When facing rising construction costs, unpredictable weather damage, and the constant maintenance demands of traditional wall materials, building owners and contractors need a reliable solution that delivers long-term value without compromising quality. Corrugated Sheet Metal Wall Panels answer these challenges by offering exceptional durability, cost-effectiveness, and versatility for industrial, commercial, agricultural, and residential applications. These wavy-profiled metal panels combine structural strength with weather resistance, providing a practical solution that reduces both initial investment and lifetime maintenance costs while maintaining aesthetic appeal across diverse building projects.

Understanding Corrugated Sheet Metal Wall Panels and Their Core Advantages

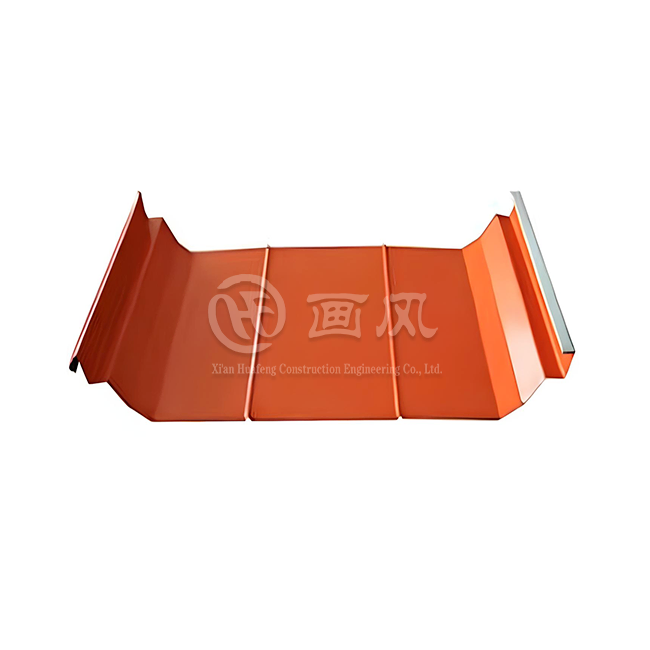

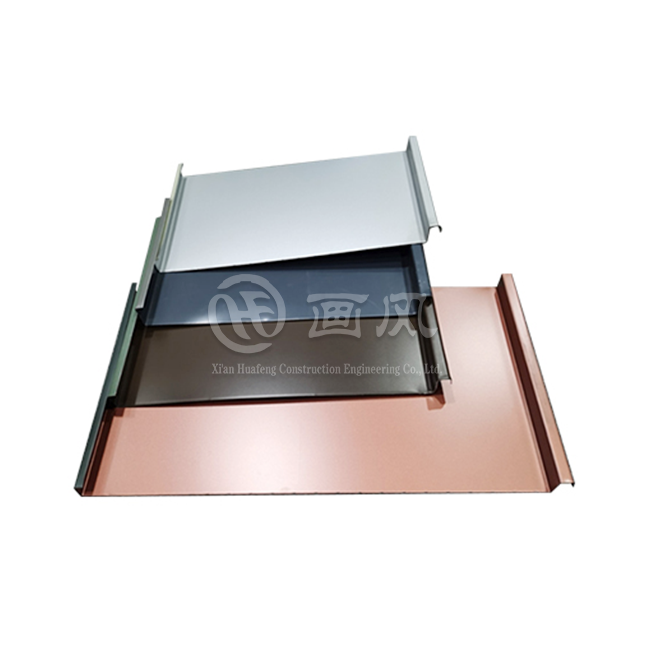

The fundamental design of Corrugated Sheet Metal Wall Panels centers on their distinctive wavy profile, which transforms flat metal sheets into structurally reinforced building components through a cold-forming or roll-forming process. This corrugated configuration significantly increases the tensile strength and load-bearing capacity of the material, creating one of the highest strength-to-weight ratios available in construction materials. The alternating ridges and valleys distribute stress evenly across the panel surface, enabling these lightweight materials to withstand substantial wind loads, impact forces, and environmental pressures that would compromise flat panels. Modern manufacturing techniques ensure that Corrugated Sheet Metal Wall Panels maintain consistent quality across production runs, with materials ranging from galvanized steel and Galvalume to aluminum, stainless steel, and specialty options like titanium-zinc plates. Each material option brings specific performance characteristics suited to different environmental conditions and project requirements. Galvanized steel provides excellent corrosion resistance through its protective zinc coating, while Galvalume combines aluminum and zinc for enhanced longevity in coastal or high-humidity environments. The standardized corrugation profiles, typically featuring wave heights between fifteen and thirty millimeters, ensure reliable performance across varied applications from exterior walls and roof systems to interior accent features and equipment screens.

