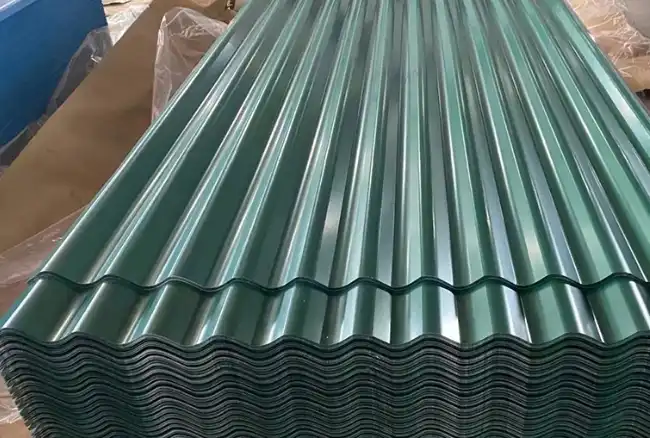

Picture this: you've invested in corrugated side panels for your industrial facility, only to watch the color fade within just a few years, leaving your building looking weathered and unprofessional. The culprit? Choosing the wrong finish. Selecting the right coating system for corrugated side panels isn't just about aesthetics—it directly impacts durability, maintenance costs, and your building's lifespan. This comprehensive guide reveals the top finishes available for corrugated side panels and helps you make an informed decision that balances performance, longevity, and budget considerations.

Understanding Finish Options for Corrugated Side Panels

When specifying corrugated side panels for your next project, the finish you choose determines far more than just the initial appearance. The coating system serves as the primary defense against environmental degradation, ultraviolet radiation, chemical exposure, and mechanical wear. Modern corrugated side panels are available with multiple finish options, each engineered to meet specific performance criteria and environmental conditions. The metal substrate itself provides structural integrity, but without proper surface treatment and coating, even the highest-grade galvanized steel or aluminum will deteriorate prematurely. Understanding the relationship between base metal preparation, primer systems, and topcoat technologies is essential for achieving optimal performance. Industrial and commercial projects demand finishes that can withstand decades of exposure while maintaining both protective qualities and visual appeal.

Base Metal Preparation and Its Impact on Finish Performance

Before any coating is applied to corrugated side panels, proper surface preparation is absolutely critical. The base metal must be thoroughly cleaned and treated to ensure maximum adhesion of subsequent coating layers. For steel panels, this typically involves chemical cleaning to remove oils, followed by conversion coating treatments that create a microscopic surface profile ideal for paint adhesion. Aluminum panels require different preparation protocols due to the metal's naturally occurring oxide layer. Quality manufacturers implement multi-stage cleaning and pretreatment processes that include alkaline cleaning, rinsing, chromate or non-chromate conversion coating, and final rinsing before any paint is applied. These preparation steps, though invisible in the final product, fundamentally determine how well the finish will adhere and perform over the panel's service life. Inadequate surface preparation is the leading cause of premature coating failure, manifesting as peeling, blistering, or loss of adhesion.

Premium Coating Systems: PVDF and HDP Performance

The two dominant premium coating systems for corrugated side panels are PVDF (Polyvinylidene Fluoride) and HDP (High Durability Polyester). These advanced formulations represent the pinnacle of coating technology, offering superior weather resistance, color retention, and longevity compared to standard polyester or acrylic systems. PVDF coatings, often marketed under trade names like Kynar 500, contain a minimum of 70% PVDF resin in their formulation. This fluoropolymer-based system provides exceptional resistance to ultraviolet degradation, chalking, and color fade. Buildings clad with PVDF-coated corrugated side panels regularly maintain their appearance for 30 years or more in harsh environments. The chemical structure of PVDF creates a surface that resists dirt accumulation and is easily cleaned by natural rainfall, reducing maintenance requirements significantly. HDP coatings incorporate advanced UV absorbers and hindered amine light stabilizers (HALS) that actively protect the coating from photodegradation. While HDP systems may experience slightly more color fade than PVDF over extended periods, they offer excellent value with service lives exceeding 15-20 years in most environments. For many commercial and industrial applications where budget considerations are significant, HDP-coated corrugated side panels provide an optimal balance of performance and cost-effectiveness.

