When industrial facility managers face constant roof leaks, escalating maintenance costs, and premature system failures that disrupt operations, the solution lies in choosing the right roofing technology from the start. Seam Metal Roof Systems have emerged as the definitive answer to these critical challenges, delivering unmatched durability, weatherproofing, and long-term value that traditional roofing simply cannot match in demanding industrial environments where downtime costs thousands per hour.

Why Seam Metal Roof Systems Dominate Industrial Roofing Solutions?

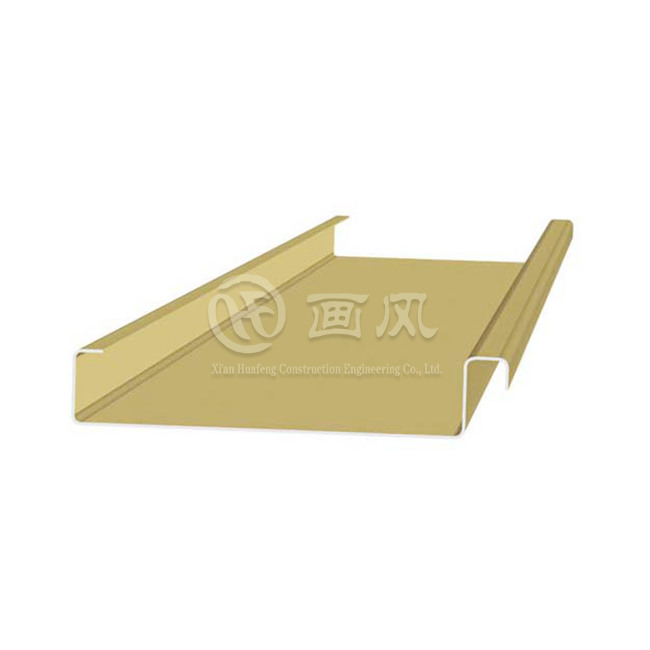

Industrial facilities demand roofing systems that can withstand extreme operational stresses while minimizing lifecycle costs. Seam Metal Roof Systems address these requirements through their sophisticated engineering and superior material composition. Unlike conventional roofing that deteriorates rapidly under industrial conditions, standing seam metal roof configurations utilize concealed fastener technology that eliminates penetration points where water infiltration typically occurs. This fundamental design advantage transforms roof reliability from a maintenance headache into a long-term asset. The aluminum-magnesium-manganese alloy composition used in premium Seam Metal Roof Systems provides exceptional corrosion resistance that outperforms standard galvanized steel by decades. Industrial environments often expose roofing to chemical vapors, temperature extremes, and mechanical stress that would compromise lesser materials within years. The AA3003 and AA3004 alloy specifications deliver both considerable strength and remarkable flexibility, enabling these systems to accommodate thermal expansion without structural damage or fastener failure. This material science advantage directly translates to extended service life, with properly installed standing seam metal roof systems regularly exceeding forty years of maintenance-free operation even in the harshest industrial settings.

