Picture this scenario: You're finalizing specifications for a high-profile commercial building, and your client demands a sleek, modern facade that balances aesthetics with durability. You've spent hours researching cladding options, but uncertainty about color permanence, finish compatibility with different metals, and long-term weathering performance keeps you second-guessing every decision. Flat Lock Wall Panels offer architects a comprehensive solution by combining customizable color options, premium finish technologies, and material versatility that transforms challenging facade projects into architectural masterpieces while ensuring decades of reliable performance.

Understanding Flat Lock Wall Panels Material and Finish Options

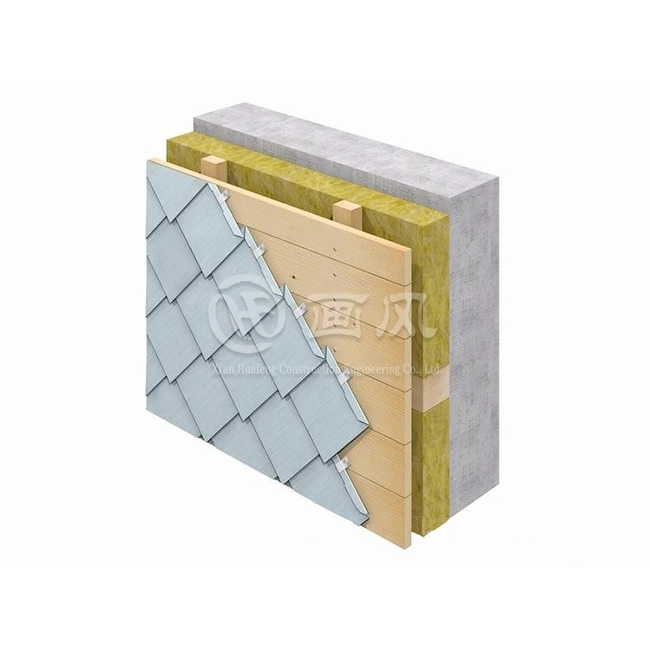

Flat lock metal panel systems represent one of the most sophisticated architectural cladding solutions available today, offering architects unprecedented control over both aesthetic expression and functional performance. These interlocking panel systems consist of flat metal sheets that create a seamless, monolithic appearance on building exteriors while maintaining excellent weather resistance through their specialized concealed fastening mechanisms. The fundamental advantage of Flat Lock Wall Panels lies in their ability to accommodate multiple premium metal substrates, each bringing distinct visual characteristics and performance attributes to the finished facade. Material selection forms the cornerstone of any successful flat lock panel specification, with titanium zinc, copper, aluminum-magnesium-manganese alloy, and stainless steel representing the primary options available to design professionals. Titanium zinc panels develop a distinctive patina over time, creating a living facade that evolves aesthetically while maintaining structural integrity for over seventy years. The natural weathering process of zinc produces a protective carbonate layer that self-heals minor scratches and provides exceptional corrosion resistance in coastal and industrial environments. Copper flat lock metal panels offer similar patina development characteristics but with warmer tones ranging from bright penny copper through rich bronze to eventual verdigris green, providing architects with a time-tested material that has adorned significant structures for centuries.

