Are you struggling with building exteriors that deteriorate quickly, fail to meet structural requirements, or exceed your project budget? Corrugated Sheet Metal Wall Panels offer a proven solution that addresses these pain points while delivering exceptional durability, versatility, and cost-effectiveness. Whether you're managing an industrial facility facing harsh weather conditions, planning a commercial development requiring rapid installation, or designing agricultural structures demanding long-term performance, understanding the features, materials, and applications of corrugated sheet metal wall panels is essential for making informed decisions that protect your investment and ensure project success.

Understanding Corrugated Sheet Metal Wall Panels and Their Core Features

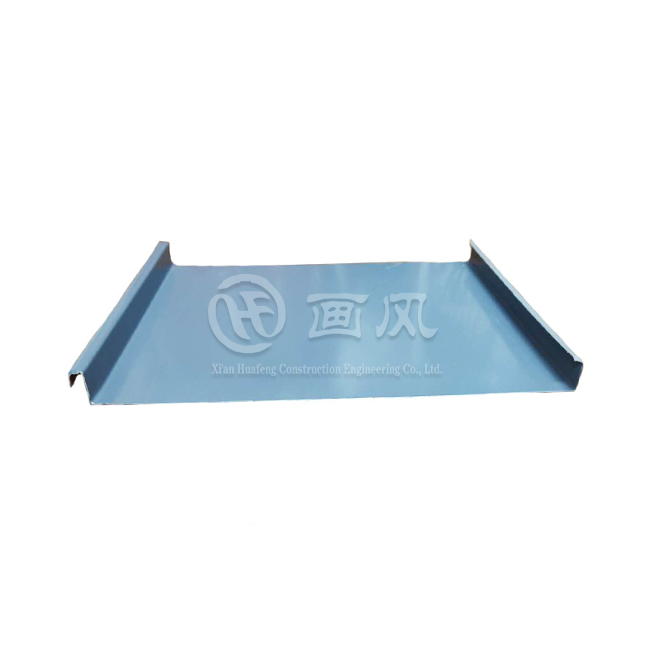

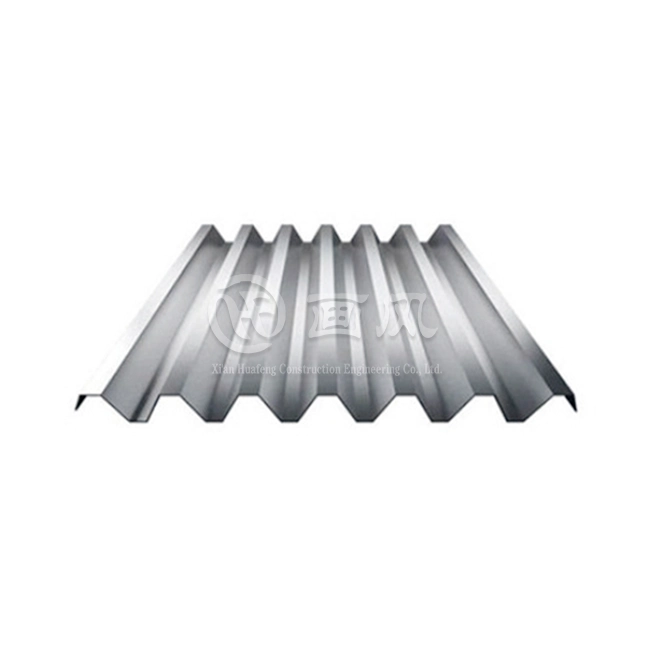

Corrugated Sheet Metal Wall Panels represent one of the most versatile and reliable cladding solutions in modern construction, characterized by their distinctive wave-like profile that provides both structural integrity and aesthetic appeal. The corrugated design, featuring alternating ridges and grooves, fundamentally enhances the panel's load-bearing capacity while maintaining a lightweight profile that simplifies installation and reduces structural support requirements. This unique geometry creates superior tensile strength compared to flat metal sheets of equivalent thickness, allowing the panels to span greater distances between supports without compromising structural integrity. The corrugation depth typically ranges from fifteen to thirty millimeters, with each wave height carefully engineered to optimize strength-to-weight ratios while facilitating efficient water drainage and weather protection. The manufacturing process for Corrugated Sheet Metal Wall Panels involves precision roll-forming techniques where flat metal coils pass through sequential forming stations, gradually creating the characteristic wave pattern through controlled pressure and shaping. This cold-forming process preserves the material's inherent strength properties while introducing the geometric advantages of the corrugated profile. Advanced production facilities like those operated by Xi'an Huafeng Construction Engineering Co., Ltd. utilize fully automated roll-forming systems capable of producing panels with consistent dimensional accuracy, ensuring proper fit during installation and eliminating on-site adjustment delays. The panels are manufactured in customizable widths ranging from six hundred to twelve hundred millimeters, with lengths extending up to twelve meters or more depending on project specifications and transportation considerations.

