Picture this: heavy rain pours down, and instead of flowing safely away from your building, water cascades over clogged or inadequate gutters, pooling around your foundation and causing thousands of dollars in structural damage. This nightmare scenario is entirely preventable with the right Roof Gutter System Parts. Understanding the different types of gutter systems available is your first step toward protecting your property investment and ensuring decades of reliable water management performance.

Understanding Gutter System Styles and Roof Gutter System Parts

When selecting a gutter system for your residential or commercial building, the style you choose directly impacts both functionality and aesthetic appeal. The market offers several distinct gutter profiles, each designed to address specific architectural requirements and drainage needs. Modern Roof Gutter System Parts come in configurations that balance water-carrying capacity, ease of installation, and visual harmony with your building's exterior design elements.

-

K-Style Gutter Systems

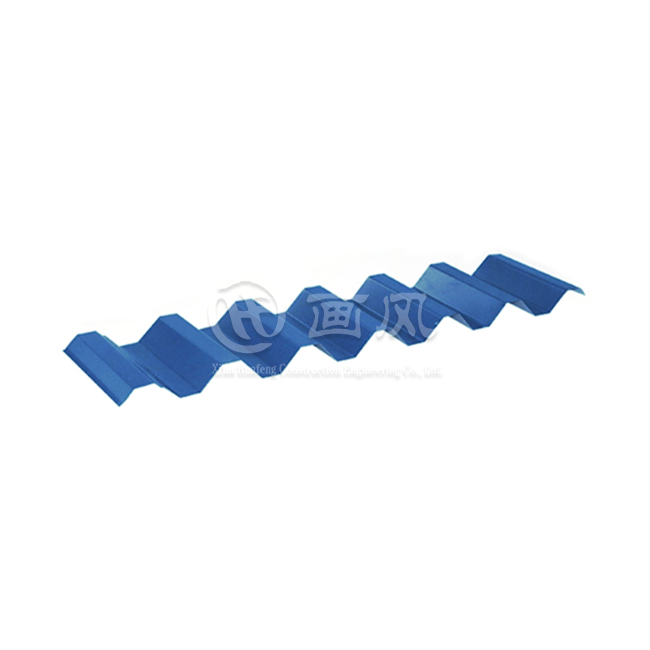

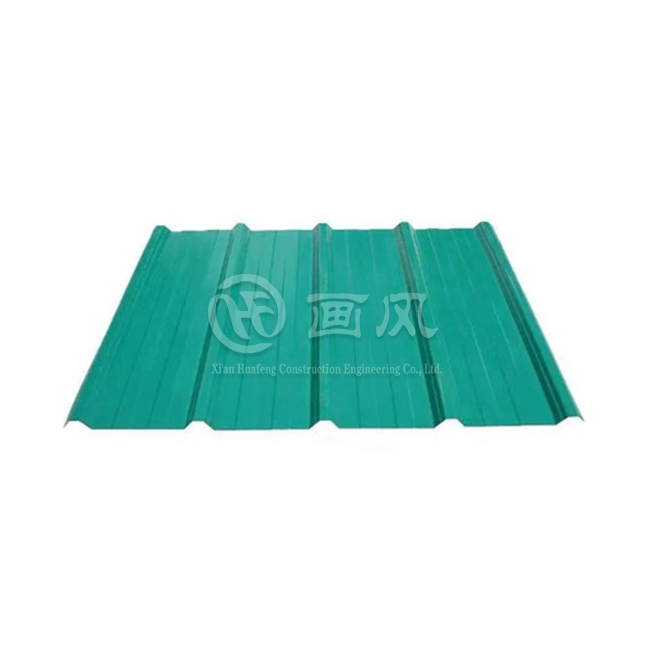

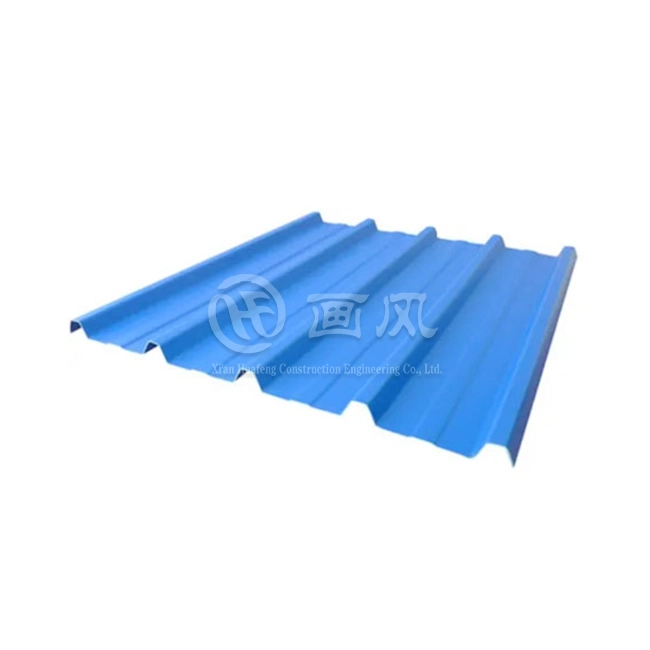

K-style gutters have become the predominant choice for contemporary construction projects, installed on approximately eighty percent of modern homes and commercial buildings. The distinctive profile of these Roof Gutter System Parts resembles decorative crown molding when viewed from street level, creating an architectural detail that enhances curb appeal rather than detracting from it. The flat back design of K-style systems allows direct attachment to fascia boards without requiring additional bracket hardware, simplifying installation procedures and reducing overall system costs. These gutters typically come in five-inch and six-inch widths, with the larger option providing nearly double the water-carrying capacity, making them ideal for regions experiencing heavy seasonal rainfall. The internal geometry of K-style Roof Gutter System Parts creates excellent structural strength, though the angular corners can accumulate debris more readily than rounded profiles, requiring regular maintenance to maintain optimal performance.

-

Half-Round Gutter Systems

