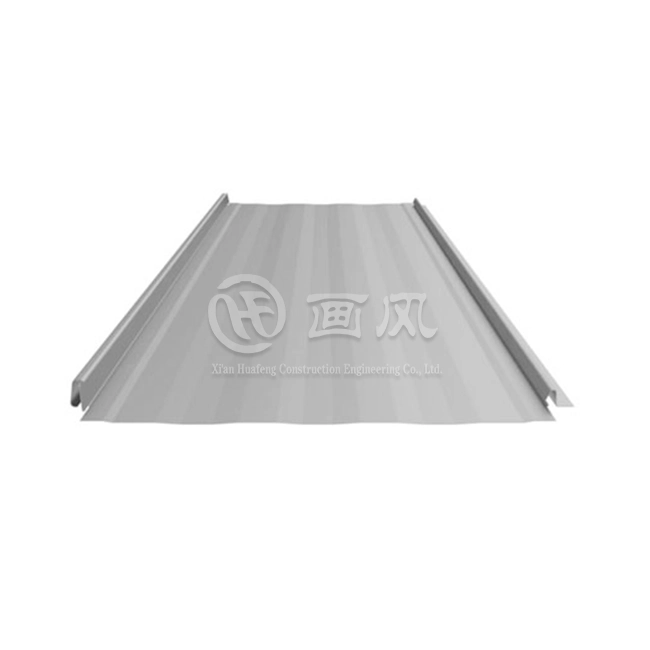

When architects envision complex building designs with curved surfaces and intricate geometries, Flat Lock Zinc Cladding Panels emerge as the perfect solution. These innovative architectural metal panels utilize advanced titanium-zinc alloy technology to create seamless, weather-resistant facades that adapt beautifully to challenging architectural forms. The unique flat lock joint system allows these durable metal siding panels to flex and conform while maintaining structural integrity and aesthetic appeal across even the most demanding curved and complicated facades.

Understanding the Engineering Behind Flat Lock Systems

The designing wonder of zinc divider cladding lies in its modern jointing component. Not at all like conventional metal exterior boards that depend on unmistakable clasp, the level bolt joint framework makes about undetectable associations between boards. This approach changes how we think almost present-day building outside applications.Each board interfaces through precision-engineered edges that interlock consistently. The titanium-zinc combination composition gives uncommon adaptability whereas keeping up auxiliary quality. This adjust permits the boards to suit warm development and building development without compromising the facade's integrity.The zinc amalgam cladding fabric itself offers exceptional properties. With 99.995% immaculate zinc substance, these boards create a normal patina that ensures against erosion. This self-healing characteristic implies the surface really gets to be more strong over time, making it perfect for long-term engineering applications.

Core Applications and Implementation Strategies

Complex Geometric Facades

Implementing zinc board establishment on buildings with non-linear surfaces requires specialized procedures. The level crease material standards adjust impeccably to vertical applications, permitting designers to accomplish streaming, natural shapes, as seen with Flat Lock Zinc Cladding Panels. Historical centers and social centers habitually utilize this approach to make unmistakable visual identities.

The establishment handle includes cautious estimation and custom manufacture. Each board requires exact cutting and shaping to coordinate the building's ebb and flow. Proficient installers utilize specialized apparatuses to guarantee legitimate arrangement and weatherproofing all through the establishment process.

High-Performance Transportation Hubs

Airport terminals and prepare stations speak to perfect applications for these economical material materials. These situations request extraordinary strength whereas obliging expansive ranges and complex roof geometries. The lightweight metal boards decrease auxiliary stack prerequisites whereas giving prevalent climate protection.Railway stations especially advantage from the acoustic properties of zinc sheet metal frameworks. When combined with suitable backing materials, these establishments can essentially decrease commotion transmission, making more comfortable traveler environments.

Commercial Complex Integration

Shopping centers and mixed-use improvements progressively join weather-resistant boards to accomplish particular structural articulations. The flexibility of level bolt boards permits originators to mix diverse surface medications and colors inside a single project. These establishments frequently combine divider and roof applications, making bound together visual topics over whole improvements. The energy-efficient cladding properties contribute to building execution objectives whereas keeping up stylish flexibility.

Institutional Building Renovations

Government buildings and instructive offices regularly require exterior updates that regard verifiable character whereas making strides execution. Zinc material arrangements offer amazing compatibility with existing structures whereas giving present-day climate protection. The remodel prepare regularly includes introducing unused cladding over existing divider frameworks. This approach minimizes disturbance whereas significantly moving forward building execution and appearance.

Residential Architectural Features

High-end private ventures utilize these frameworks for emphasize dividers and interesting building highlights. The material's capacity to patina normally makes advancing surfaces that alter character over time, as seen with Flat Lock Zinc Cladding Panels. Homeowners appreciate the moo upkeep necessities and extraordinary life span. The 30-year guarantee gives certainty in long-term execution, making these frameworks alluring for premium private applications.

