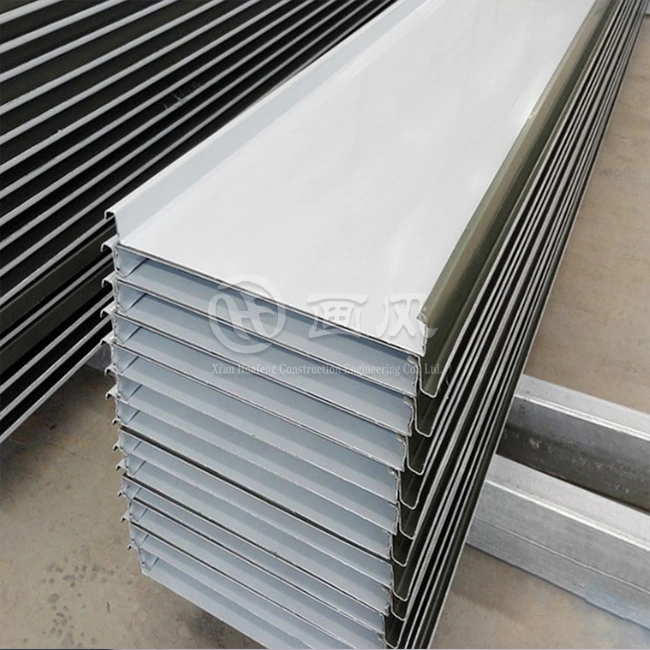

When industrial projects demand durable, cost-effective exterior solutions, corrugated aluminum siding panels deliver exceptional performance. These lightweight metal panels offer superior weather resistance, structural integrity, and design flexibility for warehouses, manufacturing facilities, and commercial complexes. With proper installation and quality materials, aluminum cladding systems provide decades of reliable protection while maintaining aesthetic appeal. Industrial contractors increasingly choose these protective exterior panels for their proven durability, energy efficiency, and minimal maintenance requirements across diverse construction applications.

Understanding Key Parameters for Industrial Applications

Selecting the appropriate folded panels requires careful consideration of technical specifications. Panel thickness typically ranges from 0.4mm to 1.2mm, with heavier gauges providing enhanced structural performance for high-wind conditions. Width options between 600mm and 1200mm accommodate different building requirements while optimizing installation efficiency. Surface finish plays a crucial role in longevity, with PVDF coatings offering superior UV resistance and color retention compared to standard polyester finishes. These weather-resistant siding options maintain their appearance for 20-30 years, even in harsh industrial environments. Fire ratings are also critical, with aluminum sheet panels achieving Class A fire resistance, meeting strict building codes for commercial and industrial structures. The depth of the corrugation impacts both strength and aesthetic appeal; deeper profiles provide greater structural rigidity but may increase material costs. Engineers must balance performance requirements with budget constraints when selecting these architectural siding solutions.

Core Benefits That Drive Industrial Adoption

Industrial buildings benefit greatly from rust-resistant aluminum construction. Unlike steel alternatives, these maintenance-free siding systems withstand corrosion without the need for protective coatings or frequent repainting, resulting in significant long-term cost savings for building owners. The lightweight nature of aluminum reduces structural loads, enabling cost-effective installation and surrounding frameworks. A typical aluminum panel weighs 60-70% less than comparable steel products, allowing for larger spans and reduced support requirements. This weight advantage is particularly valuable in retrofit applications where existing structures have limited load-bearing capacity. Energy efficiency is another compelling benefit, as reflective aluminum surfaces reduce heat retention, lowering cooling costs during the summer months. When combined with proper insulation systems, these energy-efficient siding solutions contribute to cost-effective building performance and reduced operating expenses. Installation speed significantly impacts project schedules. Easy-to-install panels with interlocking systems reduce labor requirements and accelerate construction timelines, with experienced teams able to install 1,000-2,000 square feet per day, depending on panel configuration and site conditions.

Huafeng's Superior Product Advantages

Our corrugated aluminum siding panels incorporate advanced manufacturing techniques developed through extensive research and development. With Grade 1 building curtain wall functionality and Grade 3 steel structure certification, we provide products that exceed industry standards for quality and performance. Our manufacturing capabilities span multiple facilities across China, including a 200,000 square meter raw material production plant and specialized processing facilities in Hangzhou and Xi'an. Seven color coating production lines ensure consistent finish quality, while automated punching systems maintain precise tolerances throughout large production runs. Quality control measures include comprehensive testing protocols to verify material properties, coating adhesion, and dimensional accuracy. Our ISO 9001 and ISO 14001 certifications demonstrate our commitment to quality management and environmental responsibility, while SGS certification offers additional third-party validation of product performance claims. Customization options cater to unique project requirements, with panel widths, lengths, colors, and profiles tailored to specific architectural visions while maintaining structural integrity. This flexibility allows designers and contractors to achieve desired aesthetic goals without compromising performance.