Half-round gutters feature a semicircular cross-section that creates a classic aesthetic perfectly suited to historic properties and traditional architectural styles. Many municipalities mandate this gutter style for buildings located in designated historic districts, making knowledge of these Roof Gutter System Parts essential for restoration and renovation projects. The smooth, curved interior surface promotes superior water flow characteristics compared to angular designs, as debris encounters fewer obstacles and sharp corners where it might accumulate. Half-round systems typically pair with round downspouts rather than rectangular ones, maintaining visual consistency throughout the drainage system. While these Roof Gutter System Parts offer excellent performance in managing water runoff, they generally provide lower capacity than equivalently-sized K-style alternatives, which may necessitate selecting larger dimensions or installing additional downspouts to handle peak flow volumes during severe weather events.

-

Box Gutter Systems

Box gutters represent specialized Roof Gutter System Parts designed for structures requiring exceptional water-handling capacity, particularly large commercial facilities, industrial buildings, and expansive residential properties with significant roof surface areas. Unlike conventional systems that mount along the roofline edge, box gutters integrate directly into the roof structure itself, with the high back section tucking beneath shingles or other roofing materials. This integration method creates a virtually invisible appearance from ground level while providing superior protection against water infiltration at the critical roof-to-wall junction. Box gutter systems typically start at seven or eight inches in width, with custom sizes reaching ten inches or more for extreme applications. The installation complexity of these Roof Gutter System Parts typically requires incorporation during initial construction phases, though retrofit installations remain possible when combined with comprehensive roof system renovations.

Material Selection for Roof Gutter System Parts

The material composition of your gutter system fundamentally determines its longevity, maintenance requirements, and overall cost-effectiveness over the system's service life. Modern manufacturing processes have created diverse material options for Roof Gutter System Parts, each offering distinct advantages that suit specific applications, budget constraints, and environmental conditions.

