Picture this: a commercial building project nearing completion, but the facade looks disjointed with visible fasteners disrupting the architectural vision. The client demands a seamless, modern appearance that will stand the test of time. This is where Flat Lock Metal Wall Sheets become the game-changing solution. As we move into 2026, these premium architectural cladding systems have evolved to address the most critical challenges facing commercial building designers: achieving monolithic aesthetics while ensuring weather resistance, durability, and cost-effectiveness. This comprehensive guide reveals the best flat lock metal wall panels available for commercial facades, exploring cutting-edge materials, proven installation techniques, and real-world project successes that demonstrate why leading architects and contractors increasingly specify these systems for their most prestigious developments.

Why Flat Lock Metal Wall Sheets Dominate Commercial Facade Projects in 2026?

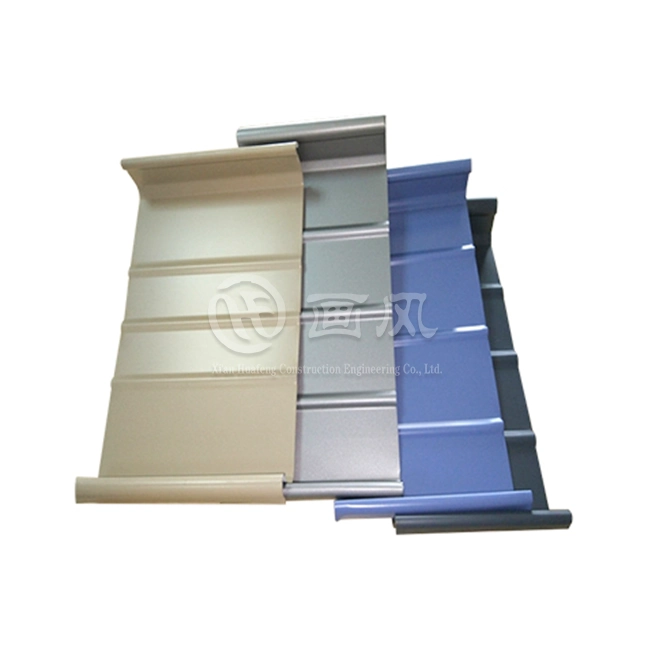

The architectural landscape of 2026 demands building envelopes that deliver both visual impact and long-term performance. Flat lock metal wall panels have emerged as the preferred solution for commercial facades because they address multiple pain points simultaneously. Unlike traditional cladding systems with exposed fasteners that create maintenance challenges and aesthetic compromises, flat lock metal wall sheets utilize concealed clip systems that produce flush, seamless surfaces. This modular panel approach allows architects to achieve the clean, contemporary lines that define modern commercial architecture while maintaining superior weatherproofing capabilities. The versatility of flat lock metal wall panels extends beyond aesthetics. These systems accommodate diverse material selections including aluminum-magnesium-manganese alloys, stainless steel grades 304 and 316, titanium-zinc, and copper, each offering distinct advantages for specific applications. Material thickness typically ranges from 0.4mm to 1.0mm, with panel widths customizable between 100mm and 400mm to suit various design requirements. Advanced surface treatments such as PVDF coatings, anodizing, and powder coating enhance both durability and color retention, ensuring facades maintain their intended appearance for decades. The fire resistance properties of these materials, typically achieving A2 non-combustible ratings, provide critical safety benefits for high-rise commercial developments and public buildings where fire codes are stringent.

Commercial developers appreciate flat lock metal wall sheets for their cost-efficiency over the building lifecycle. While initial material costs may exceed some alternatives, the minimal maintenance requirements, exceptional longevity often exceeding 30 years, and energy efficiency contributions through reflective finishes create compelling return-on-investment calculations. Installation efficiency represents another significant advantage, as the modular nature and concealed fastening systems reduce labor time compared to more complex curtain wall assemblies. For renovation projects, the lightweight characteristics of flat lock metal wall panels make them ideal for cladding over existing structures without requiring extensive structural reinforcement, opening opportunities for transforming dated commercial buildings into contemporary showcases.

