Snap Lock Metal Roof Panels dominate today's commercial roofing market through their revolutionary interlocking mechanism that eliminates complex fastening systems while delivering superior weather protection. These advanced roofing solutions combine rapid installation capabilities with exceptional durability, making them the preferred choice for large-scale construction projects. The panels' innovative design reduces labor costs by up to 40% compared to traditional roofing systems while maintaining structural integrity under extreme weather conditions. Leading manufacturers like HF have established market leadership by offering comprehensive product ranges with customizable specifications that meet diverse project requirements across commercial, industrial, and institutional sectors.

Understanding Snap Lock Metal Roof Panels: A Market Overview

The metal material industry has seen noteworthy change with the presentation of snap bolt innovation, on a very basic level changing how development experts approach large-scale material ventures. These imaginative boards include a interesting vertical crease plan that interfaces adjoining boards through mechanical interlocking, making consistent scope without uncovered fasteners.

Revolutionary Design Features

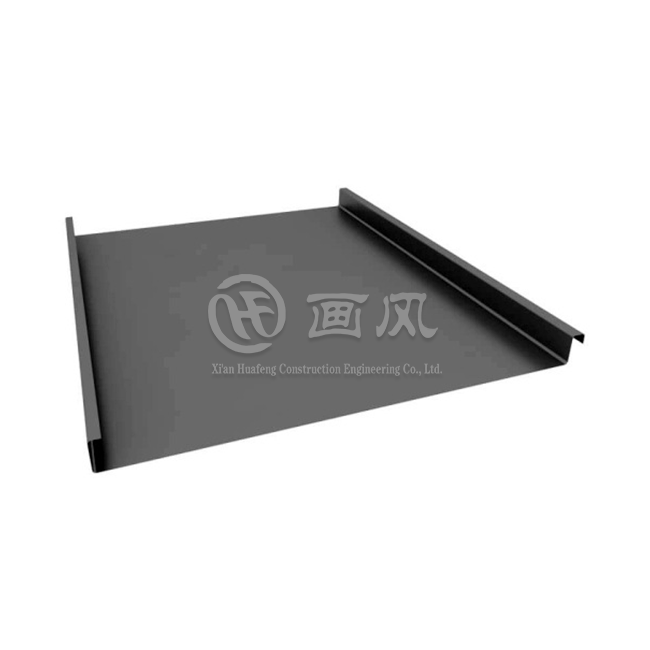

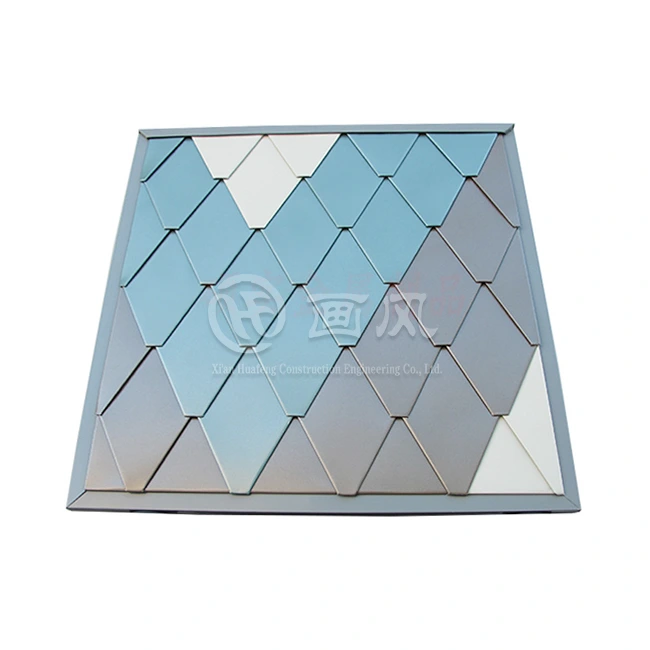

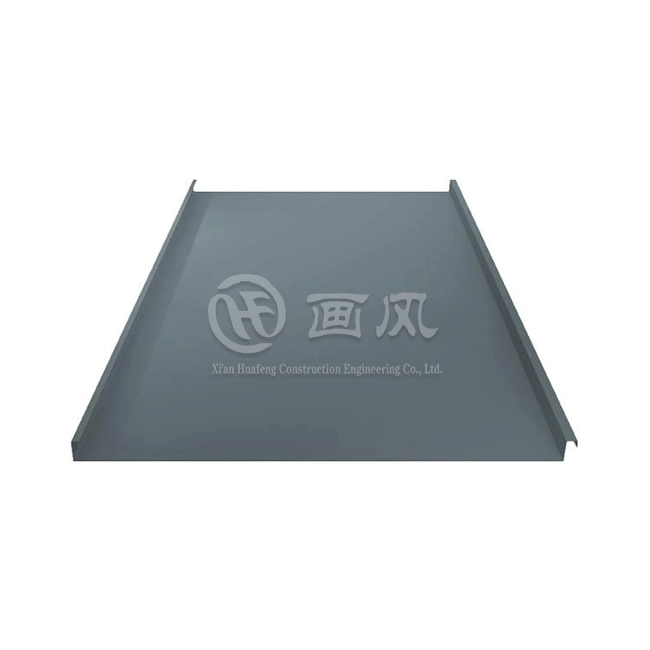

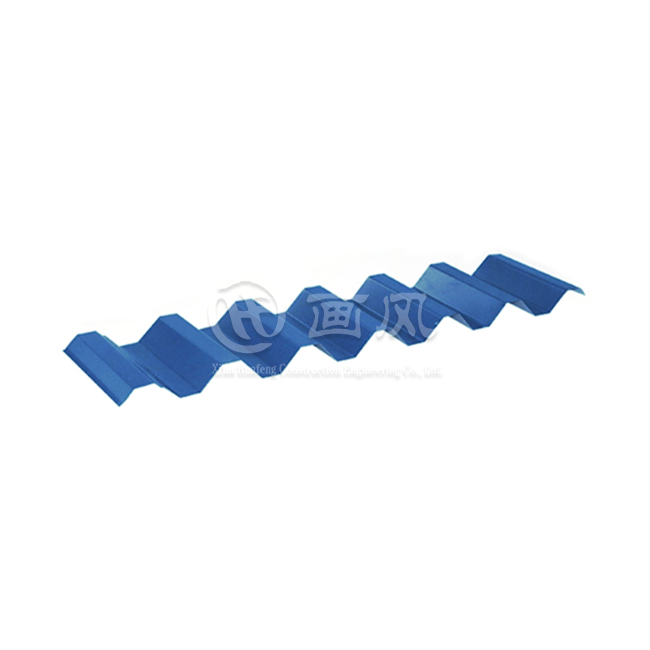

Modern snap bolt frameworks consolidate precision-engineered edges that adjust superbly amid establishment, guaranteeing steady board dividing and ideal water waste. The boards regularly degree 300mm to 600mm in covering width with customizable lengths up to 12 meters, obliging different structural necessities. Progressed fabricating forms empower thickness varieties from 0.4mm to 1.2mm, with standard statures of 45mm giving fabulous auxiliary rigidity. Material composition plays a significant part in execution characteristics. Premium aluminum amalgam choices offer prevalent erosion resistance for coastal situations, whereas galvanized steel variations give extraordinary quality for high-wind zones. Claim to fame materials counting stainless steel, copper, and titanium zinc cater to particular stylish and natural demands.

