Facing urgent construction deadlines while waiting weeks for metal siding panels can derail your entire project timeline and budget. When you need multipurpose metal siding panels delivered quickly without compromising quality, the 3-day turnaround solution with Vertical Metal Siding Sheets becomes your competitive advantage, eliminating costly project delays and ensuring your building envelope is protected on schedule.

Why Fast Turnaround Matters for Vertical Metal Siding Sheets Projects?

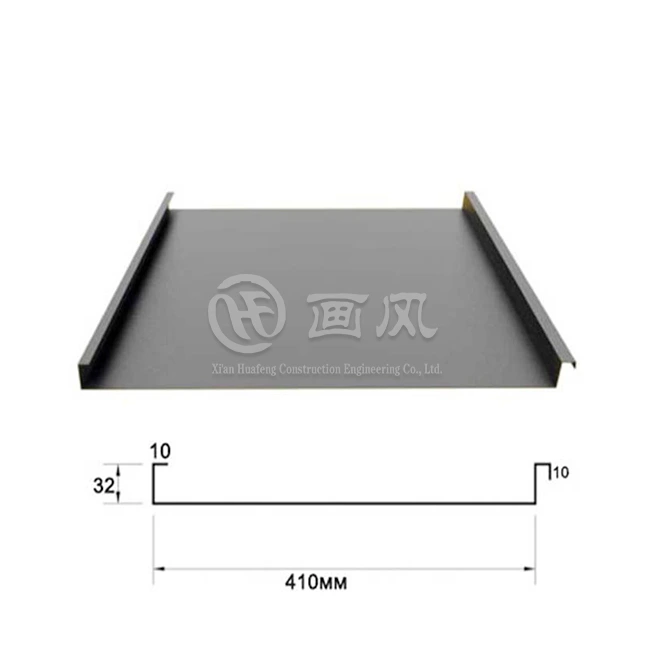

Construction professionals understand that time is money, and project schedules are increasingly compressed in today's competitive marketplace. When specifying Vertical Metal Siding Sheets for commercial buildings, industrial facilities, or residential projects, the traditional 3-6 week lead time for custom metal panels creates significant challenges. Weather windows close, labor crews sit idle, and project costs escalate when materials arrive late. The 3-day turnaround solution addresses these pain points directly by providing fully customized multipurpose metal siding panels manufactured to exact specifications in a fraction of the standard time. Vertical Metal Siding Sheets have emerged as the preferred choice for architects and contractors who demand both aesthetic flexibility and structural performance. Unlike traditional horizontal siding that can trap moisture and complicate drainage, vertical panel orientation naturally channels water away from the building envelope. The rapid production capability means projects no longer need to compromise between customization and speed. With specifications including 25-330/400/430/500 and 65-400/430/500 configurations, PE, HDP, and PVDF coating options, and customizable colors and patterns, builders receive precisely what their projects require without the typical manufacturing delays that plague the construction industry.

