Choosing the right metal for your standing seam roof can mean the difference between a system that lasts 30 years and one that needs costly repairs within a decade. Whether you're facing extreme coastal conditions with salt spray corrosion, dealing with thermal expansion challenges in desert climates, or simply seeking to maximize your return on investment while reducing long-term maintenance costs, understanding the performance characteristics of different metal options is critical. Aluminum standing seam roofing panels have emerged as one of the most versatile and reliable solutions in the metal roofing industry, offering an exceptional balance of durability, weight efficiency, and corrosion resistance that makes them suitable for diverse applications ranging from residential homes to large-scale commercial projects.

Understanding Standing Seam Metal Roofing Systems

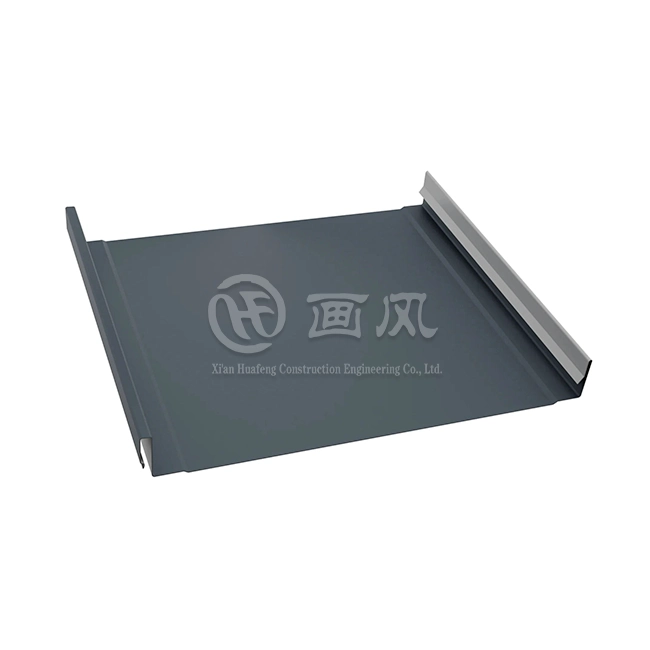

Standing seam metal roofing represents a premium roofing technology that utilizes continuous vertical panels running from the roof ridge to the eaves, connected through raised seams that interlock mechanically to create a concealed fastener system. Unlike traditional exposed fastener roofing where screws penetrate the face of panels and create potential leak points vulnerable to weathering and thermal movement, standing seam systems hide all fasteners either beneath the vertical leg of the panel or through clip attachment mechanisms that allow the roof to expand and contract freely with temperature changes. This fundamental design advantage delivers superior weather-tightness, extended service life, and enhanced aesthetic appeal that has made standing seam the preferred choice for architectural projects where performance and appearance both matter. The technology behind aluminum standing seam roofing panels specifically leverages the unique properties of aluminum alloys, typically AA3003, AA3004, or AA5052 grades, which provide optimal combinations of strength, formability, and corrosion resistance. These alloys contain carefully balanced proportions of manganese and magnesium that enhance their mechanical properties while maintaining excellent workability during the roll-forming process. When protected with advanced coating systems such as PVDF finishes, aluminum standing seam roofing panels achieve performance levels that can exceed 50 years of service life with minimal maintenance requirements, making them particularly attractive for building owners seeking long-term value and reduced lifecycle costs.

