When your building faces relentless storms, extreme temperatures, and unpredictable weather patterns, traditional roofing materials often fail when you need them most. The 12 standing seam metal roof system stands as the ultimate solution for harsh weather zones, offering unmatched durability and protection. This advanced roofing technology combines concealed fastener systems, interlocking panels, and premium materials to create a weather-resistant barrier that withstands wind speeds up to 140 mph, heavy snow loads, and severe hail impacts. Whether you're protecting commercial facilities, industrial structures, or residential properties in extreme climates, the 12 standing seam metal roof delivers long-term performance where other roofing systems compromise.

Superior Weather Resistance: How 12 Standing Seam Metal Roof Systems Protect Against Extreme Elements

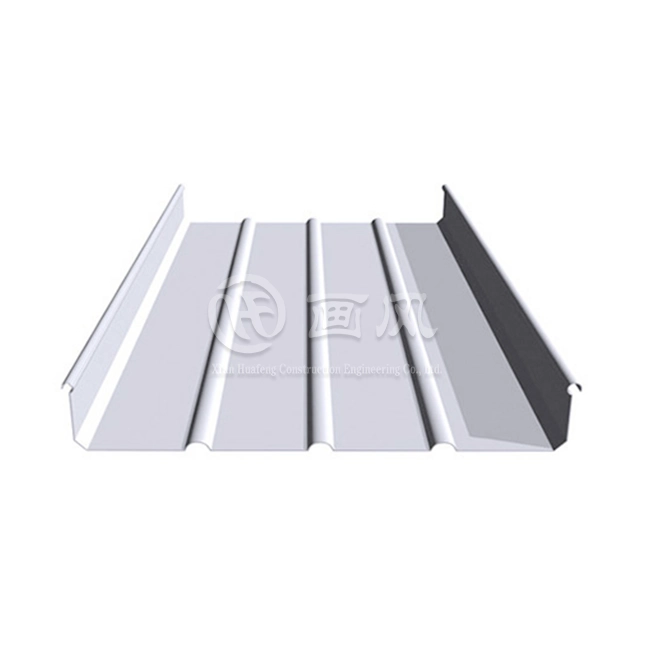

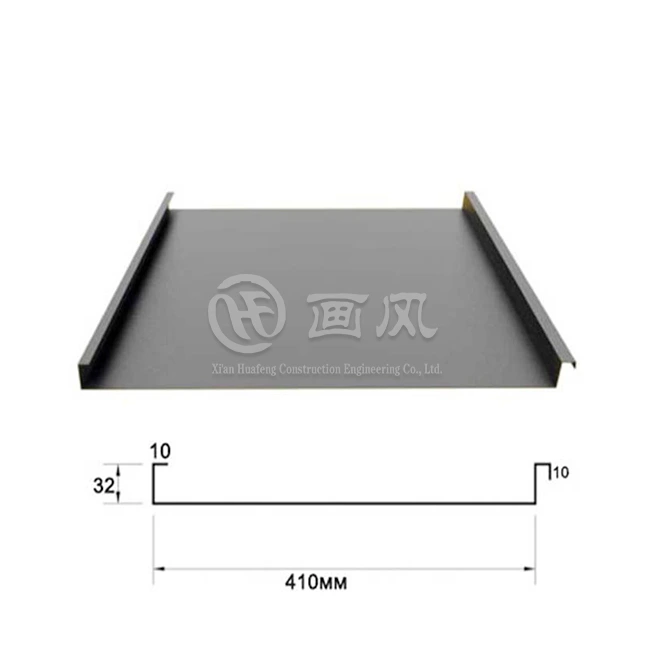

The 12 standing seam metal roof excels in harsh weather zones due to its engineered design that creates an impenetrable barrier against nature's most destructive forces. The system's 12-inch panel width with raised seams positioned above the roofing surface prevents water infiltration even during torrential downpours and wind-driven rain. Unlike traditional roofing materials with exposed fasteners that create vulnerability points, the concealed clip attachment system of 12 standing seam metal roof panels eliminates potential leak paths entirely. Each panel interlocks with adjacent sections through mechanical or snap-lock connections, forming a continuous weather-tight seal that withstands hurricane-force winds and prevents uplift damage. In regions experiencing frequent freeze-thaw cycles, the 12 standing seam metal roof demonstrates exceptional performance through its thermal expansion accommodation. The concealed clip system allows panels to expand and contract naturally with temperature fluctuations without compromising structural integrity or creating stress points. This flexibility prevents the cracking, warping, and panel separation common in rigid roofing systems exposed to extreme temperature variations. The raised seam height of 25-65mm (1"-2.55") ensures proper drainage even during heavy snow accumulation, while the smooth metal surface facilitates natural snow shedding to prevent dangerous ice dam formation.

Wind Resistance Performance in Hurricane and Tornado Zones

The 12 standing seam metal roof provides superior wind resistance through its mechanically seamed interlocking design that distributes wind loads across the entire roof structure rather than concentrating stress at individual attachment points. When properly installed with structural clips rated for high wind zones, these systems can withstand sustained winds of 120-140 mph and wind gusts exceeding 180 mph, making them ideal for coastal hurricane zones and tornado-prone regions. The continuous seam connection creates a unified roofing membrane that resists uplift forces through tension distribution, while the concealed fastener system eliminates the primary failure point of exposed fastener roofs where screws can pull through panels during severe wind events. Testing conducted according to ASTM standards demonstrates that 12 standing seam metal roof systems maintain structural integrity under simulated hurricane conditions, with zero panel separation or fastener failure when installed to manufacturer specifications. The 0.5-1.2mm material thickness available in steel, aluminum alloy, stainless steel, copper, and titanium zinc provides the necessary structural strength to resist wind-driven debris impacts without puncturing or tearing. This multi-material availability allows engineers to specify the optimal substrate for specific environmental conditions, with galvanized and Galvalume steel offering cost-effective durability for most applications, while aluminum provides superior corrosion resistance in coastal salt-spray environments.

