Imagine discovering water stains on your ceiling just five years after installing a new roof, facing another costly replacement while your neighbors' metal roofs still look pristine after decades. High Seam Metal Roofing transforms this nightmare into peace of mind by delivering exceptional durability that extends roof lifespan to over 50 years while significantly increasing property value through superior weather resistance, energy efficiency, and minimal maintenance requirements that traditional roofing materials simply cannot match.

Understanding High Seam Metal Roofing Systems and Their Superior Construction

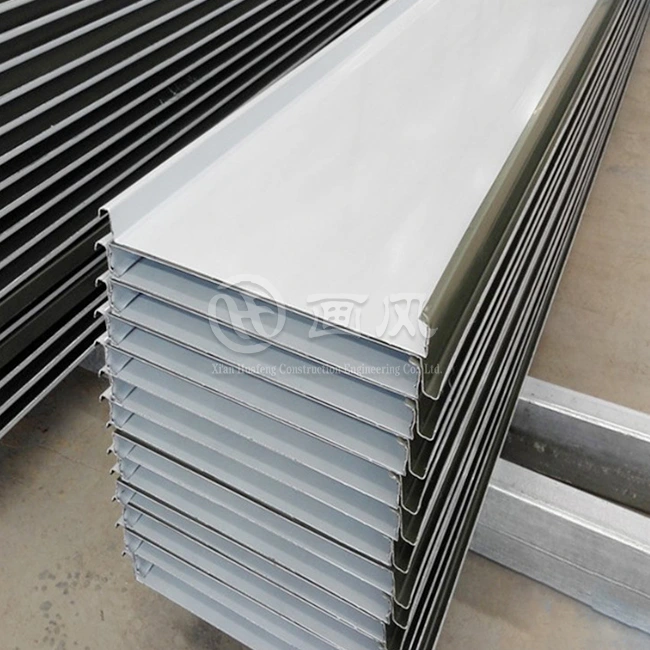

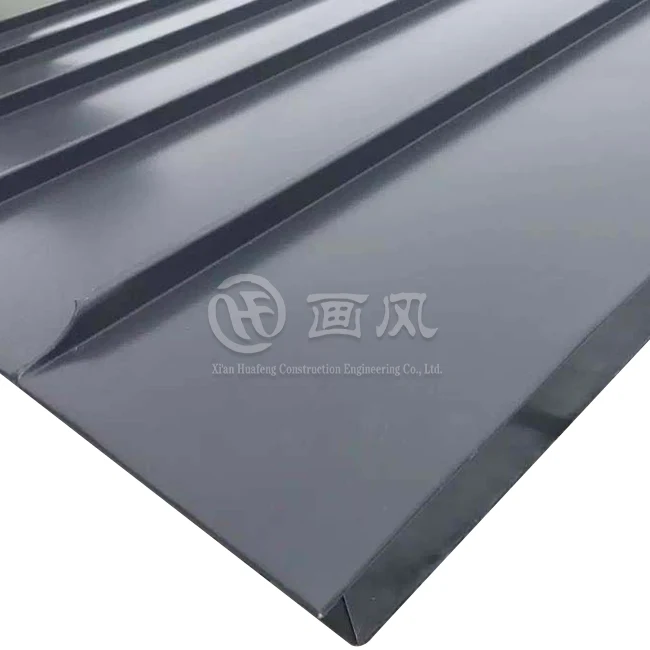

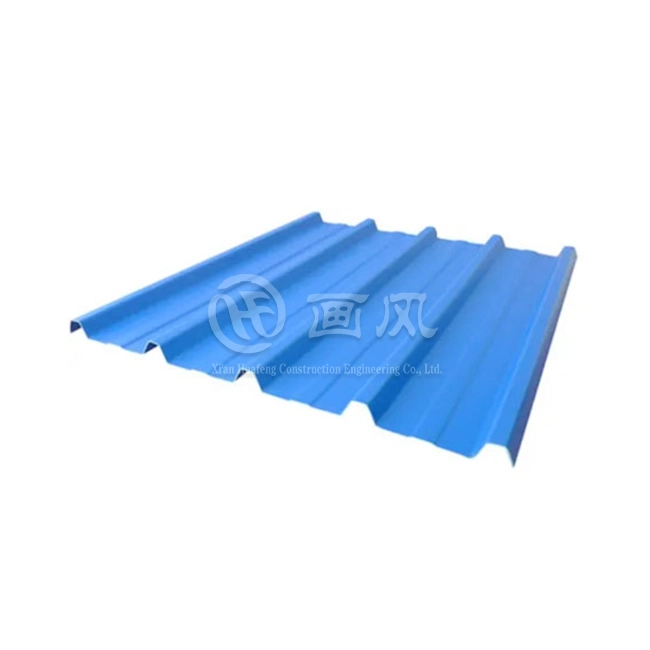

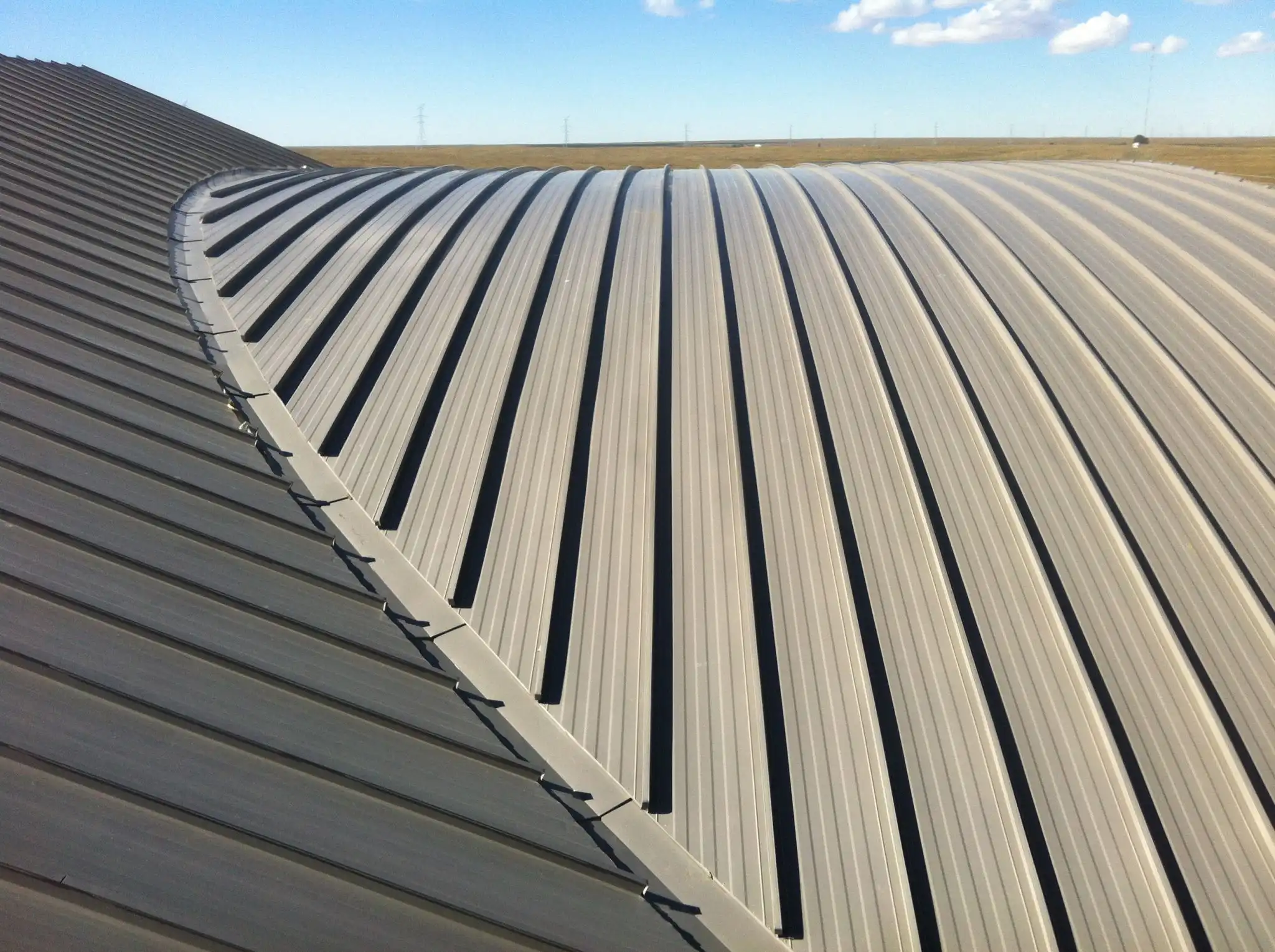

High Seam Metal Roofing represents a premium standing seam roofing system distinguished by its raised vertical seams that interlock adjacent panels, creating a weathertight barrier that outperforms conventional roofing materials in virtually every measurable category. The defining characteristic of this roofing solution lies in its concealed fastener system, where clips secure the panels to the roof deck beneath the raised seams, allowing natural thermal expansion and contraction without compromising structural integrity. This innovative design eliminates the vulnerabilities associated with exposed fasteners that plague traditional