-

The Concealed Fastener Advantage

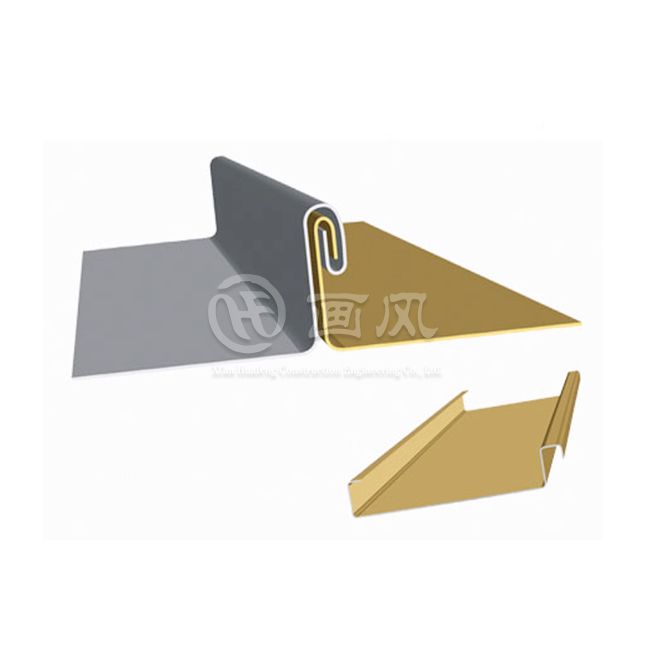

The concealed fastener design inherent in standing seam systems provides multiple performance benefits that directly address the most common failure modes in metal roofing. When fasteners penetrate through the exposed surface of roofing panels, they create puncture points where water can potentially infiltrate, rubber washers deteriorate under ultraviolet exposure, and thermal movement generates stress concentrations that can lead to fastener backing out or panel distortion. By relocating fasteners to protected positions beneath the raised seams or using sliding clip mechanisms, standing seam systems eliminate these vulnerability points entirely. Aluminum standing seam roofing panels particularly benefit from this design approach because aluminum's coefficient of thermal expansion is approximately 50 percent greater than steel, meaning that the ability to accommodate movement without stress buildup becomes even more critical for long-term performance and leak prevention.

Material Options for Standing Seam Roofing

When evaluating metal options for standing seam applications, three materials dominate the commercial and residential markets based on their proven performance records, availability, cost-effectiveness, and suitability for different environmental conditions. Understanding the specific characteristics, advantages, and limitations of each metal type enables informed decision-making that aligns material selection with project requirements, budget parameters, and long-term performance expectations.

-

Steel Standing Seam Panels: Strength and Affordability

Steel standing seam panels, typically fabricated from 24-gauge Galvalume or galvanized steel substrate, represent the most commonly specified option in the metal roofing industry due to their excellent strength-to-cost ratio and proven durability in most climatic conditions. Galvalume steel features a protective coating consisting of 55 percent aluminum, 43.4 percent zinc, and 1.6 percent silicon that provides superior corrosion resistance compared to pure zinc galvanized coatings, extending service life to 40 years or more in non-coastal environments. The inherent strength of steel allows thinner gauge materials to achieve required structural performance, and when enhanced with premium paint systems like Kynar 500 PVDF coatings that carry 30-year warranties against color fading and chalking, steel standing seam panels deliver reliable long-term performance at competitive price points. However, steel's performance limitations become apparent in coastal environments where salt spray exposure accelerates corrosion, particularly at cut edges and penetrations where the protective coating is compromised. Steel's higher density compared to aluminum also increases dead load on roof structures and may require additional structural reinforcement in retrofit applications or on buildings with limited load-bearing capacity. These factors explain why many architects and building owners increasingly specify aluminum standing seam roofing panels for projects where environmental exposure is severe or weight considerations are critical.