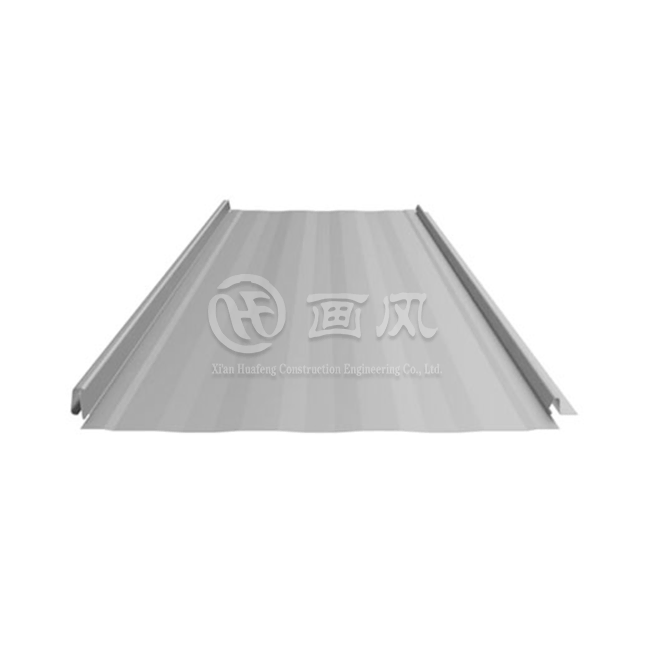

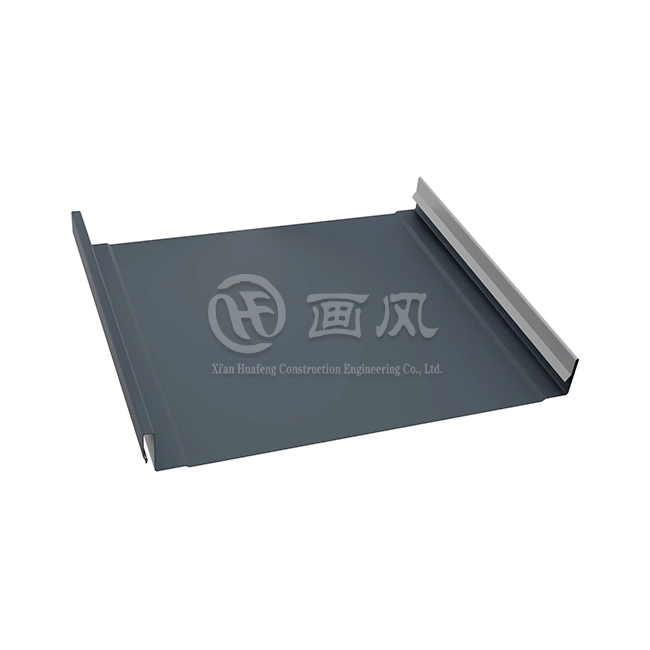

Aluminum-magnesium-manganese alloys present a contemporary alternative that combines light weight with excellent formability and corrosion resistance, making these panels particularly suitable for complex geometries and curved facade applications. The alloy composition, typically featuring 3003, 3004, or 5052 grades, provides superior strength-to-weight ratios compared to pure aluminum while maintaining the material's inherent resistance to atmospheric corrosion. Stainless steel Flat Lock Wall Panels, available in both 304 and 316 grades, deliver unmatched durability and modern aesthetic appeal, with 316 grade offering enhanced chloride resistance for marine applications. The material thickness range of 0.4mm to 0.8mm provides flexibility in structural performance while maintaining the desired flat profile that defines this panel system.

Advanced Coating Technologies and Surface Treatments

Modern Flat Lock Wall Panels employ sophisticated coating technologies that dramatically extend service life while providing architects with virtually unlimited color customization possibilities. PVDF coatings represent the premium standard for architectural metal panels, utilizing polyvinylidene fluoride resins that form molecular bonds with metal substrates to create exceptionally durable color finishes. These 70% PVDF formulations resist chalking, fading, and chemical degradation far more effectively than conventional polyester coatings, maintaining color integrity and gloss retention for decades even under intense ultraviolet exposure and harsh environmental conditions. The coating application process involves multiple preparatory stages including chemical cleaning, chromate or non-chromate conversion coating, and primer application before the topcoat layers are applied through precision roll-coating equipment. This multi-layer system typically includes a backer coat on the interior face and two topcoat layers on the exterior face, with total dry film thickness ranging from 25 to 35 microns depending on specification requirements. PE coatings provide a cost-effective alternative for applications where extreme durability requirements are less critical, offering good initial color appearance and moderate weathering resistance suitable for many commercial applications with shorter design life expectations. Surface texture options extend beyond smooth finishes to include embossed, matte, and metallic effects that add visual depth and tactile interest to flat lock metal panel installations. Matte finishes effectively conceal minor surface imperfections and reduce glare issues that can affect building occupants and neighbors, while metallic finishes create dynamic visual effects as natural lighting conditions change throughout the day. These specialized coating formulations must meet stringent quality standards including adhesion testing per ASTM D3359, impact resistance per ASTM D2794, and accelerated weathering protocols per ASTM G155 to ensure long-term performance reliability.