Color Retention and Weathering Performance

Color stability over time depends on multiple factors including pigment selection, resin chemistry, and coating thickness. Dark colors absorb more solar radiation and consequently experience greater thermal stress than lighter shades. Premium finishes utilize high-performance pigments specifically engineered for outdoor exposure, with inorganic pigments generally offering superior lightfastness compared to organic alternatives. Manufacturers typically subject corrugated side panels to accelerated weathering testing using QUV or xenon arc chambers that simulate years of outdoor exposure in compressed timeframes. Test results guide warranty offerings, with PVDF systems commonly backed by 30-year finish warranties and HDP systems warranted for 20-25 years. Understanding these performance metrics helps specifiers match coating systems to project requirements and expected service conditions.

SMP Coating: The Mid-Range Solution

Silicone Modified Polyester (SMP) coatings occupy the middle ground between standard polyester and premium PVDF systems. SMP formulations incorporate silicone resins that enhance gloss retention and resistance to chalking compared to unmodified polyester. For projects with moderate exposure conditions or shorter anticipated service lives, SMP-coated corrugated side panels deliver respectable performance at lower initial cost. The silicone component in SMP coatings improves flexibility and impact resistance, reducing the likelihood of coating damage during handling, installation, and service. While SMP will show more visible fading and chalking than PVDF or HDP over time, proper color selection—particularly lighter neutral tones—can minimize these effects. Many agricultural and light industrial applications find SMP coatings perfectly adequate for their needs, offering 10-15 years of acceptable appearance and protection.

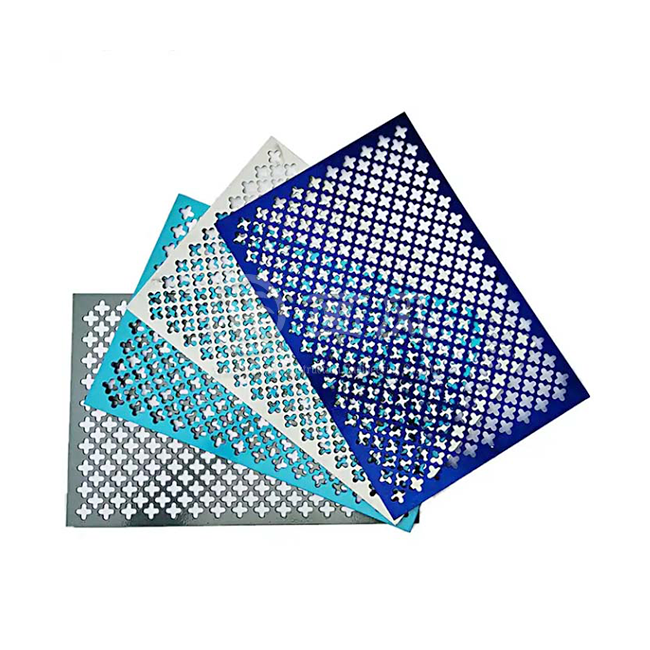

Specialty Finishes and Aesthetic Enhancements for Corrugated Side Panels

Beyond standard solid colors, contemporary corrugated side panels are available with numerous specialty finishes that expand design possibilities. These advanced surface treatments allow architects and builders to achieve specific aesthetic goals while maintaining the practical benefits of metal construction. Metallic and pearlescent finishes incorporate special effect pigments that create depth and visual interest, catching and reflecting light in distinctive ways. These finishes are particularly popular for commercial and retail applications where building appearance directly impacts brand perception. Wood grain printed finishes convincingly replicate the appearance of natural timber while delivering all the durability, fire resistance, and low maintenance characteristics of metal cladding.