-

Rapid Manufacturing Without Quality Compromise

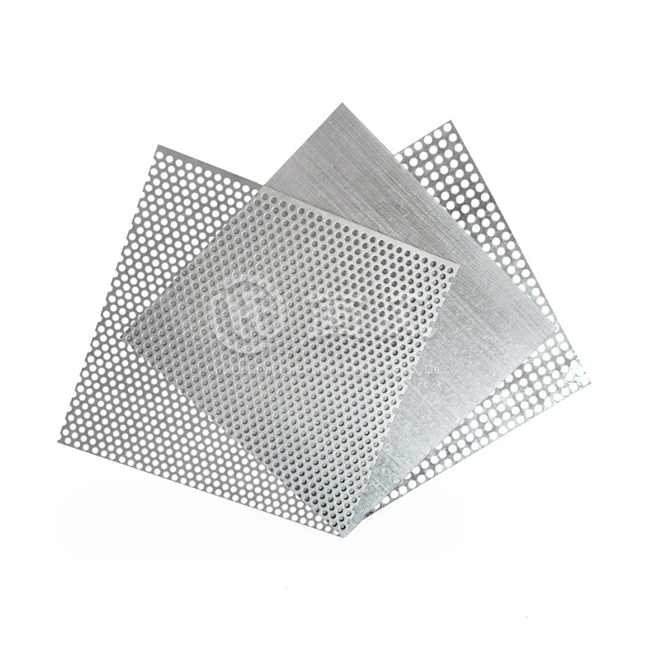

The engineering behind 3-day turnaround manufacturing represents a sophisticated balance of advanced equipment, streamlined processes, and quality control systems. Modern roll-forming systems equipped with real-time quality monitoring ensure that every panel meets stringent specifications while maintaining accelerated production schedules. The manufacturing workflow begins with material procurement from verified suppliers, where brands like Alucosuper, YATAI, and LIDAO for aluminum products, and BAOSTEEL, GUANZHOU, and XINYU for steel products ensure raw material consistency. This careful supplier selection, combined with incoming material inspection protocols that include appearance verification, dimensional accuracy checks, salt spray testing, adhesion analysis, hardness evaluation, impact resistance, film thickness measurement, acid resistance, weather resistance testing, and color difference assessment, creates a foundation for reliable fast-turnaround production. Each Vertical Metal Siding Sheet undergoes precision manufacturing that leverages seven color coating production lines, one laminating production line, and ten longitudinal and transverse shearing production lines. This extensive equipment capacity, supported by fully automatic punching production lines and more than forty shearing machines, presses, and bending machines, enables simultaneous processing of multiple project orders without bottlenecks. The finished product inspection process examines appearance, dimensions, flatness, and curvature before specialized packaging that divides products according to sectioned floor plans, complete with identification cards containing section plans and product number lists. This systematic approach ensures that rapid production never compromises the structural integrity or aesthetic quality that Vertical Metal Siding Sheets must deliver for long-term building performance.

Comprehensive Material Options for Every Application

Selecting appropriate materials for Vertical Metal Siding Sheets requires understanding how different alloys and coatings perform under specific environmental conditions and aesthetic requirements. Multipurpose metal siding panels accommodate diverse project needs through material flexibility that spans from cost-effective galvanized steel to premium stainless steel and specialized titanium-zinc compositions. Each material brings distinct advantages that align with particular building types, geographic locations, and budget parameters. Galvanized steel remains the workhorse of the metal siding industry, offering exceptional corrosion resistance through zinc coating protection at price points that make it accessible for agricultural buildings, warehouses, and light commercial structures. The cold-rolled, galvanized, and galvalume sheet options provide progressive levels of rust protection, with galvalume's aluminum-zinc coating delivering superior long-term durability in humid or coastal environments. For projects requiring lightweight solutions without sacrificing strength, aluminum Vertical Metal Siding Sheets in 3003, 3004, and 5052 alloy grades provide excellent formability and natural corrosion resistance that eliminates rust concerns entirely. Coastal properties and high-humidity regions particularly benefit from aluminum's inherent resistance to salt air degradation, making it an ideal choice for marina buildings, seaside restaurants, and beachfront commercial developments.

Premium applications demand materials that deliver both exceptional performance and distinctive aesthetics. Stainless steel Vertical Metal Siding Sheets in 316 and 304 grades represent the top tier of metal siding solutions, offering unmatched corrosion resistance in aggressive industrial environments, chemical processing facilities, and high-end architectural projects where material longevity justifies higher initial investment. Titanium-zinc panels from suppliers like NedZink provide a unique living finish that develops a natural patina over time, creating an evolving aesthetic that appeals to architects seeking organic material expressions. Copper options in T2 and TP2 grades offer similar patina development characteristics with the added benefit of natural antimicrobial properties, making them particularly suitable for healthcare facilities and food processing buildings where hygiene considerations influence material selection.