-

Aluminum Gutter Components

Aluminum has emerged as the dominant material choice for contemporary Roof Gutter System Parts due to its exceptional balance of performance characteristics and economic accessibility. The natural corrosion resistance of aluminum eliminates rust concerns even in coastal environments or regions with high humidity levels, significantly extending system lifespan without requiring protective coatings or frequent maintenance interventions. Lightweight characteristics simplify handling and installation procedures, reducing labor costs and making aluminum systems feasible for do-it-yourself projects when homeowners possess adequate construction skills. Manufacturers offer aluminum Roof Gutter System Parts in extensive color ranges, allowing precise matching with existing trim elements and architectural finishes. Standard aluminum thickness options include 0.025-inch, 0.027-inch, and 0.032-inch gauges, with heavier specifications providing enhanced resistance to denting from falling branches, hail impacts, or ladder placement during maintenance activities. The material readily accepts paint if color preferences change over time, providing long-term flexibility that rigid vinyl systems cannot match.

-

Premium Metal Roof Gutter System Parts

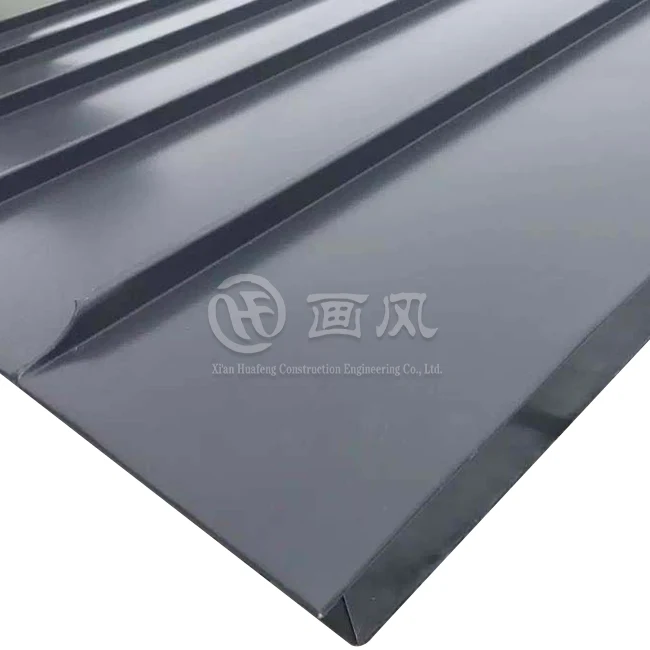

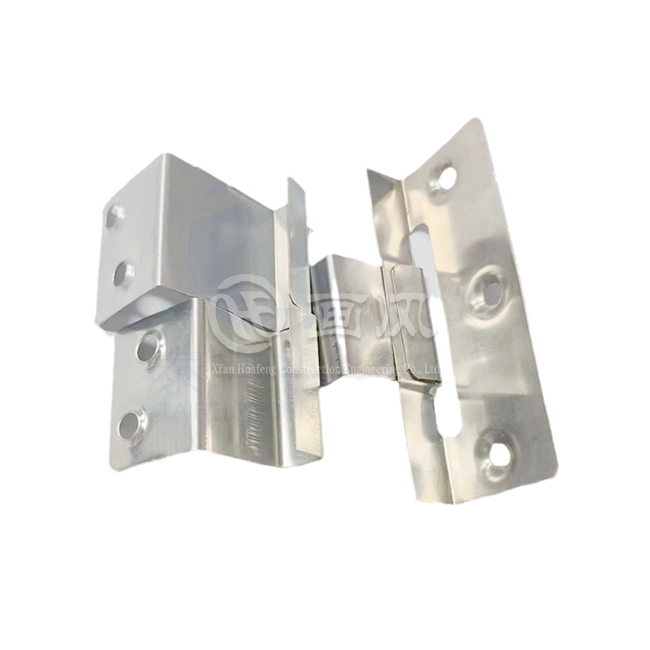

For projects demanding maximum durability and distinctive aesthetic character, premium metal options including copper, stainless steel, and specialized alloys offer performance advantages that justify their higher initial investment. Copper Roof Gutter System Parts develop a characteristic patina over time that many property owners find visually appealing, particularly on historic structures and luxury residences where the material complements traditional architectural styles. With proper installation and minimal maintenance, copper systems regularly provide fifty to one hundred years of reliable service, far exceeding the twenty-year average lifespan of conventional materials. Stainless steel alternatives deliver comparable longevity without the patina development, maintaining their original appearance indefinitely while resisting corrosion in the harshest environmental conditions. Xi'an Huafeng Construction Engineering Co., Ltd. manufactures premium Roof Gutter System Parts using AA3003 aluminum alloy, which combines the beneficial properties of standard aluminum with enhanced strength characteristics and superior corrosion resistance, making these components ideal for demanding commercial applications and high-end residential projects requiring extended warranty coverage.

-

Vinyl and Steel Alternatives

Vinyl gutters appeal to budget-conscious projects where initial cost minimization takes precedence over long-term durability considerations. These Roof Gutter System Parts typically cost significantly less than metal alternatives and resist rust and corrosion completely since they contain no metallic components. However, vinyl systems demonstrate vulnerability to temperature extremes, becoming brittle and prone to cracking during severe winter conditions while potentially warping or sagging under intense summer heat exposure. Galvanized steel and color-coated steel options provide enhanced structural strength compared to aluminum, resisting denting and physical damage more effectively, though they require protective coatings to prevent rust formation. Modern color-coated steel Roof Gutter System Parts incorporate multiple protective layers that extend service life substantially, making them suitable for regions with extreme weather patterns where material durability becomes paramount.