metal roofing systems, where screws penetrate the panels and create potential leak points that deteriorate over time. The engineering excellence behind High Seam Metal Roofing extends beyond simple panel installation to encompass a comprehensive system approach. Premium manufacturers like Xi'an Huafeng Construction Engineering Co., Ltd. utilize advanced materials including aluminum alloys (3003, 3004, 5052), galvanized steel, galvalume coatings, stainless steel, and even copper to meet specific performance requirements across diverse climate conditions and architectural applications. The metal panels typically range from 0.5mm to 1.2mm in thickness, with panel widths customizable between 300mm and 600mm to accommodate various roof configurations. Critical to longevity, these panels receive protective surface treatments including PVDF (polyvinylidene fluoride) or PE (polyester) coatings that enhance resistance to UV degradation, corrosion, and color fading, ensuring the roof maintains both functional performance and aesthetic appeal throughout its extended service life.

Material Selection Impact on Roof Performance

The choice of base metal material fundamentally determines the longevity characteristics and value proposition of High Seam Metal Roofing installations. Aluminum roofing panels excel in coastal environments where salt-laden air accelerates corrosion of ferrous metals, offering exceptional resistance to oxidation while maintaining a lightweight profile that reduces structural load requirements. Steel-based systems, particularly those with galvalume coatings combining 55% aluminum and 45% zinc, provide superior strength and puncture resistance ideal for areas experiencing heavy snow loads or potential impact from falling branches and hail. Research conducted on standing seam metal roof systems with galvalume coatings demonstrates projected service lives ranging from 60 to 375 years for panel surfaces, depending on local precipitation pH levels and environmental conditions. Copper and stainless steel represent premium material options that deliver unparalleled longevity, with copper installations documented to perform effectively for up to 200 years in optimal conditions while developing a distinctive patina that many architects and property owners find aesthetically desirable. Stainless steel grades 304 and 316 offer exceptional corrosion resistance in aggressive industrial atmospheres and coastal regions, maintaining structural integrity and appearance without the oxidation concerns associated with carbon steel substrates. The material selection process must consider not only initial cost factors but also the total lifecycle value, including maintenance requirements, energy performance benefits, and the ultimate return on investment through extended service life and enhanced property valuation.