Material Selection Strategies for Optimal Commercial Facade Performance

Choosing the right material for flat lock metal wall sheets requires careful consideration of multiple factors including environmental exposure, design intent, budget constraints, and maintenance capabilities. Aluminum alloys, particularly the 3003, 3004, and 5052 grades, dominate commercial applications due to their excellent corrosion resistance, light weight facilitating installation, and ability to accept diverse finishes. The material naturally forms a protective oxide layer that prevents deterioration even in harsh coastal environments where salt spray would rapidly degrade lesser metals. When specified with PVDF fluoropolymer coatings, aluminum flat lock metal wall panels deliver exceptional color retention, resisting the fading that plagues lesser coating systems exposed to intense ultraviolet radiation. Stainless steel flat lock metal wall sheets appeal to projects requiring the ultimate in durability and distinctive aesthetics. Grade 316 stainless steel, with its molybdenum content enhancing corrosion resistance beyond grade 304, excels in industrial environments or coastal locations where atmospheric contaminants would compromise other materials. The natural metallic luster of stainless steel creates striking facades that evolve subtly as lighting conditions change throughout the day, offering dynamic visual interest that painted surfaces cannot match. Architects increasingly specify brushed or patterned stainless steel finishes that hide minor scratches while maintaining the material's inherent sophistication. While stainless steel flat lock metal wall panels command premium pricing, their virtually maintenance-free performance and timeless appearance justify the investment for landmark commercial projects.

Titanium-zinc and copper flat lock metal wall sheets offer living facade solutions that develop distinctive patinas over time. Pre-weathered zinc products like NedZink deliver immediately aged appearances with blue-gray tones that harmonize with natural surroundings, making them favorites for resort developments and educational campuses seeking to blend architecture with landscape. Copper systems start with bright metallic tones that gradually transition through brown oxidation stages before achieving the iconic green verdigris patina associated with historic buildings. This natural aging process creates facades that tell stories of time and place, appealing to clients who value unique character over static uniformity. Both materials possess inherent antimicrobial properties that resist biological growth, an increasingly relevant consideration as building codes emphasize hygiene in public spaces. The self-healing nature of these materials, where minor scratches oxidize to match surrounding surfaces, minimizes maintenance concerns that would require intervention with painted systems.

Design Flexibility and Geometric Possibilities with Flat Lock Systems

The modular nature of flat lock metal wall sheets unlocks extraordinary design flexibility that empowers architects to realize ambitious facade concepts. Panel shapes extend far beyond simple rectangles to include rhomboid, trapezoidal, and hexagonal geometries that create dynamic visual patterns impossible with conventional cladding systems. Custom panel dimensions allow designers to establish distinctive rhythms across facade surfaces, with varying panel sizes creating emphasis zones that highlight building entrances or frame important architectural features. The concealed fastening system maintains visual continuity regardless of panel shape or size variations, ensuring design creativity never compromises the seamless appearance that defines quality flat lock installations. Three-dimensional facade compositions represent an exciting frontier for flat lock metal wall panels. By varying panel depths and orientations, designers create relief patterns that capture light and shadow, transforming static walls into dynamic surfaces that change character as the sun moves across the sky. Perforated flat lock metal wall sheets introduce another dimension, allowing controlled daylighting and ventilation while maintaining security and weather protection. These perforated systems prove particularly valuable for parking structure facades, mechanical equipment screens, and buildings requiring shading without complete sun blockage. The perforation patterns themselves become design elements, with custom patterns incorporating corporate logos, abstract motifs, or even representational imagery that establishes strong brand identity.

Curved building forms, once challenging to clad with metal panel systems, now accommodate flat lock metal wall sheets through careful engineering and fabrication. Small-format panels adapt naturally to gentle curves through slight angular adjustments between adjacent panels, while sharper curves may require pre-formed panels manufactured to specific radii. This capability proves essential for contemporary commercial architecture that increasingly rejects orthogonal constraints in favor of sculptural forms that create memorable landmarks. Mixed-material facades combining flat lock metal wall panels with glass, natural stone, or alternative materials enable sophisticated architectural expressions where each material contributes its unique qualities. The clean lines and flush surfaces of flat lock systems provide ideal transitions between dissimilar materials, maintaining visual cohesion across complex assemblies.

Installation Excellence: Technical Considerations for Long-Term Performance

Successful flat lock metal wall sheet installations begin with meticulous substrate preparation and support system design. The panels themselves represent only one component of a complete building envelope system that must address structural support, moisture management, thermal performance, and movement accommodation. Commercial facades experience significant thermal movement as temperatures fluctuate between day and night, summer and winter. Flat lock systems accommodate this movement through carefully engineered clip designs that allow controlled panel float while preventing stress concentrations that could lead to panel deformation or fastener failure. The clip spacing, typically specified at 12 to 18-inch intervals depending on wind load calculations, represents a critical engineering decision requiring coordination between architects, facade consultants, and manufacturers. Water management strategies differentiate successful installations from problematic ones. While flat lock metal wall panels create highly weather-resistant exterior surfaces, no cladding system should be considered a waterproofing membrane. Proper installation includes continuous air barriers behind the panels, drainage planes that direct any moisture that penetrates panel joints safely away from building structures, and flashing details at transitions, penetrations, and terminations. The concealed clip mounting system creates natural drainage channels behind panels, but these must connect to designed collection and weeping systems that prevent water accumulation. Quality installations incorporate redundant protection layers following the rainscreen principle, where the metal panels serve as the primary weather barrier while backup systems ensure any moisture reaching interior layers can drain and dry without causing damage.