-

Aluminum Standing Seam Roofing Panels: The Optimal Balance

Aluminum standing seam roofing panels have gained substantial market share in recent years as building owners and design professionals recognize the material's superior performance characteristics in demanding applications. With a density approximately one-third that of steel, aluminum dramatically reduces structural loading requirements, often eliminating the need for roof structure reinforcement during retrofit projects and enabling longer unsupported panel spans that reduce installation labor and substrate costs. More importantly, aluminum develops a natural aluminum oxide layer immediately upon exposure to atmosphere, creating a self-healing protective barrier that provides inherent corrosion resistance without requiring additional metallic coatings. This characteristic makes aluminum standing seam roofing panels the preferred choice for coastal installations, chemical processing facilities, agricultural buildings exposed to corrosive atmospheres, and any application where long-term durability without ongoing maintenance is paramount. Modern aluminum standing seam roofing panels manufactured by companies like Xi'an Huafeng Construction Engineering Co., Ltd. incorporate advanced PVDF coating systems applied over premium AA3003, AA3004, or AA5052 aluminum alloy substrates with thicknesses ranging from 0.7mm to 1.2mm. These specifications deliver panel systems capable of spanning up to 12 meters without intermediate support while maintaining structural performance under wind uplift and snow load conditions. The mechanical properties of these aluminum alloys provide excellent formability for creating the precise panel profiles and seam geometries required for reliable weather-tight performance, while the combination of natural corrosion resistance and premium coating protection enables warranty periods extending to 50 years or more. For projects requiring maximum longevity, minimal maintenance, and proven performance in challenging environmental conditions, aluminum standing seam roofing panels represent the optimal material choice despite their higher initial cost compared to steel alternatives.

-

Premium Metal Options: Copper and Zinc

Beyond the mainstream steel and aluminum options, premium metals including copper and zinc offer unique aesthetic characteristics and exceptionally long service lives that appeal to high-end architectural projects where initial cost considerations are secondary to achieving distinctive appearance and maximum longevity. Copper standing seam roofing develops natural patina over time, transitioning from bright metallic finish through bronze tones to the characteristic green verdigris that provides both corrosion protection and timeless aesthetic appeal. With properly detailed installations, copper roofing systems can achieve service lives exceeding 100 years, making them attractive for historic renovation projects and landmark buildings where lifecycle cost analysis justifies the substantial initial investment. Titanium-zinc alloy panels similarly develop protective patina surfaces and offer service lives of 60 to 100 years with minimal maintenance requirements. However, both copper and zinc require specialized installation expertise, careful attention to galvanic corrosion prevention when interfacing with dissimilar metals, and significantly higher material costs that typically limit their application to premium residential and signature commercial projects. For the vast majority of commercial, industrial, and residential applications, aluminum standing seam roofing panels provide the optimal combination of performance, durability, aesthetics, and value.

Key Performance Factors in Metal Selection

Successful metal roofing system performance depends on careful evaluation of multiple interrelated factors that influence long-term durability, maintenance requirements, and lifecycle cost. Understanding how different metal options perform across these critical parameters enables selection decisions that optimize project outcomes.

-

Corrosion Resistance and Environmental Durability

Corrosion resistance represents perhaps the most critical performance parameter for metal roofing systems, as atmospheric corrosion directly determines service life and maintenance requirements. Aluminum's natural ability to form a protective oxide layer provides inherent corrosion resistance that performs reliably even in severe coastal environments with salt spray exposure, industrial atmospheres containing acidic pollutants, and agricultural settings with ammonia or hydrogen sulfide contamination from livestock operations. This self-healing oxide layer continuously regenerates when damaged, eliminating the catastrophic failure mode that occurs when protective coatings on steel substrates are compromised and moisture reaches the base metal. Aluminum standing seam roofing panels manufactured with premium PVDF coating systems combine this inherent substrate corrosion resistance with organic coating protection that prevents surface oxidation, maintains color stability, and provides easy-clean surfaces that resist dirt accumulation and atmospheric staining. This dual-layer protection strategy ensures that aluminum standing seam roofing panels maintain both structural integrity and aesthetic appearance throughout service lives extending 50 years or more, even in the most challenging environmental conditions. By contrast, steel-based systems require ongoing inspection and maintenance attention to coating condition, particularly at seams, fastener locations, and panel edges where protective coating coverage may be compromised during fabrication or installation.

