift forces across the entire roof area rather than concentrating loads on individual fasteners, which explains why properly installed standing seam systems routinely survive storms that destroy conventional roofing. The thermal performance benefits of concealed fastening become particularly apparent in climates experiencing significant temperature swings. Exposed fasteners create thermal bridges that allow heat transfer directly through the roof assembly, increasing energy consumption for heating and cooling. Standing Seam Metal Roof Sheets with concealed clips and continuous insulation layers achieve superior R-values while preventing the condensation formation that leads to rust, mold growth, and structural deterioration in humid environments. These performance advantages translate directly into lower lifecycle costs and extended service life compared to exposed fastener alternatives.

Top Five Standing Seam Metal Roof Sheet Materials for Demanding Environments

Aluminum-Magnesium-Manganese Alloy Panels

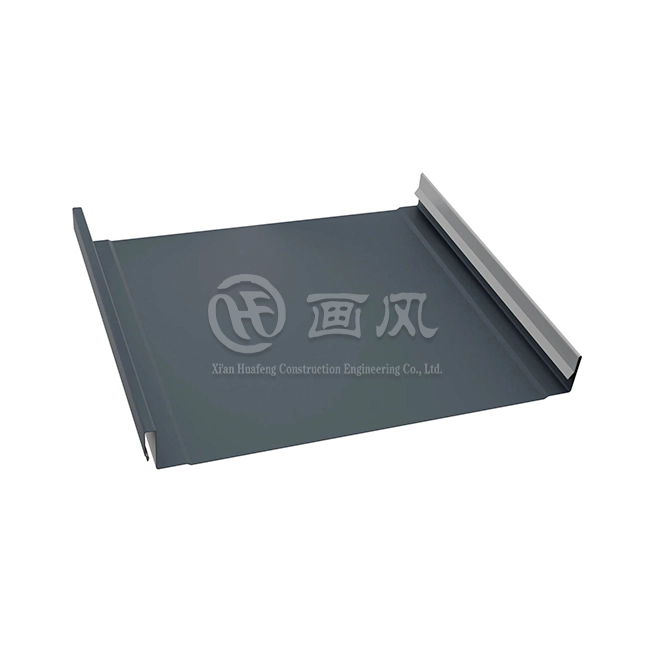

Aluminum-magnesium-manganese alloy Standing Seam Metal Roof Sheets represent the premier choice for structures in coastal areas, industrial zones, or any environment where corrosion resistance is paramount. These specialized alloys combine aluminum's natural resistance to oxidation with magnesium and manganese additions that significantly increase strength and formability. The resulting material withstands direct salt spray exposure without requiring additional protective coatings, making it ideal for oceanfront properties, chemical processing facilities, or buildings located near roadways where de-icing salt creates corrosive conditions. The mechanical properties of aluminum-magnesium-manganese Standing Seam Metal Roof Sheets provide exceptional wind resistance despite their relatively light weight. Modern manufacturing techniques produce panels with seam heights up to sixty-five millimeters and thicknesses ranging from zero point seven to one point two millimeters, creating profiles that resist panel flutter and wind-driven rain infiltration in extreme weather events. The material's excellent thermal conductivity facilitates rapid temperature equilibration, reducing thermal stress that can cause panel distortion in regions experiencing intense daytime heating followed by rapid nighttime cooling. Installation versatility represents another significant advantage of aluminum-magnesium-manganese panels. These Standing Seam Metal Roof Sheets can be curved on-site to accommodate complex architectural geometries without special equipment, enabling their use on dome structures, barrel vaults, or transitional surfaces that would require custom fabrication with steel alternatives. The natural patina that develops over time creates an aesthetically pleasing finish that actually enhances corrosion protection rather than indicating material degradation. With a projected service life exceeding fifty years in most environments, these panels deliver exceptional value for projects requiring maximum durability and minimal maintenance.

