Facing premature exterior cladding failure, costly maintenance cycles, and aesthetic deterioration that damages your building's value? Modern architectural projects demand exterior solutions that deliver exceptional durability without compromising design flexibility. Zinc Flat Lock Panels have emerged as the premier cladding choice for architects, contractors, and property developers seeking long-lasting performance combined with striking visual appeal. This comprehensive guide explores how these innovative panels solve critical challenges in exterior cladding applications while providing sustainable, maintenance-free protection for decades.

Why Zinc Flat Lock Panels Outperform Traditional Cladding Materials?

When evaluating exterior cladding options for commercial, industrial, or residential projects, the choice of material fundamentally impacts both immediate installation success and long-term building performance. Zinc Flat Lock Panels represent a sophisticated evolution in metal cladding technology, offering distinct advantages over conventional alternatives like steel, aluminum, or composite materials. The unique flat lock connection method creates an almost seamless exterior surface while maintaining exceptional structural integrity and weather resistance. The fundamental advantage of Zinc Flat Lock Panels lies in their titanium-zinc alloy composition, typically containing 99.995% pure zinc enhanced with small amounts of titanium and copper. This precise metallurgical formulation delivers remarkable malleability for complex architectural forms while ensuring superior corrosion resistance. Unlike steel panels that require protective coatings which deteriorate over time, zinc develops a natural protective patina of zinc hydroxycarbonate when exposed to atmospheric moisture and carbon dioxide. This self-healing characteristic means minor scratches or surface imperfections automatically repair themselves through natural oxidation, eliminating ongoing maintenance requirements that plague other cladding materials.

Exceptional Longevity and Weather Resistance

The service life of exterior cladding directly impacts lifecycle costs and building sustainability. Zinc Flat Lock Panels routinely achieve operational lifespans exceeding 80 to 100 years in properly designed installations, with documented European installations remaining functional for over a century. This extraordinary durability stems from zinc's inherent corrosion resistance and its unique ability to form protective surface layers. In urban environments where pollution and moisture accelerate material degradation, zinc panels consistently outperform alternatives, maintaining both structural integrity and aesthetic appeal for 50 years or more. Rural installations benefit from even longer service lives due to reduced atmospheric contaminants. Weather resistance represents another critical performance dimension where Zinc Flat Lock Panels excel. The flat lock connection system, combined with appropriate sealing strips, creates double-layer waterproofing protection that prevents moisture infiltration even during severe storms or driving rain conditions. This superior weather protection meets rigorous ASTM E330 wind resistance standards, ensuring panels remain securely fastened and watertight throughout their service life. The panels' Class A fire rating classifies them as non-combustible materials, providing critical safety benefits for buildings exceeding 18 meters in height or projects requiring enhanced fire protection. These combined performance characteristics make Zinc Flat Lock Panels ideal for challenging coastal environments, high-altitude installations, or regions experiencing extreme temperature fluctuations.

