High-end architectural projects demand cladding solutions that deliver both exceptional aesthetics and long-term performance. Traditional facade materials often fail when exposed to harsh weather conditions, requiring frequent maintenance and costly replacements. Zinc Flat Lock Panels emerge as the premium solution for architects and developers seeking a facade system that combines timeless elegance with proven durability. This comprehensive guide explores how Zinc Flat Lock Panels transform building exteriors into architectural statements while providing decades of reliable service in the most demanding environments.

Understanding Zinc Flat Lock Panel Technology for Premium Facades

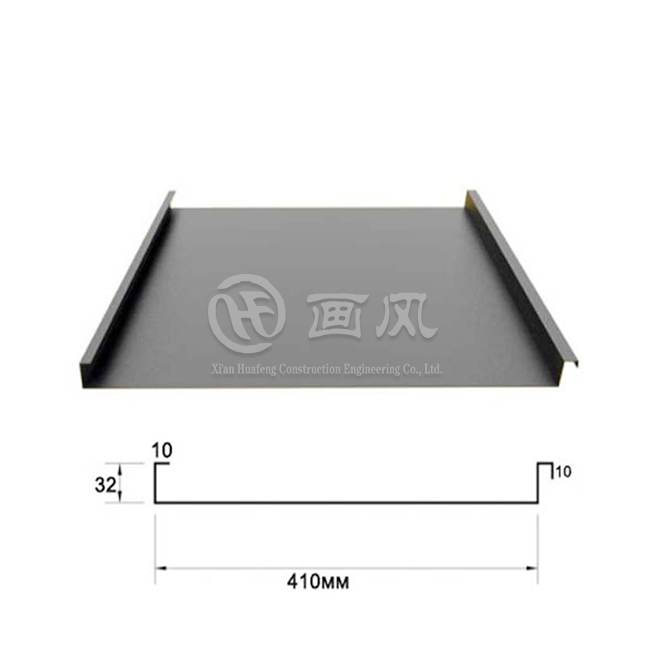

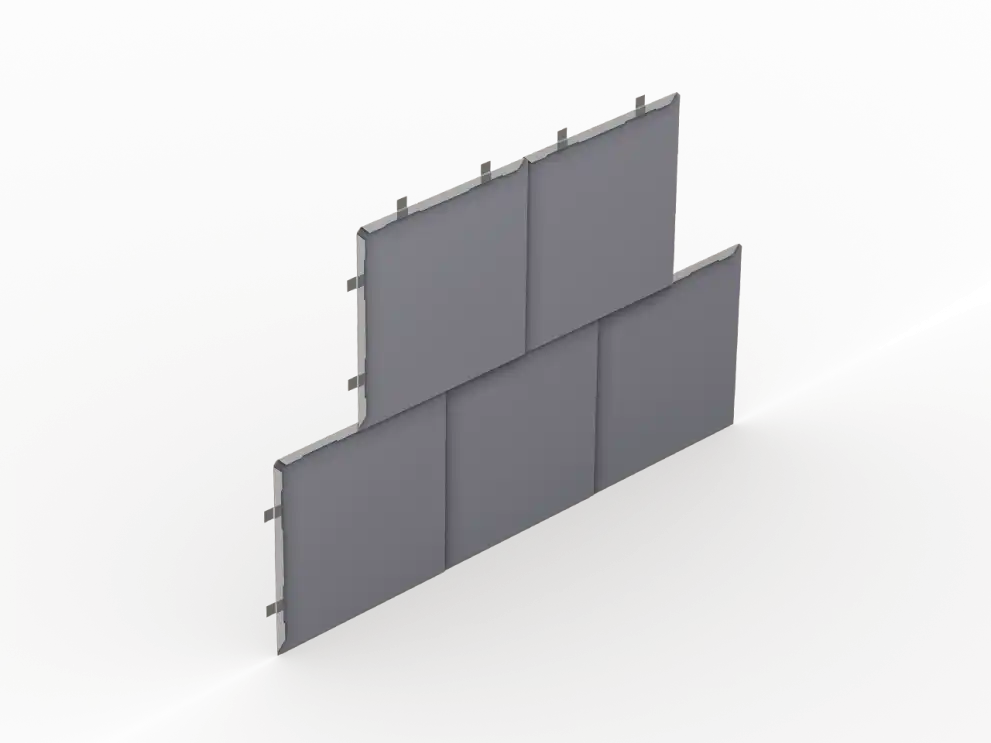

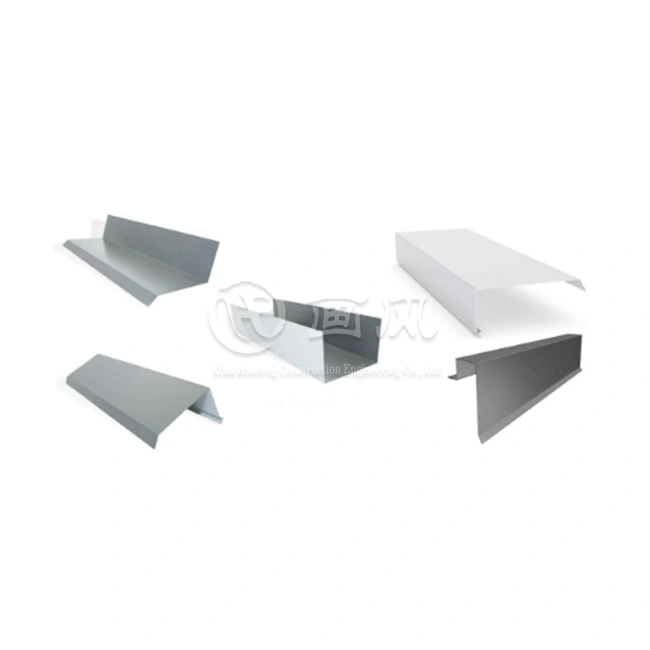

Zinc Flat Lock Panels represent a sophisticated architectural cladding system manufactured from titanium zinc alloy containing 99.995% pure zinc enhanced with titanium and copper. This flat lock connection method creates interlocking panels with precisely engineered 180-degree hems approximately one inch wide, forming a nearly seamless exterior surface. The panels connect through concealed sliding clips that allow natural thermal expansion while maintaining structural integrity. This traditional yet technologically advanced system has been refined over decades to meet modern performance standards including ASTM E330 wind resistance requirements and Class A fire ratings. The flat lock design produces a subtle stepped appearance between panels, typically creating an eight-millimeter shadow line that adds visual depth and texture to building facades. Unlike exposed fastener systems, Zinc Flat Lock Panels utilize hidden attachment mechanisms that preserve the clean