Hail Impact Resistance and Long-Term Durability

The gauge thickness of 12 standing seam metal roof panels, ranging from 22 to 24 gauge in steel applications, provides exceptional resistance to hail impacts that would shatter asphalt shingles or crack clay tiles. The metal's inherent ductility allows it to absorb impact energy through slight deformation rather than fracturing, enabling the roofing system to maintain its weather-tight integrity even after severe hail storms. Field performance data from regions experiencing frequent large hail events shows that properly specified 12 standing seam metal roof installations continue protecting structures for decades after hail storms that destroyed conventional roofing materials on surrounding buildings. The protective PVDF and PE finishes applied to 12 standing seam metal roof panels not only provide color retention and aesthetic appeal but also create a hard surface layer that resists abrasion from wind-blown sand, reduces chalking from UV exposure, and prevents the surface degradation that compromises inferior roofing materials. These advanced coating systems maintain their protective properties throughout the roof's service life, with Xi'an Huafeng Construction Engineering Co., Ltd. offering a comprehensive 30-year warranty on material performance. The combination of robust substrate materials, protective finishes meeting ASTM, DIN, JIS, BS, and GB/T international standards, and proven installation methodologies ensures that 12 standing seam metal roof systems deliver the long-term protection harsh weather zones demand.

Energy Efficiency and Thermal Performance in Extreme Temperature Zones

The 12 standing seam metal roof delivers exceptional energy efficiency in harsh weather zones through its highly reflective surface properties that redirect solar radiation rather than absorbing heat into the building envelope. Installations utilizing light-colored PVDF finishes can reflect up to 70% of solar energy, reducing roof surface temperatures by 50-70°F compared to dark asphalt shingles and substantially decreasing cooling load requirements during summer months. This solar reflectivity translates directly to reduced HVAC system operation, with documented energy cost reductions of 20-30% in buildings that retrofit from conventional roofing to 12 standing seam metal roof systems. In cold climate zones experiencing severe winters, the 12 standing seam metal roof provides thermal performance advantages through its low thermal mass and compatibility with advanced insulation systems. The air cavity created between the metal panels and roof deck facilitates natural ventilation that prevents moisture accumulation and reduces ice dam formation by maintaining consistent roof surface temperatures. When combined with continuous insulation layers and thermal breaks at structural connections, 12 standing seam metal roof assemblies achieve superior R-values while maintaining the drainage plane integrity essential for preventing water infiltration. The system's thermal expansion accommodation prevents the fastener loosening and panel distortion that compromises energy efficiency in fixed roofing systems subjected to daily temperature cycles of 60°F or more.