Galvanized Steel with PVDF Coating

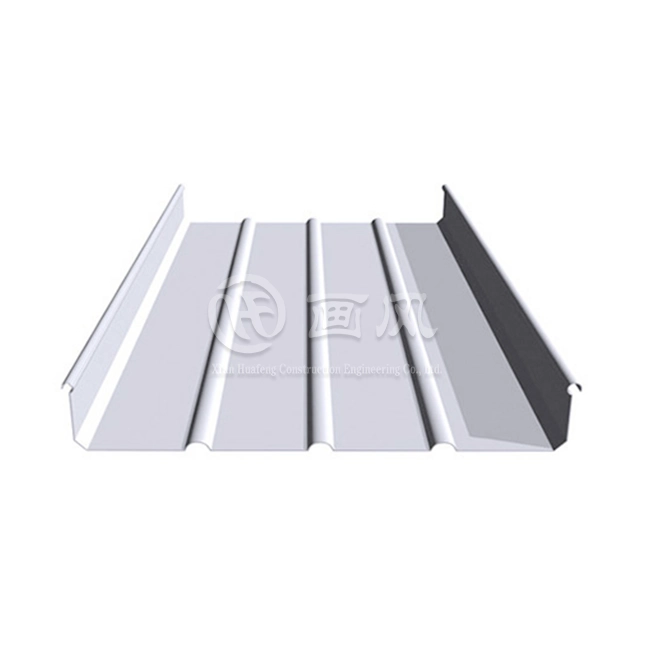

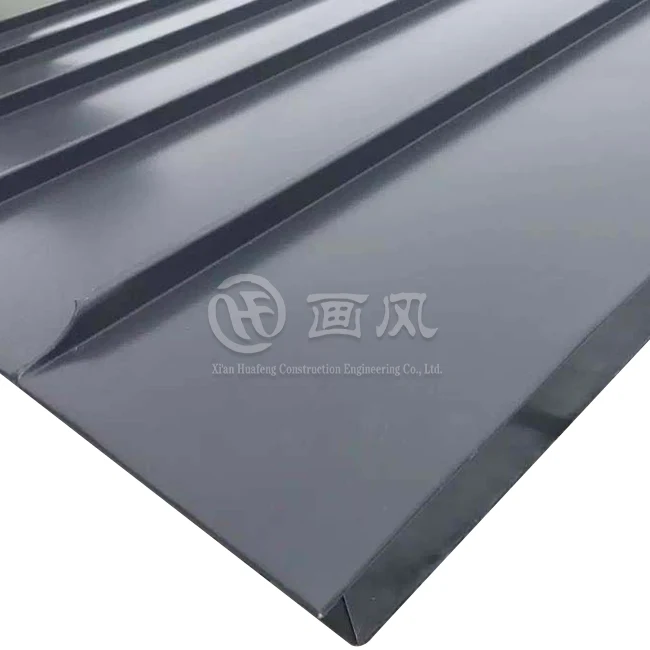

Galvanized steel Standing Seam Metal Roof Sheets with PVDF surface treatment provide an optimal balance of strength, weather resistance, and cost-effectiveness for harsh climate applications. The base steel substrate delivers superior structural capacity compared to aluminum, making these panels the preferred choice for large-span roofs, buildings in high-snow-load regions, or structures requiring enhanced impact resistance. The galvanized zinc coating applied through hot-dip processes creates a metallurgical bond that protects the underlying steel from corrosion even if the surface coating sustains minor damage during installation or service. The addition of PVDF coating technology elevates these Standing Seam Metal Roof Sheets to premium performance levels that justify their use on the most demanding projects. PVDF formulations create an extremely durable finish that resists chalking, fading, and color change even after decades of intense UV exposure, maintaining aesthetic appeal throughout the building's lifecycle. This coating system demonstrates exceptional chemical resistance, protecting the roof from acid rain, industrial pollutants, and agricultural chemicals that would rapidly degrade alternative finishes. The hydrophobic properties of PVDF surfaces promote rapid water shedding and resist dirt accumulation, keeping the roof clean and reducing maintenance requirements. Thermal performance distinguishes PVDF-coated Standing Seam Metal Roof Sheets in both hot and cold climates. Light-colored PVDF finishes reflect up to seventy percent of incident solar radiation, significantly reducing cooling loads in tropical and desert environments while qualifying for energy efficiency incentives and cool roof certifications. The coating's flexibility accommodates the thermal expansion and contraction cycles that occur daily in extreme temperature environments without cracking or delaminating. When combined with twenty-four gauge steel substrate and proper installation techniques, these panels routinely achieve service lives exceeding forty years while maintaining their protective and aesthetic functions.