Seamless Versus Sectional Roof Gutter System Parts

The construction methodology employed for your gutter system significantly influences its vulnerability to leakage, maintenance requirements, and overall aesthetic presentation. Understanding the fundamental differences between seamless and sectional Roof Gutter System Parts helps property owners make informed decisions aligned with their specific project requirements and long-term maintenance capabilities.

-

Seamless Gutter Systems

Seamless gutters are custom-fabricated on-site using specialized roll-forming equipment that shapes continuous sections of material to exact specifications matching your building's dimensions. This manufacturing approach eliminates joints along horizontal runs, removing the primary failure points where traditional sectional systems experience leakage as sealants deteriorate and fasteners loosen over time. Professional installation becomes mandatory for seamless Roof Gutter System Parts since the fabrication equipment and technical expertise required exceed typical do-it-yourself capabilities. The higher initial investment for seamless systems typically generates positive returns through reduced maintenance expenses and extended service life, with properly installed seamless gutters frequently operating trouble-free for decades. The continuous, joint-free appearance of seamless Roof Gutter System Parts creates superior visual appeal compared to sectional alternatives, enhancing property aesthetics while providing functional benefits that protect building foundations and landscaping from water damage.

-

Sectional Gutter Components

Sectional gutters consist of pre-manufactured lengths, typically ten or twenty feet long, connected using splice fittings and sealed with specialized caulking compounds designed to remain flexible across temperature variations. The modular nature of sectional Roof Gutter System Parts facilitates do-it-yourself installation projects and simplifies future repairs since damaged sections can be replaced individually without affecting the entire system. Home improvement retailers stock extensive selections of sectional components, providing immediate availability that eliminates the scheduling delays sometimes associated with custom seamless fabrication. However, the multiple joints inherent in sectional designs create ongoing maintenance obligations as sealants require periodic inspection and renewal to prevent leakage. Temperature fluctuations cause expansion and contraction that gradually stresses joint connections, potentially leading to separation if maintenance is deferred. For projects where immediate cost minimization outweighs long-term considerations, sectional Roof Gutter System Parts provide functional performance at accessible price points.

Complete Gutter System Components and Accessories

A comprehensive gutter system extends far beyond the horizontal channels that collect roof runoff. Understanding the complete array of Roof Gutter System Parts and their respective functions ensures proper system design that effectively manages water from initial collection through final discharge away from building foundations.