Enhanced Structural Performance Through Corrugated Design

The engineering behind Corrugated Sheet Metal Wall Panels demonstrates how geometric configuration directly impacts structural performance. When metal sheets undergo the corrugation process, the material achieves significantly greater rigidity and spanning capability compared to flat sheets of identical thickness. This increased structural efficiency means builders can use thinner gauge materials while maintaining required strength specifications, resulting in reduced material costs and lighter overall building loads. The corrugations act as continuous structural ribs running the length of each panel, effectively creating built-in reinforcement that eliminates the need for additional framing in many applications. The wave pattern inherently provides superior resistance to oil canning, the cosmetic waviness that often appears in flat metal panels due to thermal expansion, installation stress, or substrate irregularities. The deliberate corrugations effectively disguise any minor deformations that might occur, maintaining a visually consistent appearance throughout the panel's service life. This characteristic makes Corrugated Sheet Metal Wall Panels particularly suitable for large wall expanses where aesthetic consistency matters. Additionally, the corrugated profile facilitates efficient water drainage by channeling moisture away from fastener penetrations and horizontal seams, significantly reducing the risk of water infiltration and associated structural damage.

Weather Resistance and Environmental Durability

Corrugated Sheet Metal Wall Panels excel in demanding environmental conditions, providing reliable protection against diverse weather challenges including heavy rain, snow accumulation, high winds, hail impact, and extreme temperature fluctuations. The protective coatings applied to these panels, whether galvanized zinc, aluminum-zinc alloy, or advanced paint systems like PVDF and polyester, create multiple barriers against moisture penetration and oxidation. These coating systems work synergistically with the base metal to prevent corrosion from initiating, even when minor surface damage exposes the substrate material. The non-combustible nature of metal construction materials provides critical fire resistance benefits, particularly important for industrial facilities, agricultural buildings, and commercial structures where fire safety regulations demand stringent compliance. Corrugated Sheet Metal Wall Panels typically achieve Class A fire ratings, offering building owners and insurance providers confidence in the structure's ability to resist flame spread and maintain integrity during fire events. Furthermore, the material's dimensional stability across temperature ranges prevents the warping, cracking, and degradation common in wood, vinyl, and other conventional wall materials. Panels maintain their structural geometry and protective function through decades of thermal cycling, from intense summer heat to winter freeze-thaw conditions, without requiring the frequent repairs or replacements associated with less durable materials.

Cost-Effectiveness and Economic Benefits of Corrugated Sheet Metal Wall Panels

The economic advantages of Corrugated Sheet Metal Wall Panels extend far beyond their competitive initial purchase price, encompassing reduced installation labor, minimal maintenance requirements, and exceptional service life that can span three to five decades under normal conditions. When compared to standing seam metal panels, concealed fastener systems, or architectural panel options, corrugated panels typically cost fifty percent less while delivering comparable weather protection and structural performance. This significant cost differential stems from simpler manufacturing processes, standardized profiles that don't require custom tooling, and exposed fastener systems that eliminate expensive clip components and associated hardware.

Lower Installation Costs and Simplified Construction

The installation process for Corrugated Sheet Metal Wall Panels requires fewer specialized skills and less complex equipment compared to concealed fastener systems, expanding the pool of qualified contractors and reducing labor rates. Exposed fastener installation allows workers to secure panels directly to structural framing using self-drilling screws with weather-sealing washers, eliminating the time-consuming clip installation and panel seaming required by more complex systems. This straightforward installation methodology reduces on-site labor hours by thirty to fifty percent compared to standing seam installations, translating directly into lower project costs for building owners. The wider coverage width of corrugated panels, typically ranging from 600 to 1200 millimeters, means fewer individual panels are needed to cover equivalent wall areas. Fewer panels result in fewer seams to seal, fewer fastener penetrations to install, and faster overall project completion. Additionally, the forgiving nature of exposed fastener systems allows for easier adjustments during installation to accommodate minor framing irregularities or field modifications, reducing the waste and rework that can inflate project costs. The accessible installation techniques also make Corrugated Sheet Metal Wall Panels viable for do-it-yourself projects, allowing property owners to eliminate professional labor costs entirely on suitable applications like agricultural buildings, storage sheds, and residential outbuildings.