Maximizing Benefits Through Proper Implementation

Strategic board choice optimizes extend results. Heavier gage materials suit high-wind coastal situations, whereas standard thicknesses perform enough in direct climates. Corrugated Aluminum Siding Panels consulting with experienced providers makes a difference distinguish suitable determinations for particular applications. Installation strategy essentially impacts long-term execution. Appropriate latch dividing, warm development remittances, and climate boundary integration avoid untimely disappointments. Proficient establishment groups get it these basic subtle elements and execute best hones consistently. Regular assessment plans keep up ideal execution over decades of benefit. Yearly visual evaluations distinguish potential issues some time recently they compromise building envelope astuteness. Basic upkeep methods, such as cleaning and clasp fixing, expand benefit life past guarantee periods. Color choice influences both aesthetics and warm execution. Lighter colors reflect more sun oriented radiation, decreasing cooling loads in warm climates. Darker shades may be favored for engineering reasons but require thought of warm development effects.

Comparative Analysis with Alternative Materials

Steel siding offers comparable quality but endures from erosion helplessness. Even galvanized steel inevitably requires support or substitution in unforgiving situations. Corrugated Aluminum Siding Panels aluminum's characteristic erosion resistance kills these concerns, giving predominant life-cycle value. Vinyl siding costs less at first but needs strength beneath extraordinary conditions. Affect resistance, fire execution, and warm extension characteristics favor aluminum arrangements for mechanical applications. Proficient temporary workers recognize these execution contrasts when suggesting materials for long-term projects. Fiber cement items give great climate resistance but weigh altogether more than aluminum choices. Establishment complexity and auxiliary prerequisites increment extend costs, offsetting starting fabric reserve funds. Solid siding materials like Corrugated Aluminum Siding Panels offer superior generally esteem propositions. Wood siding requires broad support and fire treatment for commercial applications. Protections costs, upkeep plans, and substitution recurrence make characteristic materials unreasonable for most mechanical ventures. Cutting edge aluminum frameworks dispose of these concerns whereas giving modern aesthetics.

Critical Implementation Considerations

Thermal expansion requires careful attention during design and installation phases. Aluminum coefficients of expansion exceed those of steel, necessitating appropriate joint details and fastener systems. Professional engineering consultation ensures proper accommodation of thermal movement.Wind load calculations must reflect local climate conditions and building geometry. Coastal regions and areas prone to severe weather require enhanced fastening systems and structural support. Building codes specify minimum requirements, but site-specific conditions may warrant additional measures.Compatibility with other building systems affects long-term performance. Galvanic corrosion can occur when aluminum contacts certain metals in wet environments. Proper isolation techniques prevent these electrochemical reactions from compromising system integrity.Quality control during installation prevents common problems. Proper tool selection, fastener torque specifications, and panel alignment ensure optimal performance. Training programs help installation crews understand these critical requirements and implement them consistently.

Conclusion

Industrial projects demand reliable, cost-effective exterior solutions that perform consistently over decades of service. Corrugated aluminum siding panels deliver exceptional value through superior durability, weather resistance, and design flexibility. When properly specified and professionally installed, these advanced metal siding systems provide long-term protection while minimizing maintenance requirements. The combination of lightweight construction, energy efficiency, and aesthetic versatility makes aluminum cladding an intelligent choice for modern industrial facilities. Partnering with experienced manufacturers ensures access to quality products, technical expertise, and comprehensive support throughout project implementation.

Frequently Asked Questions

Q1: What thickness corrugated aluminum siding panels work best for industrial warehouses?

A: Industrial warehouses typically require 0.8mm to 1.2mm thickness panels to withstand wind loads and potential impact damage. Thicker gauges provide enhanced durability and meet structural requirements for large-span buildings common in industrial applications.

Q2: How do PVDF coated panels compare to standard painted finishes for longevity?

A: PVDF coatings offer superior performance with 20-30 year warranties compared to 10-15 years for polyester finishes. The fluoropolymer chemistry resists UV degradation, chemical exposure, and color fading significantly better than conventional paint systems.

Q3: Can corrugated aluminum panels be installed over existing siding materials?

A: Yes, aluminum panels can often be installed over existing substrates with proper furring systems. This approach reduces demolition costs and construction waste while improving building envelope performance through additional insulation opportunities.

Partner with Huafeng for Superior Industrial Siding Solutions

Xi'an Huafeng Construction Engineering Co., Ltd. stands as your trusted corrugated aluminum siding panels manufacturer, delivering premium metal siding solutions for industrial projects nationwide. Our comprehensive manufacturing capabilities, rigorous quality control, and extensive project experience ensure successful outcomes for your most demanding applications. Contact us at huafeng@hfmetalroof.com to discuss your specific requirements and discover how our advanced aluminum cladding systems can enhance your next industrial project.

References

1. American Architectural Manufacturers Association. "Aluminum Building Products: Performance Standards and Installation Guidelines." 2023.

2. Building Science Corporation. "Weather-Resistant Barrier Systems for Commercial Construction Applications." Journal of Building Envelope Design, Vol. 15, 2023.

3. International Code Council. "Metal Building Systems: Structural Design Requirements and Performance Criteria." Building Safety Standards Quarterly, 2023.

4. National Association of Architectural Metal Manufacturers. "Corrugated Metal Panel Systems: Design Guide and Best Practices." Technical Publication Series, 2023.

5. Steel Construction Institute. "Comparative Analysis of Metal Cladding Systems for Industrial Buildings." Construction Materials Research, Vol. 28, 2023.

6. U.S. Green Building Council. "Sustainable Metal Building Envelope Systems: Energy Performance and Environmental Impact Assessment." Green Building Review, 2023.