Key Performance Characteristics

The performance characteristics of Corrugated Sheet Metal Wall Panels extend well beyond basic weather protection, encompassing fire resistance, thermal performance, acoustic properties, and long-term durability under diverse environmental conditions. Fire resistance ratings vary depending on the substrate material and coating system, with steel-based panels typically achieving Class A fire ratings that comply with stringent building codes for commercial and industrial applications. The panels' thermal performance can be significantly enhanced through the application of insulated backing systems or installation over continuous insulation layers, creating high-performance wall assemblies that meet contemporary energy efficiency standards while maintaining the aesthetic and structural benefits of exposed metal cladding. Acoustic performance represents another crucial consideration, particularly for industrial facilities where noise control impacts worker safety and community relations. The corrugated profile inherently provides some sound dampening through its three-dimensional geometry, though additional acoustic insulation typically proves necessary for applications requiring substantial noise reduction. Modern installation techniques incorporate sound-dampening gaskets, resilient mounting systems, and acoustic insulation materials that work synergistically with Corrugated Sheet Metal Wall Panels to achieve specified sound transmission class ratings without compromising the system's weather resistance or structural performance.

Material Options for Corrugated Sheet Metal Wall Panels

Material selection profoundly influences the performance, longevity, and lifecycle cost of Corrugated Sheet Metal Wall Panels, with each substrate offering distinct advantages suited to specific application requirements and environmental conditions. Galvanized steel remains the most widely specified material for corrugated wall panels, featuring a protective zinc coating applied through hot-dip galvanizing that provides excellent corrosion resistance at a competitive price point. The zinc coating thickness, measured in coating weight per unit area, directly correlates with corrosion protection performance, with G90 coating (approximately 275 grams per square meter) representing the industry standard for general-purpose applications while heavier G115 or G140 coatings serve high-corrosion environments such as coastal regions or industrial facilities with aggressive atmospheric conditions. Galvalume-coated steel, composed of fifty-five percent aluminum and forty-five percent zinc alloy coating, delivers superior corrosion resistance compared to traditional galvanized steel, particularly in environments subject to sulfur dioxide pollution or marine exposure. The aluminum component provides barrier protection while the zinc offers galvanic protection at cut edges and scratches, creating a synergistic corrosion resistance mechanism that extends panel service life significantly. Thickness options for steel-based Corrugated Sheet Metal Wall Panels typically range from 0.3 millimeters to 1.2 millimeters, with thicker gauges specified for applications requiring enhanced structural performance, impact resistance, or extended unsupported spans between framing members.

Premium Material Alternatives

Aluminum corrugated panels offer exceptional corrosion resistance without protective coatings, making them ideal for coastal installations, chemical processing facilities, and other aggressive environments where steel panels would require more frequent maintenance or replacement. The material's low density, approximately one-third that of steel, substantially reduces dead load on supporting structures while simplifying handling and installation processes. Aluminum Corrugated Sheet Metal Wall Panels are typically manufactured from 3003, 3004, or 5052 alloys, each offering specific combinations of formability, strength, and corrosion resistance tailored to different application requirements. The natural oxide layer that forms on aluminum surfaces provides inherent weather resistance, though factory-applied coatings enhance appearance consistency and provide expanded color options for architectural applications. Stainless steel represents the premium choice for Corrugated Sheet Metal Wall Panels in applications demanding maximum durability, minimal maintenance, and distinctive aesthetic appeal. Type 304 stainless steel provides excellent general-purpose corrosion resistance suitable for most architectural applications, while Type 316 grades incorporate molybdenum for superior resistance to chloride-induced pitting and crevice corrosion in marine or chemical processing environments. The initial cost premium for stainless steel panels is offset by their exceptional longevity, minimal maintenance requirements, and sustained aesthetic appeal throughout decades of service life. Copper and titanium-zinc alloy panels serve specialized architectural applications where unique aesthetic characteristics justify their premium cost, with these materials developing natural patinas that evolve gracefully over time.