-

Concealed Fastening Technology Eliminates Common Failure Points

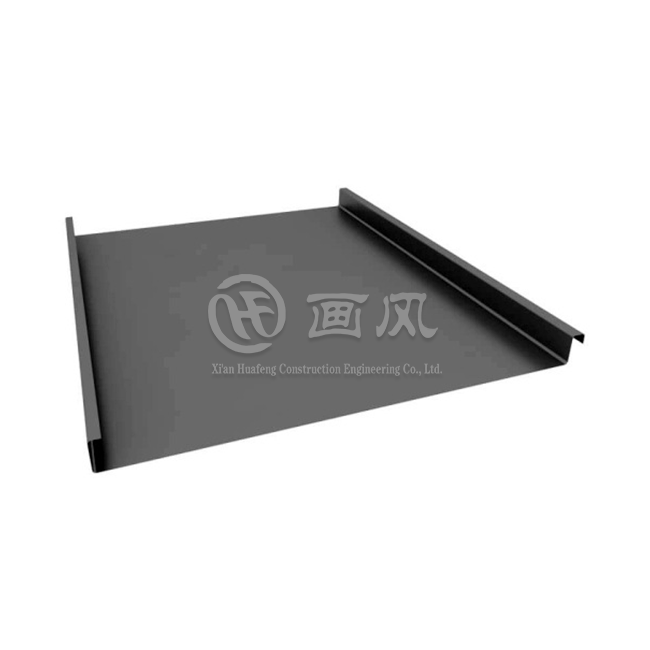

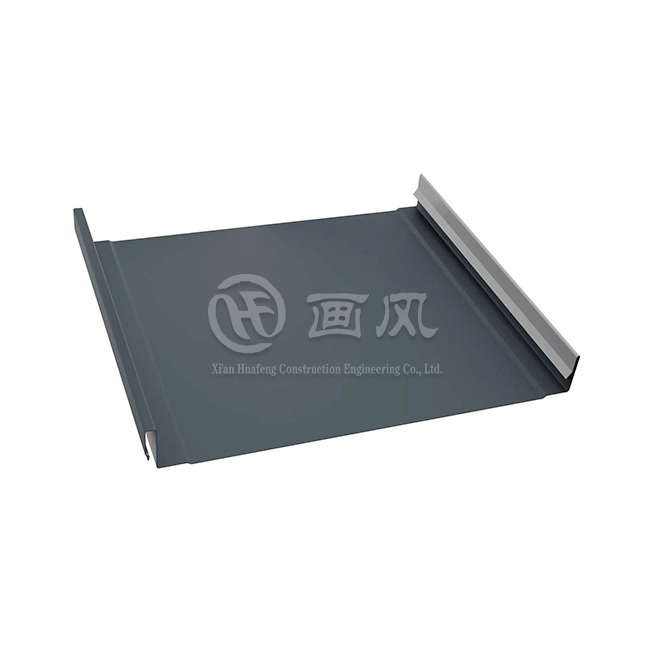

The revolutionary aspect of Seam Metal Roof Systems lies in their concealed fastening methodology, which fundamentally changes how metal roofing performs over time. Traditional exposed fastener systems create thousands of potential leak points where weather seals deteriorate, fasteners work loose through thermal cycling, and rubber washers degrade under ultraviolet exposure. Each fastener represents a maintenance liability that compounds exponentially across large industrial roof areas. Standing seam metal roof panels eliminate this vulnerability entirely by securing panels through hidden clips that allow controlled thermal movement while maintaining absolute weatherproofing integrity. This concealed fastener approach delivers multiple performance advantages critical to industrial applications. First, the mechanical seaming process creates continuous weather barriers along panel connections, with double-lock configurations providing redundant protection against wind-driven rain and capillary water migration. Second, sliding clip systems accommodate thermal expansion and contraction that would otherwise stress fastening points and cause oil-canning distortion in rigidly attached panels. Third, the absence of exposed fasteners eliminates galvanic corrosion issues that occur when dissimilar metals contact in the presence of moisture, a common failure mode in coastal or chemical-exposure industrial environments.

-

Superior Load-Bearing Capacity for Industrial Equipment Installation

Industrial roofing must support more than just environmental loads; these systems serve as platforms for mechanical equipment, solar arrays, ventilation systems, and maintenance access infrastructure. Seam Metal Roof Systems provide exceptional structural capacity through their vertical rib geometry and continuous panel lengths that can span up to thirteen meters without transverse seams. This structural efficiency allows for optimized purlin spacing that reduces substructure costs while maintaining code-required load ratings for snow accumulation, wind uplift, and concentrated equipment loads. The standing seam profile creates inherent structural depth that resists deflection under load better than flat or corrugated alternatives. When industrial facilities need to retrofit rooftop HVAC units or install photovoltaic systems after initial construction, Seam Metal Roof Systems accommodate these additions through their robust clip attachment points and continuous seam configurations that allow non-penetrating mounting solutions. This adaptability protects the weatherproofing integrity while enabling facility modernization without compromising the roof warranty or requiring extensive reinforcement work that would necessitate costly production shutdowns.

Advanced Waterproofing Performance in High-Risk Industrial Environments

Industrial facilities cannot tolerate water intrusion that damages sensitive equipment, contaminates products, or creates safety hazards through electrical system exposure. Seam Metal Roof Systems deliver superior waterproofing through multiple integrated protection layers that function synergistically to eliminate moisture penetration under all weather conditions. The primary defense comes from the raised seam configuration itself, which elevates panel connections well above the drainage plane where ponding water could create hydrostatic pressure against seals.

-

Multi-Layer System Architecture Provides Redundant Protection

Beyond the visible metal panels, properly engineered standing seam metal roof assemblies incorporate comprehensive underlayment systems that create backup waterproofing even if the primary metal surface is somehow compromised. High-density polyethylene breathable membranes installed beneath the metal panels block wind-driven moisture while allowing vapor transmission that prevents condensation accumulation within the roof assembly. This breathability proves crucial in industrial applications where interior temperature and humidity differentials drive moisture migration through the building envelope. The complete system structure includes vapor barriers that control interior moisture movement, thermal insulation layers that minimize temperature-driven condensation, and sound-absorbing materials that reduce noise transmission from rainfall or hail impact. Rock wool insulation typically provides both thermal resistance and acoustic dampening, with thickness calculations customized to specific facility requirements and local climate conditions. The structural base plate, usually perforated galvanized steel with perforation rates optimized for acoustic performance, supports the insulation layers while providing a finished interior ceiling appearance. This comprehensive approach to Seam Metal Roof Systems design ensures that waterproofing performance extends throughout the entire assembly depth, not just at the visible metal surface.

