Are you tired of dealing with leaking roofs, expensive repairs, and the constant worry about weather damage? Installing Snaplock roofing panels offers a revolutionary solution that transforms traditional roofing challenges into a streamlined, durable system. This comprehensive guide walks you through every step of installing Snaplock standing seam metal roofing panels on your house, from initial preparation to final inspection. Whether you're a professional contractor or an ambitious DIY homeowner, understanding the proper installation techniques for Snaplock roofing will ensure a watertight, long-lasting roof that protects your investment for decades to come.

Understanding Snaplock Roofing Systems and Pre-Installation Requirements

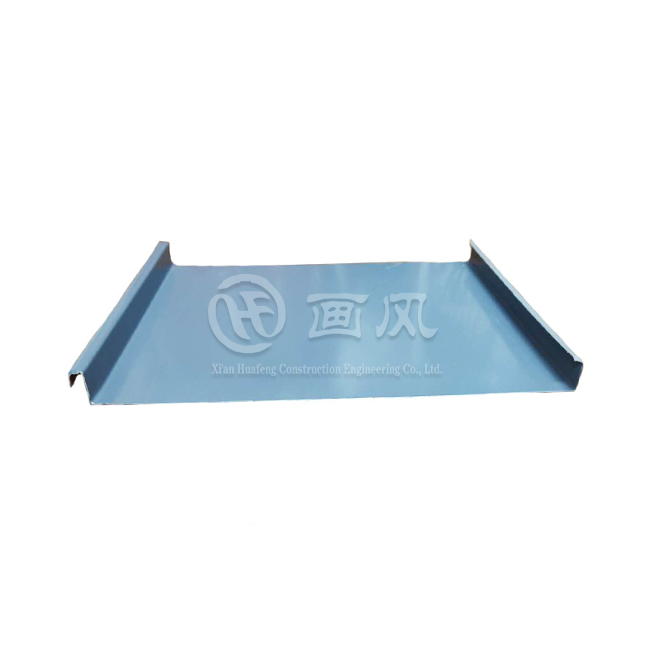

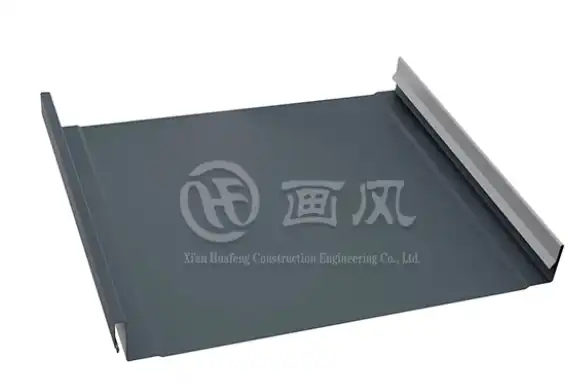

Before beginning any Snaplock roofing installation project, understanding the fundamental characteristics of this innovative system is essential for achieving optimal results. Snaplock roofing represents a significant advancement in metal roofing technology, combining the aesthetic appeal of traditional standing seam profiles with a simplified installation process that eliminates the need for expensive mechanical seaming equipment. Unlike conventional field-seamed metal roofing systems that require specialized crimping tools and extensive training, Snaplock roofing panels feature pre-engineered male and female edges that interlock together with minimal effort, creating a secure weathertight connection that allows for thermal expansion and contraction throughout seasonal temperature fluctuations. The system's design incorporates hidden fasteners secured through metal clips attached to the roof deck, which means the roofing surface remains free of exposed penetrations that could potentially compromise waterproofing integrity over time. This concealed fastener approach not only enhances the roof's aesthetic appearance with clean, uninterrupted lines but also significantly extends the system's service life by protecting fasteners from direct exposure to UV radiation, moisture, and thermal cycling. When selecting materials for your Snaplock roofing project, considerations include substrate options ranging from aluminum alloy and galvanized steel to stainless steel and copper, with thickness specifications typically ranging from 0.4mm to 1.2mm depending on structural requirements and local building codes.

