Imagine standing in front of a commercial building where water seeps through exterior walls during heavy rainfall, causing interior damage and costly repairs. This scenario haunts architects and building owners worldwide, driving the urgent need for superior wall cladding solutions. A Standing Seam Wall System represents a revolutionary architectural metal cladding solution featuring concealed fasteners and vertical interlocking seams that deliver exceptional waterproofing, structural integrity, and contemporary aesthetics for modern construction projects. As building codes tighten and sustainability becomes paramount in 2026, understanding this innovative wall technology has become essential for anyone involved in commercial, industrial, or public building projects seeking long-term performance and reduced lifecycle costs. The Standing Seam Wall System has transformed from a niche roofing application into a mainstream architectural choice, addressing critical challenges that traditional wall cladding systems fail to solve. This comprehensive guide explores why this metal cladding technology matters more than ever in 2026, examining its technical specifications, installation advantages, and real-world performance data that architects and builders need to make informed decisions.

Understanding Standing Seam Wall System Technology

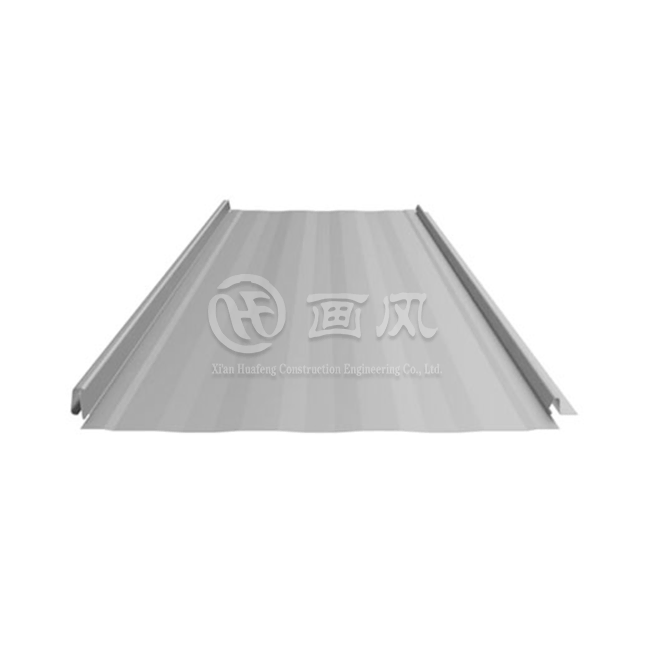

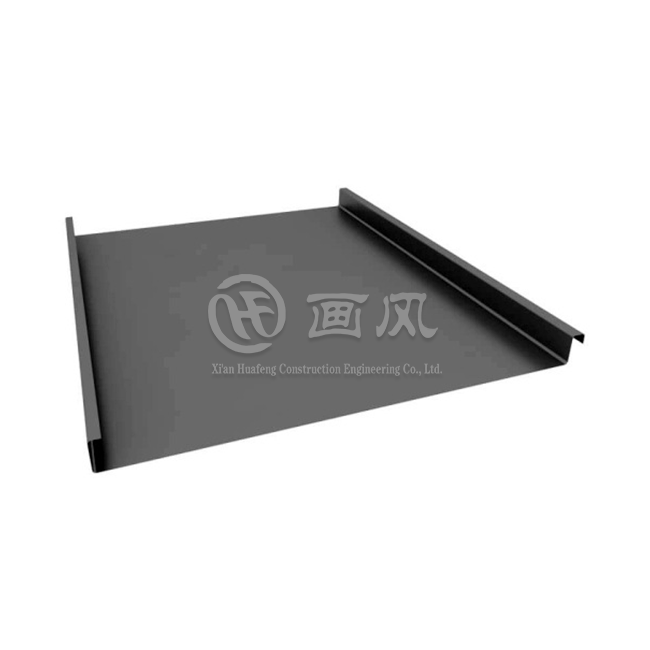

The Standing Seam Wall System fundamentally differs from conventional wall cladding through its sophisticated interlocking mechanism and hidden fastener design. This metal curtain wall solution utilizes vertical panels with raised seams that mechanically lock together, creating a continuous protective barrier without exposed screws or rivets that could compromise weatherproofing. The system's engineering allows for thermal expansion and contraction through sliding clips, preventing the oil-canning effect and structural stress that plague rigid attachment methods. Modern Standing Seam Wall System applications extend far beyond simple aesthetics. The technology incorporates advanced materials including aluminum alloy grades AA3003, AA3004, and AA5052, aluminum-zinc steel plates with AZ150 coating, and premium stainless steel options. These base materials receive additional protection through sophisticated coating systems such as PVDF fluorocarbon coatings, which provide exceptional weather resistance and color retention exceeding twenty years. The thickness ranges from 0.7mm to 1.5mm, carefully calibrated to meet specific wind pressure resistance requirements and structural demands of individual projects.