Surface Finishes and Coating Systems

Surface finish selection dramatically impacts both the functional performance and aesthetic appeal of Corrugated Sheet Metal Wall Panels, with modern coating technologies offering unprecedented durability, color retention, and environmental resistance. High-performance fluoropolymer coatings, particularly those based on polyvinylidene fluoride (PVDF) resin systems, represent the industry standard for architectural metal panel applications demanding superior color stability and resistance to chalking, fading, and environmental degradation. These coating systems typically incorporate seventy percent PVDF resin content, providing exceptional ultraviolet radiation resistance that maintains color integrity and gloss retention for decades even under intense solar exposure conditions common in commercial and industrial settings. Polyester coating systems offer a cost-effective alternative for applications where extreme color retention proves less critical, delivering good general-purpose performance at approximately half the cost of premium PVDF coatings. Modified polyester formulations, incorporating silicone or other additives, provide performance characteristics intermediate between standard polyester and full PVDF systems, representing an attractive value proposition for many commercial projects. Coating thickness significantly influences durability, with premium systems typically applying film builds exceeding twenty-five microns that provide robust protection against abrasion, chemical exposure, and environmental weathering throughout the panel's service life.

Color and Texture Options

Color selection for Corrugated Sheet Metal Wall Panels extends far beyond aesthetic considerations, influencing thermal performance, maintenance requirements, and long-term appearance retention. Light-colored finishes reflect solar radiation more effectively than dark colors, reducing heat absorption that can cause thermal expansion, increase cooling loads, and accelerate coating degradation. Cool-pigment technologies enable dark color options that achieve solar reflectance values approaching those of traditional light colors, expanding design possibilities while maintaining thermal performance benefits. Xi'an Huafeng Construction Engineering Co., Ltd. maintains extensive color libraries encompassing standard architectural colors, metallic finishes, and custom-matched options that coordinate with existing building elements or corporate branding requirements. Texture selection influences both visual appearance and practical performance characteristics, with options ranging from smooth mill finishes to embossed patterns that replicate natural materials or provide enhanced slip resistance. Stucco-embossed textures prove particularly popular for Corrugated Sheet Metal Wall Panels, offering reduced glare, concealing minor surface imperfections, and providing a distinctive aesthetic character that differentiates projects while maintaining the inherent benefits of metal cladding systems. The embossing process introduces subtle three-dimensional surface variations that interact with natural and artificial lighting to create dynamic visual effects that evolve throughout the day, enhancing architectural interest without compromising the panels' structural or protective performance.

Diverse Applications Across Building Types

The versatility of Corrugated Sheet Metal Wall Panels enables their successful application across an extraordinarily diverse range of building types, each benefiting from the material's unique combination of structural efficiency, weather resistance, and design flexibility. Industrial facilities represent perhaps the most common application, where the panels' durability, low maintenance requirements, and ability to withstand harsh operating environments make them the logical choice for manufacturing plants, warehouses, distribution centers, and processing facilities. The rapid installation characteristics of Corrugated Sheet Metal Wall Panels minimize construction schedules, allowing facilities to commence operations sooner and begin generating revenue while the building envelope remains protected throughout its service life with minimal ongoing maintenance expenditure. Commercial applications increasingly specify corrugated metal panels for retail centers, office buildings, hospitality projects, and mixed-use developments where the material's contemporary aesthetic aligns with modern architectural trends emphasizing honest material expression and industrial-inspired design vocabularies. The panels' ability to create bold visual statements through color, texture, and installation orientation patterns enables architects to achieve distinctive building identities that differentiate projects within competitive market segments. Agricultural buildings benefit enormously from the cost-effectiveness and durability of Corrugated Sheet Metal Wall Panels, with livestock housing, equipment storage structures, and crop processing facilities requiring weather protection that withstands decades of exposure to moisture, temperature extremes, and agricultural chemical atmospheres without deterioration or performance degradation.

Specialized Application Considerations

Residential applications for Corrugated Sheet Metal Wall Panels continue expanding as homeowners and designers recognize the material's architectural potential, energy efficiency benefits, and minimal maintenance requirements. Contemporary residential designs frequently incorporate corrugated metal as accent elements, complete siding systems, or privacy screens that introduce textural variety and industrial-inspired aesthetic character. The material's compatibility with sustainable design principles, including high recycled content, recyclability at end of life, and energy efficiency contributions through reflective coatings, aligns perfectly with environmentally conscious homeowners seeking durable, responsible building materials that reduce long-term environmental impact. Temporary and semi-permanent structures represent another significant application category where the quick installation, relocatable nature, and durability of Corrugated Sheet Metal Wall Panels prove advantageous. Construction site offices, temporary classrooms, emergency shelters, and event facilities benefit from the panels' ability to provide weather protection rapidly while supporting potential relocation or repurposing as project requirements evolve. The material's resistance to vandalism, fire, and environmental degradation makes it particularly suitable for these applications where security concerns and minimal maintenance access influence material selection decisions.