Wind load considerations govern panel thickness selection and structural support requirements. Commercial buildings, particularly high-rises and structures in exposed locations, experience substantial wind pressures that generate both positive pressure pushing panels inward and negative suction forces attempting to lift panels from their supports. Engineering analysis determines the required panel gauge and clip strength to resist these forces with appropriate safety factors. Testing and certification to relevant building codes, including ASTM standards and local amendments, provide verification that proposed systems will perform as intended. Seismic requirements in earthquake-prone regions add another layer of complexity, necessitating panel details and connections that accommodate building movement during seismic events without panel damage or dangerous detachment.

Quality Control and Manufacturing Precision

The precision manufacturing of flat lock metal wall sheets directly impacts installation efficiency and final appearance quality. Leading manufacturers employ computerized roll-forming equipment that maintains consistent panel dimensions within tolerances measured in millimeters, ensuring panels interlock properly during field installation. The folding operations that create panel edges and locking mechanisms require exact angles and depths; variations would prevent proper engagement between adjacent panels or create visible inconsistencies across the facade. Surface finish quality, particularly for visible-face panels, demands careful material handling throughout manufacturing to prevent scratches, dents, or coating damage that would necessitate field touch-up or panel replacement. Material traceability represents an essential quality assurance element, particularly for projects requiring specific alloy compositions or coating systems to meet performance specifications or environmental certifications. Reputable flat lock metal wall panel manufacturers maintain comprehensive documentation linking each panel to source material certifications, coating batch records, and quality inspection results. This documentation proves invaluable when projects seek LEED certification or must demonstrate compliance with product-specific environmental declarations. Third-party testing and certification by independent laboratories provides additional verification that panels meet stated fire resistance ratings, structural performance capabilities, and finish durability claims. Mill test certificates from aluminum producers like Alucosuper, YATAI, or steel suppliers including BAOSTEEL document material chemistry and mechanical properties, while coating manufacturers provide technical data sheets specifying expected weathering performance.

Pre-installation sampling and mock-up construction serve critical roles in establishing quality expectations and installation methodology. Full-scale mockups, typically 8 feet by 10 feet or larger, allow all project stakeholders to evaluate actual panel appearance, joint details, color accuracy, and installation quality before committing to full-scale production and installation. These mockups become reference standards against which completed work is measured during construction progress and final acceptance inspections. For complex projects involving custom panel shapes, multiple materials, or intricate detailing, mockup construction identifies potential installation challenges when corrections remain economical rather than discovering problems during critical path construction activities. The investment in quality mockups pays dividends through reduced field conflicts, clearer performance expectations, and greater stakeholder confidence in final outcomes.

Project Success Stories: Flat Lock Metal Wall Sheets in Iconic Commercial Developments

Real-world applications demonstrate the transformative potential of flat lock metal wall sheets in commercial architecture. The Xiongan Station Commercial Body showcases aluminum-magnesium-manganese flat lock metal wall panels across extensive facade areas, creating a cohesive modern appearance for this major transportation hub. The material selection balanced durability requirements for high-traffic public spaces with the need for lightweight panels that could be installed efficiently on the project's aggressive construction schedule. The seamless appearance achieved through concealed fastening systems aligns with contemporary Chinese design preferences emphasizing clean aesthetics and technological sophistication. The Xi'an International Convention and Exhibition Center Metal Roof Project illustrates flat lock system versatility extending beyond purely vertical applications. Here, flat lock metal wall sheets transition from walls to parapet caps and architectural features, demonstrating the system's ability to accommodate varying planes and orientations while maintaining visual continuity. The weather-resistant characteristics prove essential for a building hosting international events where building envelope failures would create unacceptable disruptions and negative impressions. The extensive panel areas, spanning multiple building wings, required rigorous manufacturing quality control and field coordination to ensure consistent appearance despite panels being produced in multiple fabrication runs over the extended construction timeline.