Minimal Maintenance and Long-Term Value

The exceptional durability of Corrugated Sheet Metal Wall Panels translates into remarkably low maintenance requirements throughout their service life, dramatically reducing the total cost of ownership compared to materials requiring regular painting, sealing, or replacement. Factory-applied paint systems using high-performance coatings like PVDF or polyester maintain color consistency and surface protection for decades without repainting, while the inherent corrosion resistance of properly coated metal prevents the rust and deterioration that would necessitate expensive repairs. Annual maintenance typically involves nothing more than removing accumulated debris and occasional washing to maintain appearance, activities that property maintenance staff can handle without specialized contractors or expensive equipment. The longevity of quality Corrugated Sheet Metal Wall Panels, often backed by manufacturer warranties extending twenty-five to thirty years or more, eliminates the replacement cycles that plague shorter-lived materials. When building owners amortize the initial investment over the panel's expected service life, the annual cost becomes remarkably competitive with less durable alternatives that may require replacement every ten to fifteen years. This extended service life also avoids the disruption and lost productivity associated with major building envelope renovations, allowing facilities to maintain continuous operations without the downtime required for extensive wall system replacements. The recyclability of metal materials at the end of their useful life provides additional economic value, as panels removed during renovations or demolition retain scrap value that offsets disposal costs.

Design Flexibility and Aesthetic Applications

Despite their utilitarian reputation, Corrugated Sheet Metal Wall Panels offer substantial design flexibility through varied material options, diverse finish selections, and multiple installation orientations that accommodate contemporary architectural aesthetics alongside traditional industrial appearances. Modern manufacturing capabilities produce corrugated panels in extensive color ranges using durable paint systems that maintain vibrancy and resist fading under prolonged ultraviolet exposure. Beyond standard colors, specialty finishes including metallic effects, stone-coated textures, and wood-grain patterns enable corrugated metal to integrate seamlessly into design concepts ranging from sleek modern commercial buildings to rustic agricultural structures.

Versatile Installation Options for Diverse Aesthetics

Corrugated Sheet Metal Wall Panels adapt to vertical or horizontal installation orientations, creating distinctly different visual effects that designers can leverage to achieve specific aesthetic goals or complement surrounding architectural elements. Vertical installation emphasizes building height and creates strong linear patterns that draw the eye upward, particularly effective on tall commercial or industrial structures. Horizontal orientation produces a more traditional appearance reminiscent of classic agricultural buildings while visually broadening structures and creating shadow lines that add depth and texture to wall surfaces. Some contemporary designs combine both orientations within a single facade, using directional changes to delineate functional zones, highlight building entrances, or create visual interest through geometric patterns. The corrugated profile itself contributes aesthetic value through the interplay of light and shadow across the panel's wavy surface. Throughout the day, changing sun angles create dynamic visual effects as light reflects off the ridges while shadows pool in the valleys, producing a constantly evolving appearance that flat panels cannot match. This inherent texture adds dimensional richness to building exteriors without requiring additional applied ornamentation or complex installation techniques. Interior applications of Corrugated Sheet Metal Wall Panels have gained popularity in commercial, retail, and hospitality environments where the industrial aesthetic communicates authenticity, durability, and contemporary design sensibility. Restaurant accent walls, retail store displays, office feature walls, and residential basement finishing projects all benefit from the unique character that corrugated metal provides.

Material and Finish Options for Specific Design Requirements

The range of base materials available for Corrugated Sheet Metal Wall Panels enables designers to specify options suited to particular environmental conditions, aesthetic preferences, or budget constraints without compromising essential performance characteristics. Aluminum panels offer exceptional corrosion resistance and lightweight properties ideal for coastal environments or structures with limited load-bearing capacity, while maintaining excellent formability for complex profiles. Stainless steel provides the ultimate durability and requires virtually no maintenance, making it appropriate for demanding industrial applications, food processing facilities, or architectural features requiring centuries of service life. Galvanized and Galvalume steel strike the optimal balance between performance and cost for most commercial and agricultural applications, delivering reliable protection at accessible price points. Surface finish selection further expands design possibilities while influencing long-term performance characteristics. Pre-painted panels with PVDF coatings deliver superior color retention and chalk resistance, maintaining like-new appearance for decades even in harsh sunlight and aggressive industrial atmospheres. Polyester and epoxy coating systems provide economical alternatives with good durability for protected locations or applications where appearance evolution is acceptable. Bare metal finishes including mill finish aluminum, weathering steel, or naturally patinated copper create distinctive appearances that change gradually over time, developing character through controlled oxidation that many designers value for specific aesthetic effects. The thickness options available, ranging from 0.3 to 1.2 millimeters, allow specification based on required strength, spanning distance between structural supports, and local building code requirements.