Protective Coatings and Surface Treatment Technologies

The protective coating systems applied to High Seam Metal Roofing panels serve as the first line of defense against environmental degradation, directly influencing both functional longevity and aesthetic preservation over decades of service. PVDF coating systems, such as the industry-standard Kynar 500 formulation, provide superior resistance to chalking, color fading, and chemical exposure compared to conventional polyester coatings. These fluoropolymer-based finishes maintain their integrity and appearance for 30 years or more, backed by manufacturer warranties that specifically address excessive fading and film adhesion failure. The molecular structure of PVDF coatings forms exceptionally strong bonds with the metal substrate while resisting breakdown from ultraviolet radiation, acid rain, and atmospheric pollutants that rapidly degrade lesser coating systems. Polyester-based coatings offer a more economical alternative suitable for applications where budget constraints exist or where environmental exposure proves less severe, though property owners should understand these coatings typically exhibit greater susceptibility to fading and chalking over extended timeframes. The coating application process itself critically impacts performance, with factory-applied finishes utilizing controlled temperature curing processes that ensure uniform coverage and optimal adhesion compared to field-applied alternatives. Xi'an Huafeng Construction Engineering Co., Ltd. employs seven color coating production lines equipped with precision application technology that delivers consistent film thickness ranging from specific microns to meet international standards including ASTM, DIN, JIS, BS, and GB/T specifications, ensuring every panel leaving the facility meets rigorous quality benchmarks that translate directly to extended field performance.

The Engineering Advantages That Extend Roof Longevity

High Seam Metal Roofing achieves its remarkable longevity through fundamental engineering principles that address the primary failure mechanisms affecting conventional roofing systems. The concealed fastener design represents perhaps the most significant innovation, as it eliminates the cyclic stress and weathering exposure that causes exposed fasteners to loosen, corrode, and ultimately fail, creating leak pathways that compromise roof integrity. In traditional screw-down metal roofing or asphalt shingle systems, fastener penetrations through the weather-resistant layer create thousands of potential vulnerability points where water intrusion can occur, particularly as gaskets deteriorate, fasteners back out due to thermal cycling, or wind-driven rain finds access around degraded seals. The raised seam configuration of High Seam Metal Roofing creates a capillary break that prevents water from migrating laterally across the roof surface, channeling precipitation downslope along predetermined drainage paths without allowing moisture to accumulate around fasteners or panel overlaps. This fundamental design principle proves especially critical in low-slope applications where water tends to pond rather than rapidly shed, as the vertical orientation of the seams maintains weathertightness even when roof pitch falls to minimum levels of 0.5:12 where other systems would fail. Metal roof seam repair requirements remain minimal throughout the service life when proper installation techniques ensure adequate sealant application at panel terminations and penetrations, with quality butyl sealants demonstrating no significant degradation in cohesive tensile strength even after 35 years of field service according to comprehensive research studies.

Thermal Movement Management and System Flexibility

Metal roofing materials inherently expand when heated by solar radiation and contract as temperatures drop, with thermal movement potentially reaching several inches across long panel runs depending on metal type, color, and climate conditions. High Seam Metal Roofing systems accommodate this natural movement through specially designed clips that secure panels to the structural deck while allowing controlled sliding as the metal expands and contracts. This engineered flexibility prevents the stress concentrations, panel buckling, and fastener pullout that occurs when metal panels are rigidly attached without provision for thermal movement, directly contributing to extended service life by eliminating cyclic fatigue damage that accumulates over thousands of heating and cooling cycles. The clip attachment system typically employs either fixed clips at one end of each panel to establish a datum point, with sliding clips along the remainder of the panel length, or alternatively utilizes two-piece clip designs that allow controlled movement in all directions. This sophisticated approach ensures that thermal stresses dissipate through intended movement pathways rather than concentrating at vulnerable connection points, preserving both waterproofing integrity and structural performance throughout temperature extremes ranging from subzero winter conditions to summer roof surface temperatures exceeding 160°F. Property owners can observe High Seam Metal Roofing installations that remain perfectly flat and weathertight after decades of service, while improperly constrained metal roofing systems develop characteristic "oil canning" waviness and fastener problems within just a few years.