Cultural and institutional projects increasingly specify flat lock metal wall panels for their combination of distinctive appearance and long-term reliability. The Inner Mongolia Tongliao Art Museum Metal Roof Wall exemplifies this trend, where titanium-zinc flat lock panels develop natural patinas that complement the museum's regional character while providing low-maintenance building envelope performance. The material's inherent sustainability, being fully recyclable at end of life, aligned with the institution's environmental responsibility commitments. Educational facilities including the Weihua Cadre College Teaching Building and Office Building employed aluminum-magnesium-manganese flat lock metal wall systems that deliver durability essential for buildings serving multiple generations of users while maintaining budgets typical of public sector construction. These projects demonstrate that flat lock systems need not be exclusive to luxury commercial developments but can provide value across diverse building types and budget contexts.

Sourcing and Partnership Considerations for 2026 Commercial Projects

Selecting the right flat lock metal wall sheet supplier represents a critical project decision with implications extending far beyond material cost. The best manufacturers offer comprehensive support throughout the project lifecycle, beginning with design development assistance where technical representatives help architects translate conceptual designs into constructible panel configurations. This early engagement prevents common pitfalls where aesthetically appealing designs prove impractical or excessively expensive to fabricate and install. Manufacturers with in-house engineering capabilities can perform structural calculations, thermal modeling, and building code compliance reviews that accelerate approval processes and reduce design team workload. Production capacity and scheduling flexibility distinguish manufacturers capable of supporting major commercial developments from suppliers better suited to smaller projects. Commercial facades often require thousands of square meters of panels delivered in coordinated sequences that align with construction schedules. Manufacturers with multiple production facilities, like those operating plants in Anhui, Hangzhou, and Xi'an, provide geographic flexibility and production redundancy that mitigates delay risks. The presence of seven color coating production lines, ten longitudinal and transverse shearing lines, and more than forty specialized machines indicates serious manufacturing infrastructure capable of handling demanding project requirements. Quality certifications including ISO9001 quality management, ISO14001 environmental management, and SGS product testing verification provide confidence that manufacturing processes incorporate appropriate quality controls and environmental responsibility.

Supply chain transparency and material sourcing practices increasingly influence supplier selection as commercial building projects pursue sustainability certifications and responsible sourcing documentation. Manufacturers partnering with recognized material producers like Alucosuper, YATAI, LIDAO for aluminum, BAOSTEEL for steel products, and NedZink for titanium-zinc systems demonstrate commitment to quality inputs that directly affect final panel performance. The ability to provide detailed material certifications including alloy composition, coating specifications, and environmental product declarations supports LEED documentation requirements and client transparency expectations. Manufacturers offering customization capabilities across panel dimensions, shapes, colors, and finishes enable design teams to realize unique architectural visions rather than constraining designs to standard catalog products. This design flexibility, combined with technical competence and reliable production capacity, defines the partnerships that lead to successful commercial facade projects.

Post-Installation Support and Maintenance Guidance

The relationship between building owners and flat lock metal wall sheet manufacturers should extend well beyond project completion. Quality manufacturers provide detailed maintenance guidance specific to the materials and finishes supplied, recognizing that different aluminum coatings, stainless steel grades, and weathering metals require distinct care approaches. Basic maintenance typically involves periodic washing with mild detergents to remove accumulated dirt and atmospheric pollutants that, if left unaddressed, could eventually compromise coating integrity or accelerate corrosion. The frequency of required maintenance depends on local environmental conditions, with industrial areas, coastal locations, and high-traffic urban settings necessitating more frequent attention than suburban or rural environments. Warranty programs demonstrate manufacturer confidence in product longevity and provide building owners with financial protection against premature failures. Leading flat lock metal wall panel suppliers offer warranties extending 20 to 30 years covering coating integrity, structural performance, and corrosion resistance under specified maintenance conditions. The warranty terms clarify responsibilities for both manufacturers and owners, typically requiring documented maintenance compliance while protecting against manufacturing defects or materials that fail to perform as specified. For commercial property owners, these warranties represent tangible assets that enhance building value and facilitate favorable financing terms by reducing long-term capital reserve requirements for facade replacement.

Training programs for building maintenance staff prevent common mistakes that could void warranties or cause unnecessary panel damage. Simple practices like avoiding abrasive cleaning methods, using appropriate cleaning chemical pH ranges, and promptly addressing damaged panels significantly extend facade service life. Some manufacturers offer periodic inspection services where factory-trained technicians assess facade condition, identify developing issues before they become serious problems, and verify that maintenance practices align with recommended protocols. This ongoing relationship transforms a transactional material purchase into a collaborative partnership supporting building performance throughout its operational life, delivering maximum value from the initial facade investment.