Matte and Textured Finish Options

The surface sheen of corrugated side panels significantly influences their visual character and practical performance. High-gloss finishes maximize color vibrancy and create dramatic reflections, but they also show dirt, fingerprints, and minor imperfections more readily. Matte and low-gloss finishes have gained considerable popularity in contemporary architecture for their sophisticated, understated appearance. Matte PVDF and HDP coatings absorb rather than reflect light, creating a soft, uniform appearance that complements modern design aesthetics. These finishes hide minor surface imperfections and weather more gracefully than glossy alternatives, as slight chalking or fading is less visually apparent. Textured finishes, including embossed patterns and stucco effects, add tactile dimension to corrugated side panels while providing additional concealment of oil-canning and other surface irregularities.

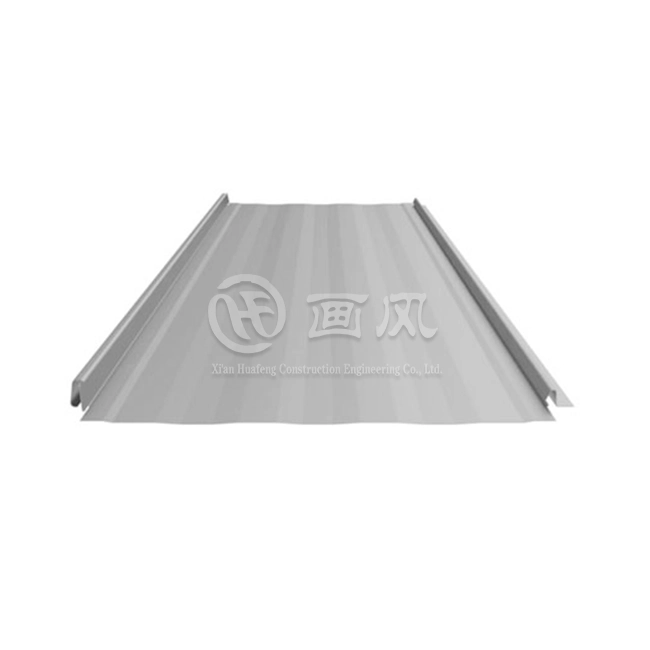

Metallic Coatings: Galvanized, Galvalume, and Bare Metal

For applications where painted finishes are unnecessary or undesired, metallic coatings provide robust protection with minimal processing. Galvanized corrugated side panels feature a zinc coating that sacrificially protects the underlying steel from corrosion. The characteristic spangled appearance of hot-dip galvanizing appeals to industrial and agricultural aesthetics while delivering decades of reliable performance. Galvalume, a 55% aluminum-zinc alloy coating, offers enhanced corrosion resistance compared to pure zinc, particularly in marine and industrial environments. The coating's aluminum component provides barrier protection while the zinc offers galvanic protection, creating a synergistic system that can last 50 years or more in moderate exposure conditions. Galvalume corrugated side panels can be left unpainted or used as an excellent substrate for paint systems, with the metallic coating providing additional protection if the paint is scratched or damaged.