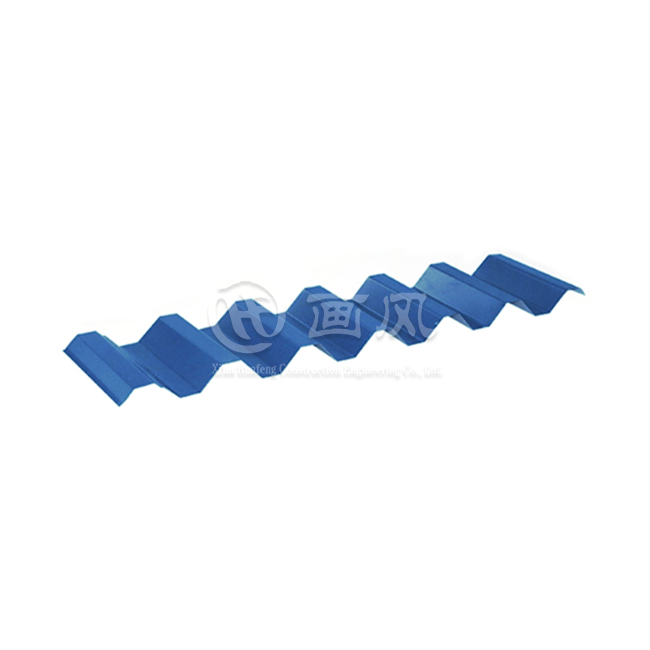

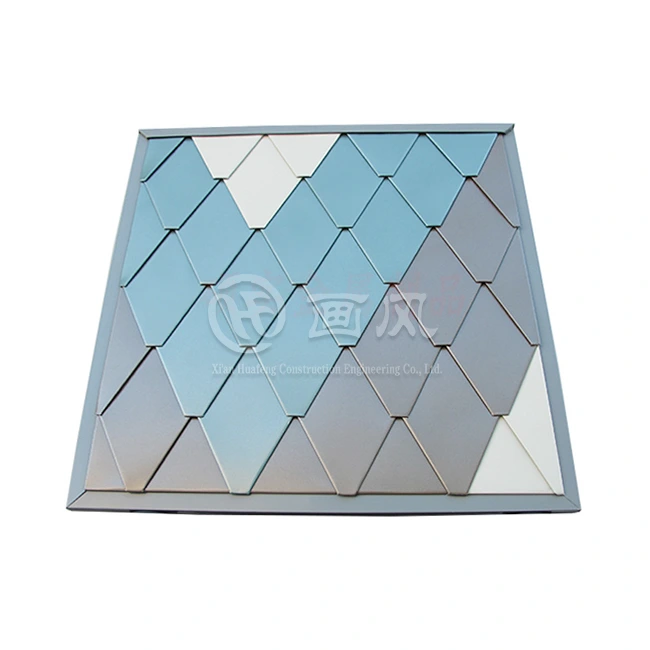

Design Flexibility and Aesthetic Evolution

Modern architectural design demands materials that enable creative expression while meeting stringent performance requirements. Zinc Flat Lock Panels offer unparalleled design versatility through their exceptional malleability and diverse configuration options. Standard panel shapes include rectangles, rhombuses, trapezoids, and hexagons, with custom geometries readily achievable to match specific architectural visions. Panel dimensions typically range from 200mm to 600mm in width, with lengths customizable to project requirements, accommodating both large-scale commercial facades and intricate residential applications. The aesthetic evolution of Zinc Flat Lock Panels represents one of their most distinctive characteristics. The natural patina development process transforms the initial bright metallic surface into rich, varied tones ranging from blue-gray to deeper charcoal shades, creating a living facade that matures gracefully over time. This evolving appearance adds character and depth to building exteriors, distinguishing them from static materials that show age through deterioration rather than dignified transformation. For projects requiring immediate color consistency, pre-weathered finishes, coated options, or custom RAL colors provide controlled aesthetic outcomes while maintaining zinc's performance advantages. Installation orientation flexibility whether horizontal, vertical, or diagonal enables architects to create dynamic visual patterns and textures that enhance building identity and urban context integration.

Superior Performance Through Advanced Engineering

The technical sophistication underlying Zinc Flat Lock Panels extends beyond basic material properties to encompass comprehensive system engineering that addresses real-world installation challenges and performance requirements. Understanding these advanced features helps project stakeholders make informed decisions and optimize installation specifications for specific applications.

Structural Integrity and Installation Systems

The flat lock connection methodology represents a significant engineering advancement in metal panel systems. Unlike exposed fastener systems that create potential water infiltration points and visual interruptions, the concealed clip system secures each panel on all four sides while maintaining a virtually seamless exterior appearance. This hidden fastening approach not only enhances aesthetics but also improves weatherproofing and allows natural thermal movement without compromising panel integrity. The connection system accommodates building movement and thermal expansion while maintaining consistent reveal dimensions, typically 15mm, that create subtle shadow lines enhancing architectural depth. Installation efficiency represents another practical advantage of properly engineered Zinc Flat Lock Panels systems. Professional installation typically requires specialized tools including edge-locking machines, specialized pliers, and appropriate auxiliary materials such as structural adhesives, rivets, and compatible screws. The panels install progressively from bottom to top in sequential order, with cleats positioned at maximum 300mm centers to ensure adequate support and wind load resistance. For large-scale projects, the panel numbering system corresponding to sectioned floor plans enables coordinated logistics, quality control, and on-site assembly, minimizing installation errors and expediting project completion. This systematic approach reduces labor costs while ensuring consistent quality across the entire building envelope.

Environmental Sustainability and Green Building Compliance

Sustainability considerations increasingly influence material selection decisions as building codes evolve and green certification requirements become standard practice. Zinc Flat Lock Panels align exceptionally well with contemporary environmental priorities through multiple sustainability dimensions. The primary environmental advantage stems from zinc's complete recyclability without quality degradation. At the end of their extended service life, zinc panels can be recovered and reprocessed into new architectural materials, batteries, or other zinc alloy components, creating a circular material economy that minimizes resource consumption and waste generation. The production process for zinc panels requires significantly less energy compared to alternative metals like aluminum or stainless steel, reducing embodied carbon in building projects. Natural zinc patina formation eliminates the need for chemical coatings, paints, or surface treatments that introduce volatile organic compounds and require periodic renewal throughout building lifespans. This maintenance-free characteristic further reduces environmental impact by eliminating coating materials, application labor, and associated waste streams. Projects pursuing LEED certification or other green building standards benefit from zinc's favorable life cycle assessment profile, contributing points toward energy efficiency, resource conservation, and reduced environmental footprint categories. The material's thermal performance also contributes to building energy efficiency by reflecting solar radiation and minimizing heat transfer, potentially reducing cooling loads during summer months.