-

Essential Tools and Materials for Snaplock Roofing Installation

Proper preparation with the correct tools and materials significantly impacts installation efficiency and final quality when working with Snaplock roofing systems. Professional installers recommend assembling a comprehensive toolkit that includes aviation snips or electric metal shears for precise panel cutting, a cordless drill with adjustable torque settings for fastener installation, measuring tapes and chalk lines for accurate layout marking, and specialized hand seamers or rubber mallets for engaging the snap-lock connections. Additionally, safety equipment including fall protection harnesses, non-slip footwear, and cut-resistant gloves are mandatory given the inherent risks of working at elevation with sharp-edged metal materials. Material procurement for Snaplok roofing installation extends beyond the panels themselves to include a complete system of compatible components. High-quality synthetic underlayment provides essential secondary water protection and should be selected over traditional felt paper for superior tear resistance and UV stability during extended exposure periods before panel installation. Metal clips specifically engineered for your chosen Snaplock roofing profile must be sourced to ensure proper panel retention while permitting necessary thermal movement. Closure strips, whether foam-based or profiled metal configurations, seal panel ends at eaves, ridges, and transitions to prevent water infiltration and pest entry while maintaining ventilation requirements where specified.

The substrate preparation phase demands attention to structural adequacy, with most building codes requiring minimum 15/32-inch structural plywood or 5/8-inch OSB sheathing supported on rafters spaced no more than 24 inches on center. Any irregularities in the roof deck, including warped boards, protruding fasteners, or uneven transitions between sheathing panels, must be corrected before underlayment installation to prevent telegraph-through imperfections that could manifest as oil-canning or dimpling in the finished Snaplock roofing surface. When working with pressure-treated lumber in any roof penetrations or mounting situations, installers must ensure proper isolation between treated wood and metal roofing components to prevent galvanic corrosion that could compromise system integrity over time.

Proper Deck Preparation and Underlayment Installation for Snaplock Roofing

Creating an ideal substrate for Snaplock roofing installation begins with meticulous roof deck preparation that addresses structural integrity, surface uniformity, and moisture management considerations. The underlying roof structure must meet or exceed local building code requirements for both dead load capacity from the roofing system itself and live loads including snow accumulation, maintenance access, and potential equipment installation such as solar arrays or HVAC units. Professional installers conduct thorough inspections of existing sheathing to identify and remediate any compromised areas showing signs of rot, delamination, or excessive deflection that could telegraph through to the finished Snaplock roofing surface or create unsupported spans that fail to properly secure metal clips. Surface preparation for Snaplok roofing systems demands particular attention to eliminating protrusions and depressions that could interfere with panel flatness or clip engagement. Protruding nail or screw heads from sheathing attachment must be driven flush or removed entirely, while gaps between sheathing panels wider than 1/4 inch should be filled with appropriate backing material to prevent sagging of underlayment or panels. When transitioning from roof tear-off projects where existing shingles are being removed, all residual roofing cement, nails, and debris must be cleared to provide a clean working surface. Some installation scenarios allow for Snaplock roofing panels to be installed over existing asphalt shingles provided proper vertical battens or purlins are installed to create adequate ventilation and provide a suitable fastening base that maintains the system's thermal expansion capabilities.

Synthetic underlayment installation represents a critical waterproofing layer that protects the building envelope during construction and provides long-term secondary weather resistance beneath the Snaplock roofing panels. Modern synthetic products offer substantial advantages over traditional felt papers, including superior tear resistance during installation, excellent UV stability allowing extended exposure without degradation, and enhanced walking surface traction for improved installer safety. Application begins at the eaves and progresses toward the ridge with each successive course overlapping the previous by at least six inches on horizontal seams and four inches at vertical end laps.

