Imagine investing thousands in building exteriors only to face constant maintenance costs, premature degradation from harsh weather, and aesthetic deterioration that diminishes property value within just a few years. Industrial and commercial facility managers face this challenge daily when selecting inferior cladding systems. Aluminum Metal Siding Panels offer a proven solution that combines exceptional durability, minimal maintenance requirements, and long-term cost efficiency for buildings that demand performance under extreme conditions while maintaining professional aesthetics throughout their service life.

Understanding Aluminum Metal Siding Panels and Their Industrial Applications

Aluminum Metal Siding Panels represent a revolutionary advancement in building envelope technology, specifically engineered to address the demanding requirements of industrial and commercial construction projects. These panels are manufactured from high-grade aluminum alloys, typically AA3003, AA3004, or AA5052, which provide superior mechanical properties compared to traditional siding materials. The manufacturing process involves precision roll-forming operations that create consistent profile dimensions while maintaining the structural integrity essential for large-scale applications. The versatility of Aluminum Metal Siding Panels extends across multiple sectors including logistics warehouses, manufacturing facilities, commercial complexes, transportation hubs, and institutional buildings. In coastal environments where salt spray accelerates corrosion, aluminum's natural oxide layer provides inherent protection that steel simply cannot match. The panels excel in high-altitude installations where temperature fluctuations are extreme, maintaining dimensional stability that prevents thermal expansion issues common with other materials. Industrial facilities benefit particularly from aluminum's non-combustible properties, meeting stringent fire safety codes without requiring additional protective treatments. Xi'an Huafeng Construction Engineering Co., Ltd. has successfully deployed these panels in projects ranging from airport terminals to exhibition centers, demonstrating their adaptability across diverse architectural requirements.

Material Composition and Engineering Specifications

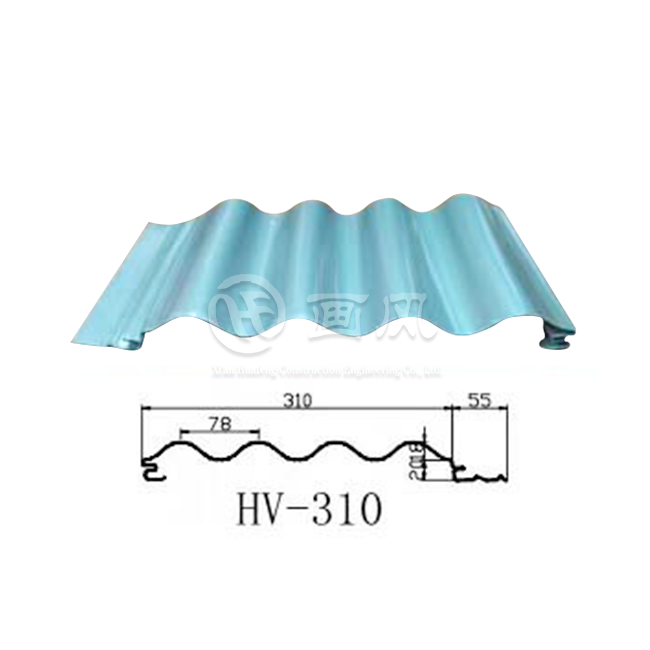

The technical specifications of professional-grade Aluminum Metal Siding Panels reflect decades of engineering refinement and real-world performance validation. Xi'an Huafeng manufactures panels with plate widths ranging from 400mm to 600mm and thicknesses between 0.7mm and 1.2mm, optimized for different structural load requirements. The rib height, typically between 25mm and 65mm, is engineered specifically for wind pressure resistance, a critical factor in high-rise and exposed installations. Standard panel lengths exceed 12 meters, which significantly reduces on-site joints and potential water infiltration points compared to shorter panels that require more frequent seaming. Surface coating systems represent perhaps the most critical specification for long-term performance. Polyester coatings offer economical protection suitable for moderate climates and protected exposures. High-Durability Polyester coatings provide enhanced UV resistance and color retention for more demanding applications. PVDF coatings, containing 70% polyvinylidene fluoride resin, deliver the ultimate in weatherability, chemical resistance, and color stability, backed by Xi'an Huafeng's 30-year warranty. The company's quality control protocols ensure compliance with ISO9001, ISO14001, and SGS standards, with over a dozen inspection steps including salt spray testing, adhesion verification, hardness measurement, impact resistance evaluation, and accelerated weathering simulation that predicts decades of real-world exposure.

