Traditional building facades struggle with water infiltration, thermal expansion, and aesthetic limitations that lead to costly maintenance and premature failure. Vertical Standing Seam Metal Cladding solves these critical challenges through advanced mechanical locking technology and concealed fastening systems. This comprehensive guide explores specifications, material options, installation techniques, and performance standards to help architects, contractors, and building owners select the optimal cladding solution for demanding commercial and industrial applications.

Understanding Vertical Standing Seam Metal Cladding Systems

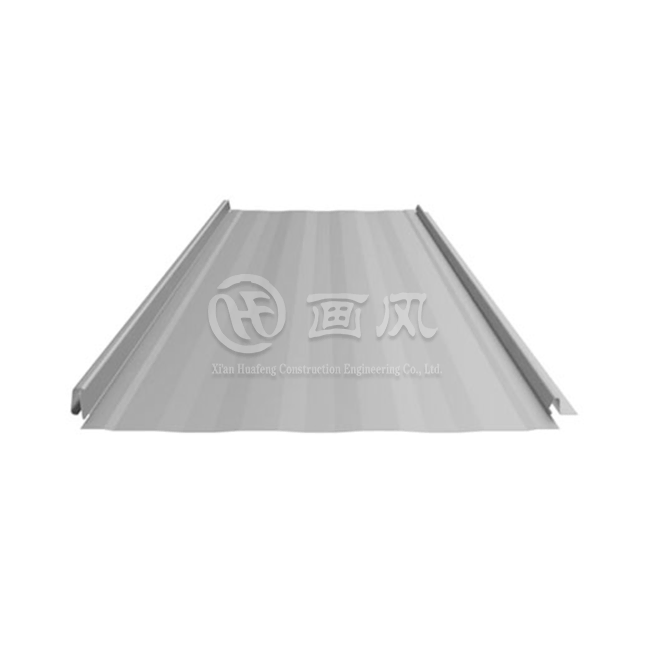

Vertical Standing Seam Metal Cladding represents an advanced architectural facade system engineered for superior weather resistance and aesthetic excellence. This high-performance enclosure solution utilizes vertically-oriented metal panels joined through mechanical interlocking seams that create continuous, watertight barriers without exposed fasteners. The system's distinctive raised seams not only deliver exceptional structural integrity but also accommodate thermal movement while maintaining a sleek, contemporary appearance that enhances building value and curb appeal. The fundamental design principle behind Vertical Standing Seam Metal Cladding involves connecting adjacent panels through precisely formed male and female edges that crimp together using specialized seaming tools. This mechanical connection method eliminates penetrations through the panel face, preventing potential leak points that compromise traditional cladding systems. The concealed clip attachment system allows panels to expand and contract independently with temperature fluctuations, reducing stress concentrations that cause premature failure in rigid cladding installations.