-

Establishing Accurate Panel Layout and Starting Lines

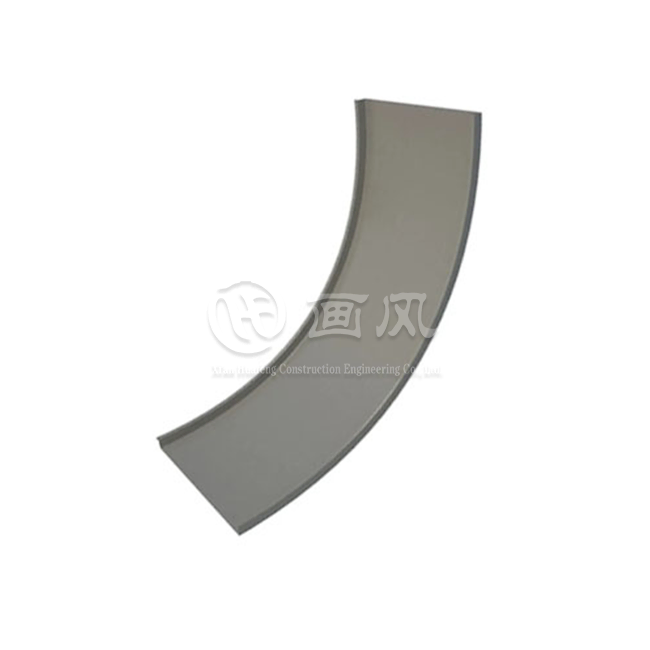

Precision in initial layout directly impacts the visual quality and weather performance of completed Snaplock roofing installations, making this preparatory phase one of the most critical steps in the entire process. Professional installers begin by carefully measuring and marking the roof to establish reference lines that will guide panel placement and ensure seams run perfectly straight from eave to ridge regardless of any out-of-square conditions in the existing roof structure. The first step involves determining panel orientation based on prevailing weather patterns, with the general principle being to start installation at the gable end opposite the direction of rain-bearing winds to minimize the potential for wind-driven moisture infiltration under panel laps. For gable roof configurations featuring Snaplok roofing on both slopes meeting at a central ridge, equal-width panels at both rake edges create the most aesthetically pleasing appearance and demonstrate attention to installation detail. Achieving this symmetry requires careful calculation of the roof width divided by the panel coverage width, with any remainder split equally and added to the width of the panels at each rake edge. This planning prevents the visually displeasing outcome of having full-width panels on one rake while the opposite side features a narrow strip that appears as an afterthought. Complex roof geometries incorporating valleys, dormers, or multiple ridgelines demand even more sophisticated layout planning to ensure standing seams align properly across architectural transitions and that panel widths maintain consistent visual rhythm throughout the installation.

Establishing the critical first chalk line requires measuring one full panel coverage width from the rake edge trim location and snapping a perfectly straight reference line from eave to ridge. This line serves as the alignment guide for positioning the first Snaplock roofing panel and must be verified for straightness at multiple points along its length. Any bow or irregularity in this initial reference line will compound across successive panel installations, potentially resulting in progressively worse alignment issues that become impossible to correct without removing and reinstalling panels. Experienced installers often verify their layout by dry-fitting several panels before permanent fastening to confirm spacing works correctly around roof penetrations, valleys, and other features that could create complications if not properly anticipated during the planning phase.

Step-by-Step Installation Process for Snaplock Roofing Panels

The actual installation sequence for Snaplock roofing panels follows a logical progression that ensures proper panel engagement, maintains alignment, and creates the weathertight envelope that defines quality metal roofing systems. Installation begins after all perimeter flashings including drip edges, rake trims, and valley flashings have been properly secured and sealed, as these components provide the foundation upon which panels terminate and must be in place before panel work commences. The first panel represents the most critical installation element since it establishes the reference position for all subsequent panels, making precise alignment along the previously marked chalk line absolutely essential for achieving professional results. Positioning the initial Snaplok roofing panel involves aligning its female edge exactly along the reference line while maintaining the specified overhang at the eave edge, typically 1 to 1-1/4 inches beyond the drip edge to ensure proper water shedding without back-flow beneath the roofing system. A bead of high-quality butyl sealant applied along the eave flashing provides additional weather protection at this vulnerable transition point where panel ends meet perimeter trim. Metal clips specifically designed for the Snaplock roofing profile are positioned according to manufacturer specifications, generally spaced 12 to 24 inches apart depending on local wind and snow load requirements, with closer spacing mandated for high-wind coastal regions or areas subject to significant uplift forces during severe weather events.