-

Drainage Efficiency Prevents Ponding and Ice Dam Formation

The panel geometry of standing seam metal roof configurations maximizes water flow efficiency through generous cross-sectional drainage areas and smooth panel surfaces that shed water rapidly. Industrial facilities with low-slope roof sections particularly benefit from this enhanced drainage capacity, as water evacuation speed directly correlates with reduced leak risk and extended system lifespan. The mechanical seaming of panel connections creates positive water barriers that direct moisture toward drainage paths rather than allowing lateral migration that could penetrate overlaps or find pathways through thermal expansion gaps. In cold climate industrial applications, ice dam prevention becomes critical to avoiding structural damage and interior water infiltration. Seam Metal Roof Systems address this challenge through their low friction metal surfaces that encourage snow shedding, their thermal break capabilities that reduce heat loss through the roof assembly, and their continuous panel lengths that eliminate mid-slope horizontal seams where ice accumulation typically initiates. For facilities in regions with heavy snowfall, the addition of heat trace systems or snow retention devices integrates seamlessly with standing seam metal roof profiles without compromising waterproofing integrity or requiring roof penetrations that would create new leak vulnerabilities.

Exceptional Longevity and Lifecycle Cost Advantages

Industrial roofing investment decisions require comprehensive lifecycle cost analysis rather than simple initial price comparison. Seam Metal Roof Systems demonstrate superior economic value through their extended service life, minimal maintenance requirements, and retained performance characteristics that eliminate premature replacement costs. The material durability inherent in aluminum-magnesium-manganese alloys resists degradation mechanisms that limit alternative roofing systems to twenty-year service lives at best.

-

Corrosion Resistance Ensures Decades of Maintenance-Free Service

The AA3004 alloy specification used in premium Seam Metal Roof Systems provides inherent corrosion resistance that allows these panels to self-heal minor surface damage through natural oxide layer formation. Unlike painted steel systems where coating damage exposes base metal to accelerated corrosion, aluminum alloy panels maintain their structural integrity even when scratched or abraded during installation or subsequent maintenance activities. This damage tolerance proves invaluable in active industrial environments where rooftop equipment service, material handling, and construction activities create surface contact that would compromise coating-dependent systems. Surface treatment options further extend the already impressive durability of standing seam metal roof panels through PVDF fluoropolymer coatings that resist ultraviolet degradation, chemical exposure, and chalking that dulls appearance over time. These twenty-five to thirty micrometer thick coatings contain seventy percent fluororesin content that maintains color stability and gloss retention for decades while providing additional protection against atmospheric pollutants common in industrial areas. The British National Standards Bureau certification documenting minimum forty-year service life in ordinary environments provides objective validation of these longevity claims, giving facility managers confidence in their roofing investment decisions.

-

Reduced Maintenance Requirements Lower Total Ownership Costs

The maintenance demands of Seam Metal Roof Systems remain minimal throughout their service life, requiring only periodic inspections to verify drainage function and confirm that no equipment modifications have compromised roof integrity. The smooth PVDF-coated surfaces shed dirt and biological growth naturally, eliminating the cleaning and treatment cycles necessary with porous roofing materials. Industrial facilities avoid the recurring costs of roof coating reapplication, fastener replacement, and emergency leak repairs that consume significant maintenance budgets with conventional roofing systems. This maintenance reduction translates directly to operational cost savings and productivity improvements. Manufacturing facilities avoid production interruptions for roofing work, warehouses eliminate inventory protection measures during repair activities, and facility managers redirect maintenance resources to value-adding improvements rather than reactive roof repairs. The total cost of ownership analysis consistently favors standing seam metal roof systems despite their higher initial installation cost, with breakeven typically occurring within the first decade of operation as maintenance and early replacement costs accumulate for alternative systems.

Architectural Flexibility Accommodates Complex Industrial Building Designs

Modern industrial architecture increasingly incorporates aesthetic considerations alongside functional requirements, with building appearance influencing corporate identity, community relations, and employee satisfaction. Seam Metal Roof Systems provide exceptional design flexibility through their clean contemporary appearance, extensive color palette options, and ability to accommodate complex geometric forms that would challenge alternative roofing technologies.