Weather Resistance and Structural Performance

High Seam Metal Roofing delivers exceptional resistance to extreme weather conditions that rapidly age or destroy alternative roofing materials, directly translating to extended service life and reduced lifecycle costs. Wind resistance proves particularly impressive, with properly installed standing seam systems tested to withstand wind speeds exceeding 140 miles per hour without panel displacement or damage, meeting the most stringent building code requirements for hurricane-prone coastal regions. The interlocking seam design creates a continuous structural connection that distributes wind uplift forces across the entire roof assembly rather than concentrating loads at individual fastener points, preventing the progressive failure pattern where wind successively removes sections of conventional roofing as each compromised fastener fails and exposes additional vulnerable areas. Heavy snow load capacity ranks among the critical performance attributes in northern climates, where accumulated precipitation can impose hundreds of pounds per square foot of additional loading on roof structures. High Seam Metal Roofing panels engineered with appropriate material gauge, rib spacing, and structural support spacing easily accommodate design snow loads while the smooth metal surface and dark colors available facilitate snow shedding through solar heating and reduced friction coefficient. The fire resistance inherent in metal roofing materials provides Class A fire rating, the highest classification available, offering superior protection against ignition from external sources like flying embers during wildfire events while contributing zero fuel to fire spread. This non-combustible characteristic not only enhances life safety but also frequently qualifies property owners for insurance premium reductions that provide ongoing financial value throughout the roof's service life.

Value Creation Through Energy Efficiency and Sustainability

High Seam Metal Roofing generates substantial property value through documented energy performance benefits that reduce operating costs while supporting environmental sustainability objectives increasingly important to commercial property owners, facility managers, and environmentally conscious homeowners. The reflective properties of metal roofing surfaces, particularly those with specialized cool roof coatings, dramatically reduce solar heat gain compared to traditional dark asphalt shingles that absorb and transfer thermal energy into building interiors. Studies document cooling cost reductions ranging from 10% to 25% in air-conditioned buildings, with the magnitude of savings correlating to climate zone, building insulation levels, and roof color selection. The mechanism underlying these energy savings involves both solar reflectance, which bounces incoming radiation back toward the atmosphere rather than converting it to heat, and thermal emittance, which efficiently radiates absorbed heat away from the roof surface. High Seam Metal Roofing systems specified with light colors and advanced reflective coatings achieve total solar reflectance values exceeding 0.70 (reflecting 70% of incident solar energy) while maintaining thermal emittance above 0.75, qualifying for cool roof certifications that satisfy energy code requirements and contribute points toward LEED certification in commercial construction projects. The temperature differential proves substantial, with conventional dark roofing surfaces reaching peak temperatures of 180°F while cool metal roofing under identical conditions may not exceed 120°F, directly reducing heat transfer through the roof assembly and decreasing cooling system runtime.

Lifecycle Cost Analysis and Return on Investment

Comprehensive lifecycle cost analysis consistently demonstrates that High Seam Metal Roofing delivers superior financial value compared to alternative roofing systems despite higher initial installation costs, with the extended service life and reduced maintenance requirements generating positive return on investment within the functional life of a single roof installation. Traditional asphalt shingle roofing requires replacement every 15 to 20 years, meaning property owners face multiple roof replacement projects over a typical building lifespan, each incurring complete material costs, installation labor, waste disposal fees, and business disruption impacts. In contrast, High Seam Metal Roofing installations from reputable manufacturers like Xi'an Huafeng Construction Engineering Co., Ltd. routinely achieve service lives exceeding 50 years for steel and aluminum systems, with premium materials like copper and stainless steel documented to perform effectively for 70 to 200 years under appropriate conditions. The maintenance differential proves equally significant, as High Seam Metal Roofing requires minimal intervention beyond periodic inspections to verify sealant integrity at penetrations and ensure debris accumulation does not impede drainage. Asphalt shingle roofs demand continuous attention to address granule loss, shingle damage from storms, flashing deterioration, and moss growth in humid climates, with repair costs accumulating substantially over decades of service. Energy savings compound the financial advantages, particularly in commercial and industrial facilities where roof surface area represents a substantial percentage of the building envelope and cooling loads significantly impact operating expenses. Property owners can reasonably project energy cost reductions of several thousand dollars annually for large facilities, creating cumulative savings that exceed the incremental cost premium of metal roofing within 10 to 15 years while the roof continues providing these benefits for decades beyond the payback period.