Installation Methods and Technical Considerations

Proper installation proves critical to achieving optimal performance from Corrugated Sheet Metal Wall Panels, with multiple fastening systems and installation techniques available to accommodate different substrate conditions, aesthetic preferences, and performance requirements. Exposed fastener systems represent the most economical and straightforward installation approach, utilizing self-drilling screws with integrated weather-sealing washers that penetrate through the panel face into supporting purlins or girts. Fastener placement typically occurs at every corrugation valley along intermediate supports and at panel ends, with specific spacing patterns determined by wind load calculations, panel gauge, and local building code requirements. Color-matched fastener caps maintain aesthetic consistency while providing additional weather protection at penetration points. Standing seam installations, while less common for traditional corrugated profiles, offer concealed fastening solutions that eliminate visible fasteners from the building's exterior appearance while accommodating significant thermal movement without imposing stress on fastener connections. These systems utilize clips that attach to structural supports and engage panel seams, allowing panels to expand and contract freely with temperature variations while maintaining weather-tight performance throughout. The installation complexity and cost premium for standing seam systems must be weighed against their aesthetic benefits and enhanced weather performance when selecting appropriate installation methods for specific project requirements.

Quality Assurance During Installation

Installation quality control begins with proper substrate preparation, ensuring structural supports are aligned, level, and capable of supporting imposed loads without excessive deflection that could compromise panel performance or appearance. Moisture barriers, air barriers, and insulation systems must be properly installed and sealed before Corrugated Sheet Metal Wall Panels are attached, creating integrated wall assemblies that manage moisture effectively while meeting energy code requirements. Panel alignment requires careful attention during initial installation, as any misalignment compounds progressively across subsequent panels, potentially resulting in noticeable appearance defects or installation difficulties that require time-consuming corrections. Weather protection during installation proves essential for maintaining project schedules and preventing water infiltration into building interiors or wall cavities where it could compromise insulation performance or promote mold growth. Xi'an Huafeng Construction Engineering Co., Ltd. provides comprehensive installation guidance including detailed drawings, fastener schedules, and sequencing recommendations that enable contractors to achieve optimal results efficiently. Upon completion, thorough inspection verifies proper fastener installation, adequate panel overlap, proper sealant application at terminations and penetrations, and overall system integrity that ensures decades of reliable weather protection with minimal maintenance requirements.

Conclusion

Corrugated Sheet Metal Wall Panels deliver unmatched versatility combining structural strength, weather resistance, aesthetic flexibility, and cost-effectiveness across diverse building applications, making them the intelligent choice for projects demanding long-term performance and value.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

Transform your building vision into reality with Xi'an Huafeng Construction Engineering Co., Ltd., a China Corrugated Sheet Metal Wall Panels factory, China Corrugated Sheet Metal Wall Panels supplier, and trusted China Corrugated Sheet Metal Wall Panels manufacturer since 2018. We offer China Corrugated Sheet Metal Wall Panels wholesale pricing with Corrugated Sheet Metal Wall Panels for sale backed by our 30-year warranty, competitive Corrugated Sheet Metal Wall Panels price, and High Quality Corrugated Sheet Metal Wall Panels certified to ASTM, DIN, JIS, BS, and GB/T standards. Our three factories housing seven production lines and over forty specialized machines deliver customized solutions including color, pattern, and design options with fast 15-20 day delivery and flexible 500㎡ MOQ. With recognition as a Shaanxi Province high-tech enterprise, first-level curtain wall qualifications, over 20 registered patents, and ISO9001/ISO14000/SGS certifications, we provide complete one-stop service from engineering design through precision manufacturing to seamless installation. Contact us at huafeng@hfmetalroof.com to receive your customized quote and discover why Fortune 500 companies trust Huafeng for their metal building envelope solutions.

References

1. American Institute of Steel Construction. Steel Construction Manual: Design of Metal Building Systems. AISC, 2023.

2. Johnson, Robert and Martinez, Elena. Architectural Metal Panels: Materials, Manufacturing, and Installation Best Practices. Construction Industry Press, 2024.

3. National Roofing Contractors Association. Metal Panel Roof and Wall Systems Design Guide. NRCA, 2023.

4. Smith, David and Chen, Wei. Corrosion Protection Systems for Metal Building Envelopes. Journal of Building Enclosure Design, 2024.

5. Zhang, Li and Thompson, James. Sustainable Metal Cladding Systems: Performance, Durability, and Environmental Impact. International Journal of Construction Materials, 2023.