Customization and Color Selection Strategy

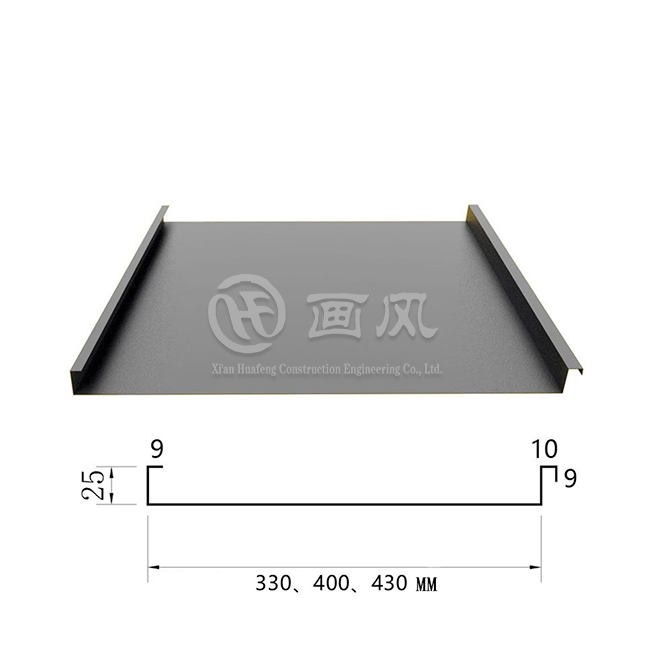

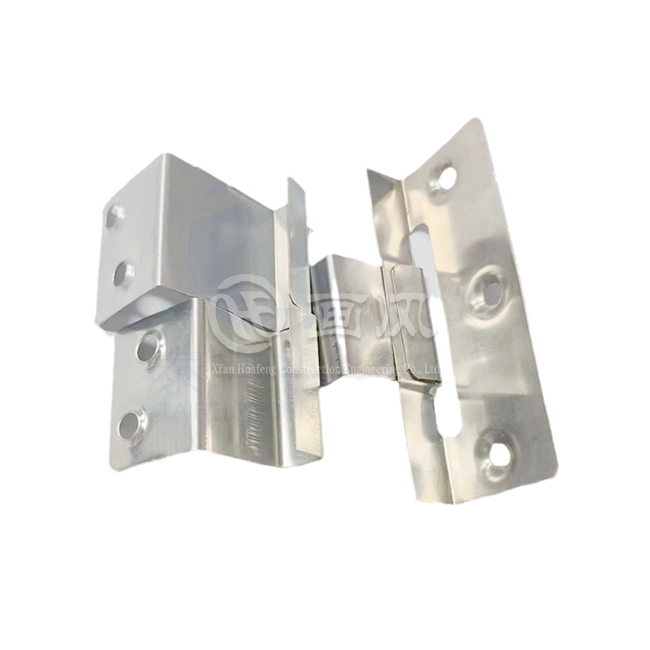

With hundreds of standard colors available and virtually unlimited custom color capabilities, selecting the optimal finish for corrugated side panels requires strategic thinking. Color choice impacts not only aesthetic considerations but also thermal performance, maintenance requirements, and long-term appearance retention. Lighter colors reflect solar radiation more effectively than dark shades, reducing thermal load on the building and potentially lowering cooling costs. This consideration is particularly relevant for roof applications and wall panels with significant sun exposure. However, very light colors may show dirt and discoloration more readily in environments with significant airborne particulates. Dark colors provide dramatic visual impact and hide dirt effectively, but they experience greater thermal cycling and may show fading more noticeably over time. Xi'an Huafeng Construction Engineering Co., Ltd. offers corrugated side panels in widths from 600-1200mm and thicknesses from 0.3-1.2mm, with both HDP and PVDF coating options available. This flexibility allows precise matching to project specifications and performance requirements. The company provides customization services for color, pattern, and design, ensuring corrugated side panels integrate seamlessly with overall architectural vision while meeting technical performance criteria.

Regional and Environmental Considerations

Geographic location and specific site conditions should inform finish selection for corrugated side panels. Coastal environments with salt spray require premium corrosion-resistant systems, typically PVDF coatings over Galvalume substrates. Industrial areas with chemical exposure benefit from the superior chemical resistance of fluoropolymer coatings. Agricultural applications in rural settings may perform adequately with SMP or even high-quality metallic coatings without paint. Climate also influences finish selection. Regions with intense ultraviolet radiation accelerate coating degradation, making premium UV-resistant systems more cost-effective over the building's lifetime. Areas with significant temperature fluctuations benefit from coatings with excellent flexibility to accommodate thermal expansion and contraction without cracking. Manufacturers like Xi'an Huafeng, with certifications including ISO9001, ISO14001, and SGS compliance, ensure corrugated side panels meet international quality standards for diverse environmental conditions.

Manufacturing Quality and Application Standards

The best coating formulation delivers poor results if improperly applied. Professional manufacturers utilize continuous coil coating lines that apply primer and topcoat under precisely controlled conditions. These automated systems ensure uniform coating thickness, proper cure, and consistent quality that cannot be achieved with field-applied paints. Coil coating processes typically involve unwinding metal coil, cleaning and pretreating the surface, applying primer, curing in high-temperature ovens, applying topcoat, final curing, and rewinding. This continuous process produces corrugated side panels with coating coverage that extends into panel edges and corrugations uniformly. Film thickness is monitored continuously, typically ranging from 0.7-1.0 mils for primer and 0.8-1.2 mils for topcoat in premium systems. Xi'an Huafeng operates three factories with seven color coating production lines and over 40 specialized machines, enabling consistent production of high-quality corrugated side panels. With a supply capacity of 1000 tons per month and delivery times of 15-20 days, the company efficiently serves projects of all scales. Quality control includes rigorous incoming material inspection, in-process monitoring, and finished product testing for appearance, dimensions, flatness, and coating performance.