aesthetic while eliminating potential water infiltration points. The manufacturing process involves precision roll-forming or brake-forming techniques using high-grade titanium zinc sheets ranging from 0.7mm to 1.0mm thickness, with 0.8mm being the industry standard for optimal balance between workability and structural performance.

Material Composition and Performance Characteristics

The titanium zinc alloy used in premium Zinc Flat Lock Panels incorporates carefully controlled proportions of titanium and copper to enhance mechanical properties and patina formation. This specialized composition enables the material to develop a protective natural patina layer that shields the underlying metal from corrosion while creating distinctive aesthetic qualities. The patina typically evolves from bright metallic zinc to blue-gray tones in most environments, with variations depending on local climate conditions and atmospheric composition. In marine environments where salt-laden air predominates, the patina tends toward lighter shades, while urban industrial settings may produce darker graphite-gray appearances. This self-healing characteristic means surface scratches and minor damage naturally blend into the surrounding patina over time without requiring touch-up paint or remediation. The material demonstrates exceptional resistance to UV degradation, maintaining color stability and structural integrity through decades of direct sunlight exposure. Zinc Flat Lock Panels withstand temperature extremes from negative forty degrees to sustained high heat without warping, cracking, or compromising weather-tight seals. The inherent antimicrobial properties of zinc surfaces prevent biological growth that can deteriorate other facade materials, particularly in humid climates.

