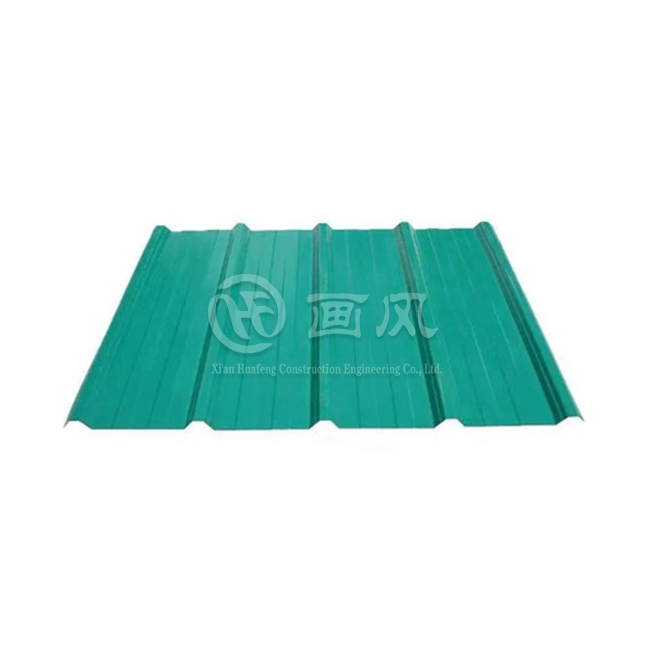

When designing large-scale commercial or industrial projects, choosing the right roofing solution can make or break your construction timeline and budget. Classic Rib Corrugated Panel systems offer exceptional durability, cost-effectiveness, and aesthetic appeal that perfectly align with the demanding requirements of modern metal buildings. These versatile structural panels deliver superior weather resistance while maintaining the professional appearance essential for high-profile developments.

Key Performance Indicators and Technical Specifications

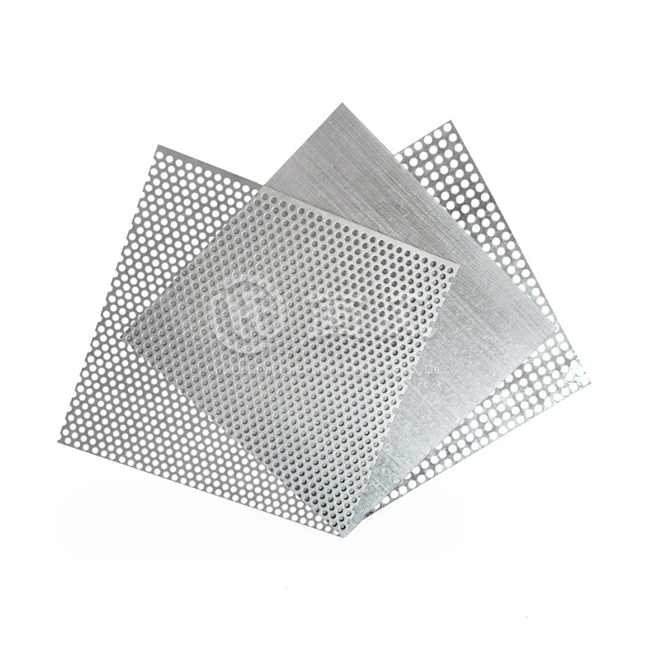

Understanding these specialized specifications helps contractors make informed procurement decisions. Our folded steel panels offer customizable widths ranging from 600 mm to 1200 mm, accommodating diverse engineering requirements. Thickness options span from 0.3 mm to 1.2 mm, allowing engineers to select optimal gauge specifications based on structural load calculations. The galvanized steel construction provides excellent corrosion protection, while PE, HDP, and PVDF coating options ensure long-term color retention and surface durability. Wave heights typically range from 10 mm to 50 mm, forming a distinctive ribbed profile that enhances both structural integrity and visual appeal. In addition, temperature resistance from −40 °F to 160 °F makes these metal sheets suitable for varied North American climates, while wind uplift resistance meets or exceeds ASTM standards, ensuring reliable performance during severe weather events.

Core Benefits for Large-Scale Construction Projects

Enhanced Structural Performance

The ribbed panel design significantly increases load-bearing capacity compared to flat metal sheets. This enhanced structural performance allows for longer span installations, reducing the need for additional supporting structures. Contractors commonly value this advantage because it streamlines the construction process while maintaining required safety standards. Load distribution characteristics are greatly improved by the folded profile, as the geometry creates natural channels that direct water away from critical connection points, preventing moisture accumulation that could compromise structural integrity over time. This benefit is especially evident in the Classic Rib Corrugated Panel, ensuring long-term durability and reliable performance.

Superior Weather Protection

Weather-resistant properties make these panels ideal for transportation hubs, commercial complexes, and public buildings where dependable protection is essential. The interlocking design creates multiple barriers against water intrusion, while the sloped profile promotes rapid drainage. Snow load performance exceeds that of conventional flat metal systems, as the ribbed surface allows snow to shed naturally, reducing ice dam formation and minimizing maintenance requirements during winter months.