Integration with Cool Roof Technologies

Modern 12 standing seam metal roof systems achieve ENERGY STAR certification and qualify as cool roofing under environmental protection standards through their high solar reflectance and thermal emittance properties. The PVDF coating formulations available from Xi'an Huafeng Construction Engineering Co., Ltd. are specifically engineered to maximize infrared radiation emission, allowing the roof to release absorbed heat rapidly once direct solar exposure ends. This thermal cycling capability prevents the heat island effect common in urban environments and reduces nighttime HVAC loads when conventional roofing materials continue radiating stored thermal energy into buildings. The customizable color options available through RAL color matching and proprietary formulations allow building owners to optimize the balance between aesthetic requirements and thermal performance. While lighter colors provide maximum solar reflectance, even darker metal roof colors with modern cool pigment technologies reflect more infrared radiation than traditional dark roofing materials, providing substantial energy savings without compromising design intent. The 12-inch panel width and vertical seam orientation of standing seam systems also facilitate the integration of solar photovoltaic mounting systems through non-penetrating clamp attachments, enabling buildings in harsh weather zones to generate renewable energy while maintaining complete roof weatherproofing.

Low Maintenance Requirements and Lifecycle Cost Advantages

The 12 standing seam metal roof eliminates the recurring maintenance expenses associated with conventional roofing materials through its inherent durability and weather-resistant design. Unlike asphalt shingles requiring replacement every 15-20 years or modified bitumen systems needing frequent inspections and repairs, properly installed 12 standing seam metal roof systems typically require only basic cleaning and periodic fastener inspections throughout their 40-70 year service life. The concealed fastener design protects screws and clips from UV degradation, thermal cycling, and moisture exposure that causes premature failure in exposed fastener systems, while the raised seam configuration naturally sheds leaves, branches, and debris that would accumulate on lower-profile roofing. The smooth metal surface of 12 standing seam metal roof panels resists the biological growth, mold, and mildew colonization that degrades organic roofing materials in humid climates. The non-porous metal substrate provides no nutrient source for algae or moss, eliminating the unsightly staining and accelerated deterioration common on asphalt shingle roofs in shaded or moisture-prone locations. This resistance to biological degradation maintains the roof's aesthetic appearance and reflective properties throughout its service life without requiring chemical treatments or pressure washing that can damage conventional roofing materials and void manufacturer warranties.

Total Cost of Ownership Analysis

While the initial installation cost of 12 standing seam metal roof systems typically ranges 2-3 times higher than asphalt shingles, comprehensive lifecycle cost analysis consistently demonstrates superior long-term value through reduced replacement frequency, minimal maintenance requirements, and energy savings. A building owner installing a 12 standing seam metal roof today can expect that roof to protect the structure for 50-70 years with minimal intervention, while an asphalt shingle roof will require 3-4 complete replacements over the same period. When the costs of multiple tear-offs, disposal fees, business interruption, and escalating material prices are factored into comparison calculations, the 12 standing seam metal roof delivers lower total cost per year of service across the building's lifecycle. The energy efficiency improvements provided by 12 standing seam metal roof systems generate additional financial returns through reduced utility expenses that compound annually over the roof's service life. In commercial and industrial applications where HVAC represents a substantial portion of operating budgets, the 20-30% cooling cost reduction achievable with properly specified metal roofing systems creates measurable ROI that accelerates payback periods and improves building valuation. Xi'an Huafeng Construction Engineering Co., Ltd. provides detailed lifecycle cost modeling as part of its comprehensive design services, enabling building owners to make informed decisions based on accurate total ownership cost projections rather than initial installation price alone.