-

Weight and Structural Considerations

The significant weight difference between aluminum and steel roofing systems creates important implications for project feasibility and installation costs, particularly in retrofit applications where existing roof structures may not have adequate load-bearing capacity for heavier roofing materials. At approximately 0.45 kg per square meter for 0.9mm thickness, aluminum standing seam roofing panels impose minimal structural loading that often enables direct installation over existing roof systems without structural reinforcement. This weight advantage reduces project costs by eliminating expensive structural upgrades, shortens installation schedules by simplifying logistics and material handling, and expands the range of buildings suitable for metal roofing upgrades. The lightweight nature of aluminum standing seam roofing panels also enables longer unsupported spans between purlins or structural supports, potentially reducing substrate costs and simplifying roof framing details. For large commercial and industrial buildings where roof area can extend to tens of thousands of square meters, the cumulative weight savings from specifying aluminum versus steel can eliminate entire structural support systems, delivering substantial cost savings that offset aluminum's higher material cost per square meter. These structural advantages, combined with easier handling during installation that improves worker safety and productivity, make aluminum standing seam roofing panels increasingly attractive for large-scale roofing projects.

-

Thermal Performance and Energy Efficiency

Metal roofing systems offer inherent thermal performance advantages compared to conventional roofing materials through their high solar reflectance and thermal emittance properties that reduce heat gain and cooling energy consumption. When enhanced with light-colored or specially formulated cool roof coating systems that achieve solar reflectance values exceeding 0.60 and thermal emittance above 0.85, aluminum standing seam roofing panels can reduce roof surface temperatures by 30 to 50 degrees Celsius compared to dark-colored conventional roofing materials. This temperature reduction translates directly to decreased cooling loads in conditioned buildings, improved thermal comfort in unconditioned structures, and extended service life of roofing components by reducing thermal stress and ultraviolet exposure. The raised seam design of standing seam systems also facilitates integration of above-sheathing ventilation strategies that create air circulation paths between the metal panels and underlying roof substrate, further enhancing thermal performance by removing heat through natural convection. Aluminum standing seam roofing panels manufactured with appropriate panel profiles and rib heights create efficient ventilation channels that can reduce cooling energy consumption by 10 to 15 percent in hot climates. These energy performance benefits, combined with aluminum's recyclability and low embodied energy compared to other roofing materials, position aluminum standing seam roofing panels as environmentally responsible choices that support sustainable building design objectives.

Installation and Design Flexibility

The installation characteristics and design flexibility of standing seam metal roofing systems significantly influence project costs, construction schedules, and architectural possibilities. Understanding these factors helps optimize system selection and project planning.

-

Panel Forming and Customization

Modern aluminum standing seam roofing panels are manufactured using precision roll-forming equipment that shapes flat coil stock into finished panel profiles with consistent dimensions and tight tolerances. Xi'an Huafeng Construction Engineering Co., Ltd. operates advanced production facilities with 7 color coating production lines and more than 40 roll-forming machines capable of producing panels in custom lengths up to 25 meters, eliminating end laps that represent potential leak points and creating cleaner aesthetic appearance. This continuous panel capability also reduces installation labor by minimizing the number of panel sections required to cover a given roof area, improving productivity and reducing potential for installation errors. The formability characteristics of aluminum alloys used in standing seam roofing panels enable creation of complex panel profiles with rib heights ranging from 25mm to 65mm, effective coverage widths from 300mm to 600mm, and various seam configurations including double-lock mechanical seams, snap-lock systems, and batten-seam profiles. This design flexibility allows aluminum standing seam roofing panels to satisfy diverse architectural aesthetics ranging from contemporary minimalist designs favoring wide panels with subtle seam profiles to traditional appearances featuring narrower panels with prominent raised seams. The availability of hundreds of standard and custom colors through RAL, Pantone, and proprietary color systems ensures that aluminum standing seam roofing panels can complement any architectural color palette.