Design Flexibility and Architectural Applications

Zinc Flat Lock Panels accommodate virtually unlimited design possibilities through customizable dimensions, shapes, and installation orientations. Standard rectangular panels can be specified in widths from 200mm to 600mm with lengths extending to two meters or more, while diamond, rhombus, trapezoid, and hexagonal configurations enable distinctive pattern creation. Architects utilize these geometric variations to establish unique visual rhythms across building facades, creating signature appearances that distinguish landmark structures. The panels install successfully in horizontal, vertical, or diagonal orientations, allowing designers to emphasize specific architectural features or create dynamic visual movement. Complex building geometries including curved surfaces, rounded corners, and irregular profiles accommodate Zinc Flat Lock Panels through smaller tile formats that flex to follow building contours. For convex and concave facades, panels can be pre-formed to match specific radii, ensuring proper fit and maintaining consistent appearance across challenging architectural elements. This adaptability extends to building types ranging from cultural institutions and commercial towers to residential complexes and transportation facilities. Historic renovation projects particularly benefit from Zinc Flat Lock Panels, as the system successfully replicates traditional metal roof and wall appearances while incorporating modern performance enhancements.

Superior Weatherproofing and Climate Resilience

High-end facades must deliver absolute protection against water infiltration, wind-driven rain, and extreme weather events that threaten building envelope integrity. Zinc Flat Lock Panels achieve exceptional weatherproofing through the combination of overlapping panel design and concealed sealing mechanisms that create multiple barriers against moisture penetration. The flat lock connection itself forms the primary weather defense, with each panel's upper hem overlapping the adjacent panel's lower hem to shed water effectively down the facade surface. Behind this visible protection, continuous sealing strips provide secondary weather resistance while accommodating thermal movement. The system's wind resistance capabilities meet stringent testing standards, with properly installed Zinc Flat Lock Panels withstanding sustained winds exceeding 150 miles per hour in hurricane-prone regions. This performance stems from the secure mechanical connection between panels and their concealed clip attachment to structural substrates, distributing wind loads across the entire facade rather than concentrating stress at individual fastening points. The natural drainage characteristics of the flat lock profile prevent water accumulation that could lead to ice dam formation in cold climates or promote biological growth in warm humid environments.

Long-Term Durability and Maintenance Advantages

Zinc Flat Lock Panels deliver service lifespans extending from 80 to 100 years or more with minimal maintenance requirements, dramatically outperforming alternative facade materials that demand frequent intervention. The protective patina layer that develops naturally on exposed zinc surfaces provides continuous corrosion resistance that actually strengthens over time rather than degrading. This self-renewing characteristic eliminates the need for protective coatings, paint refreshing, or surface treatments that burden building owners with ongoing expense and disruption. Routine maintenance consists primarily of periodic rinsing with clean water to remove accumulated dirt and debris, particularly in marine environments where salt deposits might otherwise accelerate surface weathering. The concealed fastener system prevents exposure of connection points to weathering, eliminating common failure modes associated with exposed fastener corrosion and sealant deterioration. When panels do require replacement due to damage from impacts or other extraordinary events, the interlocking design enables individual panel removal and replacement without disturbing adjacent sections. This repairability extends the practical service life indefinitely, as localized damage never necessitates complete facade replacement. The material's inherent recyclability ensures that zinc removed during renovation or demolition retains full value, with recycled zinc requiring only five percent of the energy needed for primary zinc production.