Global Market Dynamics

The around the world request for metal material frameworks proceeds extending, especially in locales encountering extraordinary climate designs. Coastal zones with tall salt introduction progressively indicate aluminum-based boards, whereas inland commercial locale favor steel compositions for their cost-effectiveness and strength. This developing showcase acknowledgment stems from recorded execution focal points counting fire resistance evaluations of Course A and least slant necessities as moo as 1:12. Construction experts appreciate the flexibility these frameworks give over different building sorts, from shopping centers and stockrooms to air terminals and instructive offices. The technology's versatility to different engineering styles whereas keeping up useful fabulousness has set up snap lock metal roof panels as a foundation arrangement in modern development hones.

Key Factors Establishing Snap Lock Panels as Market Leaders

Several basic points of interest position these material frameworks at the bleeding edge of commercial development markets, in a general sense reshaping industry guidelines and temporary worker preferences.

Installation Efficiency and Labor Cost Reduction

The snap-together plan disposes of the require for specialized instruments or complex affixing strategies, empowering establishment groups to accomplish exceptional efficiency picks up. Experienced teams report completing establishments 60% quicker than comparable standing crease frameworks, specifically deciphering to diminished extend timelines and labor costs. This proficiency gets to be especially profitable on large-scale ventures where plan adherence is critical. The interlocking instrument guarantees exact board arrangement consequently, decreasing establishment mistakes and the require for field alterations. Weather-tight creases shape promptly upon association, permitting work to proceed indeed amid light precipitation, assist improving extend planning flexibility.