-

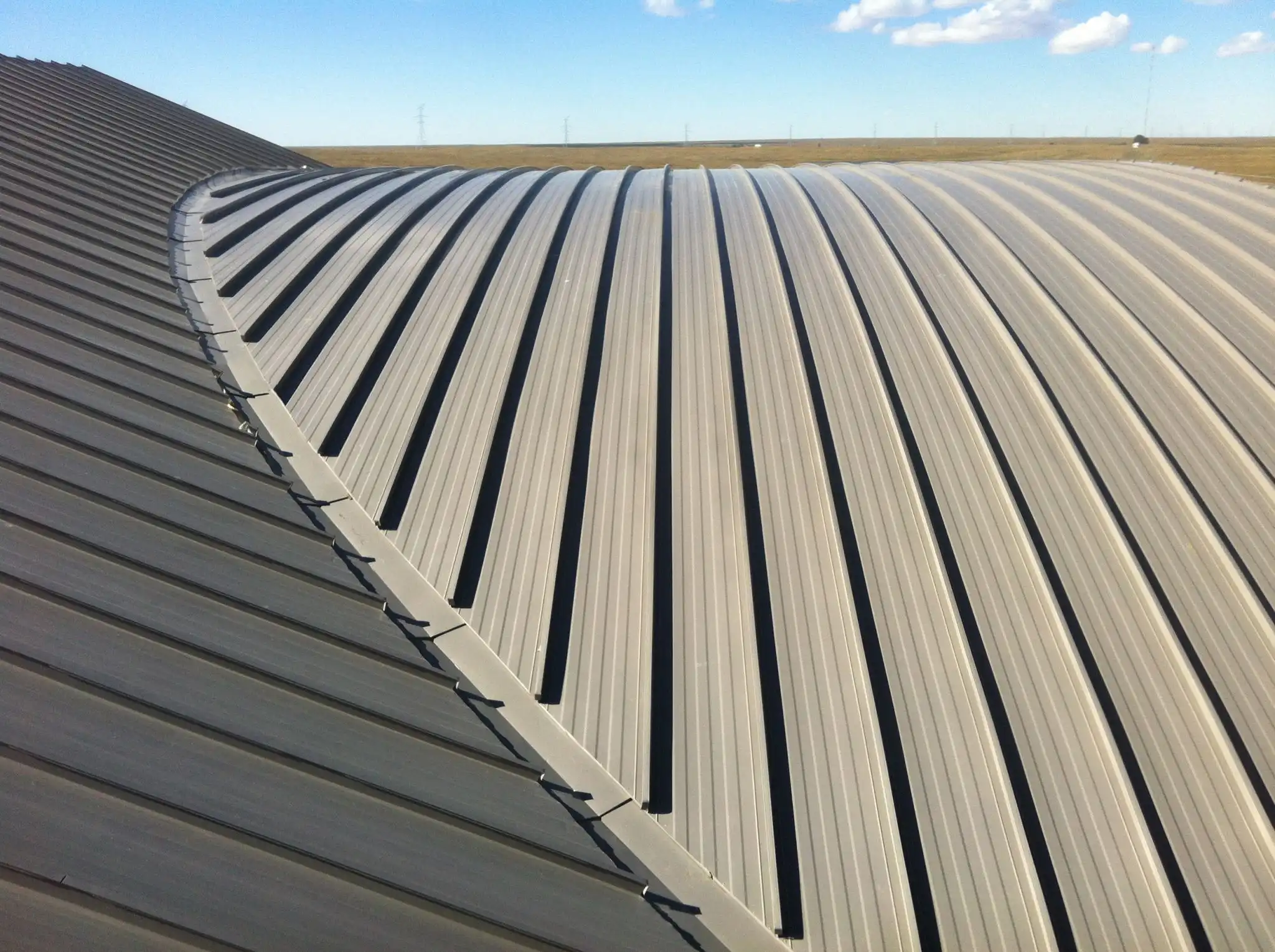

Curved and Radius Applications Enable Signature Design Features

The aluminum-magnesium-manganese alloy composition that provides superior corrosion resistance also delivers the flexibility necessary to form curved panels, radius sections, and complex three-dimensional roof shapes. Industrial facilities can incorporate barrel vault entries, curved parapet caps, and radiused roof-to-wall transitions that create architectural interest while maintaining the superior performance characteristics of standing seam metal roof systems. This formability advantage allows architects to specify metal roofing even for challenging geometries that would require multiple materials and complex waterproofing details with rigid roofing systems. The specialized production technology for fan-shaped plates, curved panels, and fan-curved panels enables Seam Metal Roof Systems to realize virtually any design vision while preserving waterproofing capability through continuous formed seams that follow the panel curvature. Mobile roll-forming equipment can produce these custom profiles directly at the job site, eliminating transportation length restrictions and ensuring perfect fit for complex geometric requirements. This on-site fabrication capability proves particularly valuable for retrofit applications where existing building conditions may not match original construction documents or where field verification of dimensions is necessary before panel production.