Comprehensive Color Selection Strategies for Flat Lock Wall Panels

Architects navigating color specification for Flat Lock Wall Panels must balance multiple considerations including client aesthetic preferences, regional architectural context, building energy performance, and maintenance accessibility. The RAL color system provides a standardized reference framework encompassing over 200 distinct hues organized into logical color families, enabling precise color communication between design teams, manufacturers, and contractors. While RAL colors offer excellent standardization benefits, custom color matching capabilities allow architects to achieve brand-specific colors or unique aesthetic visions that differentiate projects in competitive markets. Color psychology plays a fundamental role in facade design, with different hues evoking distinct emotional responses and cultural associations that influence how occupants and visitors perceive architectural spaces. Neutral tones including various shades of gray, beige, and taupe provide timeless elegance and excellent compatibility with diverse architectural styles, making these colors particularly popular for corporate headquarters, government facilities, and institutional buildings seeking to project professionalism and permanence. Earth tones ranging from warm terracotta through olive green to deep brown create harmonious connections with natural surroundings and have gained popularity in sustainable architecture projects seeking to minimize visual impact on sensitive landscapes.

Bold color choices including vibrant reds, blues, and greens enable architects to create landmark buildings that command attention and express organizational identity through architectural form. However, these saturated colors require careful consideration of regional climate conditions, as intense ultraviolet exposure in tropical and high-altitude locations can accelerate color fading despite premium PVDF coating protection. Dark colors absorb significantly more solar radiation than light colors, potentially affecting building cooling loads and creating thermal expansion challenges that must be addressed through proper panel detailing and joint spacing calculations.

Metallic Finishes and Natural Metal Aesthetics

Natural metal finishes represent a distinct category within flat lock metal panel specifications, offering architects the opportunity to showcase the inherent beauty of premium metals without applied paint coatings. Pre-weathered zinc surfaces provide consistent appearance immediately upon installation, eliminating the gradual patina development period that occurs with natural zinc weathering and ensuring predictable aesthetic results for clients requiring immediate visual completion. Mill finish stainless steel creates striking contemporary facades through its reflective surface qualities and cool metallic appearance, though this finish requires more frequent cleaning to maintain visual appeal in urban and industrial environments where airborne particulates can dull surface luster. Anodized aluminum finishes provide exceptional corrosion resistance while offering a range of color options achieved through electrolytic oxidation processes that create controlled oxide layers on aluminum surfaces. These finishes maintain the metallic character of aluminum while providing color consistency and durability superior to conventional painted finishes, making anodized Flat Lock Wall Panels particularly suitable for projects requiring both aesthetic distinction and minimal lifecycle maintenance. Bronze tones achieved through anodizing complement brick and stone materials commonly found in historical district renovations, while champagne and silver anodized finishes create elegant modern aesthetics appropriate for contemporary commercial developments.

The interaction between natural and coated metal finishes within single facade compositions enables architects to create visual hierarchies and accentuate architectural features through material contrast. Combining natural copper accent panels with painted aluminum field panels, for example, draws attention to entrance features or building corners while maintaining cost efficiency across larger facade areas. These mixed-material strategies require careful detailing to prevent galvanic corrosion where dissimilar metals contact each other, necessitating appropriate isolation methods including compatible fasteners, gaskets, and sealants specified according to industry best practices.