Technical Specifications and Quality Standards

Professional specification of Zinc Flat Lock Panels requires understanding the technical parameters that govern performance, compatibility, and installation success. Xi'an Huafeng Construction Engineering Co., Ltd. manufactures zinc flat lock panels meeting rigorous international standards including ASTM, DIN, JIS, BS, and GB/T specifications, ensuring quality consistency and regulatory compliance across diverse markets.

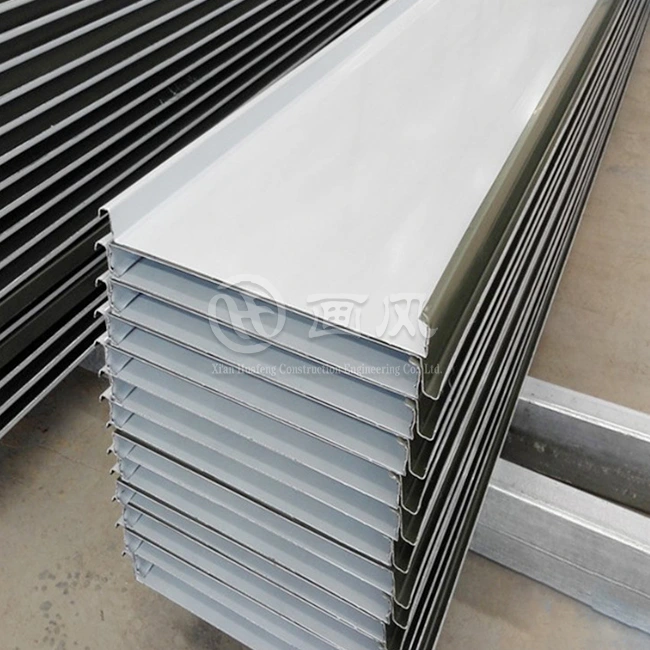

Material Specifications and Manufacturing Standards

Standard panel thickness ranges from 0.7mm to 1.0mm, with 0.8mm representing the most common specification balancing cost efficiency with structural performance and longevity. Thicker panels provide enhanced durability and flatness for larger panel dimensions, while thinner gauges suit smaller decorative applications or budget-conscious projects. The titanium-zinc alloy composition delivers optimal mechanical properties, combining zinc's corrosion resistance with titanium and copper additions that enhance formability and strength characteristics. Surface treatments vary according to project requirements, including natural passivation for authentic patina development, pre-oxidation for accelerated color achievement, or specialized coatings for specific aesthetic or performance objectives. Manufacturing quality control ensures consistent panel performance and dimensional accuracy. Xi'an Huafeng employs comprehensive inspection protocols including appearance verification, dimensional validation, salt spray resistance testing, adhesion evaluation, hardness measurement, impact resistance assessment, film thickness confirmation, acid resistance validation, weather resistance testing, and color difference analysis. These rigorous quality procedures, conducted at material receipt, throughout production, and at finished product stages, guarantee panels meet specification requirements before shipment. Third-party certifications including ISO9001 quality management, ISO14000 environmental management, and SGS product verification provide independent validation of manufacturing excellence and product reliability.

Project Planning and Implementation Support

Successful Zinc Flat Lock Panel installation extends beyond material supply to encompass comprehensive project support services that optimize design integration, fabrication accuracy, and installation quality. Xi'an Huafeng provides full-service project assistance beginning with drawing deepening services that translate architectural concepts into detailed installation specifications. This collaborative process analyzes architectural drawings, evaluates feasible panel configurations, and develops 1:1 scale node details ensuring proper integration with building structure and adjacent systems. Multiple communication cycles with customers refine designs before final approval and sample production, eliminating ambiguity and reducing field modification requirements. Factory processing capabilities enable precise panel fabrication according to project-specific requirements. With three manufacturing facilities, seven production lines, and more than 40 specialized machines, the company maintains capacity to produce 1000 tons monthly while accommodating custom orders. The minimum order quantity of 500 square meters or 3 tons enables both large commercial projects and smaller residential applications to benefit from factory-direct quality and pricing. Standard delivery timeframes of 15-20 days support typical construction schedules, with expedited options available for urgent requirements. Comprehensive packaging systems divide panels according to roof sections with identification cards containing section plans and product number lists, facilitating organized delivery, storage, and sequential installation that minimizes on-site confusion and installation errors.