Sustainable Building Performance and Environmental Benefits

Contemporary architectural projects increasingly prioritize environmental responsibility and sustainable material selection to achieve green building certifications and reduce operational carbon footprints. Zinc Flat Lock Panels align with these objectives through multiple sustainability attributes that benefit both project stakeholders and the broader environment. The material's 100-percent recyclability without quality degradation enables true circular economy participation, as end-of-life panels return to manufacturing streams for conversion into new architectural products. Primary zinc production generates relatively low carbon emissions compared to alternative metals, while the extreme durability of installed Zinc Flat Lock Panels eliminates the embodied carbon associated with frequent replacement cycles required by less durable materials. The natural patina formation process occurs without chemical treatments or applied coatings that introduce volatile organic compounds or other pollutants into building environments. Zinc's thermal properties contribute to building energy efficiency by reflecting solar heat gain during summer months while providing effective thermal mass during winter conditions. The lightweight nature of Zinc Flat Lock Panels reduces structural requirements compared to heavier cladding systems, enabling material savings in building frames and foundations that compound environmental benefits.

Contribution to Green Building Certification

Zinc Flat Lock Panels support achievement of LEED, BREEAM, Green Globes, and other recognized green building rating systems through multiple performance categories. The material's recycled content, low embodied energy, and extended service life contribute points in materials and resources credits while reducing lifecycle environmental impacts. Local manufacturing capabilities in multiple regions minimize transportation distances and associated carbon emissions from product delivery to project sites. The absence of toxic components ensures that zinc weathering does not leach heavy metals or harmful substances into soil or water systems surrounding buildings. Installation processes generate minimal waste, as panels fabricate to precise dimensions with efficient material utilization and any trim scrap remains fully recyclable. The thermal performance of properly detailed Zinc Flat Lock Panel systems reduces heating and cooling loads, contributing to energy and atmosphere credits in most rating systems. Documentation including environmental product declarations, health product declarations, and cradle-to-cradle certifications supports transparent material evaluation and informed decision-making throughout the design and specification process.

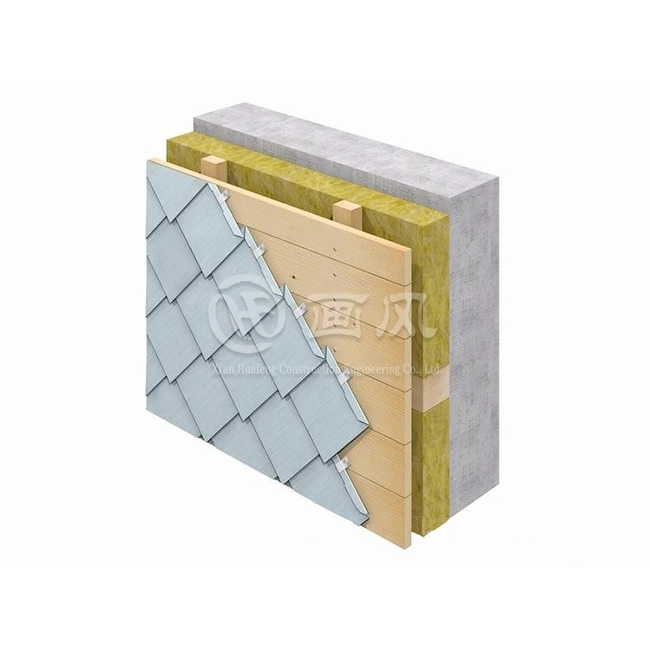

Professional Installation and Quality Assurance

Successful Zinc Flat Lock Panel performance depends fundamentally on proper installation following manufacturer specifications and industry best practices developed through decades of field experience. The system requires continuous vented substrates that provide adequate structural support while enabling air circulation behind panels to prevent moisture accumulation and condensation damage. Installation typically progresses from bottom to top in sequential order, with each panel's concealed clips fixed to substrate framing at predetermined intervals calculated to resist anticipated wind loads and accommodate thermal movement. Qualified contractors utilize specialized tools including edge-locking machines, seaming hammers, and precision measuring instruments to ensure accurate alignment and proper connection formation. Weather-resistant barriers and drainage planes integrate with Zinc Flat Lock Panel installations to create complete water management systems that channel any penetrating moisture safely to exterior without compromise to building interiors. Quality control procedures verify substrate flatness, clip spacing, panel alignment, and seam integrity throughout installation, with comprehensive documentation demonstrating compliance with project specifications. Final inspection protocols include water testing to confirm zero leakage under simulated rain conditions, ensuring the completed facade delivers promised performance.