Durability and Performance Excellence

Advanced surface medicines counting PVDF and polyester coatings give uncommon resistance to UV corruption, chemical presentation, and warm cycling. These defensive wraps up keep up color steadiness and sparkle maintenance for decades, guaranteeing long-term stylish offer nearby utilitarian performance. The basic plan disseminates wind loads successfully over the whole roof gathering, accomplishing prevalent elevate resistance compared to mechanically affixed options. Testing illustrates steady execution beneath extraordinary conditions, counting hurricane-force winds and overwhelming snow loads, making these frameworks reasonable for differing geological regions.

Thermal and Acoustic Benefits

Modern snap bolt boards consolidate warm break innovation that minimizes warm exchange, contributing to moved forward building vitality proficiency. The standing crease profile makes characteristic ventilation channels that decrease cooling loads amid summer months whereas giving great separator execution in cold climates. Acoustic properties merit break even with thought, especially for involved buildings close airplane terminals or mechanical offices. The board arrangement viably hoses outside clamor transmission, making more comfortable insides situations whereas assembly progressively exacting building code prerequisites for sound control.

Comparative Analysis: Snap Lock Metal Roof Panels vs Other Roofing Solutions

Understanding competitive points of interest requires exhaustive assessment against built up material innovations, empowering acquirement experts to make data-driven choices based on project-specific requirements.

Performance Comparison with Standing Seam Systems

While both advances utilize concealed securing strategies, Snap Lock Metal Roof Panels offer particular establishment points of interest. Standing crease frameworks require specialized seaming gear and talented administrators, possibly constraining temporary worker accessibility and expanding labor costs. The snap instrument dispenses with these prerequisites whereas accomplishing comparable climate performance. Aesthetic contemplations moreover separate these approaches. Snap Lock Metal Roof Panels give cleaner lines with steady crease dividing, engaging to modelers looking for refined appearances. The uniform profile upgrades visual consistency over huge roof zones, especially vital for unmistakable commercial buildings where engineering affect matters.

Advantages Over Traditional Roofing Materials

Compared to built-up material or layer frameworks, metal snap bolt boards offer prevalent life span with negligible upkeep prerequisites. Whereas starting fabric costs may surpass a few options, lifecycle taken a toll examination reliably favors metal frameworks due to decreased substitution recurrence and support expenses.Fire resistance speaks to another basic advantage. Lesson A fire appraisals give upgraded security compared to natural material materials, frequently coming about in favorable protections premiums and administrative compliance benefits. This characteristic gets to be especially profitable for regulation buildings and fabricating offices where fire security is paramount.

Cost-Benefit Analysis

Initial obtainment costs must be assessed against long-term operational benefits. Whereas snap bolt boards may require higher forthright venture than fundamental layered alternatives, the combination of establishment reserve funds, support decrease, and expanded benefit life ordinarily creates positive returns inside the to begin with decade of operation.Energy effectiveness commitments encourage upgrade financial benefits through diminished HVAC working costs. Intelligent coatings accessible in different colors can essentially diminish cooling loads, especially important in warm climates where discuss conditioning speaks to considerable operational costs.

Procurement Insights for B2B Clients: Making Informed Decisions

Successful procurement of snap lock metal roofing systems requires comprehensive evaluation of supplier capabilities, product specifications, and project-specific requirements to ensure optimal outcomes and long-term satisfaction.

Supplier Evaluation Criteria

Reputable manufacturers demonstrate their commitment through comprehensive certifications and quality management systems. Grade 1 building curtain wall qualifications and Grade 3 steel structure certifications indicate advanced technical capabilities, while high-tech enterprise recognition suggests ongoing innovation investments. Snap Lock Metal Roof Panels production capacity represents another crucial consideration. Facilities with multiple manufacturing lines and substantial monthly output capabilities, such as 1000-ton monthly capacity, ensure reliable delivery schedules even for large-scale projects. The presence of multiple factories provides supply chain redundancy and regional service advantages.

Quality Assurance and Standards Compliance

International standards including ASTM, DIN, JIS, BS, and GB/T ensure product consistency and performance reliability across global markets. These certifications become particularly important for projects requiring specific regulatory compliance or international coordination.Warranty terms reflect manufacturer confidence in product quality. Extended warranties covering 30 years provide assurance of long-term performance while demonstrating manufacturer commitment to customer satisfaction. Such warranty periods significantly exceed industry averages, indicating superior product engineering and manufacturing quality.

Customization and Technical Support

Modern projects increasingly demand customized solutions addressing specific architectural or environmental requirements. Leading suppliers offer extensive color options including RAL standards and custom formulations, enabling precise aesthetic coordination with project designs.Technical support capabilities including design assistance, installation training, and post-installation service distinguish premium suppliers from commodity providers. Access to engineering expertise during project planning phases can prevent costly field modifications and ensure optimal system performance.