Core Design Features and Technical Specifications

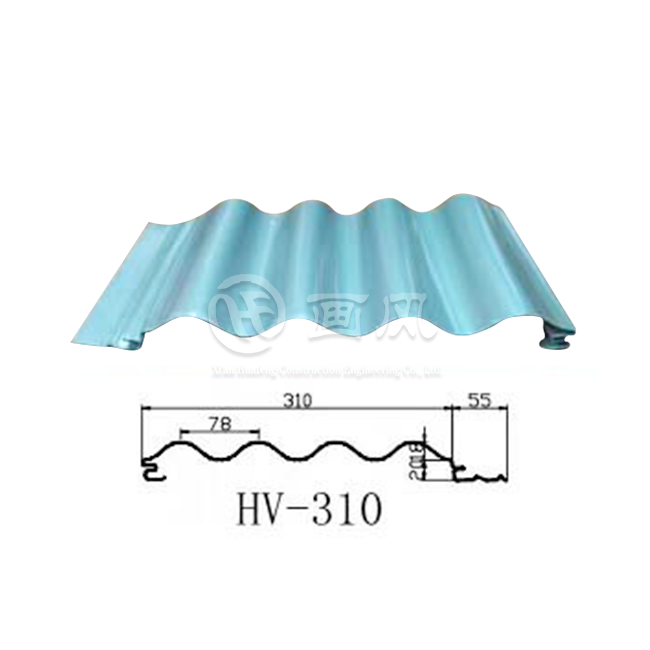

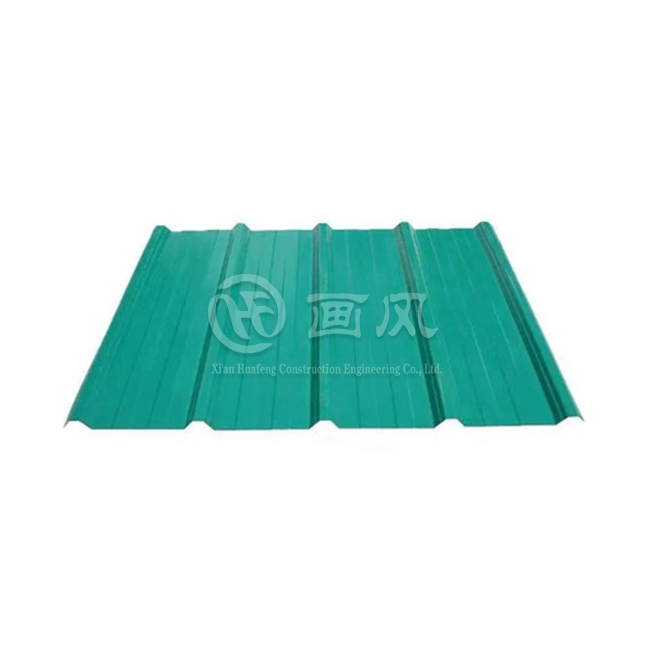

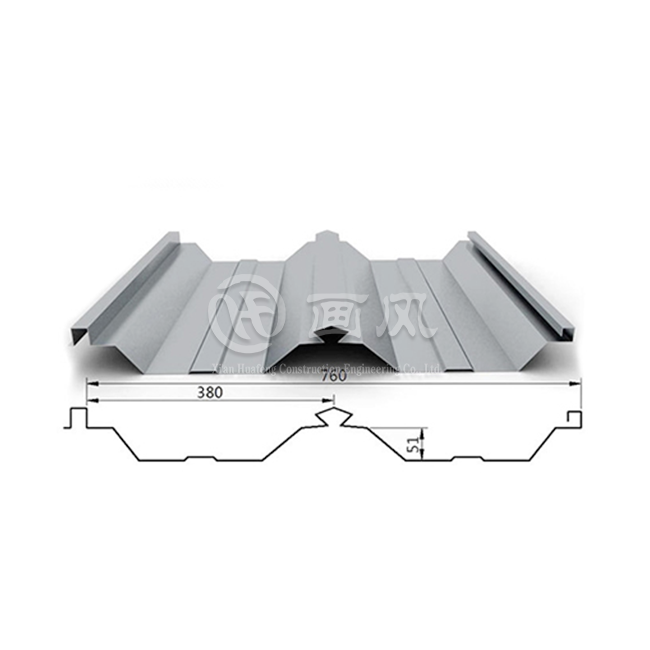

Modern Vertical Standing Seam Metal Cladding systems incorporate sophisticated engineering features that optimize performance across diverse climate conditions. Panel widths typically range from 400mm to 600mm with customization available from 300mm to 800mm depending on project requirements and aesthetic preferences. Rib heights between 25mm and 65mm provide varying degrees of shadow lines and visual depth, enabling architects to create distinctive facade expressions while maintaining structural adequacy for wind load resistance. Material selection plays a crucial role in system longevity and maintenance requirements. Aluminum alloy panels fabricated from AA3003, AA3004, or AA5052 grades offer exceptional corrosion resistance with minimal maintenance over their 30-50 year service life. These aluminum substrates typically range from 0.7mm to 1.5mm thickness, providing optimal strength-to-weight ratios for large-span applications. Steel alternatives utilizing aluminum-zinc coating (AZ150) deliver enhanced durability in corrosive environments, with thickness specifications from 0.4mm to 1.2mm depending on structural demands and project budgets. Premium coating systems protect substrate materials while delivering desired color and finish characteristics. Polyvinylidene fluoride (PVDF) coatings provide superior UV resistance and color retention exceeding 20 years in harsh environmental exposures. Polyester (PE) and High Durability Polyester (HDP) alternatives offer cost-effective protection for moderate climate applications where extreme weathering is less critical. These factory-applied coatings eliminate field painting requirements, reducing installation time and ensuring consistent finish quality across entire building facades.