The panel geometry plays a crucial role in system performance. Standard panel widths typically range from 300mm to 600mm, with customization available for unique architectural requirements. Single panels can reach lengths up to 13 meters, dramatically reducing the number of horizontal joints and enhancing waterproofing effectiveness. Rib heights between 25mm and 65mm directly influence wind pressure resistance and drainage performance, with taller ribs providing greater structural capacity for high-rise applications or exposed locations. Installation methodology distinguishes the Standing Seam Wall System from traditional approaches. The mechanical locking edge system employs specialized on-site seaming machines that crimp adjacent panels together, forming a continuous weathertight seal. Hidden fixing mechanisms utilize sliding clips that attach to the building substrate while allowing the metal panels to move independently during thermal cycles. This floating attachment system prevents fastener backout, reduces stress concentrations, and extends overall system longevity compared to through-fastened alternatives.

Technical Performance Characteristics

Wind pressure resistance represents a critical performance metric for exterior wall systems, particularly in high-rise construction and coastal environments. The Standing Seam Wall System achieves superior wind resistance through its vertical lock edge design and reinforced rib structure, capable of withstanding extreme wind events that would compromise lesser cladding systems. Engineering calculations and physical testing verify load capacities, providing architects with documented performance data required for building permit applications and insurance certifications. Waterproofing performance defines the fundamental purpose of any exterior wall assembly. The Standing Seam Wall System employs a double waterproofing strategy combining the mechanical lock edge bite with internal waterproof membranes, ensuring zero water infiltration even during wind-driven rain events. This redundant protection eliminates the common failure modes associated with sealant-dependent systems, where ultraviolet degradation and thermal cycling eventually compromise joint integrity. Thermal expansion adaptability addresses a challenge that has plagued metal wall systems throughout construction history. The sliding clip attachment system permits metal panels to expand and contract freely across seasonal temperature variations without inducing structural stress or visible distortion. This engineering solution prevents the buckling, warping, and fastener failure that occurs when thermal movement is restrained, ensuring the facade maintains its architectural appearance throughout decades of service. Fire resistance classification meets stringent building code requirements through metallic substrate composition. Metal Standing Seam Wall Systems achieve Class A fire protection standards, the highest rating available, providing crucial passive fire protection for occupied structures. This classification often eliminates the need for additional fire-resistant barriers, simplifying construction details and reducing overall project costs while enhancing life safety performance.

