Imagine facing another brutal winter with roof leaks, ice dams forming overnight, or watching your energy bills skyrocket because your roofing system simply cannot withstand extreme weather conditions. For facility managers, architects, and property owners operating in harsh climates characterized by heavy snow loads, intense UV radiation, dramatic temperature swings, and hurricane-force winds, the Standing Seam Pitched Metal Roof emerges as the definitive solution. This advanced roofing system combines mechanical seaming technology with premium materials to deliver unparalleled weather resistance, thermal management capabilities, and structural integrity that conventional roofing materials cannot match. When environmental conditions demand performance beyond standard specifications, Standing Seam Pitched Metal Roof systems provide the engineered resilience necessary to protect critical infrastructure investments across decades of service.

Understanding Standing Seam Pitched Metal Roof Technology for Extreme Weather Performance

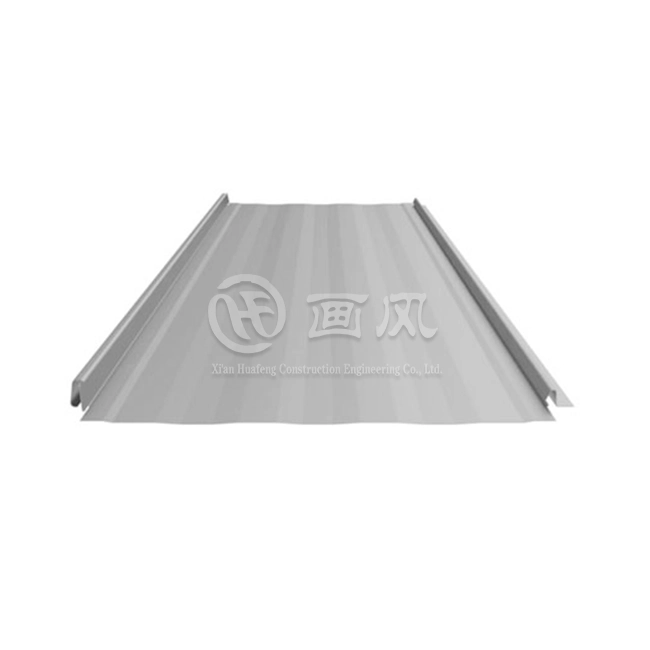

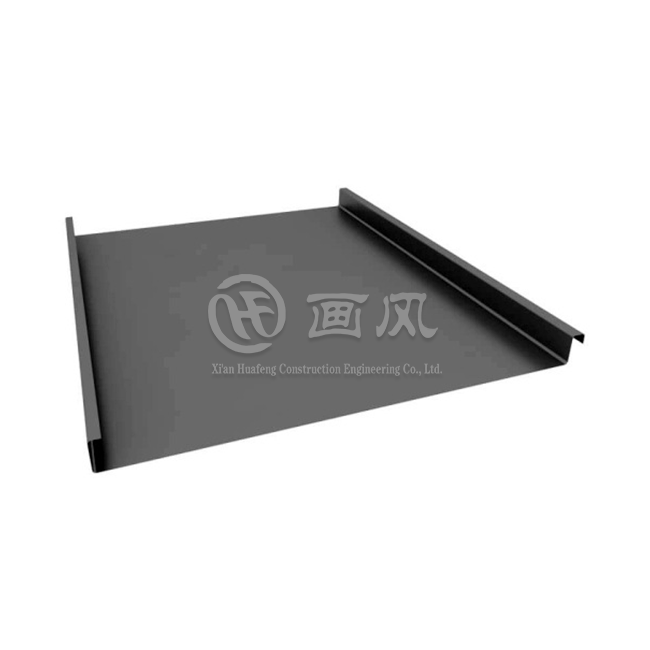

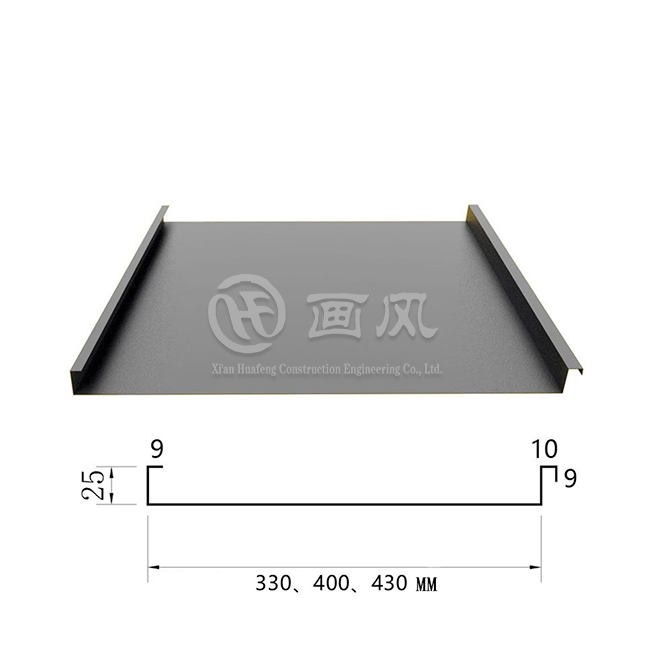

Standing Seam Pitched Metal Roof systems represent the pinnacle of modern roofing engineering, specifically designed to address the multifaceted challenges presented by harsh environmental conditions. Unlike traditional roofing materials that rely on overlapping shingles or exposed fasteners vulnerable to weather infiltration, the Standing Seam Pitched Metal Roof utilizes a sophisticated mechanical locking process that joins adjacent metal panels along raised vertical seams. This concealed fastener system creates a continuous, watertight surface without penetration points, effectively eliminating the primary vulnerability pathways that compromise conventional roofing systems during extreme weather events. The pitched configuration, designed for sloped surfaces with minimum angles of five degrees, works synergistically with gravity to facilitate rapid water drainage and prevent moisture accumulation that leads to structural degradation over time. The engineering excellence of Standing Seam Pitched Metal Roof construction becomes particularly evident when examining its thermal expansion management capabilities. Metal roofing materials naturally expand and contract in response to temperature fluctuations, a phenomenon that can create stress concentrations and compromise weatherproofing integrity in poorly designed systems. However, Standing Seam Pitched Metal Roof installations incorporate sliding clip attachment mechanisms that