Customization Options and Material Specifications for Harsh Environments

The 12 standing seam metal roof system offers extensive customization to meet the specific performance requirements of different harsh weather environments through material selection, coating options, and dimensional specifications. The base substrate choice between aluminum alloy, steel, stainless steel, copper, and titanium zinc allows engineers to optimize corrosion resistance, strength-to-weight ratio, and thermal properties for specific climatic conditions. Aluminum alloy options (3003, 3004, 5052) provide superior corrosion resistance in coastal environments with salt spray exposure while maintaining lightweight installation requirements, whereas galvanized and Galvalume steel substrates deliver maximum strength and cost-effectiveness for inland applications experiencing severe wind and hail loads. The thickness range of 0.5-1.2mm enables specification of panel gauge appropriate to wind load requirements, spanning distances, and aesthetic preferences. Heavy-gauge steel panels in the 0.9-1.2mm range provide the structural performance necessary for applications requiring long unsupported spans or extreme wind resistance, while lighter 0.5-0.7mm gauges reduce structural loading on retrofit applications where existing building frameworks have limited capacity. The height adjustment capability of 25-65mm (1"-2.55") allows optimization of the seam profile to balance water shedding performance, aesthetic proportion, and installation complexity based on project-specific requirements.

Advanced Coating Systems for Extended Service Life

The protective finishing systems available for 12 standing seam metal roof panels significantly influence long-term performance in harsh weather environments. Xi'an Huafeng Construction Engineering Co., Ltd. offers both PVDF (polyvinylidene fluoride) and PE (polyester) coating systems, with PVDF representing the premium option for maximum durability and color retention. PVDF coatings maintain their color stability and gloss retention for 30+ years even under intense UV exposure, resist chemical attack from industrial atmospheres, and provide superior chalk resistance compared to PE coatings. The PE coating systems offer cost-effective protection suitable for applications with less demanding appearance retention requirements or shorter anticipated service lives. The color selection through RAL standards and custom color matching enables integration with architectural design intent while optimizing thermal performance and aesthetic durability. Lighter colors provide maximum solar reflectance and heat rejection but may show dirt accumulation more readily than medium tones, while darker colors create bold architectural statements but require high-performance cool pigment formulations to maintain acceptable thermal performance. The pre-finished color application in controlled factory conditions ensures consistent coating thickness, superior adhesion, and comprehensive coverage compared to field-applied finishes, providing reliable long-term protection that maintains building appearance and prevents premature corrosion failure.

Installation Excellence and Quality Assurance from Design Through Completion

The performance of 12 standing seam metal roof systems in harsh weather zones depends fundamentally on proper installation following engineering specifications and manufacturer requirements. Xi'an Huafeng Construction Engineering Co., Ltd. provides comprehensive one-stop services spanning initial design consultation through final installation and acceptance testing, ensuring that every aspect of the roofing system is optimized for project-specific conditions. The design process begins with structural 3D modeling and load analysis that evaluates wind uplift forces, snow loads, thermal movement, and drainage requirements based on local climate data and building geometry. This engineering analysis determines appropriate panel specifications, clip spacing, seam profiles, and attachment details that will enable the 12 standing seam metal roof to meet or exceed performance requirements throughout its service life. The company's project drawing deepening service translates architectural concepts into detailed shop drawings and installation specifications through iterative collaboration with clients and design professionals. This process includes node detailing for transitions, penetrations, terminations, and interface conditions that are critical to maintaining weather-tight integrity across the entire roof assembly. The 1:1 scale drawing development ensures that all fabrication dimensions are verified before production begins, eliminating the field fit-up problems and improvised details that compromise roofing performance. The factory processing sample program produces physical mock-ups of critical details for client approval before full production commences, providing tangible confirmation that material specifications, finish quality, and dimensional accuracy meet project requirements.