Applications and Architectural Versatility of Standing Seam Wall Cladding

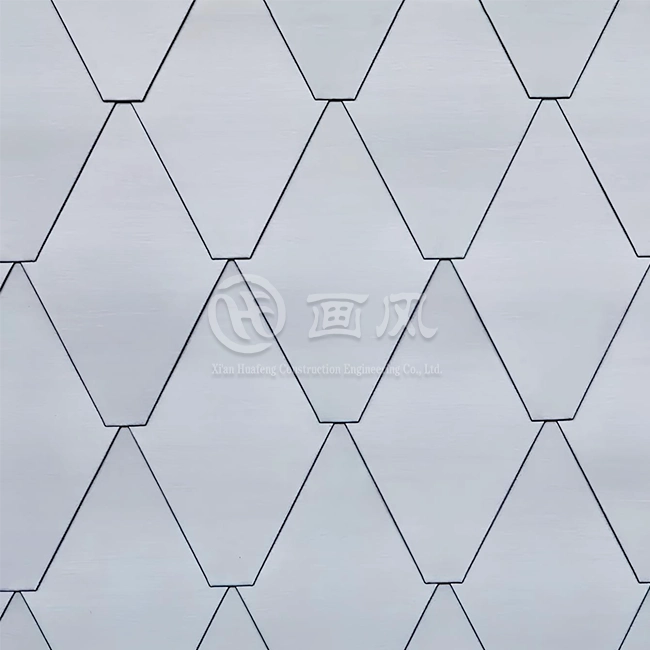

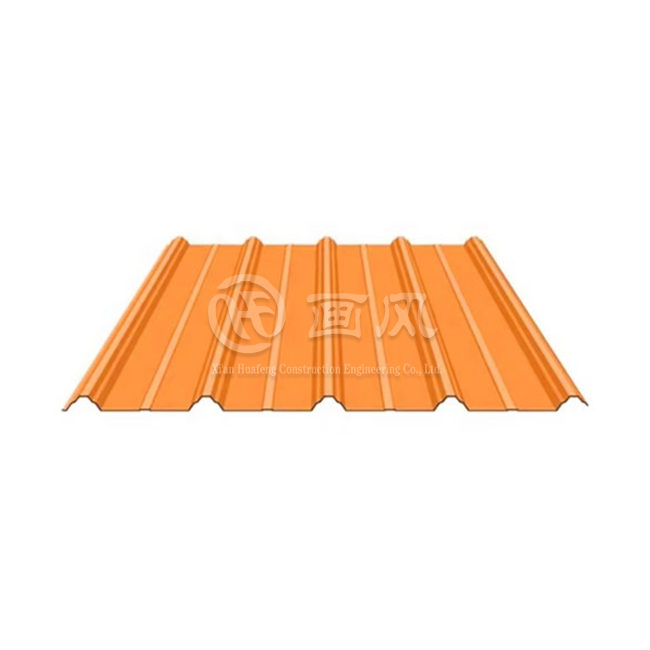

The Standing Seam Wall System demonstrates remarkable versatility across diverse building typologies and architectural styles. In high-end commercial construction, including office towers, hotels, and shopping centers, the system delivers the sleek contemporary aesthetic that defines modern urban architecture. The clean vertical lines and concealed fasteners create sophisticated facades that align with current design trends emphasizing minimalism and precision detailing. Large public buildings represent another significant application sector. Airports, convention centers, sports stadiums, and cultural institutions increasingly specify Standing Seam Wall Systems for their combination of durability, low maintenance requirements, and design flexibility. These high-profile projects demand materials that perform reliably across decades of intensive use while maintaining their visual appeal despite exposure to weather extremes and heavy public traffic. Industrial facilities including manufacturing plants, distribution warehouses, and logistics centers benefit from the system's exceptional durability and cost-effectiveness. The long panel lengths reduce installation time, while the maintenance-free nature of PVDF-coated metal eliminates ongoing painting and repair expenses that burden traditional wall materials. The inherent strength allows for fewer structural supports, potentially reducing overall building framework costs. Special architectural geometries showcase the system's adaptability. Curved facades, wave-form designs, and other complex three-dimensional shapes become achievable through careful panel profiling and custom fabrication. This design freedom enables architects to realize bold creative visions without sacrificing the practical performance characteristics essential for building envelope integrity.

Material Selection and Finish Options

Aluminum alloy compositions offer distinct advantages for specific applications. The AA3003 and AA3004 grades provide excellent corrosion resistance combined with good formability, making them ideal for complex architectural profiles. The AA5052 alloy delivers higher strength for applications requiring enhanced structural capacity or resistance to impact damage. Each alloy selection represents a calculated engineering decision balancing performance requirements against project budget constraints. Steel substrate options address different performance priorities. Cold-rolled steel sheets provide economical solutions for protected environments, while galvanized steel offers enhanced corrosion protection through zinc coating. Galvalume steel, featuring an aluminum-zinc alloy coating, represents the premium choice for maximum corrosion resistance in harsh coastal or industrial atmospheres. Color-coated steel combines the structural benefits of steel with factory-applied finish systems that eliminate field painting requirements. Stainless steel substrates serve specialized applications where ultimate corrosion resistance justifies higher material costs. Grade 304 stainless steel suits most architectural applications, while Grade 316 provides superior performance in marine environments or locations with aggressive atmospheric conditions. The inherent beauty of stainless steel finishes appeals to architects seeking distinctive metallic appearances that evolve gracefully through weathering processes. Coating systems determine long-term appearance retention and maintenance requirements. Polyester coatings provide basic weather protection suitable for moderate climates and shorter expected service lives. High-durability polyester formulations extend performance for more demanding applications. PVDF fluorocarbon coatings represent the premium standard, delivering exceptional ultraviolet resistance, color stability, and surface cleanability that maintains architectural appearance for over twenty years without repainting.