Installation Systems and Fastening Technologies

Aluminum Metal Siding Panels employ two primary installation methodologies, each optimized for specific performance criteria and aesthetic preferences. Exposed fastener systems offer straightforward installation economics, with visible screws that penetrate directly through the panel face into the supporting structure. While more economical initially, these systems require careful attention to fastener placement, proper sealing washers, and periodic maintenance inspection to ensure long-term weather tightness. The visible fastener pattern becomes part of the building's aesthetic character, often preferred for industrial facilities where functionality takes precedence over refined appearance. Concealed fastener systems represent the premium approach to Aluminum Metal Siding Panels installation, utilizing hidden clips and interlocking panel joints that eliminate visible fasteners entirely. These systems provide superior weather protection by keeping all penetrations protected within the panel overlaps, dramatically reducing potential water infiltration points. The resulting smooth, uninterrupted surface delivers contemporary architectural aesthetics demanded by high-profile commercial projects. Xi'an Huafeng's engineering team provides comprehensive installation support including structural load calculations, thermal movement accommodation details, and custom flashing solutions that integrate seamlessly with the concealed fastener methodology, ensuring both visual excellence and long-term performance reliability.

Manufacturing Excellence and Quality Control Standards

Xi'an Huafeng Construction Engineering Co., Ltd. operates three strategically located facilities that collectively represent over 200,000 square meters of advanced manufacturing infrastructure. The primary raw material production plant in Anhui province houses seven color coating production lines, one specialized laminating production line, and ten longitudinal and transverse shearing production lines. This vertical integration ensures complete control over material quality from coil processing through finished panel fabrication. The company's plate and accessories processing facilities in Hangzhou and Xi'an provide regional manufacturing flexibility that reduces transportation costs and delivery timelines while maintaining consistent quality standards across all production locations. Material procurement follows rigorous protocols that begin with approved supplier registrations for brands including Alucosuper, YATAI, and LIDAO for aluminum alloys, along with BAOSTEEL, GUANZHOU, and XINYU for steel substrates when composite applications require them. Incoming material inspection encompasses both full inspection methodologies for small-quantity, high-value materials and statistical sampling protocols for high-volume commodities. Every incoming coil undergoes verification of material certifications and third-party testing reports before warehouse acceptance. The inspection regime includes surface appearance evaluation, dimensional verification, salt spray corrosion testing, coating adhesion measurement, hardness assessment, impact resistance validation, film thickness gauging, acid resistance verification, accelerated weathering simulation, and color consistency documentation against established standards.

Production Process and Finished Product Verification

The transformation from raw aluminum coil to finished Aluminum Metal Siding Panels follows a precisely controlled manufacturing sequence that leverages advanced roll-forming technology. Computer-controlled positioning systems ensure panel profile accuracy within tolerances measured in fractions of millimeters, critical for achieving proper panel interlocking and weather sealing in the field. The company's automated punching production lines create fastener holes and drainage perforations with robotic precision, eliminating the dimensional variations that plague manual fabrication methods. Over forty specialized machines including shearing equipment, hydraulic presses, and precision bending machines provide the manufacturing flexibility necessary to accommodate custom profiles and non-standard geometries requested by architectural specifications. Finished product inspection represents the final quality gate before packaging and shipment. Every panel undergoes visual appearance inspection for surface defects, coating imperfections, or handling damage. Dimensional verification confirms that manufactured panels match design specifications for width, length, profile depth, and hole locations. Flatness measurements ensure panels meet installation tolerances, while curvature assessment verifies that any intentional curving for architectural effect matches design requirements precisely. The packaging methodology employed by Xi'an Huafeng deserves particular attention, as products are organized by roof or wall section according to installation drawings, with each package containing a section plan and product number list that facilitates efficient on-site material management and eliminates confusion during construction sequencing.