Each clip attaches to the roof deck through the underlayment using appropriate fasteners, with pancake-head screws being the standard choice for their low-profile heads that won't interfere with panel seating. Critical attention must be paid to fastener installation torque, as over-driven screws can dimple the clip and prevent proper panel engagement, while under-driven fasteners may allow clip movement that compromises the system's ability to secure panels against uplift. The panel's male edge then snaps over these installed clips, creating the mechanical interlock that simultaneously secures the panel while allowing the necessary lateral movement to accommodate thermal expansion and contraction without inducing stress that could cause fastener failure or panel distortion.

-

Installing Successive Panels and Maintaining Alignment

Continuation of Snaplock roofing panel installation requires systematic attention to maintaining precise alignment while efficiently progressing across the roof surface. The second panel installation demonstrates the fundamental snap-lock mechanism that defines this system's efficiency advantage, with the female edge of the new panel positioning over the male edge of the previously installed panel. A firm hand pressure or light mallet tapping along the seam engages the snap-lock connection, producing an audible click that confirms proper engagement. Professional installers develop a rhythm of positioning clips along the panel's attachment flange, securing them to the deck with proper fastener spacing, and then snapping the next panel into place with confident, even pressure that avoids over-stressing the connection. Alignment verification becomes crucial as installation progresses across the roof, with experienced installers frequently stepping back to visually confirm that standing seams remain perfectly vertical and evenly spaced. Small alignment deviations in early panels compound dramatically as installation continues, potentially resulting in panels that no longer align with valleys, ridges, or opposing roof slopes where visual continuity is critical for professional appearance. Periodic measurement from the installed panel edges back to the original rake edge confirms that cumulative installation hasn't drifted from the intended layout, allowing for minor adjustments in subsequent panels if necessary before alignment issues become uncorrectable.

Panel length management represents another critical consideration during Snaplok roofing installation, particularly on longer roof slopes where thermal expansion can be substantial. Panels are typically available in custom lengths up to 12 meters to minimize the need for horizontal end laps that create potential weak points in the weather envelope. However, transportation constraints or architectural features may necessitate shorter panel lengths with properly executed end laps using specialized closure systems. When end laps are required, they should occur in staggered patterns across the roof rather than aligning across multiple adjacent panels, and they must incorporate proper underlapping configurations with adequate sealant to prevent water infiltration during the most severe weather conditions.

Critical Details: Valleys, Ridges, and Penetration Flashing for Snaplock Roofing

Valley installations represent one of the most technically demanding aspects of Snaplock roofing systems, requiring careful attention to water management principles and proper flashing integration to prevent the leaks that commonly plague poorly executed valley details. Open valley configurations utilizing W-shaped valley flashing provide the most reliable long-term performance by creating a dedicated water channel that handles the concentrated flow where two roof slopes converge. The valley flashing, typically fabricated from material matching or exceeding the Snaplok roofing panel gauge and coating specification, installs over ice and water shield membrane that extends at least 12 inches to either side of the valley centerline for enhanced protection in this critical area. Snaplock roofing panels terminating at valley edges require precise measurement and cutting to create the proper alignment while maintaining adequate clearance from the valley center to allow unobstructed water flow. The panel cut edge typically receives a hemmed finish that adds rigidity and presents a clean appearance while eliminating the sharp edge that could pose safety concerns during installation and maintenance activities. Special valley clips or joggle cleats secure the panel ends without penetrating the valley flashing itself, maintaining the integrity of this critical water management feature. Proper sealant application between panel hems and valley flashing creates additional insurance against wind-driven moisture while accommodating the differential thermal movement between these components.

Ridge details for Snaplok roofing installations offer multiple approaches depending on aesthetic preferences, ventilation requirements, and architectural context. Vented ridge systems have become increasingly popular for their ability to exhaust heat and moisture from attic spaces while maintaining a clean exterior appearance. These systems incorporate specially designed ridge venting products that allow airflow while preventing rain, snow, and insect entry. The Snaplock roofing panels terminate at the ridge with a small gap that permits upward airflow, covered by a profiled ridge cap that attaches through concealed fasteners engaging z-shaped closure strips secured to both roof slopes. Non-vented ridge installations utilize similar caps but incorporate solid closure strips that create a complete weather seal without the ventilation openings.