The Standing Seam Wall System Installation Process

Professional installation methodology directly impacts system performance and longevity. The process begins with careful substrate preparation, ensuring the supporting structure meets flatness tolerances and provides adequate attachment points. Installation technicians verify that all structural members align properly and that the building envelope incorporates appropriate weather barriers before metal panel installation commences. Panel sequencing follows engineered shop drawings that detail every component location and connection detail. Each panel receives a unique identification number corresponding to its position in the assembly, preventing installation errors that could compromise weatherproofing or visual alignment. This systematic approach enables quality control throughout the installation process, with inspections occurring at defined intervals to verify compliance with specifications. The seaming operation requires specialized equipment operated by trained technicians. Hand-held or cart-mounted seaming tools progressively crimp adjacent panel edges together, creating the characteristic vertical standing seam. Proper seaming technique ensures consistent seam height and complete engagement of the interlocking profiles, establishing the waterproof joint that defines system performance. Quality seaming produces uniform appearance while achieving the structural connection strength verified through engineering analysis. Clip installation demands precise positioning and secure fastening to the building substrate. The sliding clips must be located at specified intervals matching structural calculations, with each clip properly oriented to permit thermal movement while resisting wind uplift forces. Fastener selection matches substrate materials and load requirements, with special attention to preventing galvanic corrosion through appropriate material compatibility.

Quality Control and Testing Protocols

Incoming material inspection establishes the foundation for quality assurance. Every shipment of base metal undergoes verification testing including dimensional checks, coating thickness measurement, and visual examination for surface defects. Material certifications from manufacturers must accompany deliveries, documenting conformance to specified alloy compositions and coating standards. This rigorous receiving inspection prevents defective materials from entering the construction process where detection and correction become exponentially more expensive. In-process inspections occur at critical construction milestones. Substrate preparation receives verification before panel installation begins, confirming flatness, fastener spacing, and weather barrier integrity. Seaming operations undergo continuous monitoring to ensure proper tool settings and technique. Clip installation receives inspection verifying correct positioning, orientation, and fastening adequacy. This multi-stage inspection protocol identifies and corrects deficiencies before subsequent work conceals the condition. Final acceptance testing validates overall system performance. Water testing using calibrated spray equipment simulates wind-driven rain conditions, verifying that no water penetrates the wall assembly. Visual inspection confirms uniform appearance, proper alignment, and absence of damage. Documentation photographs create a permanent record of completed installation quality, providing reference for future maintenance activities or warranty claims. Long-term performance monitoring tracks actual in-service behavior. Periodic inspections identify any developing issues before they progress to serious problems requiring extensive repairs. This proactive maintenance approach preserves the architectural appearance and functional performance that justified the original material selection, protecting the building owner's investment throughout the expected service life.

Why Standing Seam Wall Systems Matter More in 2026?

Current building codes and sustainability mandates have elevated performance expectations beyond historical standards. Energy efficiency requirements demand exterior wall assemblies that minimize thermal bridging and air infiltration. The Standing Seam Wall System contributes to these objectives through continuous insulation compatibility and inherent airtightness achievable with proper installation. These attributes help buildings achieve certification under green building rating systems including LEED, BREEAM, and local equivalents. Material sustainability considerations influence specification decisions as environmental consciousness grows among building owners and occupants. Metal wall panels offer complete recyclability at end of service life, unlike composite materials that enter waste streams. The durability and low maintenance characteristics reduce lifetime environmental impact by eliminating repeated painting cycles that consume resources and generate hazardous waste. Factory finishing in controlled environments minimizes volatile organic compound emissions compared to field-applied coatings. Lifecycle cost analysis increasingly drives material selection as sophisticated owners recognize that initial price represents only one component of total cost of ownership. The Standing Seam Wall System's minimal maintenance requirements, extended service life exceeding thirty years with proper specification, and high salvage value at building end-of-life produce favorable economic returns when evaluated across complete ownership periods. These financial advantages often justify premium initial costs compared to cheaper alternatives requiring frequent maintenance and earlier replacement. Design flexibility responds to architectural trends emphasizing bold forms and distinctive building identities. The Standing Seam Wall System enables creative expression through custom colors, multiple finish textures, varied panel widths, and integration with other facade materials. This versatility helps buildings achieve signature appearances that distinguish them within competitive real estate markets, supporting property values and tenant attraction objectives.