-

Surface Finishes That Protect and Perform

The coating applied to Vertical Metal Siding Sheets significantly impacts both longevity and appearance throughout the building's service life. PVDF coatings represent the premium finish option, offering superior fade resistance, chalk resistance, and chemical resistance that maintains color integrity for 30 years or more. This high-performance coating system withstands ultraviolet radiation, acid rain, salt spray, and industrial pollutants without significant degradation, making it essential for high-visibility projects where appearance retention justifies the investment. Polyester paint finishes provide cost-effective protection for projects with moderate environmental exposure, delivering reliable performance in typical suburban and rural settings where extreme weathering factors are absent. The 30-year warranty accompanying properly specified and installed Vertical Metal Siding Sheets reflects manufacturer confidence in material and coating system durability. This extended warranty coverage provides building owners with financial protection and peace of mind regarding their exterior cladding investment. The warranty typically covers coating adhesion, color fade beyond specified limits, and material structural integrity, though specific terms vary based on coating type, material selection, and environmental exposure classification. High-quality Vertical Metal Siding Sheets meeting ISO9001, ISO14000:14001, and SGS guidelines demonstrate adherence to international standards for quality management, environmental responsibility, and product testing, providing additional assurance beyond basic warranty coverage.

Design Flexibility with Multiple Profile Options

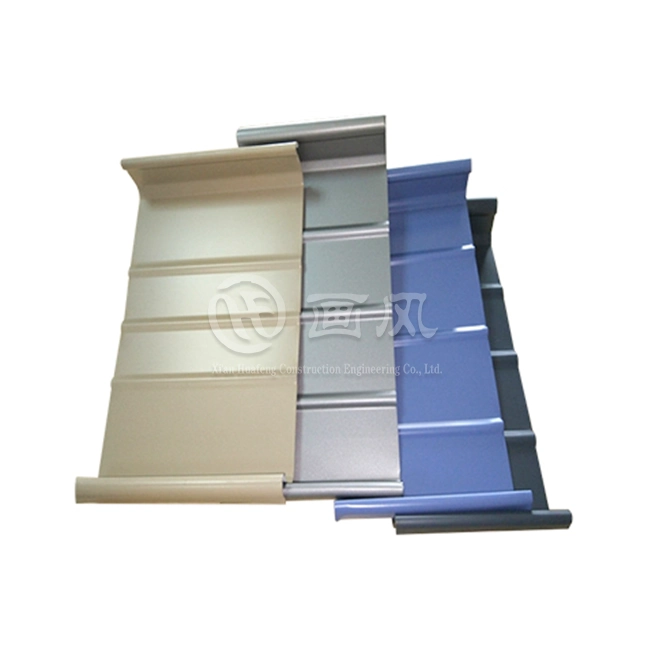

Architectural expression through Vertical Metal Siding Sheets extends far beyond simple flat panel installations, encompassing diverse profile configurations that create visual interest while addressing specific performance requirements. The standing seam profile, characterized by raised vertical seams with concealed fasteners, delivers clean contemporary aesthetics particularly valued in modern commercial architecture and upscale residential applications. This profile type allows for thermal movement accommodation through clip attachment systems, preventing oil-canning and panel distortion across wide temperature ranges. The concealed fastener design eliminates exposed screw heads that can become rust points or water infiltration pathways, contributing to enhanced long-term weatherproofing and reduced maintenance requirements. Corrugated Vertical Metal Siding Sheets feature wavy patterns that provide inherent structural stiffness through geometric shape rather than material thickness alone, making them ideal for agricultural buildings, industrial structures, and budget-conscious projects where traditional appearance and cost-effectiveness rank as primary decision factors. The corrugation depth and spacing influence both strength characteristics and visual texture, with deeper corrugations offering greater span capabilities for wide-bay buildings with minimal secondary framing. Flat lock panels create smooth, monolithic facades with subtle joint lines that emphasize horizontal proportions while maintaining vertical panel orientation. This profile works exceptionally well for contemporary office buildings, retail centers, and mixed-use developments where refined architectural aesthetics require panel joints to remain visually subordinate to overall building form.