-

Proper Techniques for Roof Penetrations and Transitions

Roof penetrations including plumbing vents, electrical masts, and chimney chases require meticulous flashing details to maintain the weathertight integrity that defines quality Snaplock roofing installations. The fundamental principle involves creating a flashing assembly that sheds water around the penetration while accommodating the thermal movement of surrounding metal roofing panels without compromising seals. Penetration flashings typically consist of a base component that integrates with or replaces panels at the penetration location, secured with appropriate fasteners and sealants, topped by a storm collar or adjustable flashing that completes the weather seal while permitting slight relative movement between the roofing surface and the penetration itself. For cylindrical penetrations like plumbing vent pipes, specialized metal roofing pipe flashings designed specifically for standing seam applications offer the most reliable performance. These products feature an adjustable base that can conform to various roof slopes while maintaining proper alignment with the Snaplok roofing panel ribs. The installation sequence involves cutting panels to create the necessary opening, installing the base flashing component with generous sealant application to all contact surfaces, and then snapping adjacent panels into their normal engagement while carefully working around the flashing perimeter. A storm collar completes the upper seal, crimped around the pipe and sealed to prevent water infiltration at this vulnerable junction.

Sidewall transitions where Snaplock roofing panels meet vertical building surfaces demand careful coordination between roofing and wall cladding systems to create lasting weather protection. Step flashing remains the proven approach for these applications, with individual L-shaped flashing pieces installed progressively up the slope, each piece lapping the previous one by at least three inches while integrating beneath wall cladding and over roofing panels. The Snaplok roofing panels terminate against these flashings with proper hemming or z-closure details that secure the panel edge while permitting the thermal movement characteristic of metal roofing systems. Counter-flashing installed over the step flashing and integrated into wall assembly joints provides the final weather barrier while creating a clean visual transition between roofing and wall materials.

Quality Control, Final Inspection, and Maintenance Recommendations

Comprehensive quality control throughout the Snaplock roofing installation process significantly reduces the likelihood of callbacks and ensures the system performs as designed throughout its service life. Professional installers implement checkpoints at key stages including substrate preparation verification, underlayment inspection before panel installation begins, periodic alignment checks during panel installation, and detailed examination of all flashing interfaces before project completion. This systematic approach identifies potential issues when they're easily corrected rather than after the installation is complete and remediation requires disassembly of properly installed components to access and repair the deficient area. The final inspection phase should include both visual assessment and functional testing to confirm that every aspect of the Snaplok roofing system meets quality standards and performance expectations. Visual inspection examines panel alignment for consistent reveal and straightness of standing seams, verifies that all fasteners are properly installed without over-driving or strip-out, confirms adequate and consistent sealant application at all vulnerable joints, and checks that trim components properly integrate with panels without gaps or misalignment. Surface cleanliness receives attention as well, with removal of any metal shavings, fastener debris, or construction residue that could cause staining or create opportunities for corrosion initiation.

Functional testing for Snaplock roofing installations involves careful water testing of valleys, penetrations, and transitions using controlled water application that simulates rainfall without overwhelming the system with unrealistic flow volumes. This testing reveals any areas where water can penetrate beneath the roofing surface, allowing for corrective action before the roofing contractor leaves the site. Testing should occur under calm conditions initially, and if possible, observation during actual rainfall provides the ultimate verification of system performance. Any identified leakage points require investigation to determine whether the issue stems from workmanship deficiencies, incompatible component selection, or design inadequacies that require engineering consultation to properly resolve.

-

Long-Term Performance and Maintenance for Snaplok Roofing Systems

Properly installed Snaplock roofing systems provide decades of reliable service with minimal maintenance requirements, though periodic inspections and basic upkeep activities help ensure optimal performance throughout the system's design life. Annual inspections, ideally conducted in spring and fall, should examine the roof surface for any signs of damage from fallen tree limbs, hail impact, or other physical insults that could compromise panel integrity. These inspections also verify that all fasteners remain secure, sealants maintain flexibility and adhesion, and that no debris accumulation in valleys or behind snow retention systems creates conditions for accelerated corrosion or ice dam formation. The self-cleaning nature of Snaplok roofing systems represents one of their significant maintenance advantages, with rainfall typically sufficient to remove most accumulated dirt and organic matter that might otherwise degrade the finish or support biological growth. However, in regions with extended dry periods or where significant tree pollen, industrial fallout, or coastal salt spray exposure occurs, periodic gentle washing with mild detergent and low-pressure water application helps maintain both appearance and coating integrity. Harsh chemicals, abrasive cleaning methods, and high-pressure washing should be strictly avoided as they can damage protective coatings and create conditions for premature corrosion initiation that compromises the substantial service life these systems are designed to provide.