HF's Excellence in Snap Lock Metal Roof Panel Manufacturing

Xi'an Huafeng Construction Engineering Co., Ltd. has established itself as a premier manufacturer through comprehensive capabilities spanning design, production, and installation support for complex roofing projects worldwide.

Advanced Manufacturing Infrastructure

Our manufacturing excellence stems from substantial infrastructure investments including three dedicated factories, seven production lines, and more than 40 specialized machines. This extensive capacity enables us to maintain consistent quality while meeting demanding delivery schedules for large-scale commercial projects.The integration of seven color coating production lines with automated punching and forming equipment ensures precise dimensional control and superior surface finish quality. Our production facilities in Anhui, Hangzhou, and Xi'an provide strategic geographic coverage, enabling efficient service to diverse markets while maintaining competitive logistics costs.

Comprehensive Product Portfolio

HF's snap lock metal roof panels incorporate premium materials including aluminum alloy, galvanized steel, stainless steel, copper, and titanium zinc, each optimized for specific performance requirements. Thickness options from 0.4mm to 1.2mm accommodate varying structural and aesthetic demands across commercial, industrial, and institutional applications.Our standard 45mm panel height provides excellent structural performance while maintaining compatibility with diverse building designs. PVDF and polyester coating options ensure long-term appearance retention and corrosion protection, backed by comprehensive 30-year warranties that demonstrate our confidence in product durability.

Technical Innovation and Certification

Recognition as a high-tech enterprise in Shaanxi Province reflects our commitment to continuous innovation and technical advancement. Our portfolio includes more than 20 registered patents for roofing systems, various trademarks, and computer software certificates, demonstrating ongoing investment in product development and intellectual property creation.Quality management systems compliance with ISO9001 and ISO14000:14001 standards ensures consistent manufacturing processes and environmental responsibility. These certifications, combined with SGS verification, provide customers with confidence in our quality control systems and manufacturing capabilities.

Conclusion

Snap Lock Metal Roof Panels maintain market leadership through their unique combination of installation efficiency, long-term durability, and comprehensive performance advantages across diverse commercial applications. The technology's ability to reduce labor costs while delivering superior weather protection has established these systems as the preferred choice for demanding construction projects. Leading manufacturers like HF continue advancing the technology through material innovations, manufacturing excellence, and comprehensive customer support, ensuring continued market evolution and customer satisfaction.

FAQ

What distinguishes snap lock panels from traditional metal roofing systems?

A: Snap lock panels feature innovative interlocking edges that connect without specialized tools or exposed fasteners, significantly reducing installation time and labor costs compared to traditional mechanically fastened systems.

How do snap lock panels perform in extreme weather conditions?

A: These panels achieve Class A fire ratings and demonstrate excellent performance under hurricane-force winds and heavy snow loads through their structural design and secure interlocking mechanisms.

What maintenance requirements apply to snap lock metal roofing systems?

A: Minimal maintenance is required, typically consisting of periodic inspections and cleaning to ensure drainage systems remain clear, contributing to the system's excellent lifecycle cost performance.

Partner with HF for Your Next Snap Lock Metal Roof Panel Project

Ready to experience the advantages of premium snap lock metal roof panels for your commercial project? HF combines advanced manufacturing capabilities with comprehensive technical support to deliver exceptional roofing solutions that meet your specific requirements. Our experienced team provides detailed specifications, customized quotations, and expert consultation services tailored to your project needs. As a leading snap lock metal roof panels supplier, we maintain 1000-ton monthly production capacity with 15-20 day delivery schedules to keep your projects on track. Contact us at huafeng@hfmetalroof.com or visit hfmetalroof.com to explore our complete product portfolio and discuss how our proven expertise can contribute to your project success.

References

1. Metal Roofing Alliance. "Performance Standards for Commercial Metal Roofing Systems." Construction Industry Research Report, 2023.

2. Building Research Institute. "Comparative Analysis of Modern Roofing Technologies: Installation Efficiency and Lifecycle Costs." Journal of Construction Engineering, Vol. 45, 2023.

3. American Society of Civil Engineers. "Wind Resistance Performance of Interlocking Metal Roof Panel Systems." Structural Engineering Guidelines, 2022.

4. International Code Council. "Fire Safety Performance of Metal Roofing Materials in Commercial Construction." Building Safety Standards Review, 2023.

5. Green Building Council. "Energy Efficiency Benefits of Reflective Metal Roofing Systems in Commercial Buildings." Sustainable Construction Practices, 2022.

6. Construction Industry Institute. "Labor Productivity Analysis: Modern Metal Roofing Installation Methods." Project Management Research, Vol. 38, 2023.

_1768986098819.webp)

_1757558889992.webp)