Zinc-Titanium Standing Seam Panels

Zinc-titanium Standing Seam Metal Roof Sheets offer unique advantages for projects requiring exceptional longevity, environmental sustainability, and distinctive architectural character. These specialty materials develop a protective patina within months of installation that actually increases corrosion resistance over time, creating a self-healing surface that repairs minor scratches and abrasions automatically. The material's softness compared to steel or aluminum enables intricate forming operations and allows thermal movement without generating the stress concentrations that can cause fastener failure or panel distortion in other materials. The environmental credentials of zinc-titanium Standing Seam Metal Roof Sheets appeal to projects pursuing green building certifications or operating under strict sustainability mandates. Zinc production requires significantly less embodied energy than aluminum or coated steel manufacturing, and the material remains fully recyclable at end-of-service without quality degradation. The natural patination process eliminates the need for organic coatings containing volatile compounds, while the material's antimicrobial properties resist biological growth that can compromise roof appearance and performance in humid climates. These characteristics make zinc-titanium panels particularly appropriate for healthcare facilities, educational institutions, or civic buildings seeking to demonstrate environmental stewardship.

Performance in harsh maritime environments represents a particular strength of zinc-titanium Standing Seam Metal Roof Sheets. The material demonstrates superior resistance to salt spray and chloride exposure compared to galvanized steel, maintaining structural integrity and appearance for seventy-five to one hundred years in coastal installations. The patina formation creates a distinctive gray finish that complements contemporary architectural aesthetics while providing visual evidence of the roof's protective capabilities. When specified with appropriate thickness, typically zero point seven to zero point eight millimeters for most applications, these panels deliver exceptional weather resistance combined with the flexibility needed to accommodate structural movement and thermal cycling.

Color-Coated Galvalume Steel Panels

Galvalume steel Standing Seam Metal Roof Sheets combine aluminum-zinc alloy coating with organic color systems to create versatile roofing solutions suitable for diverse climatic challenges. The Galvalume substrate provides exceptional barrier protection against corrosion through a combination of sacrificial protection from the zinc component and barrier protection from the aluminum layer. This dual-action corrosion resistance mechanism enables these panels to perform reliably in environments that would rapidly degrade either pure galvanized or aluminum-coated alternatives, including regions with acid rain, industrial fallout, or mixed rural-coastal exposure. The color coating systems applied to Galvalume Standing Seam Metal Roof Sheets offer extensive customization opportunities while enhancing weather resistance and thermal performance. Polyester, SMP, and PVDF coating options provide varying levels of durability and fade resistance to match project budgets and performance requirements. Premium PVDF formulations deliver color retention exceeding ninety percent after twenty years of exposure while maintaining gloss and resisting environmental degradation. The availability of hundreds of standard colors plus custom matching capabilities enables architects to achieve specific aesthetic visions while maintaining the structural and protective advantages inherent in standing seam technology.

Thermal performance optimization through color selection represents a critical advantage of color-coated Galvalume Standing Seam Metal Roof Sheets in extreme climate regions. Light colors with high solar reflectance values dramatically reduce heat gain in tropical and desert environments, potentially lowering cooling energy consumption by twenty to thirty percent compared to dark conventional roofing. Conversely, darker colors in cold climates can facilitate snow melting and ice prevention while reducing heating costs through solar heat gain. The combination of corrosion-resistant substrate, durable coating systems, and thermal performance optimization creates Standing Seam Metal Roof Sheets capable of delivering thirty-five to forty-five years of reliable service across virtually any climatic condition.