Environmental Sustainability and Green Building Contributions

High Seam Metal Roofing aligns with contemporary sustainability values and green building standards through multiple attributes including recycled content, recyclability at end of service life, reduced urban heat island effects, and compatibility with renewable energy systems. Metal roofing panels typically contain 25% to 95% recycled content depending on material type and manufacturer, diverting substantial material from landfills while reducing the environmental impact of virgin material extraction and processing. At the end of their exceptionally long service lives, metal roofing panels retain full recyclability, with the scrap value helping offset removal costs while enabling the material to enter new product cycles rather than contributing to landfill accumulation like asphalt shingles, which generate millions of tons of waste annually that offers no recycling pathway. The cool roof performance of reflective High Seam Metal Roofing contributes to urban heat island mitigation by reducing the temperature differential between developed areas and surrounding rural regions, helping moderate local climate impacts while reducing energy consumption for building cooling. Many jurisdictions now recognize these benefits through building codes that mandate minimum roof reflectance values or offer expedited permitting for projects incorporating cool roof technologies. The structural characteristics of standing seam systems facilitate solar photovoltaic integration through specialized mounting hardware that attaches to the raised seams without roof penetrations, enabling property owners to generate renewable electricity while preserving roof warranty coverage and weatherproofing integrity. Xi'an Huafeng Construction Engineering Co., Ltd. specifically engineers solar-ready roof configurations that accommodate PV mounting systems, positioning forward-thinking property owners to capitalize on renewable energy incentives while their roof continues providing decades of reliable weather protection.

Professional Installation and Quality Assurance Requirements

The exceptional longevity potential of High Seam Metal Roofing materializes only through proper installation by experienced contractors utilizing appropriate techniques, quality materials, and rigorous attention to critical details that differentiate premium installations from problematic projects. The complexity of standing seam installation exceeds conventional roofing systems, requiring specialized equipment including panel seaming machines, precision measuring tools, and panel forming equipment when custom field fabrication proves necessary to accommodate unique roof geometries. Installer training and experience directly correlate with installation quality, as subtle errors in panel alignment, clip spacing, sealant application, or thermal movement provision can compromise performance even when using premium materials. Xi'an Huafeng Construction Engineering Co., Ltd. exemplifies the comprehensive approach necessary for successful High Seam Metal Roofing projects through their integrated process spanning design development, precision manufacturing, and professional installation or guidance services. Their methodology begins with detailed project drawing deepening that analyzes architectural engineering drawings to develop feasible roof panel configurations optimized for the specific roof structure, followed by iterative communication with customers to confirm panel type selection and node detail development conducted at 1:1 scale to ensure constructability and performance. The production process incorporates rigorous incoming material inspection procedures that verify raw material quality through sampling, testing, and certification review before materials enter production, with inspection protocols encompassing over a dozen evaluation criteria including appearance, dimensions, salt spray resistance, adhesion, hardness, impact resistance, film thickness, acid resistance, weather resistance, and color consistency.