allow individual panels to move independently along their longitudinal axis without creating tension at connection points. This engineered thermal accommodation prevents the buckling, warping, and seam separation that plague rigid fastening systems in climates experiencing temperature swings exceeding one hundred degrees Fahrenheit annually. Premium surface treatments including PVDF coatings with minimum thickness of twenty-five microns provide additional thermal regulation while maintaining color stability under intense ultraviolet exposure that would degrade lesser coating systems within years rather than decades.

-

Material Selection Strategies for Harsh Climate Applications

The performance characteristics of Standing Seam Pitched Metal Roof systems depend fundamentally upon appropriate material selection aligned with specific environmental challenges. Aluminum-magnesium-manganese alloys offer exceptional corrosion resistance in coastal environments where salt spray accelerates oxidation, while their superior thermal conductivity properties facilitate heat dissipation that reduces cooling loads in high-solar-radiation climates. These alloys, available in grades including 3003, 3004, and 5052, provide optimal strength-to-weight ratios that minimize structural loading requirements without compromising wind uplift resistance. For projects demanding maximum durability in industrial environments with chemical exposure or extreme pollution levels, stainless steel options in 304 and 316 grades deliver unmatched longevity, though at premium cost structures that require lifecycle analysis justification. Zinc-titanium alloys represent another sophisticated material choice for Standing Seam Pitched Metal Roof applications in harsh climates, particularly those experiencing significant freeze-thaw cycling. The self-healing patina that develops on zinc surfaces provides continuously regenerating corrosion protection that actually improves over time, making these systems ideal for regions where maintenance access proves challenging or cost-prohibitive. Color-coated steel substrates incorporating advanced galvalume or galvanized protection layers offer economical performance when properly specified with adequate coating thickness and appropriate surface treatments. The critical consideration involves matching material properties to specific environmental stressors rather than selecting based solely on initial cost metrics, as inappropriate material choices inevitably result in premature failure requiring complete system replacement decades before design service life expectations.