Manufacturing Quality and Supply Chain Advantages

Selecting Corrugated Sheet Metal Wall Panels from established manufacturers ensures product consistency, reliable performance, and supply chain efficiency that directly impacts project success. Leading manufacturers like Xi'an Huafeng Construction Engineering Co., Ltd. operate comprehensive production facilities encompassing raw material processing, coating application, panel forming, and quality control testing under integrated management systems. This vertical integration provides greater control over material specifications, reduces dependence on external suppliers, and enables customization capabilities that accommodate unique project requirements. Facilities maintaining multiple production lines with advanced roll-forming equipment and automated quality control systems can meet demanding delivery schedules while maintaining stringent quality standards. The manufacturing process for quality Corrugated Sheet Metal Wall Panels begins with carefully selected raw materials meeting international standards such as ASTM, DIN, JIS, BS, and GB/T specifications. Reputable manufacturers maintain approved supplier lists for base metals including aluminum alloys, steel substrates, and specialty materials, requiring material certifications and third-party testing documentation for every batch received. Incoming inspection protocols verify that material thickness, coating weight, surface quality, and mechanical properties conform to specifications before materials enter production. This rigorous quality control prevents defective materials from reaching customers and ensures that finished panels deliver the performance characteristics promised in product literature and project specifications.

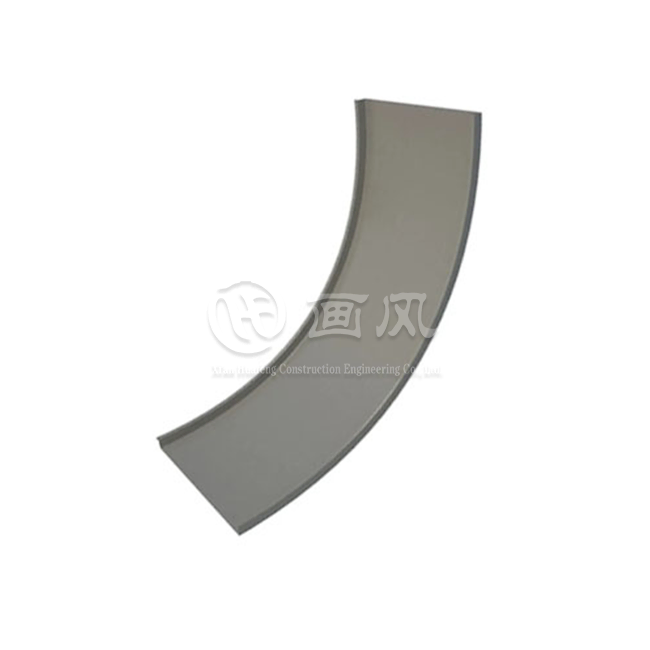

Advanced Production Capabilities and Customization Services

Modern corrugated panel manufacturing facilities employ sophisticated roll-forming technology that precisely shapes flat coil stock into corrugated profiles with consistent dimensions throughout production runs. Computer-controlled equipment maintains exact spacing between corrugations, uniform wave height, and proper panel width regardless of production volume, eliminating the dimensional variations that complicated installation and compromised weather-tightness in earlier manufacturing eras. Automated cutting systems produce panels to exact lengths specified in project drawings, minimizing field cutting requirements and reducing waste during installation. Some manufacturers offer micro-perforated panel options for acoustic control applications, stone-coating application for enhanced texture, and embossed patterns that simulate traditional materials while retaining metal's durability advantages. Customization services extend beyond panel dimensions to encompass color matching, special coating formulations, and unique corrugation profiles developed for specific architectural visions or performance requirements. Manufacturers with in-house design departments can assist with technical drawings, structural calculations, and installation details that ensure proper integration of corrugated panels within complex building envelope assemblies. Sample production capabilities allow designers and building owners to evaluate actual materials before committing to full-scale orders, verifying that color, finish, and profile match project expectations. Efficient production scheduling and logistics coordination ensure that materials arrive on site when needed, avoiding storage costs and reducing exposure to damage during extended on-site periods.