Technical Considerations for Color and Finish Performance

Architects specifying Flat Lock Wall Panels must understand the complex relationship between color selection, solar reflectance, and building thermal performance to optimize both aesthetic outcomes and energy efficiency targets. Solar Reflectance Index ratings quantify how effectively surfaces reflect solar radiation, with higher values indicating cooler surface temperatures under direct sunlight exposure. Light-colored panels with SRI values exceeding 70 can reduce cooling loads in warm climates by minimizing heat gain through building envelopes, potentially contributing to LEED certification points under Heat Island Reduction credits and improved building energy modeling results. Conversely, dark colors with low SRI values may benefit buildings in heating-dominated climates by capturing solar energy during winter months and reducing heating loads, though these benefits must be weighed against increased cooling requirements during summer periods. Thermal expansion coefficients vary between different metal substrates, with aluminum expanding approximately twice as much as steel over equivalent temperature ranges, requiring careful panel length limitations and joint spacing calculations to prevent buckling or fastener failure. Flat lock metal panel systems accommodate thermal movement through their interlocking seam design, which allows controlled expansion and contraction without compromising weather resistance or visual appearance when properly installed according to manufacturer specifications.

Color fade resistance represents a critical long-term performance parameter that directly affects building lifecycle costs and client satisfaction. Premium PVDF coatings typically guarantee minimal color change over ten to twenty-year warranty periods, with delta E color difference values limited to five units or less under standardized testing protocols. These warranties specifically cover chalking, cracking, peeling, and loss of adhesion under normal atmospheric exposure, though they typically exclude damage from chemical contamination, abrasion, or improper maintenance procedures. Understanding warranty limitations and exclusions enables architects to set realistic client expectations regarding appearance evolution over building service life.

Installation Pattern Influence on Color Perception

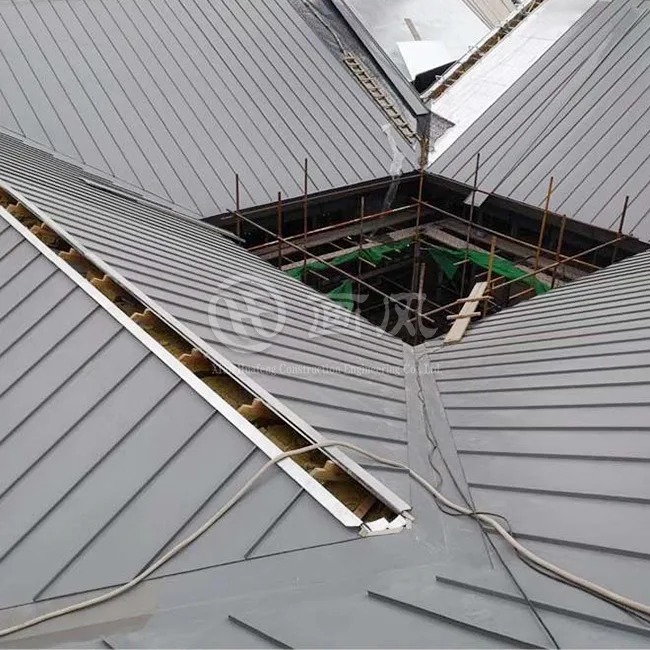

The installation orientation and pattern arrangement of Flat Lock Wall Panels significantly influences how color and finish characteristics are perceived under varying lighting conditions throughout daily and seasonal cycles. Horizontal panel installations create strong shadow lines at each seam joint, emphasizing the linear geometry of the facade and potentially making color appear darker than vertical installations due to reduced direct light reflection. Vertical orientations minimize shadow effects while creating visual emphasis on building height, making this arrangement particularly effective for mid-rise and high-rise structures where architects wish to accentuate vertical proportions. Diamond pattern installations, achieved by rotating square panels 45 degrees, create dynamic visual interest and distinctive architectural character that differentiates buildings in competitive commercial markets. This arrangement requires precise layout planning and increased labor costs compared to orthogonal installations but delivers unique aesthetic effects that justify premium investment for signature projects. The geometric pattern created by interlocking seams becomes a dominant visual element that can either complement or compete with base color selection, requiring architects to carefully balance pattern prominence with color intensity to achieve desired overall facade composition. Panel width variation within single facade compositions enables architects to create subtle visual rhythms and texture effects without introducing multiple colors or materials. Alternating 100mm, 200mm, and 300mm wide Flat Lock Wall Panels produces banding patterns that add visual complexity while maintaining material consistency and installation efficiency. These dimensional variations must be coordinated with structural framing layouts and window opening locations to ensure proper alignment and avoid awkward partial panel conditions at building corners and penetration perimeters.