Stainless Steel Premium Panels

Stainless steel Standing Seam Metal Roof Sheets represent the ultimate solution for environments where conventional materials cannot provide adequate service life or where absolute reliability is essential. These premium panels utilize chromium-nickel alloy compositions, typically 304 or 316 grades, that demonstrate remarkable resistance to corrosion, staining, and chemical attack across extreme temperature ranges and exposure conditions. The material's inherent corrosion resistance eliminates the need for protective coatings, ensuring consistent appearance and performance regardless of surface damage or abrasion that would compromise coated alternatives. The mechanical properties of stainless steel Standing Seam Metal Roof Sheets provide exceptional wind and impact resistance for structures in hurricane-prone regions, hail belts, or areas vulnerable to airborne debris during severe weather events. The material's high tensile strength allows reduced panel thickness compared to carbon steel alternatives while maintaining superior structural capacity. This strength advantage becomes particularly valuable for long-span applications or roofs with minimal structural support where panel self-support capability is critical. The material's excellent low-temperature toughness ensures reliable performance in arctic conditions where other metals become brittle and prone to fracture.

Economic justification for stainless steel Standing Seam Metal Roof Sheets focuses on lifecycle cost analysis rather than initial material expense. While procurement costs significantly exceed carbon steel or aluminum alternatives, the projected service life of sixty to one hundred years combined with essentially zero maintenance requirements create compelling total cost of ownership advantages for institutional, infrastructure, or landmark buildings. The material's aesthetic appeal improves with age as the surface develops a subtle patina that enhances rather than diminishes visual character. For projects requiring absolute reliability, such as emergency services facilities, data centers, or critical infrastructure, stainless steel Standing Seam Metal Roof Sheets provide unmatched peace of mind and long-term value.

Material Specifications and Performance Standards

Understanding the technical specifications that govern Standing Seam Metal Roof Sheets enables informed material selection and ensures compliance with applicable building codes and performance standards. Panel thickness represents a critical parameter that directly influences structural capacity, weather resistance, and service life. Most commercial and industrial applications specify twenty-four gauge steel or equivalent aluminum thicknesses ranging from zero point five to one point two millimeters. These dimensions provide adequate strength to resist wind uplift, snow loads, and impact forces while maintaining formability for complex geometries and transitions. Seam height specifications for Standing Seam Metal Roof Sheets typically range from twenty-five to sixty-five millimeters, with taller profiles providing enhanced weather resistance and visual prominence. The twenty-five to thirty-three millimeter range suits residential and light commercial applications with moderate weather exposure, while forty-five to sixty-five millimeter profiles are specified for large commercial, industrial, or institutional buildings requiring maximum performance. Panel width dimensions commonly fall between three hundred and six hundred millimeters, with wider panels reducing installation time and seam quantities while narrower panels facilitate tighter radius curves and complex geometries.

Surface treatment standards significantly impact Standing Seam Metal Roof Sheets performance and longevity. PVDF coatings must meet AAMA 2605 specifications ensuring fade and chalk resistance, while polyester systems comply with AAMA 2604 requirements for moderate durability applications. Galvanized and Galvalume coatings are specified according to ASTM standards defining minimum coating weights and adhesion properties. These standardized specifications enable reliable performance comparisons across manufacturers and ensure that specified materials will deliver anticipated service lives. Quality Standing Seam Metal Roof Sheets suppliers provide comprehensive test data documenting compliance with ISO9001 quality management systems, ISO14001 environmental standards, and product-specific certifications verifying wind resistance, fire ratings, and weathertightness performance.