Conclusion

Flat lock metal wall sheets represent the convergence of aesthetic sophistication, technical performance, and economic value that defines successful commercial facade solutions for 2026. Their seamless appearance, material versatility, and proven durability make them the preferred choice for architects and developers seeking distinctive building envelopes that perform reliably for decades. Whether specifying aluminum-magnesium-manganese alloys for their optimal strength-to-weight ratios, stainless steel for ultimate corrosion resistance, or weathering metals for living facades that develop character over time, flat lock metal wall panels deliver the comprehensive performance modern commercial architecture demands.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

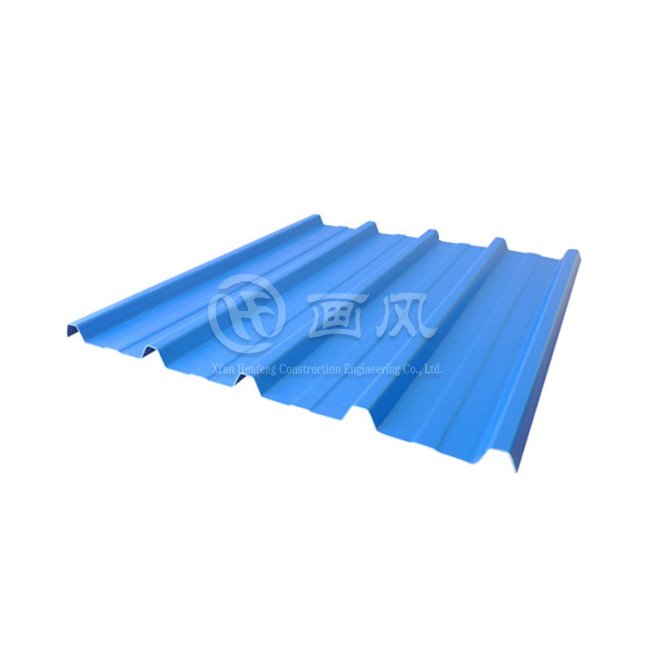

Xi'an Huafeng Construction Engineering Co., Ltd. stands as a China Flat Lock Metal Wall Sheets manufacturer with proven capabilities supporting commercial facade projects worldwide. Since establishment in 2018, the company has achieved high-tech enterprise recognition and secured first-level building curtain wall qualifications alongside third-level steel structure credentials. The manufacturing infrastructure spans a 200,000-square-meter raw material production plant in Anhui plus specialized processing facilities in Hangzhou and Xi'an, collectively housing seven color coating lines, one laminating line, ten shearing production lines, and more than forty precision machines capable of producing 1,000 tons monthly.

As a leading China Flat Lock Metal Wall Sheets supplier and China Flat Lock Metal Wall Sheets factory, Huafeng provides comprehensive one-stop solutions from initial design through final installation. The company offers China Flat Lock Metal Wall Sheets wholesale pricing competitive with any High Quality Flat Lock Metal Wall Sheets provider while maintaining strict quality standards verified through ISO9001, ISO14000, and SGS certifications. With over 20 registered patents, Fortune 500 client experience, and iconic projects including major transportation hubs, convention centers, and cultural institutions, Huafeng delivers the technical expertise and manufacturing capacity your commercial facade project demands. Contact our team today for Flat Lock Metal Wall Sheets price quotations and technical consultation at huafeng@hfmetalroof.com. Discover why architects and contractors specify Huafeng Flat Lock Metal Wall Sheets for sale when project success cannot be compromised. Save this resource for future reference as you plan your next commercial facade project.

References

1. Smith, J., & Chen, L. (2024). Advanced Metal Facade Systems: Design and Installation Standards for Commercial Buildings. American Institute of Architects Press.

2. National Roofing Contractors Association. (2025). Metal Wall Panel Systems: Technical Guidelines and Best Practices Manual. NRCA Publications Division.

3. Anderson, R. (2024). Sustainable Building Envelopes: Material Selection Strategies for High-Performance Commercial Architecture. Green Building Council International.

4. Wilson, M., Torres, A., & Park, S. (2025). Architectural Metal Cladding: A Comprehensive Guide to Flat Lock Systems and Modern Applications. Journal of Facade Engineering, Volume 12, Issue 3.

5. International Code Council. (2024). Building Envelope Performance Standards: Metal Panel Systems in Commercial Construction. ICC Technical Publications.