Maintenance Requirements and Long-Term Color Retention

Proactive maintenance planning ensures that Flat Lock Wall Panels maintain their intended appearance and performance characteristics throughout building service life while minimizing unexpected repair costs and building owner dissatisfaction. Cleaning frequency requirements vary significantly based on geographical location, atmospheric conditions, and specific finish types, with urban and industrial environments typically requiring more frequent intervention than suburban or rural locations. Regular washing with mild detergent solutions removes accumulated dirt and environmental contaminants before they bond permanently to coating surfaces, preserving color vibrancy and preventing premature degradation of protective finish systems. PVDF-coated Flat Lock Wall Panels generally require professional cleaning every two to three years in moderate exposure environments, with frequency increasing to annual intervals in locations subject to heavy industrial fallout, marine salt spray, or frequent acid rain events. Cleaning procedures must follow manufacturer-specific protocols to avoid voiding finish warranties, typically involving low-pressure water application, soft brush agitation with approved cleaning solutions, and thorough rinsing to remove all chemical residues. High-pressure washing can damage coating systems by forcing water behind panel seams or compromising coating adhesion through mechanical stress, making this cleaning method specifically prohibited under most manufacturer warranty terms.

Natural metal finishes including copper and zinc develop protective patina layers that actually improve corrosion resistance over time, requiring minimal maintenance beyond periodic inspection for mechanical damage or fastener corrosion. However, these surfaces may experience streaking or uneven patina development in areas subject to differential moisture exposure, such as beneath overhangs or adjacent to dissimilar materials that shed runoff onto panel surfaces. While some clients appreciate the organic variation that natural weathering produces, others prefer more uniform appearance, necessitating clear communication during design development about realistic appearance expectations for living metal facades.

Conclusion

Selecting appropriate colors and finishes for Flat Lock Wall Panels requires comprehensive understanding of material properties, coating technologies, environmental performance factors, and maintenance implications that collectively determine long-term project success and client satisfaction.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

Xi'an Huafeng Construction Engineering Co., Ltd. stands as a China Flat Lock Wall Panels manufacturer and China Flat Lock Wall Panels supplier with comprehensive capabilities spanning design through installation. As a recognized high-tech enterprise holding first-level building curtain wall qualifications and third-level steel structure qualifications, Huafeng delivers China Flat Lock Wall Panels wholesale solutions backed by three factories, seven color coating production lines, and more than forty advanced machines ensuring consistent High Quality Flat Lock Wall Panels production. Our one-stop service includes structural 3D modeling, drainage system simulation, customized Flat Lock Wall Panels for sale in various RAL colors with PVDF or PE coatings, precision roll-forming systems with real-time quality control, and seamless installation with safety compliance documentation. Collaborate with our China Flat Lock Wall Panels factory to access competitive Flat Lock Wall Panels price structures, 15-20 day delivery schedules, free samples, and engineering excellence demonstrated across landmark projects including Xiongan Station and Xi'an International Convention Center. Contact our technical team at huafeng@hfmetalroof.com to discuss your architectural vision and receive customized specifications that transform design concepts into enduring architectural achievements.

References

1. American Architectural Manufacturers Association. "Metal Wall Panel Systems: Design and Performance Standards." AAMA Publication Committee, 2023.

2. Johnson, Michael R., and Patricia K. Stevens. "Advanced Coating Technologies for Architectural Metal Surfaces." Journal of Protective Coatings and Linings, Vol. 40, No. 3, 2024.

3. National Roofing Contractors Association. "Metal Panel Design Manual: Technical Guidelines for Architectural Applications." NRCA Technical Services, 2023.

4. Thompson, David L. "Color Science in Architecture: Psychological and Physical Considerations for Building Facades." Architectural Research Quarterly, Vol. 27, No. 2, 2024.

5. Wilson, Catherine E., and Robert A. Martinez. "Sustainable Metal Cladding Systems: Material Selection and Lifecycle Performance." Green Building and Design Magazine, Winter 2024.

(1)_1763110678300.webp)