-

Color and Finish Options Support Corporate Branding Requirements

Industrial facilities represent significant corporate investments where building appearance communicates organizational values and professionalism. Seam Metal Roof Systems accommodate these branding considerations through extensive color selections available in both polyester and PVDF coating systems. From bold corporate colors that reinforce brand identity to neutral earth tones that harmonize with natural surroundings, standing seam metal roof panels deliver the aesthetic flexibility industrial clients require without compromising performance characteristics. The natural metallic finish of uncoated aluminum panels provides another aesthetic option that appeals to facilities seeking contemporary industrial design vocabulary. This original surface exhibits strong metallic luster that develops a stable protective patina over time, eliminating long-term appearance maintenance while providing a distinctive architectural character. For facilities where appearance maintenance is impractical or where environmental regulations discourage coating systems, the natural mill finish option delivers both aesthetic appeal and superior long-term performance.

Conclusion

Seam Metal Roof Systems distinguish themselves in industrial applications through superior waterproofing, exceptional durability, and comprehensive lifecycle value that traditional roofing cannot match. Their concealed fastener technology, advanced material composition, and architectural flexibility make standing seam metal roof configurations the optimal solution for demanding industrial environments.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

Xi'an Huafeng Construction Engineering Co., Ltd. has established itself as a premier China Seam Metal Roof Systems manufacturer and China Seam Metal Roof Systems supplier since 2018, specializing in comprehensive metal roofing solutions that integrate design, production, and construction excellence. As a recognized high-tech enterprise in Shaanxi Province with first-level building curtain wall qualifications and third-level steel structure qualifications, our company delivers High Quality Seam Metal Roof Systems backed by more than twenty registered patents and rigorous ISO9001, ISO14000:14001, and SGS certifications. Our manufacturing infrastructure includes a two-hundred-thousand square meter raw material production facility in Anhui and two dedicated plate processing plants in Hangzhou and Xi'an, equipped with seven color coating lines, ten longitudinal and transverse shearing production lines, and over forty specialized fabrication machines. This comprehensive production capability enables us to serve as your trusted China Seam Metal Roof Systems factory, offering customized Seam Metal Roof Systems for sale with specifications from sixty-five to five-hundred millimeter seam heights, PVDF and PE coating options, and thirty-year warranty protection. Our China Seam Metal Roof Systems wholesale programs provide competitive Seam Metal Roof Systems price structures with minimum order quantities of five hundred square meters and delivery within fifteen to twenty days.

As your one-stop solution provider, we integrate green sustainable development principles with cutting-edge metal roof technology to deliver systems that add production capacity benefits while transforming underutilized building roofs into valuable assets. Our engineering team provides comprehensive design optimization services including structural 3D modeling, drainage system simulation, and material specification advisory, followed by precision manufacturing with real-time quality control and complete raw material traceability. From project drawing deepening through factory sample production, processing drawing refinement, and seamless on-site installation with safety compliance documentation, we manage every aspect of your metal roofing project. Our project portfolio includes prestigious installations at Xiongan Station Commercial Body, Xi'an International Convention and Exhibition Center, Xi'an Station East Auxiliary Building, and numerous other high-profile commercial and public facilities across China. Whether you need standing seam metal roofing panels, aluminum-magnesium-manganese plates, titanium-zinc plates, or complete building envelope solutions, Xi'an Huafeng delivers the expertise and manufacturing excellence your project demands. Contact us today at huafeng@hfmetalroof.com to discuss how our High Quality Seam Metal Roof Systems can optimize your industrial facility's performance and value. Save this information for future reference as you plan your next roofing project with confidence in China's leading metal roofing solutions provider.

References

1. Sheffield Metals International. "Standing Seam Metal Roofing: Performance Characteristics and Installation Standards." Technical Documentation Series for Commercial and Industrial Applications.

2. McElroy Metal Industries. "Engineered Metal Roof Systems: Design Guide for Commercial and Industrial Construction." Professional Specification Manual.

3. American Institute of Steel Construction. "Metal Building Systems: Standing Seam Roof Panel Design and Application." Industry Standards Publication.

4. National Roofing Contractors Association. "Metal Roofing Best Practices: Concealed Fastener Systems for Industrial Facilities." Technical Reference Guide.