-

Mechanical Seaming and Connection Methods

The mechanical seaming process that connects adjacent standing seam panels represents a critical installation step that directly determines system weather-tightness and long-term performance. Double-lock mechanical seaming creates a folded connection that brings the vertical legs of adjacent panels together through two 180-degree bends, producing a rigid connection that provides excellent resistance to wind uplift while maintaining weather-tight integrity. This seaming method requires specialized power seaming equipment operated by trained installation crews, but delivers premium performance justified for commercial and institutional projects where maximum reliability is essential. Snap-lock seaming systems offer simplified installation that reduces labor costs and accelerates construction schedules by enabling panels to be connected without mechanical seaming equipment. While snap-lock systems provide adequate performance for most residential and light commercial applications, they do not achieve the same level of weather-tightness and wind uplift resistance as mechanically seamed systems. Aluminum standing seam roofing panels work effectively with both connection methods, with selection driven by project performance requirements, budget parameters, and installer capabilities. The availability of both options provides flexibility to optimize system selection for specific project conditions.

Why Choose Aluminum Standing Seam Roofing Panels from Xi'an Huafeng?

Selecting the right manufacturer and supplier for aluminum standing seam roofing panels significantly influences project success through impacts on product quality, technical support, delivery reliability, and long-term performance. Xi'an Huafeng Construction Engineering Co., Ltd. has established itself as a leading China aluminum standing seam roofing panels manufacturer through comprehensive capabilities spanning material procurement, precision manufacturing, quality assurance, and technical support.

-

Manufacturing Excellence and Quality Control

Xi'an Huafeng operates three manufacturing facilities totaling more than 200,000 square meters of production space, equipped with 7 advanced color coating lines and more than 40 precision roll-forming machines capable of producing aluminum standing seam roofing panels to the highest quality standards. The company's vertical integration extends from raw material procurement through final panel production, ensuring consistent quality control throughout the manufacturing process. All aluminum substrates are sourced from premium suppliers including Alucosuper, YATAI, and LIDAO, with specifications limited to AA3003, AA3004, and AA5052 alloys that provide optimal combinations of strength, formability, and corrosion resistance for roofing applications. Comprehensive incoming material inspection procedures verify that all aluminum coil stock meets specified chemical composition, mechanical properties, surface quality, and dimensional tolerances before acceptance for production. These inspection protocols include verification of material certifications, third-party test reports, and internal testing covering appearance, dimensions, salt spray resistance, coating adhesion, hardness, impact resistance, film thickness, acid resistance, weather resistance, and color consistency. This rigorous quality control process ensures that every aluminum standing seam roofing panel produced by Xi'an Huafeng meets or exceeds international standards including ASTM, DIN, JIS, BS, and GB/T requirements.

-

Comprehensive Technical Support

Beyond manufacturing excellence, Xi'an Huafeng provides comprehensive technical support services that help ensure successful project outcomes from initial design through final installation. The company's engineering team offers structural 3D modeling and load analysis services that optimize panel specifications and support spacing for specific project wind and snow load conditions. Drainage system simulation capabilities enable evaluation of water flow patterns and sizing of gutters and downspouts to handle expected rainfall intensities. Material specification advisory services help architects and contractors select optimal aluminum alloy grades, panel thicknesses, coating systems, and colors for specific environmental conditions and aesthetic objectives. For complex projects, Xi'an Huafeng provides detailed shop drawing preparation services that develop installation-ready fabrication drawings from architectural plans, ensuring that panel lengths, seam locations, penetration details, and trim components are properly coordinated before production begins. This front-end engineering support minimizes field coordination issues and reduces installation time by providing complete, accurate information to installation crews. Post-installation support includes on-site technical guidance, leak testing verification, and maintenance training that helps building owners maximize the service life and performance of their aluminum standing seam roofing panels.