Quality Control Throughout Manufacturing and Installation

Manufacturing quality control extends throughout the production sequence, with finished product inspection verifying appearance, dimensional accuracy, flatness, and curvature before products receive specialized packaging organized according to roof sections to facilitate efficient field installation. Product identification systems correlate packaging with detailed floor plans and component numbering schemes that enable installers to locate and install panels in the correct sequence without confusion, significantly reducing installation errors while improving project efficiency. On-site construction management begins with thorough preparation including construction area layout confirmation, material receipt verification against packaging documentation, and pre-installation tool and material completeness checks conducted by technicians who visit job sites one day in advance to identify and resolve potential issues before work commences. Technical briefing meetings ensure installation crews thoroughly understand project details and safety protocols before beginning work, while on-site guidance from experienced professionals helps navigate unexpected conditions that inevitably arise during construction. Upon installation completion, comprehensive testing verifies zero leakage, providing property owners with confidence in their investment while establishing baseline conditions for future maintenance planning. Xi'an Huafeng Construction Engineering Co., Ltd. maintains this quality-focused approach across their portfolio of high-profile projects including the Xiongan Station Commercial Body, Xi'an International Convention and Exhibition Center, Jinghe New City International Culture and Art Center, and numerous other installations where High Seam Metal Roofing delivers the combination of aesthetic distinction and reliable long-term performance demanded by architects, developers, and property owners.

Maintenance Requirements and Inspection Protocols

While High Seam Metal Roofing requires dramatically less maintenance than alternative roofing systems, establishing and following appropriate inspection and maintenance protocols maximizes service life and protects the substantial investment these premium roofing systems represent. Recommended inspection frequency typically ranges from annual to biennial for most installations, with more frequent inspections warranted in environments with heavy debris accumulation from deciduous trees, pine straw, or airborne particulates, or in coastal regions where salt spray accelerates corrosion if not periodically removed. Inspection checklists should address sealant condition at panel terminations and penetrations, noting any cracking, separation, or loss of adhesion that could permit water intrusion, along with verification that drainage pathways remain unobstructed and functioning as designed. Panel surface examination identifies potential problems including coating degradation, corrosion initiation particularly at cut edges or damaged areas, and mechanical damage from falling objects or roof traffic. The concealed fastener clips and structural connections beneath the raised seams should be evaluated where accessible to ensure thermal movement proceeds normally without binding or stress concentration development. In wet climates prone to algae or moss growth, periodic cleaning at five-year intervals prevents organic accumulation that retains moisture against metal surfaces and potentially accelerates coating breakdown. Metal roof seam repair needs remain minimal with quality installations, though any identified problems should receive prompt attention to prevent minor issues from progressing to more significant damage requiring extensive remediation.

Enhancing Property Value Through High Seam Metal Roofing Investment

Real estate professionals and property appraisers increasingly recognize the substantial value premium commanded by properties featuring High Seam Metal Roofing systems, reflecting buyer recognition of the reduced ownership costs, enhanced aesthetics, and reduced risk associated with premium roofing installations. Residential property studies document resale value increases ranging from 1% to 6% of total property value attributable to metal roofing, with the magnitude varying based on local market conditions, property price ranges, and the quality of the specific installation. In premium residential markets and architectural designs where standing seam metal roofing complements contemporary or industrial aesthetic themes, the value contribution can reach or exceed the installed cost of the roofing system itself, particularly when buyers compare the immediate functionality of a new metal roof against conventional properties requiring imminent roof replacement. Commercial and industrial property valuations reflect even more dramatic impacts, as institutional buyers and real estate investment analysts incorporate detailed lifecycle cost models into property underwriting that explicitly value extended roof service life, reduced maintenance expenses, and energy performance characteristics. A facility with a new High Seam Metal Roofing installation commanding a 30-year service life before replacement becomes necessary presents dramatically different long-term capital requirements compared to an otherwise identical property with conventional roofing facing replacement within five to ten years. This differential directly translates to adjusted capitalization rates, improved financing terms, and higher sustainable valuations that benefit property owners during refinancing, partnership restructuring, or sale transactions.