Installation and Long-Term Maintenance

Even the highest-quality finish requires proper installation to achieve expected performance. Corrugated side panels must be handled carefully to avoid scratching or damaging the coating. Protective films should remain in place until installation is complete, then be removed promptly to prevent adhesive residue. Fasteners should be installed with appropriate torque—overtightening can damage coating at fastener points while undertightening allows water infiltration. Regular maintenance extends the service life of all coating systems. Periodic cleaning with mild detergent and water removes accumulated dirt and prevents buildup of corrosive contaminants. Annual inspections identify potential issues before they become significant problems. Touch-up paint should be available and applied promptly to any scratches or damaged areas to maintain continuous protection. With proper care, premium-finished corrugated side panels from manufacturers meeting ASTM, DIN, JIS, BS, and GB/T standards deliver decades of reliable performance.

Conclusion

Selecting the appropriate finish for corrugated side panels fundamentally determines project success. PVDF coatings deliver maximum longevity and color retention for premium applications, while HDP and SMP systems provide excellent value for diverse project requirements. Understanding the relationship between coating chemistry, environmental exposure, and performance expectations enables informed specification decisions that balance initial investment against lifecycle costs.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

Xi'an Huafeng Construction Engineering Co., Ltd., established in Shaanxi Province in 2018, specializes in comprehensive metal roofing and wall system solutions. As a recognized high-tech enterprise with first-level building curtain wall qualifications and third-level steel structure qualifications, Huafeng integrates green sustainable development throughout operations. Our 200,000 square meter raw material production facility in Anhui, combined with processing plants in Hangzhou and Xi'an, enables full-spectrum manufacturing from raw materials to finished products.

With over 20 registered patents, ISO9001, ISO14001, and SGS certifications, Xi'an Huafeng delivers quality assurance backed by rigorous testing protocols including salt spray, adhesion, hardness, impact, and weather resistance evaluation. Our engineering design experience and construction expertise create one-stop solutions from concept through installation for projects including Xiongan Station Commercial Body, Xi'an International Convention Center, and Inner Mongolia Tongliao Art Museum.

As a leading China Corrugated Side Panels factory, China Corrugated Side Panels supplier, and trusted China Corrugated Side Panels manufacturer, we offer China Corrugated Side Panels wholesale pricing on High Quality Corrugated Side Panels. Our Corrugated Side Panels for sale feature competitive Corrugated Side Panels price points backed by 30-year warranties. Partner with us for customized solutions meeting international standards (ASTM, DIN, JIS, BS, GB/T) with reliable 15-20 day delivery. Contact us at huafeng@hfmetalroof.com to discuss your project requirements and discover how our expertise transforms your vision into durable, beautiful reality.

References

1. Metal Building Manufacturers Association. "Guide Specification for Factory-Finished Architectural Coil Coated Products." MBMA Technical Publication.

2. American Architectural Manufacturers Association. "AAMA 2605: Voluntary Specification, Performance Requirements and Test Procedures for Superior Performing Organic Coatings on Aluminum Extrusions and Panels." AAMA Standards.

3. ASTM International. "ASTM D3363-20: Standard Test Method for Film Hardness by Pencil Test." West Conshohocken, PA: ASTM International.

4. National Coil Coating Association. "Technical Bulletin: Accelerated Weathering Testing of Coil Coatings." NCCA Technical Resources.

5. Zhang, W., Chen, H., and Liu, X. "Durability Assessment of PVDF and Polyester Coatings on Metal Building Panels under Various Climatic Conditions." Journal of Materials in Civil Engineering, Vol. 34, No. 8.