Integration with Modern Building Technologies

Renewable energy integration represents an emerging application where Standing Seam Wall Systems contribute to net-zero building objectives. The vertical orientation and structural capacity enable mounting of building-integrated photovoltaic panels or solar thermal collectors directly to the wall surface. This integration transforms the building envelope from passive protection to active energy generation, supporting sustainability goals while maximizing limited roof areas dedicated to mechanical equipment. Smart building sensor networks benefit from the concealed cavity space behind ventilated Standing Seam Wall System installations. Environmental sensors monitoring temperature, humidity, air quality, and other parameters can be incorporated within the facade assembly, feeding data to building management systems. This integration supports predictive maintenance strategies and occupant comfort optimization that characterize intelligent building operation. Prefabrication and modular construction methodologies align well with Standing Seam Wall System characteristics. Large facade sections can be assembled in factory-controlled environments with superior quality control, then transported to site for rapid installation. This approach reduces on-site labor requirements, shortens construction schedules, and improves overall quality consistency compared to entirely field-fabricated alternatives. Digital design tools enable precise performance prediction and construction documentation. Building information modeling software incorporates Standing Seam Wall System components with accurate dimensional and performance data, facilitating clash detection and construction coordination. This digital workflow reduces field conflicts, minimizes change orders, and supports lean construction principles that control project costs and schedules.

Selecting the Right Standing Seam Wall System for Your Project

Project-specific requirements must drive material and system selection decisions. Climate conditions including temperature extremes, precipitation patterns, wind exposure, and atmospheric corrosiveness directly influence appropriate substrate materials and coating specifications. Coastal projects demand maximum corrosion protection through stainless steel or heavily coated steel substrates, while inland locations may permit more economical material choices without compromising long-term performance. Building height and wind exposure determine structural requirements for panel profiles and attachment systems. High-rise construction in urban centers faces greater wind pressures requiring enhanced clip spacing and potentially thicker panel gauges compared to low-rise suburban buildings. Engineering analysis quantifies these load conditions, ensuring the specified system meets all safety factors with adequate reserves for unforeseen conditions. Architectural design intent establishes aesthetic parameters including panel width, seam profile, finish color, and surface texture. Contemporary minimalist designs often favor wider panels with subtle seam profiles and monochromatic color schemes. Traditional architecture might incorporate narrower panels with pronounced seams echoing historical board-and-batten precedents. Matching the Standing Seam Wall System specification to design intent requires close collaboration between architects and manufacturers during early design development. Budget constraints and value engineering opportunities require realistic assessment. While Standing Seam Wall Systems may present higher initial costs than some alternatives, the lifecycle value proposition often justifies the investment. Detailed cost modeling comparing initial installation, maintenance requirements, energy performance, and replacement cycles across twenty to thirty year analysis periods reveals the true economic position. This analytical approach supports informed decision-making based on total cost of ownership rather than first cost alone.

Specifications: Technical Parameters and Standards

Contemporary Standing Seam Wall System specifications typically include panel width options of 25mm to 500mm depending on architectural requirements and structural capacity needs. Common configurations include 330mm, 400mm, and 430mm widths that balance aesthetic proportions with economical material usage. Custom widths accommodate special design conditions or alignment with building module dimensions. Finish systems encompass PE polyester coatings for basic applications, HDP high-durability polyester for enhanced performance, and PVDF fluorocarbon coatings for maximum weather resistance and color retention. The coating selection significantly impacts lifecycle performance and maintenance requirements, justifying careful evaluation of expected service conditions and appearance retention priorities. Supply capacity considerations ensure manufacturers can meet project schedules without delays that disrupt overall construction sequencing. Leading suppliers maintain monthly production capacity exceeding 1000 tons, providing confidence for large-scale projects requiring substantial material volumes. This manufacturing capability combined with efficient logistics enables reliable delivery performance critical to fast-track construction schedules.