Market Differentiation and Competitive Advantages

Beyond pure financial metrics, High Seam Metal Roofing provides tangible competitive advantages for commercial properties in tenant attraction and retention, particularly in sectors where sustainability credentials and operational efficiency drive location decisions. Corporate tenants increasingly establish real estate criteria emphasizing green building certifications, energy performance, and environmental responsibility as components of their own corporate sustainability commitments, creating market demand for facilities that offer these attributes. Properties featuring High Seam Metal Roofing systems that contribute to LEED certification, support solar energy installation, and demonstrate superior energy efficiency gain competitive advantages in attracting and retaining quality tenants willing to pay premium lease rates for facilities aligned with their corporate values and operational objectives. The architectural distinction of High Seam Metal Roofing proves particularly valuable in hospitality, retail, and corporate office applications where building aesthetics directly impact brand perception and customer attraction. The clean lines, contemporary appearance, and design flexibility available through varied panel profiles, seam heights, and extensive color options enable architects to create distinctive building identities that differentiate properties from competitive alternatives. Xi'an Huafeng Construction Engineering Co., Ltd. offers customizable solutions including panel widths from 300mm to 600mm, seam heights of 65mm, and unlimited color options through RAL, Pantone, or custom formulations that enable design professionals to realize their creative visions while property owners benefit from the functional advantages inherent in premium metal roofing systems.

Conclusion

High Seam Metal Roofing fundamentally transforms roof longevity expectations and property value through superior engineering, exceptional material quality, and comprehensive installation excellence that traditional roofing systems cannot match.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

Xi'an Huafeng Construction Engineering Co., Ltd. stands as a China High Seam Metal Roofing manufacturer and China High Seam Metal Roofing supplier recognized as a Shaanxi Province high-tech enterprise, bringing over two decades of engineering expertise, three state-of-the-art production facilities totaling 200,000 square meters, seven color coating production lines, and more than 40 precision manufacturing machines to deliver superior China High Seam Metal Roofing wholesale solutions. Our comprehensive capabilities span custom design optimization through structural 3D modeling and load analysis, precision manufacturing utilizing premium materials from industry-leading brands including Alucosuper aluminum, Baosteel steel, and NedZink titanium-zinc, and professional installation guidance ensuring every project achieves optimal performance. With rigorous quality certifications including ISO9001, ISO14000:14001, and SGS validation, plus over 20 registered roofing system patents, we provide High Quality High Seam Metal Roofing backed by 30-year warranties, competitive High Seam Metal Roofing price structures, and proven reliability demonstrated across landmark projects including Xiongan Station, Xi'an International Convention and Exhibition Center, and Inner Mongolia Tongliao Art Museum. Partner with a trusted China High Seam Metal Roofing factory offering High Seam Metal Roofing for sale with one-stop service from design through installation, minimum order quantities of just 500 square meters, 15-20 day delivery schedules, and dedicated technical support. Contact us today at huafeng@hfmetalroof.com to discuss your project requirements and discover why leading developers, architects, and property owners choose Xi'an Huafeng Construction Engineering Co., Ltd. for metal roofing solutions that deliver exceptional longevity, value, and performance. Save this resource for future reference as you plan your next roofing project.

References

1. Bill Ragan Roofing Company, "Standing Seam Metal Roof Installation and Lifespan Analysis," Professional Roofing Trade Publication

2. Metal Construction Association, "Service Life Assessment of Low-Slope Metal Roof Systems: Field Study Results," Technical Research Report

3. American Society of Civil Engineers, "Weather Resistance and Structural Performance of Standing Seam Metal Roofing," Journal of Architectural Engineering

4. National Roofing Contractors Association, "Lifecycle Cost Analysis: Metal Roofing Systems Compared to Traditional Materials," Industry White Paper

5. United States Green Building Council, "Cool Roof Technology and Energy Performance in Commercial Buildings," LEED Technical Guidance Document

_1768986098819.webp)