-

Essential System Elements

Downspouts represent critical Roof Gutter System Parts that transport collected water from gutter channels to ground level, where it can be directed safely away from building perimeters. These vertical components typically come in rectangular or round cross-sections, with sizes ranging from three to six inches depending on the volume of water they must handle during peak rainfall events. The general guideline recommends installing one downspout for every thirty to forty linear feet of gutter, though regions experiencing intense precipitation may require closer spacing to prevent overflow conditions. Elbows and offset fittings allow downspouts to navigate around architectural features and reach desired discharge locations, with quality Roof Gutter System Parts incorporating smooth interior surfaces that minimize friction and maintain flow velocity. End caps seal gutter termination points, while outlet fittings create watertight connections between horizontal gutters and vertical downspouts. Hangers and brackets secure gutters to fascia boards or rafters, with spacing and load-bearing capacity carefully calculated to prevent sagging under the combined weight of the gutter material, accumulated water, and seasonal ice buildup.

-

Advanced Protection Accessories

Gutter guards and protective screens represent valuable additions to Roof Gutter System Parts installations, dramatically reducing maintenance requirements by preventing leaves, twigs, and other debris from entering gutter channels where they could create blockages. Multiple guard styles exist, including mesh screens, perforated metal covers, and sophisticated surface-tension systems that allow water entry while shedding solid materials. The initial investment in quality gutter protection typically recovers costs within several years through eliminated cleaning expenses and reduced risk of water damage from clogged systems. Downspout extensions carry water several feet beyond foundation walls, preventing the soil saturation that leads to basement seepage and foundation settlement. Heat cables installed within gutters and downspouts prevent ice dam formation in cold climates, ensuring continued drainage functionality throughout winter months when roof snow melts during daytime temperature rises. Xi'an Huafeng Construction Engineering Co., Ltd. provides comprehensive Roof Gutter System Parts packages including all necessary accessories, manufactured to precise tolerances using AA3003 aluminum alloy with thickness specifications ranging from 0.7 to 1.0 millimeters for gutter channels and 0.8 to 1.0 millimeters for downspout components.

Selecting Appropriate Roof Gutter System Parts for Your Project

Choosing optimal gutter components requires careful evaluation of multiple factors including building characteristics, regional climate patterns, architectural style preferences, and budget parameters. Systematic analysis of these considerations ensures selection of Roof Gutter System Parts that deliver reliable performance throughout their intended service life while complementing your property's visual presentation.

-

Climate and Environmental Considerations

Regional precipitation patterns directly influence the capacity requirements for effective Roof Gutter System Parts. Areas experiencing frequent heavy downpours need larger gutter sizes and more closely-spaced downspouts compared to arid regions with infrequent rainfall. Cold climates impose additional demands on gutter systems, with ice formation creating substantial weight loads that can damage inadequately-supported installations. Temperature cycling between freezing and thawing conditions stresses joint connections and sealants in sectional systems, making seamless alternatives particularly advantageous for northern locations. Coastal environments and industrial areas with corrosive atmospheric conditions demand Roof Gutter System Parts manufactured from materials with superior corrosion resistance, such as aluminum alloys or stainless steel. Wind exposure influences hanger spacing requirements, as structures in exposed locations experience greater wind-driven rain forces that can overwhelm undersized gutter systems or dislodge improperly secured components.