-

Performance Validation Through Extreme Weather Testing Protocols

Engineering confidence in Standing Seam Pitched Metal Roof performance under harsh climate conditions derives from comprehensive testing protocols that simulate decades of environmental exposure within controlled laboratory conditions. Wind resistance testing involves subjecting assembled panel sections to sustained wind speeds exceeding hurricane thresholds while monitoring seam integrity and fastener performance under cyclical loading conditions. Water infiltration analysis employs pressurized spray applications at various angles to verify weatherproofing effectiveness across the full range of wind-driven rain scenarios encountered in severe weather events. Thermal cycling evaluation subjects test specimens to rapid temperature transitions spanning the complete operational range, validating that thermal expansion management systems maintain their function after thousands of expansion-contraction cycles representing decades of actual service. The accumulation of performance data from Standing Seam Pitched Metal Roof installations across diverse geographic regions provides empirical validation of design calculations and theoretical models. Weather station monitoring at reference installations documents actual loading conditions during extreme events, while periodic inspection programs track long-term performance metrics including seam integrity, coating degradation, and structural deflection. This comprehensive approach to performance validation ensures that Standing Seam Pitched Metal Roof specifications for harsh climate applications rest upon demonstrated capabilities rather than theoretical projections or marketing claims unsupported by field verification.

Installation Excellence: Critical Success Factors for Harsh Climate Performance

The superior design characteristics inherent in Standing Seam Pitched Metal Roof systems can only deliver their promised performance when installation execution meets rigorous quality standards appropriate for harsh climate applications. Professional installation methodology begins with comprehensive substrate preparation including verification of structural adequacy to support anticipated snow and wind loads, installation of high-performance underlayment systems providing secondary weather protection, and establishment of proper ventilation pathways preventing moisture accumulation within the building envelope. The mechanical seaming process itself requires specialized equipment and trained technicians capable of achieving consistent seam formation that creates gas-tight joints while accommodating the thermal movement necessary for long-term system integrity. Installation quality control for Standing Seam Pitched Metal Roof projects in harsh climates demands verification protocols extending beyond visual inspection to include quantitative assessment methods. Seam integrity testing employs calibrated instruments measuring pull-apart resistance to confirm that mechanical connections achieve specified strength values throughout the installation. Thermal imaging surveys identify potential heat transfer pathways indicating inadequate insulation or ventilation deficiencies that would compromise energy efficiency and promote condensation formation. Water testing procedures conducted upon installation completion verify zero-leak performance under simulated storm conditions before final acceptance, ensuring that warranty coverage rests upon demonstrated rather than assumed weatherproofing capability.

-

Customization and Engineering Integration for Project-Specific Requirements

The adaptability of Standing Seam Pitched Metal Roof systems to accommodate diverse architectural requirements while maintaining harsh climate performance represents a significant advantage over rigid, one-size-fits-all roofing solutions. Panel specifications including width dimensions ranging from three hundred to six hundred millimeters, rib heights varying between twenty-five and forty-five millimeters, and customizable lengths extending to tens of meters enable optimization for specific project geometries and aesthetic preferences. Surface treatment options encompassing PVDF and PE coating systems in extensive RAL and Pantone color selections facilitate integration with building design vocabulary while delivering the ultraviolet resistance and weathering durability essential for long-term appearance retention in high-exposure environments. Engineering integration services provided by experienced Standing Seam Pitched Metal Roof manufacturers transform standard product offerings into comprehensive building envelope solutions tailored to harsh climate challenges. Structural three-dimensional modeling enables load analysis confirming adequacy under project-specific snow accumulation and wind pressure conditions derived from local climate data and building code requirements. Drainage system simulation identifies optimal panel layout configurations and accessory placements ensuring rapid water evacuation even during extreme precipitation events exceeding historical records. Material specification advisory services leverage manufacturer expertise matching substrate materials, coating systems, and fastening methodologies to the unique combination of environmental stressors characterizing the project location, maximizing performance while optimizing lifecycle cost structures.