Material Performance and Environmental Resistance

The exceptional durability of Vertical Standing Seam Metal Cladding stems from carefully engineered material properties and protective coating technologies. Wind resistance capabilities typically exceed 3.0kPa, meeting or surpassing typhoon-level performance standards required in coastal regions and high-exposure locations. This superior wind performance results from the continuous mechanical seaming that distributes loads uniformly across panel connections, preventing localized stress concentrations that cause failure in mechanically fastened systems. Thermal adaptation represents another critical performance advantage of Vertical Standing Seam Metal Cladding installations. The sliding clip connection methodology accommodates significant thermal expansion and contraction without generating destructive stresses within the panel assembly. This thermal flexibility proves essential in climates experiencing wide temperature variations, where rigid cladding systems develop buckling, oil-canning, and fastener distress over time. The concealed clip design allows independent panel movement while maintaining weathertight seam integrity throughout the building's service life. Fire safety compliance achieves Class A ratings according to EN13501-1 standards when properly specified and installed. This superior fire rating makes Vertical Standing Seam Metal Cladding suitable for applications requiring non-combustible construction, including high-rise commercial buildings, healthcare facilities, and educational institutions. The metal substrate and factory-applied coatings resist flame spread while eliminating fuel sources that contribute to fire propagation in polymer-based cladding alternatives.

Installation Methods and Construction Best Practices

Successful Vertical Standing Seam Metal Cladding installation requires meticulous planning, proper substrate preparation, and skilled craftsmanship throughout the construction process. The installation sequence begins with comprehensive site verification to confirm substrate planarity, structural adequacy, and weather-resistant barrier continuity. Plywood or fiber cement board substrates must achieve minimum 19mm thickness to provide adequate fastener holding capacity and sufficient rigidity to prevent panel waviness that compromises aesthetic quality. Professional installers establish precise control lines using laser levels and string lines to ensure perfect panel alignment across entire building facades. Starting panels require particular attention to plumb and position since these establish reference points for subsequent panel installation. Fixed clips anchor the first panel securely to the substrate, with clip spacing calculated based on wind load requirements and panel length. Subsequent panels snap into place using the mechanical seam connection, with sliding clips allowing thermal movement while maintaining secure attachment.

Panel Fabrication and Customization Capabilities

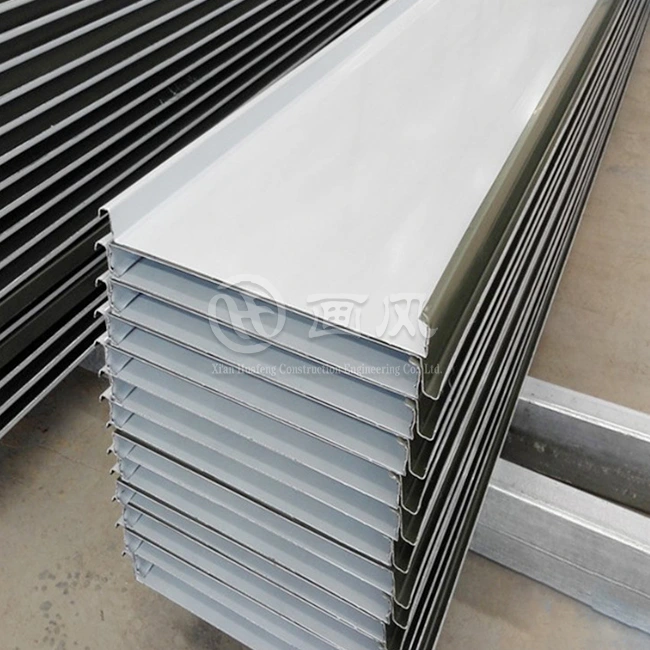

Advanced manufacturing capabilities enable Vertical Standing Seam Metal Cladding customization that meets unique architectural requirements for complex building geometries. Xi'an Huafeng Construction Engineering Co., Ltd. operates state-of-the-art production facilities featuring 7 color coating lines, 1 laminating production line, and 10 longitudinal and transverse shearing systems that deliver precision panel fabrication. This manufacturing infrastructure supports custom panel lengths up to 12 meters, minimizing horizontal joints and creating continuous vertical lines that emphasize building height and elegance. Computer-aided design integration streamlines the project coordination process from concept through installation completion. Detailed shop drawings generated from building information models ensure accurate panel sizing, accessory coordination, and flashing integration before manufacturing begins. This pre-construction coordination identifies potential conflicts and allows value engineering opportunities that optimize material usage while maintaining design intent. Factory sample production enables stakeholders to verify color, finish, and profile characteristics before full-scale fabrication, eliminating costly field changes and ensuring client satisfaction. Quality control protocols implemented throughout manufacturing and installation phases guarantee consistent product performance and aesthetic excellence. Incoming raw materials undergo rigorous testing including salt spray resistance, coating adhesion, hardness verification, and color consistency evaluation. These comprehensive quality checks ensure substrate materials and protective coatings meet specified performance standards before panel fabrication begins. Finished panel inspection verifies dimensional accuracy, surface quality, and coating integrity prior to protective packaging and shipment to project sites.