-

Architectural Integration

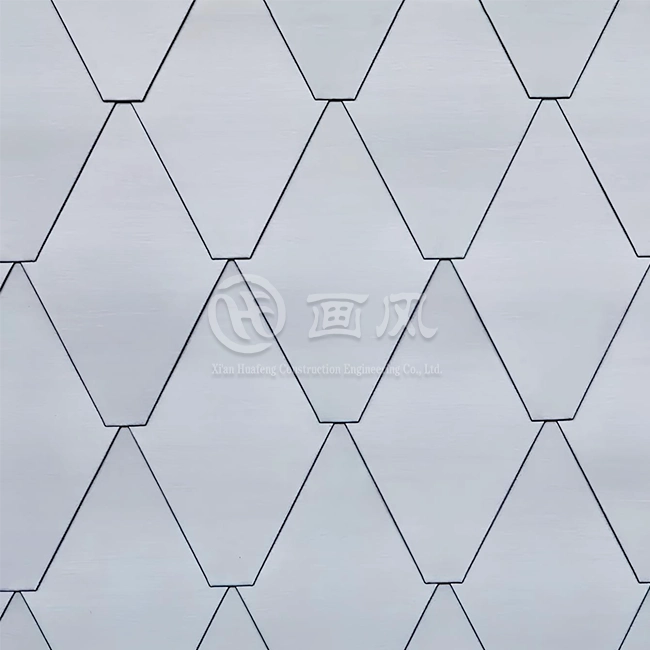

The visual relationship between gutters and overall building aesthetics significantly impacts property appearance and market value. Historic structures often require specific Roof Gutter System Parts styles to maintain architectural authenticity and comply with preservation regulations. Half-round gutters complement traditional Victorian, Colonial, and Craftsman-style homes, while contemporary properties benefit from the clean lines of K-style systems. Color selection allows gutters to either blend discreetly with trim elements or create intentional contrast that emphasizes architectural details. Custom color-matching services ensure perfect coordination with existing finishes, with options including white, gray tones, bronze, and brown for standard applications. Xi'an Huafeng Construction Engineering Co., Ltd. offers Roof Gutter System Parts in seven standard color options including white, light gray, milky white, dark gray, black, brown, and bronze, with custom color-matching available for projects requiring precise aesthetic coordination. The manufacturing capabilities include multiple K-type specifications ranging from five inches through eight inches, with custom sizing available to address unique architectural requirements.

-

Professional Installation and Quality Assurance

While some Roof Gutter System Parts installations remain within the capabilities of skilled do-it-yourself enthusiasts, complex projects benefit significantly from professional installation services that ensure proper system design, correct component selection, and expert installation techniques. Professional installers calculate precise gutter slopes to promote drainage without creating unsightly sagging, determine optimal hanger spacing based on structural loads and material properties, and integrate systems seamlessly with existing roof structures. Quality installation includes careful attention to end cap sealing, outlet fitting connections, and downspout anchoring that prevents future leakage and component separation. Xi'an Huafeng Construction Engineering Co., Ltd. provides comprehensive installation services backed by three decades of engineering experience, with projects ranging from residential applications to major commercial facilities including Xi'an International Convention and Exhibition Center, Xiongan Station Commercial Complex, and Inner Mongolia Tongliao Art Museum. The company maintains three manufacturing facilities with seven production lines and over forty specialized machines, generating monthly production capacity exceeding ten thousand tons to accommodate large-scale projects with demanding delivery schedules. All Roof Gutter System Parts comply with international standards including ASTM, DIN, JIS, BS, and GB/T specifications, with quality management systems certified to ISO9001 and ISO14000:14001 requirements.

Conclusion

Selecting appropriate gutter systems requires balancing multiple considerations including style preferences, material properties, climate demands, and budget constraints. Quality Roof Gutter System Parts manufactured from durable materials and professionally installed provide decades of reliable protection against water damage while enhancing property aesthetics and value.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

Xi'an Huafeng Construction Engineering Co., Ltd. stands as a recognized leader among China Roof Gutter System Parts factory operations, combining advanced manufacturing capabilities with comprehensive engineering expertise developed since the company's establishment in 2018. As a prominent China Roof Gutter System Parts supplier and China Roof Gutter System Parts manufacturer, the organization maintains three specialized production facilities spanning over 200,000 square meters, with locations in Anhui, Hangzhou, and Xi'an strategically positioned to serve domestic and international markets efficiently. The company achieved high-tech enterprise recognition in Shaanxi Province during 2020, holds first-level qualifications for building curtain wall construction and third-level qualifications for steel structure projects, demonstrating the comprehensive capabilities that distinguish professional China Roof Gutter System Parts wholesale providers from limited-scope competitors.