Ribbed panel profiles incorporate vertical grooves of varying depths and spacings to create shadow lines and texture without the pronounced corrugation of traditional agricultural panels. These profiles bridge the gap between smooth flat lock panels and heavily textured corrugated sheets, offering visual interest appropriate for suburban office parks, light industrial facilities, and commercial buildings seeking distinctive character without overwhelming architectural expression. The ribs add structural depth that enhances panel strength and stiffness, potentially reducing substrate framing requirements and overall system costs. Panel widths typically range from 12 inches to 24 inches of coverage, with custom lengths available up to 40 feet to minimize horizontal joints and reduce installation time on tall building facades.

-

Color and Texture Customization

The aesthetic impact of Vertical Metal Siding Sheets extends significantly beyond profile selection to encompass an extensive range of colors, textures, and finishes that enable precise architectural vision realization. Standard color offerings typically include neutral tones from whites and grays to earth tones and darker shades, while custom color matching services accommodate specific branding requirements or designer color palettes. Metallic finishes create dynamic visual effects that shift with viewing angle and lighting conditions, adding depth and sophistication to building exteriors. Matte finishes minimize glare and provide subtle elegance appropriate for residential neighborhoods and contexts where visual restraint aligns with community character. Wood grain textures applied to metal substrates deliver the aesthetic warmth of natural wood siding without the maintenance burdens, rot susceptibility, and fire vulnerabilities inherent in organic materials. These textured finishes appeal particularly to residential projects, boutique retail locations, and hospitality buildings where traditional material appearances must meet contemporary performance standards. Stone and brick textures similarly enable metal panels to emulate masonry aesthetics while maintaining the lightweight, rapid installation, and cost advantages that make Vertical Metal Siding Sheets increasingly popular across diverse building types. The ability to specify exact colors, patterns, and textures with 500-square-meter minimum order quantities makes custom solutions accessible even for moderately sized projects requiring distinctive architectural expression.

Installation Efficiency and Technical Support

The practical advantages of 3-day turnaround Vertical Metal Siding Sheets extend into the installation phase, where material availability directly impacts labor scheduling, equipment utilization, and overall project cash flow. Fast material delivery enables just-in-time construction sequencing that minimizes on-site storage requirements, reduces material handling, and decreases theft exposure. Installation crews can maintain continuous productivity without costly standby periods waiting for materials, maximizing labor efficiency and project profitability. The lightweight nature of Vertical Metal Siding Sheets, typically weighing approximately 2 pounds per linear foot or 68 pounds per 100 square feet, facilitates manual handling and reduces structural loading compared to masonry or heavyweight panel systems. Technical support beginning with project drawing deepening ensures that design intent translates accurately into constructible details. The process analyzes architectural floor plans, elevations, and node diagrams to identify feasible alternatives and optimize panel selection for specific roof and wall structures. Design departments conduct one-to-one drawing refinement of nodes throughout different project areas, with multiple communication rounds and confirmations culminating in signed approved drawings that become the construction contract documents. Factory processing samples manufactured according to confirmed parameters including board type, material, thickness, surface treatment method, and color provide physical verification before full production begins. These sealed samples establish acceptance standards for subsequent product processing, production, and field inspection, eliminating ambiguity and reducing conflict during project closeout.

Processing drawing development breaks down detailed architectural drawings into granular production documents that guide manufacturing, quality assurance, and installation activities. Sequential numbering according to project specifications and quantities ensures that production processing, quality department inspection and packaging, and on-site installation proceed systematically according to assigned numbers, preventing confusion and reducing error rates. On-site construction guidance begins with confirmation of specific layout requirements addressing product and accessory storage, along with processing areas. Product arrival and warehousing procedures verify data and arrange materials according to packaging identification cards and product number lists, while installation technicians conduct pre-construction site inspections to confirm tool readiness and auxiliary material completeness. The comprehensive approach culminating in zero-leakage testing upon installation completion demonstrates commitment to performance verification rather than simple project handoff.