Accessory Components and System Integration

Complete Vertical Standing Seam Metal Cladding installations require carefully coordinated accessory components that ensure weathertight performance at building transitions and penetrations. Custom-fabricated flashings seal panel terminations at building bases, roof intersections, window perimeters, and penetration locations. These flashings must coordinate precisely with panel profiles and substrate conditions to prevent water infiltration while accommodating differential movement between cladding and structural elements. Corner treatments demand particular attention to maintain continuous weather protection while achieving clean aesthetic transitions. Inside and outside corner flashings integrate with the panel system to provide positive water diversion without compromising the concealed fastener principle. Complex corner geometries may require specialized fabrication techniques including tapered panels or curved profiles that maintain consistent reveal dimensions throughout the building facade. Professional installation expertise proves essential for these critical details that significantly impact overall system performance and appearance. Ventilation cavities behind Vertical Standing Seam Metal Cladding panels enhance thermal performance and moisture management when properly designed and executed. Minimum 38mm airspace dimensions allow adequate ventilation while providing clearance for insulation bulging and construction tolerance accommodation. Continuous screened ventilation openings at cavity bases and tops promote air circulation that removes moisture accumulation and reduces heat gain through the building envelope. This ventilated cavity approach proves particularly beneficial in humid climates where moisture management significantly impacts building durability and occupant comfort.

Project Applications and Case Study Success

Vertical Standing Seam Metal Cladding demonstrates exceptional versatility across diverse building types and architectural styles. Commercial office buildings benefit from the system's professional appearance, low maintenance requirements, and energy efficiency contributions. The continuous vertical lines created by standing seam panels emphasize building height while the variety of available colors and finishes enables architects to achieve distinctive brand identities that differentiate projects within competitive markets. Industrial facilities require robust cladding solutions capable of withstanding harsh operational environments while providing long-term value through minimal maintenance requirements. Vertical Standing Seam Metal Cladding delivers exceptional resistance to chemical exposure, impact damage, and extreme temperature fluctuations common in manufacturing and processing operations. The system's non-combustible construction and superior fire ratings satisfy stringent industrial building codes while the rapid installation methodology minimizes construction schedules and reduces project costs.

Notable Project Portfolio and Performance Validation

Xi'an Huafeng Construction Engineering Co., Ltd. has successfully completed numerous high-profile Vertical Standing Seam Metal Cladding installations demonstrating the system's capabilities across challenging applications. The Xiongan Station Commercial Body project showcases aluminum-magnesium-manganese panel systems spanning large-scale transportation infrastructure with demanding aesthetic and performance requirements. This installation demonstrates the material's suitability for high-visibility public facilities where appearance quality and durability prove equally critical. The Xi'an International Convention and Exhibition Center Metal Roof Project illustrates the system's adaptability to complex architectural geometries including curved surfaces and dramatic cantilevers. This landmark installation required precision panel fabrication and expert installation craftsmanship to achieve the architect's vision while meeting stringent waterproofing and structural performance standards. The project's successful completion validates the comprehensive technical support and engineering expertise available from experienced manufacturers and installers. Educational facilities including the Weihua Cadre College Teaching Building and Office Building demonstrate Vertical Standing Seam Metal Cladding applications in institutional settings requiring long-term durability and minimal lifecycle costs. These installations benefit from the system's sustainable characteristics including recyclable materials, reduced maintenance requirements, and energy efficiency contributions through reflective coatings and ventilated cavity construction. The 30-year warranty coverage provided by quality manufacturers ensures educational institutions receive lasting value from their building envelope investments.