Comprehensive Design Support and Project Engineering Services

Xi'an Huafeng Construction Engineering Co., Ltd. distinguishes itself through comprehensive engineering services that transform conceptual architectural designs into constructible reality. The project drawing deepening phase begins with detailed analysis of client-provided floor plans, elevations, and preliminary node diagrams. Engineering teams evaluate multiple feasible alternatives considering structural constraints, aesthetic requirements, budget parameters, and installation logistics. Through collaborative consultation with clients, the optimal panel type, profile configuration, and fastening system are determined for each specific roof or wall structure. The company's design department then executes full-scale drawing development, creating detailed node drawings for every condition including eave details, ridge conditions, wall-to-roof transitions, penetration flashings, and expansion joint accommodations. The sample production phase provides critical validation before committing to full manufacturing. Based on confirmed parameters including panel profile, material specification, thickness, surface treatment methodology, and color selection, factory personnel produce representative samples that clients can physically inspect. This tangible review opportunity allows stakeholders to verify that material appearance, texture, color accuracy, and assembly characteristics meet expectations before production begins. Upon client approval, samples are formally sealed and retained as the standard reference for subsequent production quality control, inspection protocols, and final acceptance criteria. This systematic approach eliminates the costly surprises and specification mismatches that plague construction projects lacking such rigorous pre-production validation.

Installation Support and Site Technical Guidance

The transition from manufacturing facility to construction site receives the same meticulous attention that characterizes Xi'an Huafeng's engineering and production operations. Site layout planning begins with consultation regarding actual field conditions, confirming adequate storage space for materials and accessories, establishing protected staging areas, and identifying suitable locations for on-site panel adjustment when required. Product delivery includes detailed packaging identification cards that reference sectioned floor plans and comprehensive product number lists, enabling receiving personnel to efficiently organize materials according to installation sequence and eliminate time-consuming searches for specific components during construction. On-site technical guidance ensures installation quality meets design intent and manufacturer specifications. Xi'an Huafeng's installation technicians conduct pre-construction site visits to verify substrate conditions, confirm tool and equipment readiness including specialized items like edge-locking machines and seaming tools, and validate that all auxiliary materials including rivets, structural adhesives, and fasteners are properly specified and available. Technical briefing meetings review work sequences, safety protocols, quality benchmarks, and inspection checkpoints before installation commences. Throughout the construction process, experienced personnel provide hands-on guidance that addresses field conditions, resolves unforeseen conflicts, and maintains installation quality standards. Upon completion, rigorous testing protocols verify system weather-tightness, with zero-leakage performance validated before final acceptance procedures begin.

Long-Term Performance and Sustainability Benefits

The true value proposition of Aluminum Metal Siding Panels extends far beyond initial installation costs to encompass lifecycle performance characteristics that dramatically reduce total ownership expenses. Aluminum's inherent corrosion resistance mechanism fundamentally differs from steel's protective coating approach. When aluminum surfaces oxidize upon atmospheric exposure, they form a hard, tenacious aluminum oxide layer that bonds tightly to the underlying metal and effectively prevents further oxidation progression. This self-protecting characteristic contrasts sharply with iron oxide formation on steel, which creates a porous, expanding rust layer that continuously flakes away and exposes fresh metal to continued deterioration. Coastal installations, industrial facilities with chemical exposure, and humid climates particularly benefit from aluminum's superior corrosion resistance that maintains structural integrity and aesthetic appearance without the periodic coating renewal required by alternative materials. Maintenance requirements for properly installed Aluminum Metal Siding Panels consist primarily of periodic washing to remove accumulated dirt and atmospheric deposits. The non-porous, chemically resistant surface resists biological growth, prevents staining from environmental pollutants, and maintains color stability throughout decades of service. PVDF coating systems utilized by Xi'an Huafeng demonstrate exceptional resistance to chalking, fading, and gloss reduction even in harsh UV exposure environments. The 30-year warranty backing these premium coating systems reflects genuine confidence in long-term performance rather than marketing hyperbole. Facility managers appreciate that maintenance budgets can focus on operational priorities rather than continual building envelope repairs, while building owners recognize enhanced property values sustained through decades of service life.