Technical Support and Customization Services

Leading Zinc Flat Lock Panel manufacturers provide comprehensive technical assistance throughout project lifecycles, from initial design development through final commissioning and ongoing maintenance planning. Engineering teams conduct load analysis, drainage system simulation, and thermal movement calculations to optimize system performance for specific project conditions and geographic locations. Three-dimensional modeling capabilities enable visualization of proposed facade appearances and identification of potential installation challenges before fabrication begins. Custom panel fabrication accommodates unique project requirements including non-standard dimensions, special shapes, and coordinated color specifications that match architectural visions. Sample production allows stakeholders to evaluate actual materials, finishes, and installation techniques before committing to full-scale manufacturing, reducing uncertainty and ensuring satisfaction with final results. Detailed installation drawings and specifications guide field crews through proper procedures while documenting expected quality standards. Post-installation support includes periodic inspection services, maintenance guidance, and technical consultation to address any performance questions that arise during building operation.

Cost-Effective Investment for Premium Projects

While Zinc Flat Lock Panels command premium initial investment compared to economy facade materials, comprehensive lifecycle analysis consistently demonstrates superior economic value through reduced maintenance costs, extended service life, and enhanced property values. The elimination of painting, coating, and frequent repair requirements saves substantial ongoing expenditure over building lifespans measured in decades. Energy efficiency benefits contribute to reduced operational costs through lower heating and cooling demands compared to thermally inefficient cladding alternatives. Insurance considerations may favor zinc facades due to fire resistance, wind performance, and demonstrated durability in extreme weather events, potentially reducing premium costs. The architectural distinction and demonstrated longevity of Zinc Flat Lock Panel installations enhance property marketability and support premium rental or sale pricing in competitive real estate markets. Green building certification achievements enabled by zinc facades attract environmentally conscious tenants and buyers while qualifying properties for various incentive programs and tax benefits. The flexibility to install panels in various orientations and patterns enables budget optimization by emphasizing premium materials on highly visible facades while utilizing alternative approaches on less prominent elevations.

Conclusion

Zinc Flat Lock Panels deliver unmatched benefits for high-end facade systems through proven durability, design flexibility, weatherproofing excellence, sustainable performance, and lifecycle value that justify initial investment. These advanced cladding solutions transform architectural visions into lasting reality while protecting building envelopes for generations.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