Manufacturing Excellence and Quality Assurance for Harsh Climate Applications

The reliability of Standing Seam Pitched Metal Roof systems operating in harsh climates depends fundamentally upon manufacturing quality that ensures consistent material properties and dimensional accuracy across every panel produced. Advanced production facilities housing multiple roll-forming lines with precision control systems maintain tolerances measured in fractions of millimeters, critical for achieving proper panel alignment and seam engagement during field installation. Automated punching equipment creates fastener attachment points with consistent positioning that facilitates efficient installation while maintaining structural load paths designed into the engineering analysis. Color coating production lines applying PVDF and PE surface treatments under controlled environmental conditions deliver uniform coating thickness and complete substrate coverage that prevents premature corrosion initiation at unprotected edges or surface defects. Raw material procurement protocols for Standing Seam Pitched Metal Roof manufacturing emphasize supplier qualification and incoming quality verification procedures that eliminate substandard materials before they enter production streams. Aluminum alloys from certified producers including Alucosuper, YATAI, and LIDAO undergo compositional analysis confirming grade specifications, while steel substrates from BAOSTEEL, GUANZHOU, and XINYU receive coating thickness verification and adhesion testing. Stainless steel materials from Baosteel and Tsingshan suppliers undergo corrosion resistance qualification, and titanium-zinc plates from NedZink receive dimensional inspection. This multi-layered quality assurance approach, incorporating supplier certifications, third-party testing reports, and internal verification procedures, ensures that finished Standing Seam Pitched Metal Roof products meet the demanding performance requirements necessary for harsh climate applications.

-

Comprehensive Testing and Inspection Protocols

Manufacturing quality assurance for Standing Seam Pitched Metal Roof systems extends beyond raw material verification to encompass comprehensive testing throughout production processes and final product inspection. Incoming material inspection protocols employ both statistical sampling methods for high-volume commodity materials and complete inspection procedures for critical components, preventing defective materials from contaminating production. Testing procedures spanning appearance evaluation, dimensional verification, salt spray exposure, adhesion assessment, hardness measurement, impact resistance, coating thickness confirmation, acid resistance qualification, weather resistance validation, and color difference analysis ensure that every aspect of product performance receives verification before release for installation. Finished product inspection for Standing Seam Pitched Metal Roof panels includes geometric accuracy assessment confirming that width, length, rib height, and edge configurations fall within specified tolerance bands. Flatness evaluation across panel surfaces identifies manufacturing defects that could compromise appearance or create installation difficulties. Curvature measurement along panel edges verifies proper seaming geometry that facilitates field engagement and weathertight seal formation. Products failing to meet inspection criteria undergo rework or rejection rather than shipment to project sites where installation difficulties and performance deficiencies would compromise system integrity and generate warranty claims.

Lifecycle Performance and Maintenance Strategies for Harsh Climates

The economic justification for Standing Seam Pitched Metal Roof installations in harsh climate applications derives from exceptional lifecycle performance that extends service life far beyond conventional roofing materials while minimizing maintenance requirements and operational disruptions. Design service life expectations exceeding thirty years with comprehensive warranty coverage reflect manufacturer confidence in material durability and system engineering. The absence of organic materials susceptible to biological degradation, combined with corrosion-resistant substrates and high-performance coating systems, eliminates the primary deterioration mechanisms limiting the lifespan of asphalt shingle, modified bitumen, and single-ply membrane roofing systems commonly experiencing failures within fifteen to twenty years in harsh environments. Proactive maintenance strategies for Standing Seam Pitched Metal Roof installations optimize performance and maximize service life through periodic inspection and targeted interventions addressing minor issues before they escalate into major system failures. Annual inspection protocols conducted following severe weather events document seam integrity, coating condition, and fastener performance while identifying debris accumulation or drainage obstruction requiring remediation. Cleaning procedures employing mild detergent solutions remove accumulated contaminants that could promote localized corrosion or degrade coating effectiveness. Touch-up treatments address minor surface scratches or edge wear before substrate exposure initiates corrosion processes. This preventive maintenance philosophy, requiring minimal investment compared to complete roof replacement costs, preserves the substantial capital investment represented by Standing Seam Pitched Metal Roof installations while ensuring continuous weather protection throughout the design service life.