Material Selection and Specification Guidelines

Architects and specifiers must carefully evaluate material options when selecting Vertical Standing Seam Metal Cladding systems for specific project requirements. Aluminum alloy substrates offer superior corrosion resistance particularly valuable in coastal environments or applications exposed to industrial pollutants. The material's natural oxide layer provides inherent protection against atmospheric corrosion without requiring additional protective treatments. Aluminum's lightweight characteristics reduce structural loading requirements and simplify installation logistics, particularly beneficial for renovation projects with weight limitations. Steel substrates with aluminum-zinc metallic coatings provide cost-effective alternatives for projects requiring economical solutions without sacrificing performance. The sacrificial coating protection delivers excellent corrosion resistance in most environmental exposures when combined with appropriate factory-applied topcoats. Steel's superior strength enables reduced thickness specifications in applications with high structural demands, potentially offsetting material cost differences through reduced framing requirements and simplified connections.

Coating Technology and Finish Selection Strategies

Coating selection significantly impacts both initial appearance and long-term performance characteristics of Vertical Standing Seam Metal Cladding installations. PVDF resin-based coatings represent the premium choice for projects demanding maximum color retention and chalking resistance over extended service periods. These fluoropolymer coatings maintain gloss levels and color integrity typically exceeding 80% after 20 years exposure in harsh environmental conditions. The superior weatherability justifies the premium investment particularly for high-visibility applications where appearance maintenance proves critical to building value preservation. Polyester coating systems provide economical alternatives suitable for moderate climate exposures and budget-conscious projects. Standard polyester formulations deliver adequate performance for 10-15 year maintenance cycles when properly specified and maintained. High Durability Polyester (HDP) technologies bridge the performance gap between standard polyester and PVDF coatings, offering enhanced UV resistance and color retention at intermediate price points. These improved polyester systems suit applications where extended service life justifies modest cost premiums over standard formulations. Color selection influences both aesthetic impact and thermal performance characteristics requiring careful consideration during specification development. Light colors reflect solar radiation reducing heat gain through building envelopes, potentially decreasing cooling energy consumption in warm climates. Dark colors absorb solar energy creating higher surface temperatures that must be accommodated through proper substrate selection and panel design. The vast color palette available through factory coating processes enables architects to achieve desired aesthetic expressions while optimizing energy performance through strategic color specification.

Conclusion

Vertical Standing Seam Metal Cladding delivers unmatched performance combining weather resistance, aesthetic excellence, and lifecycle value for commercial and industrial building applications. This guide provides architects and contractors with comprehensive knowledge to specify, design, and install superior facade systems that exceed client expectations.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

Xi'an Huafeng Construction Engineering Co., Ltd. stands as a leading China Vertical Standing Seam Metal Cladding manufacturer specializing in comprehensive metal roofing and wall cladding solutions. As a premier China Vertical Standing Seam Metal Cladding supplier, we offer High Quality Vertical Standing Seam Metal Cladding backed by 20+ engineering patents, ISO9001 and ISO14000:14001 certifications, and SGS quality validation. Our 200,000 square meter manufacturing facilities in Anhui, combined with processing plants in Hangzhou and Xi'an, deliver Vertical Standing Seam Metal Cladding for sale with customizable specifications including color, pattern, and design modifications.

Since our 2018 establishment, we have emerged as a trusted China Vertical Standing Seam Metal Cladding factory providing one-stop solutions from initial design optimization through final installation guidance. Our comprehensive service portfolio includes 3D structural modeling, load analysis, raw material quality testing, and precision manufacturing using advanced roll-forming equipment. As a competitive China Vertical Standing Seam Metal Cladding wholesale provider, we maintain 1000 tons monthly production capacity with 15-20 day delivery schedules and 500㎡ minimum order quantities. Our collaboration with Fortune 500 companies validates our technical capabilities and commitment to excellence. For Vertical Standing Seam Metal Cladding price quotations and project consultation, contact our engineering team at huafeng@hfmetalroof.com to discuss your specific application requirements.

References

1. Metal Construction Association. "Architectural Sheet Metal Manual," 7th Edition. Technical Standards for Standing Seam Systems.

2. American Society for Testing and Materials. "ASTM E1646 - Standard Test Method for Water Penetration of Exterior Metal Roof Panel Systems by Static Water Pressure Differential."

3. Smith, J.R. and Chen, L. "Performance Evaluation of Metal Cladding Systems in High-Wind Environments." Journal of Architectural Engineering, Vol. 28, No. 3.

4. International Building Code. "Chapter 14: Exterior Walls and Chapter 15: Roof Assemblies and Rooftop Structures." 2021 Edition.

5. Thompson, M.D. "Sustainable Metal Building Envelopes: Design Principles for Energy Efficiency and Durability." Green Building Press.