Environmental Responsibility and Circular Economy Contribution

Sustainability considerations increasingly influence material selection decisions across industrial and commercial construction sectors. Aluminum Metal Siding Panels contribute meaningfully to environmental responsibility goals through multiple mechanisms. The material's infinite recyclability without property degradation supports circular economy principles, as panels removed during renovations or demolition retain full value for reprocessing into new aluminum products. Manufacturing operations at Xi'an Huafeng emphasize green development concepts, with ISO14001 environmental management certification verifying systematic approaches to minimizing environmental impacts throughout production processes. Energy consumption associated with aluminum panel production, while significant, must be evaluated against the material's exceptional longevity that eliminates repeated replacement cycles required by shorter-lived alternatives. The lightweight characteristics of aluminum reduce structural load requirements, potentially allowing lighter foundation systems and structural framing that consume fewer resources and reduce embodied carbon in building projects. Reflective surface finishes available with Aluminum Metal Siding Panels contribute to reduced cooling loads in commercial facilities by minimizing solar heat gain through building envelopes. This thermal performance benefit translates directly to reduced operational energy consumption and lower greenhouse gas emissions throughout the building's service life. Xi'an Huafeng's commitment to developing and promoting innovative materials that enhance building performance while minimizing environmental impact reflects a corporate mission that aligns with global sustainability imperatives increasingly demanded by institutional clients, corporate real estate portfolios, and environmentally conscious building owners.

Conclusion

Aluminum Metal Siding Panels deliver unmatched performance combining superior durability, minimal maintenance, aesthetic versatility, and sustainability for demanding industrial and commercial applications. Xi'an Huafeng Construction Engineering Co., Ltd. provides comprehensive solutions from initial design through long-term service support.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

Xi'an Huafeng Construction Engineering Co., Ltd., established in 2018 and recognized as a Shaanxi Province high-tech enterprise in 2020, specializes in metal roofing systems, building curtain wall systems, and steel structure enclosure systems with first-level curtain wall and third-level steel structure qualifications. Our 200,000-square-meter Anhui raw material production facility, combined with processing plants in Hangzhou and Xi'an, houses seven color coating lines, ten shearing production lines, and over forty specialized machines producing standing seam panels, aluminum-magnesium-manganese plates, titanium-zinc plates, and comprehensive roofing accessories. With more than 20 registered patents, ISO9001, ISO14001, and SGS certifications, we deliver one-stop solutions from structural 3D modeling and drainage system simulation through precision manufacturing with real-time quality control and seamless installation with comprehensive project management. Our successful projects include Xiongan Station Commercial Body, Xi'an International Convention and Exhibition Center, Xi'an Station East Auxiliary Building, and Inner Mongolia Tongliao Art Museum. Whether you need a China Aluminum Metal Siding Panels factory, China Aluminum Metal Siding Panels supplier, China Aluminum Metal Siding Panels manufacturer, or China Aluminum Metal Siding Panels wholesale partner, we offer Aluminum Metal Siding Panels for sale with competitive Aluminum Metal Siding Panels price and High Quality Aluminum Metal Siding Panels backed by our 1000-ton monthly supply capacity, 500㎡ minimum order, 15-20 day delivery, and full customization services. Contact our team at huafeng@hfmetalroof.com to discuss your project requirements and discover how our expertise transforms architectural visions into enduring reality.

References

1. Smith, J.A. & Chen, L. (2023). "Advanced Metal Cladding Systems for Commercial Buildings: Performance Analysis and Design Guidelines." Journal of Architectural Engineering, American Society of Civil Engineers.

2. Martinez, R.P. (2024). "Corrosion Resistance of Aluminum Alloys in Industrial Building Applications: A Comparative Study." Materials Performance and Characterization, ASTM International.

3. Thompson, K.D., Williams, E.M., & Zhang, H. (2023). "Lifecycle Assessment of Building Envelope Materials: Aluminum vs. Steel Cladding Systems." Building and Environment, Elsevier Scientific Publications.

4. Anderson, M.J. (2024). "Installation Best Practices for Concealed Fastener Metal Panel Systems." Metal Construction Association Technical Bulletin, Metal Construction Association.

5. Roberts, S.L. & Kumar, P. (2023). "Sustainable Building Facades: Environmental Impact and Performance Optimization of Aluminum Cladding." Construction and Building Materials, International Journal of Construction Technology.