Quality Assurance and Certification Standards

The reliability of 3-day turnaround Vertical Metal Siding Sheets rests upon rigorous quality assurance protocols that begin with raw material verification and continue through finished product inspection and field performance monitoring. Material traceability systems document the supply chain from primary metal producers through coating applicators to final panel manufacturers, creating accountability and enabling rapid response should quality issues emerge. Raw material manufacturers must provide material certifications and third-party testing reports confirming chemical composition, mechanical properties, and coating characteristics meet specified requirements. Incoming material inspection employs both full inspection protocols for small quantities and high-unit-price materials, along with sampling inspection methods for larger quantities and frequently purchased materials, preventing defective materials from entering production workflows. The inspection regime encompasses more than a dozen discrete tests including product appearance evaluation to identify surface defects, dimensional verification confirming thickness and width tolerances, salt spray testing simulating accelerated corrosion exposure, adhesion testing ensuring coating bonding strength, hardness measurement verifying coating cure completeness, impact resistance assessment determining coating flexibility, film thickness measurement confirming adequate protection, acid resistance testing evaluating chemical exposure performance, weather resistance verification simulating long-term ultraviolet and moisture exposure, and color difference measurement ensuring batch-to-batch consistency. This comprehensive testing framework, combined with ISO9001 quality management system certification and ISO14000:14001 environmental management certification, provides multilayered assurance that manufactured Vertical Metal Siding Sheets will deliver specified performance throughout their service life.

More than 20 registered patents for roofing and wall systems, along with various trademarks and computer software certificates, demonstrate ongoing innovation and intellectual property development that keeps manufacturing processes and product designs at the industry forefront. High-tech enterprise recognition from Shaanxi Province authorities validates technological capabilities and research commitment, while first-level qualification for building curtain walls and third-level qualification for building steel structures confirms regulatory compliance and technical competency for complex facade systems. SGS certification provides independent third-party verification of product quality and manufacturing consistency, offering international credibility that facilitates export sales and multinational project specifications.

Proven Project Performance Across Applications

The versatility of Vertical Metal Siding Sheets manifests through successful installations spanning transportation infrastructure, cultural facilities, educational buildings, and commercial developments. Notable projects demonstrate both technical capability and aesthetic flexibility across diverse building types and architectural styles. The Xiongan Station Commercial Body features aluminum-magnesium-manganese metal roofing that withstands high foot traffic and weather exposure while maintaining the sleek contemporary appearance appropriate for a major transportation hub. Xi'an International Convention and Exhibition Center's metal roof project showcases the large-scale panel installation capability required for expansive column-free spaces, where structural efficiency and visual continuity create impressive interior environments. The Metal Roof Project at Xi'an Station East Auxiliary Building illustrates integration with historic railway architecture, where metal panels complement traditional building forms while meeting modern performance standards for waterproofing, energy efficiency, and maintenance economy. South Hall 2-2 of Jinghe New City International Culture and Art Center demonstrates how Vertical Metal Siding Sheets contribute to cultural building architecture requiring distinctive facades that express institutional character and community pride. Highway infrastructure applications like the Liyuanping Highway Station Metal Roof Project prove metal panel durability under harsh exposure conditions including vehicle emissions, deicing chemicals, and temperature extremes that accelerate material degradation in lesser systems.

Educational facilities including the Weihua Cadre College Teaching Building and Office Building incorporate aluminum-magnesium-manganese metal roof and wall systems that deliver long service life with minimal maintenance, aligning with institutional budget constraints and sustainability goals. Municipal infrastructure projects such as the Hangzhou Sanpu Drainage Pump Station utilize aluminum-magnesium-manganese metal roof and wall systems in corrosive humid environments where material selection directly impacts operational reliability and lifecycle costs. Museum applications including the Archaeological Museum design deepening project and Inner Mongolia Tongliao Art Museum metal roof and wall installations demonstrate how Vertical Metal Siding Sheets accommodate complex geometries and exacting aesthetic requirements that cultural institutions demand.