-

Certifications and Proven Performance

Xi'an Huafeng's commitment to quality and performance is demonstrated through extensive certifications and successful project completions across diverse building types and environmental conditions. The company holds ISO9001 quality management certification and ISO14001 environmental management certification, confirming adherence to international standards for manufacturing processes and environmental responsibility. Product certifications include CE marking for European markets and SGS verification of performance characteristics. The company has secured more than 20 registered patents for roofing system innovations, demonstrating ongoing investment in product development and technical advancement. The proven performance of Xi'an Huafeng aluminum standing seam roofing panels is evidenced by successful installations on major projects including Xiongan Station Commercial Center, Xi'an International Convention and Exhibition Center, Xi'an Station East Auxiliary Building, Jinghe New City International Culture and Art Center, and numerous other commercial, institutional, and industrial facilities throughout China and international markets. These high-profile installations demonstrate the company's capability to deliver large-scale projects meeting demanding performance requirements and tight construction schedules while maintaining the highest quality standards. For building owners seeking reliable, high-quality aluminum standing seam roofing panels backed by comprehensive technical support and proven performance, Xi'an Huafeng represents an ideal China aluminum standing seam roofing panels supplier.

Conclusion

After evaluating the performance characteristics, lifecycle costs, and environmental durability of different metal options for standing seam roofing applications, aluminum standing seam roofing panels emerge as the optimal choice for most commercial, industrial, and residential projects. The combination of superior corrosion resistance, lightweight construction, excellent formability, and proven long-term performance positions aluminum as the best metal for standing seam roofing systems where maximum value and reliability are priorities.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

Xi'an Huafeng Construction Engineering Co., Ltd., established in 2018 in Shaanxi Province, China, specializes in the design, production, sales, and construction of metal roofing systems, building curtain wall systems, and steel structure enclosure systems. Recognized as a high-tech enterprise in Shaanxi Province in 2020, the company holds first-level qualification for building curtain walls and third-level qualification for building steel structures, demonstrating its technical capabilities and professional standing in the construction engineering industry. With a raw material production plant covering 200,000 square meters in Anhui and two plate and accessories processing plants located in Hangzhou and Xi'an, Xi'an Huafeng operates comprehensive manufacturing capabilities that ensure quality control and production efficiency throughout the supply chain. The company's commitment to green sustainable development and continuous innovation in metal roof products aligns with contemporary environmental priorities while delivering building solutions that integrate architecture, technology, and aesthetics.

As a leading China aluminum standing seam roofing panels factory and China aluminum standing seam roofing panels wholesale provider, Xi'an Huafeng offers high quality aluminum standing seam roofing panels for sale at competitive aluminum standing seam roofing panels price points. The company's one-stop service model encompasses project drawing development, factory sample production, precision manufacturing with real-time quality control, and seamless installation with on-site project management and safety compliance documentation. With 7 raw material production lines, more than 20 plate production machines, ISO certification, CE certification, SGS certification, and more than 20 patent certificates, Xi'an Huafeng delivers customized solutions backed by engineering design expertise, rigorous quality testing, and flexible transportation options.

For building owners, architects, contractors, and developers seeking a reliable China aluminum standing seam roofing panels manufacturer capable of delivering premium products with comprehensive technical support and proven project experience, Xi'an Huafeng Construction Engineering Co., Ltd. provides an ideal partnership opportunity. The company serves Fortune 500 companies and diverse clients across commercial, industrial, and public building sectors with customized products manufactured to ASTM, DIN, JIS, BS, and GB/T standards, delivered within 15-20 days with minimum order quantities of 500 square meters or 1 metric ton. Contact Xi'an Huafeng at huafeng@hfmetalroof.com to discuss your aluminum standing seam roofing panel requirements and discover how our engineering expertise, manufacturing capabilities, and commitment to customer success can contribute to your project objectives.

References

1. Metal Construction Association. "Guide to Standing Seam Metal Roof Systems: Design, Installation, and Performance Standards." Technical Committee Report, 2024.

2. American Architectural Manufacturers Association. "Aluminum Alloys for Building Construction: Properties, Specifications, and Applications." Materials Science Division, 2023.

3. National Roofing Contractors Association. "The NRCA Metal Panel and SPF Roof Systems Manual." Professional Standards and Guidelines, 2024.

4. ASTM International. "Standard Specification for Aluminum-Alloy Sheet and Plate for Building and Construction." ASTM B209-14, Committee on Non-Ferrous Metals and Alloys, 2023.