Xi'an Huafeng Construction Engineering: Manufacturing Excellence in Standing Seam Systems

Xi'an Huafeng Construction Engineering Co., Ltd. operates advanced production facilities specifically engineered for high-quality Standing Seam Metal Roof Sheets manufacturing. The company's three factories encompass over two hundred thousand square meters of manufacturing space housing seven color coating production lines, ten longitudinal and transverse shearing lines, and more than forty specialized roll-forming and finishing machines. This substantial production infrastructure enables monthly output exceeding one thousand tons of finished Standing Seam Metal Roof Sheets while maintaining rigorous quality control throughout the manufacturing process. The company's material procurement strategy ensures that Standing Seam Metal Roof Sheets meet the demanding performance requirements of harsh climate applications. Xi'an Huafeng sources aluminum from premium suppliers including Alucosuper, YATAI, and LIDAO, specifying 3003, 3004, and 5052 alloys known for superior corrosion resistance and formability. Steel substrates come from industry leaders BAOSTEEL, GUANZHOU, and XINYU, providing galvanized, galvalume, and color-coated materials that comply with ASTM, DIN, JIS, BS, and GB/T international standards. Stainless steel components utilize Baosteel and Tsingshan 304 and 316 grades, while specialty applications can incorporate NedZink titanium-zinc or Chinalco copper materials for ultimate longevity.

Quality assurance processes at Xi'an Huafeng encompass comprehensive incoming material inspection and finished product testing that verify Standing Seam Metal Roof Sheets meet specified performance criteria. Raw materials undergo verification testing including appearance inspection, dimensional measurement, salt spray exposure, adhesion testing, hardness evaluation, impact resistance, film thickness measurement, acid resistance, weather resistance simulation, and color difference analysis. Finished panels receive additional inspection for appearance quality, dimensional accuracy, flatness, and proper curvature before packaging. This rigorous quality control ensures that every Standing Seam Metal Roof Sheets shipment will perform as specified throughout decades of service in demanding environments.

Installation Considerations and Technical Support

Professional installation represents a critical factor in achieving the full performance potential of Standing Seam Metal Roof Sheets in harsh climate applications. Xi'an Huafeng provides comprehensive technical support throughout the project lifecycle, beginning with structural analysis and drainage system simulation during the design phase. The company's engineering team conducts one-to-one drawing development for complex node details, ensuring that transitions, penetrations, and interface conditions receive appropriate attention. This design optimization process identifies potential problem areas before fabrication begins, eliminating field modifications that compromise weathertightness or structural performance. The manufacturing phase for Standing Seam Metal Roof Sheets incorporates project-specific customization that simplifies installation and ensures proper fit. Panels are fabricated in continuous lengths up to twelve meters, eliminating horizontal seams that create potential leak paths and reduce structural capacity. Each component receives sequential numbering corresponding to its location on the roof plan, preventing installation errors and streamlining the construction process. Packaging organization follows the roof sectioning plan, with identification cards showing section layouts and component lists that enable efficient material staging and just-in-time delivery to installation crews. On-site technical support from Xi'an Huafeng ensures that Standing Seam Metal Roof Sheets installation proceeds according to manufacturer specifications and industry best practices. Installation technicians visit project sites to verify substrate conditions, confirm tool and accessory availability, and conduct pre-installation briefings covering work sequences and safety procedures. The company provides guidance on proper clip placement, seam engagement procedures, and interface detailing that prevents common installation errors. Upon completion, comprehensive testing verifies zero-leakage performance and confirms that the standing seam system will provide decades of reliable protection against the harshest environmental conditions.