Xi'an Huafeng Construction Engineering Co., Ltd. manufactures Snaplock roofing panels with premium materials including aluminum alloy, galvanized steel, and stainless steel substrates in thicknesses from 0.4mm to 1.2mm, all protected by advanced PVDF or PE coating systems that deliver exceptional weather resistance. Our products meet rigorous international standards including ASTM, DIN, JIS, BS, and GB/T specifications, backed by comprehensive ISO9001 and ISO14001 certifications that demonstrate our commitment to quality and environmental responsibility. With three manufacturing facilities operating seven production lines and over forty specialized machines, we maintain production capacity exceeding 1000 tons monthly while delivering customized solutions with typical lead times of just 15 to 20 days from order confirmation to shipment.

Conclusion

Installing Snaplock standing seam metal roofing panels transforms complex roofing challenges into manageable processes through innovative design and systematic installation techniques. Success requires careful planning, quality materials, proper tool selection, and meticulous attention to critical details throughout every installation phase. When executed correctly, Snaplok roofing systems deliver exceptional durability, minimal maintenance requirements, and aesthetic appeal that enhances property value for decades.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

As a leading China Snaplock Roofing factory, China Snaplock Roofing supplier, and China Snaplock Roofing manufacturer, Xi'an Huafeng Construction Engineering Co., Ltd. offers comprehensive solutions from initial design consultation through final installation support. Established in 2018 and recognized as a Shaanxi Province high-tech enterprise in 2020, we maintain first-level building curtain wall qualifications and third-level building steel structure qualifications that demonstrate our technical capabilities and regulatory compliance. Our integrated approach encompasses custom engineering design services including structural 3D modeling and load analysis, precision manufacturing utilizing roll-forming systems with real-time quality control, and seamless installation support through on-site project management and safety compliance documentation. With raw material production facilities covering 200,000 square meters in Anhui and plate processing plants in both Hangzhou and Xi'an, we control quality throughout the entire supply chain from material procurement through finished product delivery.

We specialize in China Snaplock Roofing wholesale supply with competitive Snaplock Roofing price structures that reflect our manufacturing efficiency and economies of scale. Our High Quality Snaplock Roofing products, including Snaplock Roofing for sale in customized RAL colors and various material specifications, serve prestigious projects including Xiongan Station Commercial Body, Xi'an International Convention and Exhibition Center, and numerous other landmark installations throughout China and internationally. Our commitment extends beyond product manufacturing to include comprehensive customer support with engineering design experience, construction expertise, and more than 20 patent certificates protecting our innovative roofing system technologies. CE certification, ISO certification, and SGS certification validate our quality management systems, while our collaboration with Fortune 500 companies demonstrates the trust established industry leaders place in our capabilities. We provide one-stop procurement from raw materials to accessories, customized production solutions, multiple packaging options, and flexible transportation methods tailored to project-specific requirements. Ready to transform your roofing project with professional Snaplock roofing solutions? Contact us at huafeng@hfmetalroof.com to discuss your requirements and receive detailed technical specifications, material samples, and project quotations from our experienced team.

References

1. Metal Construction Association. Metal Roofing Installation Guide for Residential and Light Commercial Applications. 2023.

2. Smith, Robert J. and Anderson, Michael P. Standing Seam Metal Roofing Systems: Design, Installation, and Performance. Building Envelope Design Publishers, 2022.

3. National Roofing Contractors Association. The NRCA Metal Panel Roof Systems Manual. 2024 Edition.

4. Thompson, Elizabeth R. Advanced Metal Roofing Techniques: From Traditional to Modern Systems. Construction Technology Press, 2021.