Cost-Effective Installation

Labor productivity increases significantly with folded panel systems. The lightweight construction reduces crane time and allows smaller installation teams to safely handle larger sections, translating into shorter project timelines and lower labor costs for general contractors. Material waste is also minimized because panels can be custom-cut to precise specifications. Our manufacturing facilities can produce exact lengths up to 12 meters, eliminating the need for on-site splicing in many applications.

Huafeng vs. Competitor Comparison

Manufacturing Capabilities

Our three factories with seven production lines provide unmatched production capacity of 1000 tons monthly. This scale ensures consistent availability for large projects, unlike smaller suppliers who may struggle with delivery schedules. The 40+ machines in our facilities maintain tight tolerances and consistent quality across all production runs.Many competitors operate single facilities with limited capacity. This constraint often leads to extended lead times during peak construction seasons. Our distributed manufacturing network provides redundancy and flexibility that protects project schedules.

Quality Certifications

Huafeng maintains Grade 1 building curtain wall and Grade 3 steel structure certifications, demonstrating our commitment to professional standards. These qualifications are essential for contractors working on government-funded projects or large commercial developments.International standard compliance includes ASTM, DIN, JIS, BS, and GB/T specifications. This comprehensive certification portfolio enables seamless integration into projects with varying technical requirements. Competitors often focus on domestic standards only, limiting their applicability for international work.

Warranty and Support

Our 30-year warranty significantly exceeds industry standards. This extended coverage provides project owners with confidence in long-term performance while reducing liability concerns for contractors. The warranty covers material defects, coating failure, and structural integrity issues.Technical support extends throughout the project lifecycle. Our engineering team assists with design optimization, installation guidance, and post-construction maintenance planning. This comprehensive approach differs from suppliers who simply deliver materials without ongoing support.

Maximizing Benefits Through Proper Implementation

Design Optimization

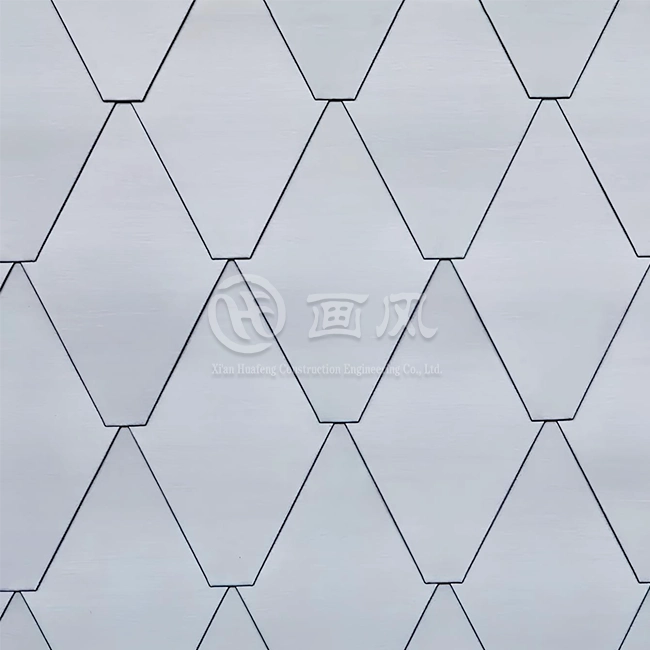

Working with our engineering team during the design phase ensures optimal panel selection and layout configuration. Proper gauge selection based on wind loads, snow loads, and seismic requirements prevents over-engineering while maintaining safety margins.Color coordination with existing architectural elements enhances overall project aesthetics. Our custom coating services can match specific color requirements, creating cohesive building appearances that satisfy demanding design standards.

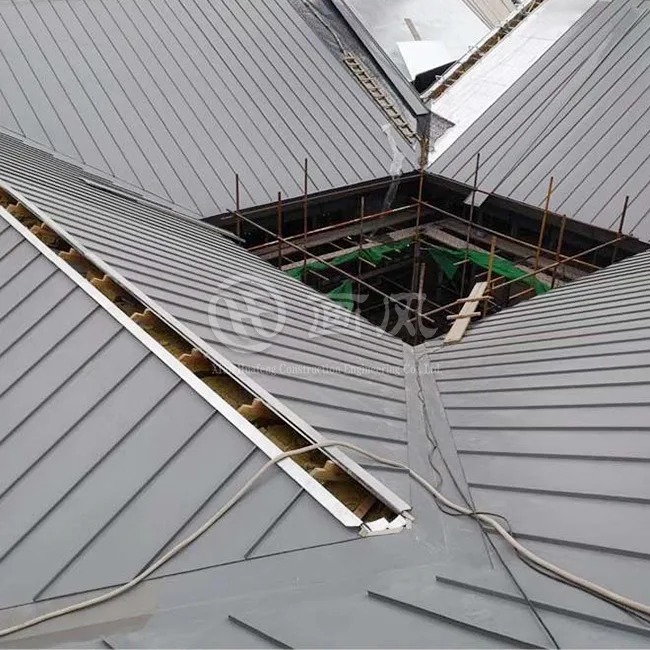

Installation Best Practices

Panel orientation significantly impacts performance and appearance. Installing ribs perpendicular to prevailing winds maximizes weather resistance while creating attractive shadow lines that enhance visual appeal. Fastener selection and spacing follow manufacturer specifications to maintain warranty coverage. Using appropriate gaskets and sealants at connection points prevents water infiltration that could compromise long-term performance. This applies to Classic Rib Corrugated Panel as well, ensuring optimal installation outcomes.