Proven Performance: Project Applications in Extreme Environments

Xi'an Huafeng Construction Engineering has successfully supplied Standing Seam Metal Roof Sheets for numerous high-profile projects demonstrating the material's capability to perform in diverse challenging climates. The Xiongan Station Commercial Body project utilized aluminum-magnesium-manganese panels to protect a major transportation facility subjected to heavy seasonal precipitation, temperature extremes, and substantial roof traffic. The Xi'an International Convention and Exhibition Center metal roof installation showcased the material's aesthetic versatility while providing weather protection for a large-span structure vulnerable to wind uplift and thermal cycling. Transportation infrastructure projects like the Xi'an Station East Auxiliary Building and Liyuanping Highway Station demonstrate Standing Seam Metal Roof Sheets performance under continuous environmental exposure and vibration loads. These installations require materials that maintain weathertightness despite structural movement and resist corrosion from vehicle emissions and road salt. Cultural and institutional buildings including the Jinghe New City International Culture and Art Center South Hall, Weihua Cadre College Teaching Building, and Inner Mongolia Tongliao Art Museum leverage standing seam technology to achieve distinctive architectural character while ensuring long-term protection with minimal maintenance requirements. Industrial and infrastructure applications including the Hangzhou Sanpu Drainage Pump Station illustrate Standing Seam Metal Roof Sheets capability to function reliably in humid, chemically aggressive environments where conventional roofing materials deteriorate rapidly. The Archaeological Museum design deepening project demonstrates the material's suitability for sensitive applications requiring climate control and artifact protection. These diverse successful installations validate Standing Seam Metal Roof Sheets as the optimal roofing solution for buildings facing nature's harshest challenges while requiring decades of maintenance-free service.

Conclusion

Standing Seam Metal Roof Sheets engineered from premium materials and manufactured to exacting standards provide unmatched protection for buildings in harsh climates. Their concealed fastener design, superior weather resistance, and exceptional durability justify specification for any project requiring reliable long-term performance regardless of environmental challenges.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

Xi'an Huafeng Construction Engineering Co., Ltd., established in 2018 and recognized as a Shaanxi Province high-tech enterprise in 2020, specializes in comprehensive metal roofing solutions from initial design through final installation. Our vertically integrated operations encompass a two-hundred-thousand-square-meter raw material production plant in Anhui plus dedicated plate and accessories processing facilities in Hangzhou and Xi'an. This extensive manufacturing infrastructure supports our one-stop service model delivering custom-engineered Standing Seam Metal Roof Sheets tailored to project-specific requirements.

Our engineering expertise spans over two decades of metal roofing system design, manufacturing innovation, and construction implementation. We maintain ISO9001 certified manufacturing processes ensuring consistent quality across our seven production lines and forty specialized machines. More than twenty registered patents for roofing systems demonstrate our commitment to continuous technical advancement. Our products comply with international standards including ISO14001 environmental management and SGS quality verification, providing assurance that specified materials will deliver anticipated performance throughout their thirty-year minimum warranty period.

Partner with a China Standing Seam Metal Roof Sheets manufacturer and China Standing Seam Metal Roof Sheets supplier offering competitive Standing Seam Metal Roof Sheets price advantages through efficient production and flexible bulk order options. As a trusted China Standing Seam Metal Roof Sheets factory and China Standing Seam Metal Roof Sheets wholesale provider, we deliver High Quality Standing Seam Metal Roof Sheets for sale with comprehensive technical support from initial specification through installation completion and ongoing maintenance. Contact us at huafeng@hfmetalroof.com to discuss your project requirements and discover how our expertise can protect your investment for decades to come. Save this article and reference it whenever you need reliable guidance on Standing Seam Metal Roof Sheets selection and specification.

References

1. Metal Construction Association. "Guide Specification for Standing Seam Metal Roof Systems." Technical Standards Committee, 2023.

2. National Roofing Contractors Association. "Metal Roofing Design and Installation Best Practices." NRCA Technical Services Department, 2024.

3. Smith, Robert and Johnson, Katherine. "Performance Evaluation of Metal Roofing Systems in Extreme Weather Conditions." Journal of Building Performance, Volume 15, Issue 3, 2024.

4. American Society for Testing and Materials. "Standard Specification for Steel Sheet, Zinc-Coated (Galvanized) or Zinc-Iron Alloy-Coated (Galvannealed) by the Hot-Dip Process." ASTM A653/A653M, 2024.

5. Wilson, David. "Durability and Lifecycle Cost Analysis of Premium Metal Roofing Materials." Construction Specifier Magazine, February 2024.