Service life expectations with proper material selection and professional installation routinely exceed thirty years, with premium PVDF-coated systems maintaining appearance and function for even longer periods. Manufacturers typically provide warranties spanning this duration, transferring performance risk from building owners to material producers who have confidence in their products' longevity. Minimum order quantities typically start around 500 square meters for custom colors or special configurations, though standard finishes may be available in smaller quantities. Delivery timeframes generally span fifteen to twenty days from order confirmation to shipment, though custom specifications may require additional lead time for material procurement and fabrication scheduling. Customization services address unique project requirements including custom color matching to corporate branding or design intent, pattern options creating visual interest through embossed or textured surfaces, and complete design customization developing specialized profiles for signature architectural expressions. These tailored solutions enable architects to realize distinctive building identities while maintaining the performance benefits inherent to Standing Seam Wall System technology. Quality standards ensure consistent performance and regulatory compliance. ISO 9001 certification verifies quality management systems governing manufacturing processes. ISO 14000:14001 environmental management certification demonstrates commitment to sustainable production practices. SGS testing and certification provide independent verification of performance claims, giving specifiers confidence in published technical data.

Conclusion

The Standing Seam Wall System has evolved into an essential architectural solution combining superior weatherproofing, structural performance, design versatility, and lifecycle value. As building codes tighten and sustainability imperatives intensify throughout 2026, this metal cladding technology delivers the comprehensive performance modern construction demands while enabling distinctive architectural expression.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

Xi'an Huafeng Construction Engineering Co., Ltd. stands as a leading China Standing Seam Wall System manufacturer, China Standing Seam Wall System supplier, and China Standing Seam Wall System factory offering High Quality Standing Seam Wall System products at competitive Standing Seam Wall System price points. Since establishment in 2018, we have delivered comprehensive one-stop solutions from design through construction, earning recognition as a Shaanxi Province high-tech enterprise with first-level curtain wall qualifications and third-level steel structure credentials.

Our manufacturing infrastructure includes a 200,000 square meter raw material production facility in Anhui, plus processing plants in Hangzhou and Xi'an equipped with seven color coating lines, one laminating line, ten shearing production lines, and over forty specialized machines. This industrial capacity enables monthly production exceeding 1000 tons of Standing Seam Wall System products available for wholesale distribution, supporting projects of any scale with fifteen to twenty day delivery schedules.

With over twenty registered patents covering roofing and wall systems, complemented by ISO 9001, ISO 14000:14001, and SGS certifications, we maintain the quality standards that global projects demand. Our engineering team provides technical support from initial concept through final acceptance, including 3D structural modeling, drainage simulation, material specification advisory, and comprehensive installation guidance. Notable project portfolio includes Xiongan Station, Xi'an International Convention Center, and Inner Mongolia Tongliao Art Museum, demonstrating proven performance across diverse applications.

We invite architects, developers, and contractors seeking China Standing Seam Wall System wholesale partners to experience our customizable solutions including tailored colors, patterns, and complete design services. Whether you need Standing Seam Wall System for sale for commercial, industrial, or public building applications, our one-stop procurement model covers everything from premium raw materials to complete accessory packages. Contact our technical team at huafeng@hfmetalroof.com to discuss your project requirements and discover how our Standing Seam Wall System solutions deliver superior value.

References

1. Sheffield Metals International. "Standing Seam Metal Roofing Systems: Technical Guide and Application Standards." Sheffield Metals Technical Publications, 2024.

2. American Architectural Manufacturers Association. "Metal Wall Panel Systems: Performance Testing and Installation Guidelines." AAMA Technical Standards Committee, 2023.

3. Metal Construction Association. "Architectural Metal Cladding: Design Considerations for Contemporary Building Envelopes." MCA Design Guidelines Series, 2025.

4. National Roofing Contractors Association. "Metal Panel Systems Manual: Installation and Performance Standards." NRCA Technical Publications, 2024.

5. Building Enclosure Technology and Environment Council. "Exterior Wall Assembly Performance: Testing Protocols and Evaluation Criteria." BETEC Research Monograph, 2023.