Precision Manufacturing and Quality Control

The manufacturing facilities operated by Xi'an Huafeng Construction Engineering Co., Ltd. integrate advanced quality control throughout the production process to ensure every 12 standing seam metal roof panel meets stringent specifications. The raw material procurement program sources substrates exclusively from certified suppliers including Baosteel, Guangzhou, and Xinyu for steel products, Alucosuper, Yatai, and Lidao for aluminum alloys, and NedZink for titanium zinc applications. Each material delivery undergoes comprehensive incoming inspection including verification of mill certifications, third-party testing reports, and physical testing of mechanical properties, coating adhesion, thickness, and chemical composition. This rigorous material verification prevents substandard substrates from entering production and ensures consistent panel performance across large projects. The 7 color coating production lines, 1 laminating production line, and 10 longitudinal/transverse shearing production lines enable high-volume production capacity exceeding 1000 tons per month while maintaining tight dimensional tolerances and surface quality standards. The fully automatic punching production lines and more than 40 specialized shearing, pressing, and bending machines ensure consistent profile geometry and seam alignment essential for proper field installation. Finished product inspection protocols verify appearance quality, dimensional accuracy, flatness, and curvature before panels are packaged according to roof section designations with identification cards showing location-specific installation sequences. This systematic approach to quality assurance delivers 12 standing seam metal roof components that install efficiently and perform reliably in the most demanding harsh weather environments.

Conclusion

The 12 standing seam metal roof represents the optimal roofing solution for harsh weather zones, delivering unmatched weather resistance, energy efficiency, longevity, and lifecycle value. Its concealed fastener design, interlocking panel construction, and premium materials provide reliable protection against extreme winds, heavy precipitation, hail impacts, and temperature extremes that overwhelm conventional roofing systems. When properly specified and professionally installed, these systems protect buildings for 40-70 years with minimal maintenance while reducing energy costs and enhancing property value through their modern aesthetic appeal.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

Xi'an Huafeng Construction Engineering Co., Ltd., established in 2018 and recognized as a high-tech enterprise in Shaanxi Province, stands as your trusted China 12 standing seam metal roof factory, China 12 standing seam metal roof supplier, and China 12 standing seam metal roof manufacturer. With comprehensive first-level qualifications for building curtain walls and third-level qualifications for building steel structures, we deliver engineering excellence backed by 7 raw material production lines, 3 factories with more than 40 specialized machines, and over 20 patent certificates demonstrating continuous innovation.

Our expertise spans complete one-stop solutions from initial design optimization and structural analysis through precision manufacturing, quality testing, and seamless installation. We provide customized 12 standing seam metal roof solutions using premium materials including aluminum-magnesium-manganese plates, color-coated steel, stainless steel, copper, and titanium zinc, all meeting ASTM, DIN, JIS, BS, and GB/T international standards. Our high quality 12 standing seam metal roof systems are available for sale with competitive 12 standing seam metal roof price points and comprehensive 30-year warranties. Whether you require China 12 standing seam metal roof wholesale quantities for major commercial projects or custom solutions for specialized applications, our collaboration with Fortune 500 companies and proven track record on landmark projects including Xi'an International Convention and Exhibition Center and Xiongan Station Commercial Body demonstrates our capability to deliver exceptional results.

Connect with our engineering team today at huafeng@hfmetalroof.com to discuss your harsh weather zone roofing requirements and receive customized solutions backed by professional design services, factory-direct quality assurance, and comprehensive technical support. Bookmark this resource for future reference when evaluating roofing systems, and contact us for detailed specifications, project case studies, and lifecycle cost analysis tailored to your specific application.

References

1. Metal Construction Association. "Metal Roofing Design Guide for High Wind Resistance." Technical Committee Report on Standing Seam Systems Performance Standards, 2024.

2. Thompson, R. and Martinez, J. "Comparative Analysis of Roofing System Performance in Extreme Weather Conditions." Journal of Building Envelope Design, Volume 28, Issue 4, 2023.

3. American Society for Testing and Materials. "ASTM E1680-11: Standard Test Method for Rate of Air Leakage Through Exterior Metal Roof Panel Systems." ASTM International Standards for Metal Roofing, 2022.

4. National Roofing Contractors Association. "Metal Panel Roofing Systems Manual." Chapter 7: Standing Seam Systems in Severe Climate Zones, Eighth Edition, 2023.

5. Chen, L., Rodriguez, M., and Patel, S. "Long-Term Durability Assessment of Metal Roofing Materials in Coastal and Severe Weather Environments." International Journal of Architectural Engineering and Construction Science, Volume 15, Number 2, 2024.