Maintenance Planning

Establishing regular inspection schedules extends service life and maintains warranty coverage. Annual visual inspections identify potential issues before they develop into costly problems. Our maintenance guidelines provide specific checkpoints and recommended intervals.Cleaning procedures maintain appearance and prevent debris accumulation in drainage channels. Simple maintenance protocols keep these metal building materials looking professional throughout their service life.

Quality Assurance and Manufacturing Excellence

Advanced Production Technology

Our manufacturing process incorporates cutting-edge roll-forming equipment that maintains consistent profiles across entire production runs. Computer-controlled systems ensure precise dimensions and eliminate variations that could affect installation efficiency.Quality control checkpoints throughout production identify and correct issues before panels leave our facilities. Statistical process control monitors key dimensions, coating thickness, and material properties to ensure consistency.

Material Sourcing Standards

Raw material sourcing follows strict specifications for chemical composition and mechanical properties. We work exclusively with certified steel suppliers who provide mill test certificates documenting compliance with applicable standards.Coating materials undergo incoming inspection to verify adhesion properties, color consistency, and environmental resistance characteristics. This attention to detail ensures reliable long-term performance in demanding applications.

Environmental and Energy Considerations

Sustainability Features

Recyclable content in our galvanized steel construction supports LEED certification requirements. At the end of service life, panels, including Classic Rib Corrugated Panel, can be recycled into new steel products without quality degradation. Manufacturing efficiency minimizes waste generation and energy consumption. Our facilities implement environmental management systems that reduce water usage and eliminate harmful emissions.

Energy Performance Benefits

Reflective coating options reduce cooling loads in commercial buildings. Light-colored finishes can achieve solar reflectance values exceeding 0.70, significantly reducing heat island effects in urban environments.Insulation compatibility allows for high-performance building envelope assemblies. The panel profile accommodates various insulation systems without thermal bridging concerns that compromise energy efficiency.

Conclusion

Selecting the right roofing system impacts project success across multiple dimensions including cost, schedule, performance, and aesthetics. Classic Rib Corrugated Panel systems deliver proven value through superior structural characteristics, weather resistance, and installation efficiency. Our manufacturing excellence, comprehensive certifications, and extended warranty coverage provide the assurance that professional contractors demand. The combination of technical performance and cost-effectiveness makes these panels an optimal choice for large-scale commercial and industrial construction projects.

Frequently Asked Questions

Q1: What is the minimum order quantity for custom Classic Rib Corrugated Panel projects?

A: Our minimum order quantity is 500 square meters, which accommodates most commercial and industrial projects while maintaining cost-effectiveness. Custom colors, patterns, and designs are available for projects meeting this threshold.

Q2: How do delivery times compare for standard versus custom panel specifications?

A: Standard specifications typically ship within 15-20 days from order confirmation. Custom specifications may require additional lead time depending on coating requirements and profile modifications. Our production planning team coordinates delivery schedules to meet project timelines.

Q3: What certifications support the use of these panels in government-funded construction projects?

A: Our panels comply with ASTM, DIN, JIS, BS, and GB/T standards, while our company maintains Grade 1 building curtain wall and Grade 3 steel structure certifications. These qualifications meet requirements for most government and institutional projects.

Ready to Transform Your Next Metal Building Project?

Huafeng stands as a trusted Classic Rib Corrugated Panel manufacturer with the expertise and capacity to support your most demanding construction projects. Our comprehensive manufacturing capabilities, international certifications, and 30-year warranty provide the reliability that general contractors and real estate developers require. Contact us at huafeng@hfmetalroof.com to discuss how our corrugated panel solutions can enhance your upcoming projects.

References

1. American Society for Testing and Materials. "Standard Specification for Steel Sheet, Metallic-Coated for Steel Core of Composite Panels for Building Applications." ASTM International, 2023.

2. Construction Industry Research Board. "Metal Roofing Systems Performance Analysis in Commercial Construction." Building Materials Quarterly, Vol. 45, No. 3, 2023.

3. International Building Code Council. "Structural Design Requirements for Metal Panel Roofing Systems in Commercial Buildings." ICC Publications, 2024.

4. National Association of General Contractors. "Cost-Benefit Analysis of Metal Roofing Materials in Large-Scale Construction Projects." Construction Economics Review, 2023.

5. Steel Construction Institute. "Durability and Lifecycle Performance of Corrugated Metal Panel Systems." Journal of Structural Engineering Applications, Vol. 28, No. 2, 2024.

6. Weather Protection Research Foundation. "Comparative Study of Metal Roofing Systems Under Extreme Weather Conditions." Building Performance Analysis, 2023.