Installation Excellence and Technical Support

Proper installation remains critical to realizing the full performance potential of Corrugated Sheet Metal Wall Panels, as even premium materials will underperform if incorrectly applied. Manufacturers committed to customer success provide comprehensive installation guidance through detailed technical manuals, instructional videos, and direct technical support from experienced field representatives. These resources address common installation challenges including proper fastener selection and placement, sealant application at terminations and penetrations, thermal expansion accommodation, and integration with adjacent building components. Understanding these installation principles helps contractors avoid the water infiltration, fastener failure, and premature panel deterioration that result from improper techniques. Professional installation services offered by experienced contractors or manufacturer-trained teams ensure that complex projects receive the expertise necessary for successful outcomes. These specialists understand the nuances of working with metal panels in varying weather conditions, recognize when substrate preparation requires attention before panel application, and possess the specialized tools that facilitate efficient, high-quality installation. Their experience identifying and resolving field conditions that deviate from idealized drawing conditions prevents costly rework and schedule delays. For projects requiring demonstration of specific performance characteristics such as AAMA testing standards or code compliance documentation, experienced installers provide the quality assurance necessary to meet those requirements.

The sequential approach to installation begins with thorough substrate inspection to verify that structural framing meets flatness and alignment tolerances necessary for proper panel support. Installers confirm that vapor barriers, weather-resistive barriers, and insulation systems are correctly positioned before panel application begins, preventing moisture management problems that could compromise building performance. Panel installation proceeds systematically from one building corner or edge, maintaining proper overlap at horizontal seams and ensuring that fasteners penetrate structural members at specified intervals. Critical details including outside corners, inside corners, window and door perimeters, and roof-to-wall transitions receive special attention to maintain weathertightness while accommodating differential movement between materials. Final inspection verifies that all fasteners are properly seated, all sealant joints are complete, and all panel terminations are correctly flashed and sealed.

Conclusion

Corrugated Sheet Metal Wall Panels deliver an unmatched combination of structural performance, economic value, design flexibility, and environmental durability that makes them the intelligent choice for diverse construction applications. Their superior strength-to-weight ratio, weather resistance, low maintenance requirements, and extended service life create long-term value that far exceeds their competitive initial cost, while modern manufacturing capabilities ensure consistent quality and customization options that meet specific project needs.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

As a China Corrugated Sheet Metal Wall Panels factory, China Corrugated Sheet Metal Wall Panels supplier, and China Corrugated Sheet Metal Wall Panels manufacturer, Xi'an Huafeng Construction Engineering Co., Ltd. stands ready to support your building projects with High Quality Corrugated Sheet Metal Wall Panels at competitive Corrugated Sheet Metal Wall Panels price points, with Corrugated Sheet Metal Wall Panels for sale including China Corrugated Sheet Metal Wall Panels wholesale options for large-scale developments.

Established in Shaanxi Province in 2018 and recognized as a high-tech enterprise with first-level curtain wall qualifications and third-level steel structure qualifications, we operate comprehensive manufacturing facilities including a 200,000 square meter raw material production plant in Anhui and processing facilities in Hangzhou and Xi'an. Our seven color coating production lines, automated punching systems, and more than forty specialized machines produce panels meeting ASTM, DIN, JIS, BS, and GB/T standards, backed by ISO9001, ISO14000:14001, and SGS certifications plus over twenty registered patents.

We provide complete one-stop solutions from custom engineering design and structural analysis through precision manufacturing with real-time quality control to seamless on-site installation and long-term maintenance support. Our 30-year warranty, customizable specifications including widths from 600-1200mm and thicknesses from 0.3-1.2mm with HDP and PVDF coating options, 15-20 day delivery times, and flexible 500 square meter minimum order quantities demonstrate our commitment to customer success. Major projects including Xiongan Station, Xi'an International Convention and Exhibition Center, and Inner Mongolia Tongliao Art Museum showcase our expertise across industrial, commercial, and institutional applications. Contact huafeng@hfmetalroof.com today to discuss how our expertise in metal roofing systems, wall systems, and building envelope solutions can add value to your next project. Save this article for reference whenever you need trusted guidance on corrugated metal wall panel solutions.

References

1. Metal Construction Association, "Design Guide for Metal Wall Panels," authored by Metal Panel Technical Committee, 2022 Edition.

2. American Iron and Steel Institute, "Cold-Formed Steel Design Manual," authored by Roger LaBoube and Wei-Wen Yu, Fifth Edition.

3 .National Roofing Contractors Association, "The NRCA Roofing Manual: Metal Panel and SPF Roof Systems," authored by NRCA Technical Operations Department, 2023 Edition.

4. ASTM International, "Standard Specification for Steel Sheet, Zinc-Coated (Galvanized) or Zinc-Iron Alloy-Coated (Galvannealed) by the Hot-Dip Process," ASTM A653/A653M, authored by ASTM Committee A05.

5. Building and Construction Authority, "Design Guide for Buildable & Productive Facades," authored by BCA Construction Productivity and Capability Group, Singapore, 2019.