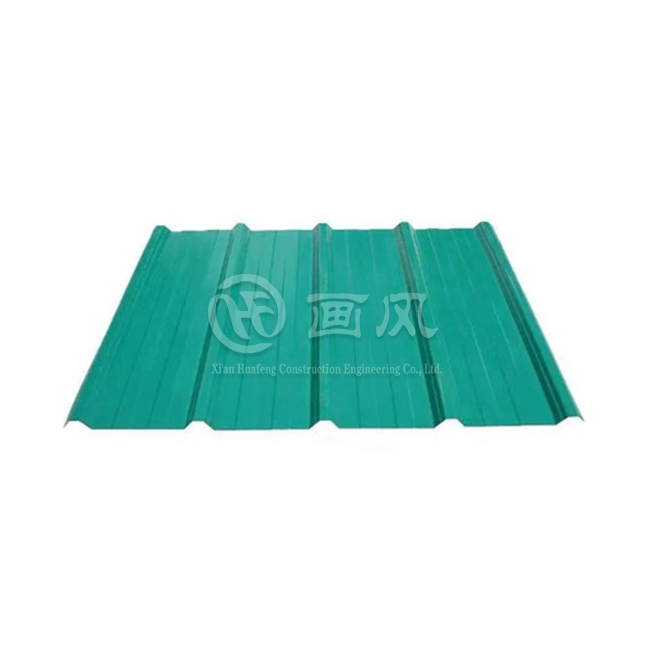

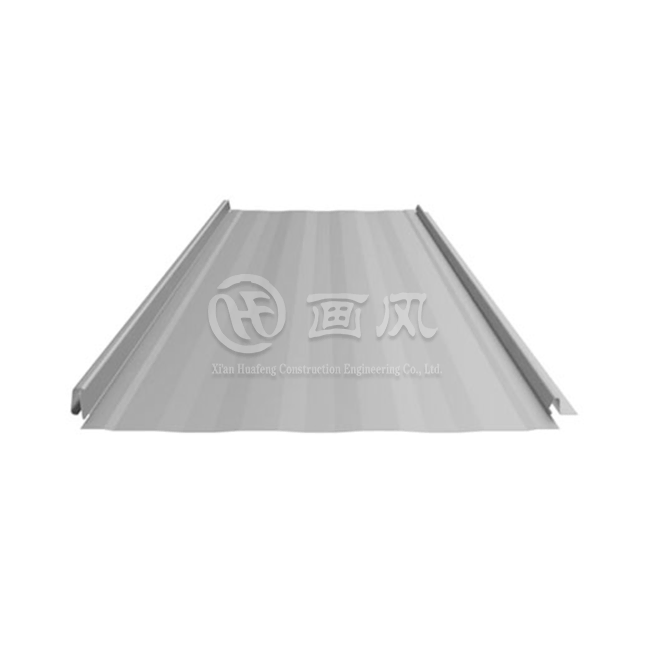

Xi'an Huafeng Construction Engineering Co., Ltd. stands as your trusted China Zinc Flat Lock Panels manufacturer and China Zinc Flat Lock Panels supplier, delivering High Quality Zinc Flat Lock Panels since 2018. As a certified high-tech enterprise with first-level building curtain wall qualifications and third-level steel structure credentials, we operate three factories spanning 200,000 square meters with seven color coating production lines and over 40 specialized machines ensuring 1000-ton monthly supply ability. Our comprehensive capabilities encompass design optimization, raw material quality testing through ISO9001, ISO14000:14001, and SGS certification standards, customized Zinc Flat Lock Panels production with competitive Zinc Flat Lock Panels price points, and complete one-stop service from engineering design through installation guidance. With over 20 registered patents and successful project delivery including Xiongan Station, Xi'an International Convention Center, and Inner Mongolia Tongliao Art Museum, we provide the expertise, manufacturing capacity, and technical support that Fortune 500 companies trust. Whether you need China Zinc Flat Lock Panels wholesale quantities or specialized Zinc Flat Lock Panels for sale, our team delivers titanium zinc solutions in customizable shapes, thicknesses from 0.7mm-1.0mm, widths to 600mm, and RAL color specifications with 15-20 day delivery. Experience the confidence of working with a China Zinc Flat Lock Panels factory that integrates architecture, technology, and aesthetics while maintaining strict quality control throughout every production phase. Contact us at huafeng@hfmetalroof.com to discuss your project requirements and discover how our engineering excellence and manufacturing precision can elevate your facade system to exceptional performance standards.

References

1. Copper Development Association, "Architectural Applications of Zinc Cladding Systems: Design and Performance Guidelines"

2. American Society for Testing and Materials, "ASTM E330 Standard Test Method for Structural Performance of Exterior Windows, Doors, Skylights and Curtain Walls by Uniform Static Air Pressure Difference"

3. Green Building Council Research Committee, "Lifecycle Assessment of Metal Facade Systems: Comparative Analysis of Environmental Performance"

4. International Zinc Association Technical Committee, "Zinc in Architecture: Material Properties, Applications and Sustainability Characteristics"

5. National Institute of Building Sciences, "Whole Building Design Guide: Metal Wall Panel Systems - Selection and Installation Best Practices"

_1757558889992.webp)