Sustainability and Lifecycle Considerations

Modern construction increasingly emphasizes environmental stewardship and resource efficiency throughout building lifecycles, positioning Vertical Metal Siding Sheets favorably within green building frameworks. Metal panels are inherently recyclable materials that retain value at end-of-service-life, contrasting sharply with vinyl siding, fiber cement, and other cladding materials that typically end in landfills. The recycling infrastructure for steel and aluminum is well-established globally, with metal scrap commanding market prices that incentivize recovery and reprocessing. This circular economy characteristic reduces embodied carbon impacts compared to virgin material production, though manufacturing energy requirements for metal panels generally exceed those for wood siding or fiber cement when analyzed cradle-to-gate. The durability advantage of properly specified and installed Vertical Metal Siding Sheets extends functional service life significantly beyond alternative cladding materials, potentially eliminating multiple replacement cycles required for wood, vinyl, or fiber cement siding over a 50-75 year building lifespan. This longevity reduces lifecycle material consumption, construction waste generation, and renovation disruptions that impose costs beyond simple material replacement expenses. The minimal maintenance requirements for metal cladding eliminate or drastically reduce paint recoating, pressure washing, rot repair, and insect damage remediation activities that consume resources and generate waste throughout typical building operation periods.

Energy performance contributions from Vertical Metal Siding Sheets depend heavily on system design and installation details, with opportunities for enhanced performance through careful specification. Reflective coatings with high solar reflectance values reduce heat gain through building envelopes, potentially lowering cooling energy consumption in warm climates. When combined with adequate insulation in wall assemblies, metal cladding systems contribute to overall building thermal performance without the thermal bridging challenges inherent in metal stud framing. Ventilated cavity details behind metal panels create rainscreen assemblies that manage moisture while allowing air movement that enhances drying potential, contributing to envelope durability and occupant comfort. The green sustainable development concept integration guiding company philosophy ensures that environmental considerations inform product development, manufacturing processes, and customer technical support.

Conclusion

Multipurpose metal siding panels with 3-day turnaround capability transform project planning and execution by eliminating material delivery delays that compromise construction schedules. Vertical Metal Siding Sheets deliver architectural flexibility, structural performance, and long-term durability within accelerated production timeframes that meet modern construction demands without quality compromise.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

Xi'an Huafeng Construction Engineering Co., Ltd. stands as your trusted China Vertical Metal Siding Sheets manufacturer and China Vertical Metal Siding Sheets supplier, offering high quality Vertical Metal Siding Sheets with competitive Vertical Metal Siding Sheets price through our China Vertical Metal Siding Sheets factory. As a leading China Vertical Metal Siding Sheets wholesale provider, we deliver Vertical Metal Siding Sheets for sale backed by over 20 patent certificates, CE certification, ISO certification, and SGS certification. Our comprehensive capabilities include engineering design expertise, construction experience, seven raw material production lines, more than 20 plate production machines, and successful partnerships with Fortune 500 companies. We provide one-stop service from design optimization and raw material quality testing through customized production, multiple packaging options, and diverse transportation methods tailored to your project requirements. Contact us at huafeng@hfmetalroof.com to discuss how our 15-20 day delivery time, 500-square-meter minimum order quantity, and customization services for color, pattern, and design can solve your building envelope challenges while adding architectural value to your projects.

References

1. American Institute of Steel Construction. "Metal Building Systems Manual." AISC Design Guide Series, 2020.

2. Metal Construction Association. "Technical Guidelines for Metal Wall Panel Installation." MCA Publication, 2022.

3. National Roofing Contractors Association. "The NRCA Metal Panel and SPF Roof Systems Manual." NRCA Technical Publications, 2021.

4. Sheet Metal and Air Conditioning Contractors' National Association. "Architectural Sheet Metal Manual." SMACNA Technical Standards, 2023.

(1)_1763110678300.webp)