Manufacturing excellence begins with premium raw materials sourced from industry-leading suppliers including Alucosuper, YATAI, and LIDAO for aluminum components, with rigorous incoming inspection protocols ensuring all materials meet exacting specifications before entering production processes. Seven color-coating production lines and over forty specialized machines including automated punching systems, longitudinal and transverse shearing equipment, and precision bending apparatus enable consistent manufacturing of High Quality Roof Gutter System Parts meeting international standards. The AA3003 aluminum alloy employed throughout the Roof Gutter System Parts for sale inventory provides optimal combinations of strength, corrosion resistance, and formability, with surface treatments including anodizing and electrostatic powder coating delivering long-lasting aesthetic appeal and environmental protection. Comprehensive product specifications accommodate diverse project requirements, with K-type gutter systems available in sizes from five through eight inches, thickness ranges from 0.7 to 1.0 millimeters, square downspouts in dimensions including 80x50mm through 120x90mm, and circular downspouts from 50mm to 100mm diameters.

The organization's one-stop service model encompasses complete project lifecycles from initial concept development through final installation and ongoing maintenance support. Engineering teams provide structural 3D modeling, load analysis calculations, and drainage system simulations that optimize designs for specific site conditions and performance requirements. The design department conducts detailed drawing development with 1:1 scale node detailing, followed by factory sample production that establishes definitive quality standards before full-scale manufacturing commences. Sequential numbering systems track individual components from production through quality inspection, packaging, and site installation, eliminating confusion and ensuring accurate assembly. On-site construction management includes pre-installation inspections, technical briefing meetings covering safety protocols and installation procedures, and post-installation testing that verifies zero-leakage performance before final acceptance. Quality assurance extends beyond manufacturing processes to encompass comprehensive warranty coverage, with thirty-year service life guarantees demonstrating confidence in product durability and performance reliability. All Roof Gutter System Parts price quotations include detailed specifications, delivery timelines typically ranging from fifteen to twenty days, and free sample provision enabling thorough evaluation before commitment to large-scale orders. More than twenty registered patents, numerous trademarks, and multiple software certifications document ongoing innovation and intellectual property development that keeps manufacturing processes at industry forefront. International standard compliance including ISO9001 quality management, ISO14000:14001 environmental management, and SGS certification provides customers with confidence that products meet global best practices for safety, performance, and environmental responsibility.

Notable project references including Xiongan Station Commercial Complex metal roofing, Xi'an International Convention and Exhibition Center installations, Hangzhou Sanpu Drainage Pump Station systems, and Inner Mongolia Tongliao Art Museum applications demonstrate successful execution across diverse building types and challenging technical requirements. Engineering design experience accumulated across hundreds of projects, construction expertise refined through complex installation challenges, and established relationships with Fortune 500 companies position the organization as the preferred partner for demanding applications where compromise is unacceptable. Whether your project requires standard Roof Gutter System Parts for sale configurations or custom-engineered solutions addressing unique architectural or performance specifications, Xi'an Huafeng Construction Engineering Co., Ltd. delivers exceptional value through integrated manufacturing and installation capabilities. Contact our technical team today at huafeng@hfmetalroof.com to discuss your specific requirements, request detailed technical specifications, obtain comprehensive project quotations, or arrange facility tours that demonstrate manufacturing capabilities firsthand. Save this resource for future reference and reach out whenever questions arise about optimal gutter system selection, installation best practices, or maintenance protocols that maximize system longevity and performance.

References

1. American Society of Civil Engineers. (2021). Minimum Design Loads and Associated Criteria for Buildings and Other Structures. ASCE/SEI 7-16 Standard.

2. National Roofing Contractors Association. (2022). The NRCA Roofing Manual: Architectural Metal Flashing, Condensation and Air Leakage Control, and Reroofing. NRCA Publications.

3. Smith, R. J., & Thompson, M. A. (2020). Building Envelope Design Guide: Water Management Systems for Residential and Commercial Construction. Construction Industry Press.

4. Wilson, J. D., Martinez, L. P., & Chen, W. (2019). Comparative Performance Analysis of Gutter Materials and Configurations in Various Climate Zones. Journal of Building Performance, 15(3), 234-256.