-

Energy Efficiency and Sustainability Benefits in Harsh Climates

The environmental performance characteristics of Standing Seam Pitched Metal Roof systems deliver significant operational benefits in harsh climate applications where heating and cooling loads represent major facility operating costs. Highly reflective surface treatments incorporating cool roof technology reduce solar heat gain during summer months, decreasing air conditioning requirements and peak electrical demand. The thermal mass properties of metal substrates facilitate rapid temperature response, eliminating the thermal lag that causes conventional roofing materials to radiate absorbed heat into building interiors long after sunset. In cold climates, proper integration of insulation systems with Standing Seam Pitched Metal Roof installations creates high-performance building envelopes minimizing heat loss while preventing ice dam formation through consistent surface temperatures. Sustainability considerations extend beyond operational energy efficiency to encompass material lifecycle impacts and end-of-service disposition. Standing Seam Pitched Metal Roof materials including aluminum, steel, and zinc maintain their fundamental material properties through recycling processes, enabling closed-loop material flows that minimize virgin resource consumption and reduce embodied energy compared to single-use roofing materials destined for landfill disposal. The extended service life characteristic of properly specified and installed Standing Seam Pitched Metal Roof systems reduces the frequency of roof replacement cycles, minimizing the cumulative environmental impact associated with material production, transportation, installation, and disposal across a building's operational lifetime. These sustainability attributes align with green building certification requirements and corporate environmental responsibility objectives while delivering tangible economic benefits through reduced material consumption and waste disposal costs.

Conclusion

Standing Seam Pitched Metal Roof systems represent the optimal roofing solution for harsh climate applications where conventional materials cannot deliver the performance, durability, and lifecycle value necessary to protect critical infrastructure investments. Through sophisticated engineering integrating advanced materials, mechanical seaming technology, and thermal management systems, these roofing solutions provide weather resistance, structural integrity, and operational efficiency across decades of service.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

Xi'an Huafeng Construction Engineering Co., Ltd. stands as a premier China Standing Seam Pitched Metal Roof manufacturer, China Standing Seam Pitched Metal Roof supplier, and China Standing Seam Pitched Metal Roof factory delivering comprehensive solutions from design through installation. Recognized as a high-tech enterprise with first-level building curtain wall qualifications and third-level building steel structure qualifications, Huafeng operates three production facilities housing seven color coating production lines and over forty precision manufacturing machines. Our raw material production plant spanning two hundred thousand square meters in Anhui, combined with plate processing facilities in Hangzhou and Xi'an, provides monthly supply capacity exceeding one thousand tons with delivery timeframes of fifteen to twenty days.

As a leading China Standing Seam Pitched Metal Roof wholesale provider, we offer High Quality Standing Seam Pitched Metal Roof products featuring aluminum-magnesium-manganese alloys, galvalume steel, titanium-zinc, and stainless steel substrates with thickness options from 0.4 to 1.2 millimeters and comprehensive PVDF/PE surface treatments. Our Standing Seam Pitched Metal Roof for sale includes specifications of 25-330/400/430, 32-410, and 45-300/400/500 with competitive Standing Seam Pitched Metal Roof price structures supported by thirty-year warranty coverage. Huafeng's one-stop solution encompasses project drawing deepening, structural 3D modeling, drainage system simulation, factory processing samples, precision roll-forming production, real-time quality control, professional on-site installation guidance, and comprehensive maintenance support. Our engineering excellence has delivered successful installations at prestigious projects including Xiongan Station Commercial Body, Xi'an International Convention and Exhibition Center, Xi'an Station East Auxiliary Building, Jinghe New City International Culture and Art Center, and Inner Mongolia Tongliao Art Museum. Contact Huafeng today at huafeng@hfmetalroof.com to discuss your Standing Seam Pitched Metal Roof requirements and experience the superior performance, customized solutions, and technical expertise that define industry leadership in harsh climate roofing applications.

References

1. Metal Construction Association. Technical Guidelines for Standing Seam Metal Roof Systems. Metal Construction Association Engineering Standards Committee.

2. American Society of Civil Engineers. Minimum Design Loads and Associated Criteria for Buildings and Other Structures (ASCE/SEI 7-22). Structural Engineering Institute.

3. National Roofing Contractors Association. The NRCA Roofing Manual: Membrane Roof Systems - Metal Panel Systems. NRCA Technical Operations Division.

4. Aluminum Association. Aluminum Design Manual: Specification for Aluminum Structures. Aluminum Association Engineering Committee.