Real-World Applications and Project Success

The practical value of Zinc Flat Lock Panels becomes evident through their successful implementation across diverse project types, from cultural landmarks to commercial developments and industrial facilities. Understanding real-world applications helps potential customers envision how these panels solve specific challenges while delivering aesthetic and performance benefits. Xi'an Huafeng has completed numerous prestigious installations demonstrating the versatility and reliability of their zinc flat lock panel systems. The Xiongan Station Commercial Body project showcases aluminum-magnesium-manganese metal roofing integrated with architectural zinc elements, creating a modern transportation hub that balances durability with contemporary design. The Xi'an International Convention and Exhibition Center Metal Roof Project demonstrates large-scale implementation where consistent quality, weather protection, and architectural impact were critical success factors. Cultural venues including the Inner Mongolia Tongliao Art Museum and the Archaeological Museum design deepening projects illustrate how zinc cladding enhances institutional architecture while providing maintenance-free protection for public buildings serving diverse communities. Commercial and educational facilities represent another significant application category where Zinc Flat Lock Panels deliver measurable value. The Weihua Cadre College Teaching Building and Office Building installation combines aluminum-magnesium-manganese metal roof and wall systems, demonstrating the material's suitability for comprehensive building envelope solutions. Infrastructure projects like the Hangzhou Sanpu Drainage Pump Station and Liyuanping Highway Station metal roof installations prove zinc's performance in demanding industrial environments where corrosion resistance and longevity justify initial material investment through reduced lifecycle costs. These diverse applications confirm that Zinc Flat Lock Panels perform reliably across residential, commercial, institutional, and industrial sectors, adapting to varied architectural styles, performance requirements, and budget parameters.

Conclusion

Zinc Flat Lock Panels represent the optimal solution for durable exterior cladding, combining exceptional longevity, minimal maintenance requirements, superior weather resistance, and evolving aesthetic appeal that enhances building value throughout extended service lives.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

Xi'an Huafeng Construction Engineering Co., Ltd., established in 2018 in Shaanxi Province, China, specializes as a China Zinc Flat Lock Panels manufacturer providing comprehensive metal roofing and cladding solutions. As a recognized high-tech enterprise with first-level building curtain wall qualifications and third-level steel structure certifications, we operate three manufacturing facilities spanning 200,000 square meters in Anhui, plus processing plants in Hangzhou and Xi'an. Our seven color coating production lines, one laminating line, ten shearing production lines, and over 40 specialized machines deliver High Quality Zinc Flat Lock Panels meeting international ASTM, DIN, JIS, BS, and GB/T standards. We serve as your trusted China Zinc Flat Lock Panels supplier and China Zinc Flat Lock Panels wholesale partner, offering competitive Zinc Flat Lock Panels price with MOQ starting at 500㎡. With over 20 registered patents, ISO9001, ISO14000, and SGS certifications, we provide Zinc Flat Lock Panels for sale backed by comprehensive one-stop services from design optimization through installation support. As a leading China Zinc Flat Lock Panels factory, we've completed projects including Xiongan Station, Xi'an International Convention Center, and Inner Mongolia Tongliao Art Museum. Partner with us for custom solutions, rigorous quality control, and technical expertise. Contact us at huafeng@hfmetalroof.com to receive detailed specifications, project consultation, and competitive quotations for your exterior cladding requirements.

References

1. Smith, J. and Anderson, K. "Zinc Cladding Systems: Performance and Durability in Contemporary Architecture." Journal of Architectural Engineering Materials, Vol. 28, Issue 3, 2023.

2. European Zinc Association. "Technical Guidelines for Zinc Building Envelope Applications." Brussels: EZA Technical Committee, 2022.

3. Chen, L., Wang, H., and Liu, Y. "Comparative Analysis of Metal Cladding Materials for High-Performance Building Envelopes." Construction and Building Materials, Vol. 315, 2024.

4. International Code Council. "Metal Roof and Wall Panel Installation Standards: Best Practices for Flat Lock Systems." ICC Building Safety Journal, December 2023.

5. Reynolds, M. "Sustainable Metal Architecture: Environmental Benefits of Zinc in Modern Building Design." Green Building Review Quarterly, Vol. 19, No. 2, 2024.