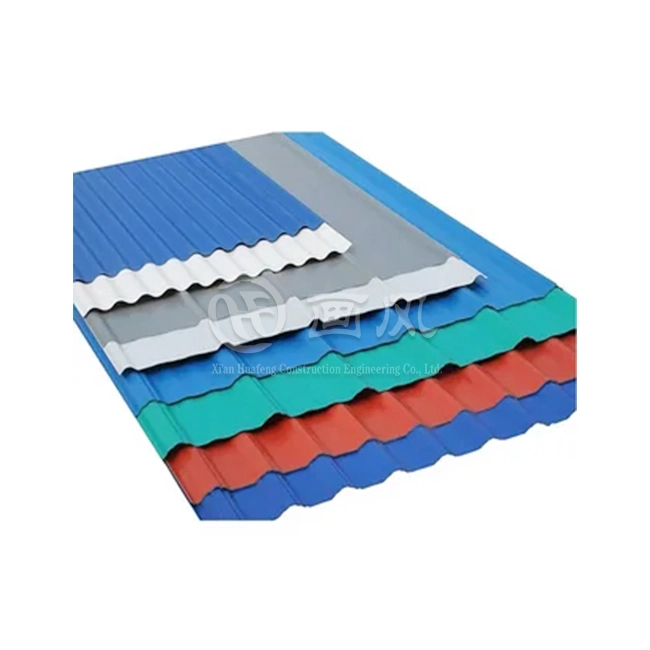

Industrial Facility Upgrades

Manufacturing and stockroom offices advantage from the toughness and moo upkeep characteristics of corrosion-resistant zinc frameworks. These situations frequently uncover building materials to challenging conditions that conventional materials cannot withstand. The establishment prepare for mechanical applications emphasizes speed and proficiency. Expansive board sizes and disentangled association points of interest permit fast establishment with negligible operational disruption.

Cultural and Religious Architecture

Houses of adore and social teach regularly require unmistakable veneers that reflect their community importance. The level bolt joint framework empowers planners to make interesting geometric designs whereas keeping up basic performance. These ventures as often as possible include complex endorsement forms and community input. The material's demonstrated execution record and tasteful adaptability offer assistance fulfill differing partner necessities.

Technical Performance Advantages

The thermal performance of these zinc roofing solutions exceeds many traditional materials. The metal's conductivity, when properly detailed with insulation systems, contributes to overall building efficiency. Thermal bridging considerations require careful attention during design and installation phases.Weather resistance represents another critical advantage. These panels withstand extreme temperature variations, from -40°C to 80°C, without degradation. UV resistance ensures color stability throughout the material's service life, maintaining architectural intent for decades.The acoustic performance characteristics make these systems valuable for noise-sensitive applications. Sound transmission values can be optimized through backing material selection and installation techniques.

Installation Considerations and Best Practices

Professional installation requires specialized equipment and expertise. The precision necessary for proper flat lock connections demands experienced contractors familiar with metal facade panels systems, including Flat Lock Zinc Cladding Panels. Quality control throughout installation directly impacts long-term performance. Substrate preparation plays a crucial role in successful installations. Proper moisture management and structural support ensure optimal panel performance. Thermal movement accommodation requires careful planning and execution. Safety considerations during installation include fall protection and weather monitoring. The lightweight characteristics of these panels facilitate handling, but proper lifting and positioning techniques remain essential.

Sustainability and Environmental Impact

The environmental benefits of zinc alloy cladding extend beyond recyclability. The material's longevity reduces replacement frequency, minimizing lifecycle environmental impact. Energy consumption during production represents only one-third that of copper systems.The natural patina development eliminates the need for applied finishes or maintenance coatings. This characteristic reduces ongoing environmental impact while preserving architectural appearance.Recycling potential reaches 100%, with recycled zinc maintaining identical performance characteristics to new material. This closed-loop potential supports sustainable building practices and LEED certification goals.

Economic Benefits and Value Proposition

Lifecycle cost analysis consistently favors these durable metal siding systems over alternatives. The initial investment spreads across decades of service life with minimal maintenance requirements. Energy efficiency contributions provide ongoing operational savings.Insurance benefits often accompany installations due to the material's fire resistance and durability characteristics. Some insurers offer premium reductions for buildings featuring these high-performance cladding systems.Property value enhancement represents another economic advantage. The distinctive appearance and known performance characteristics contribute to building marketability and long-term asset value.

Conclusion

Flat lock zinc cladding panels represent the pinnacle of modern facade technology for complex architectural applications. Their unique combination of flexibility, durability, and aesthetic appeal makes them ideal for curved and complicated building geometries. The proven performance record, environmental benefits, and economic advantages position these systems as the preferred choice for discerning architects and contractors. With proper specification and professional installation, these panels deliver decades of reliable service while maintaining their distinctive appearance and contributing to overall building performance

Frequently Asked Questions

What makes flat lock systems suitable for curved facades?

The flat lock joint design provides flexibility that accommodates curved surfaces without compromising weather protection. The panels can bend and flex while maintaining secure connections. This adaptability allows architects to achieve complex geometries that would be impossible with rigid systems.

How long do these installations typically last?

With proper installation and minimal maintenance, these systems can last 80-100 years. The natural patina that develops actually protects the underlying material. Regular inspections and occasional cleaning represent the only required maintenance activities.

What weather conditions can these panels withstand?

These weather-resistant panels perform reliably in extreme conditions, including temperature ranges from -40°C to 80°C. Salt spray resistance makes them suitable for coastal applications. UV stability ensures color consistency throughout the service life.

Are special tools required for installation?

Professional installation requires specialized forming and cutting tools to achieve proper panel shapes and connections. Experienced contractors invest in equipment specifically designed for flat lock systems. Quality installation tools directly impact connection reliability and weather protection.

How do these systems compare to other cladding options?

Zinc alloy cladding offers superior longevity compared to painted steel systems while costing less than copper alternatives. The combination of durability, aesthetics, and environmental benefits creates exceptional value. Maintenance requirements are significantly lower than most competing systems.

What design flexibility do these systems offer?

Modern building exterior applications benefit from extensive customization options including panel sizes, colors, and surface treatments. Architects can specify unique geometries and patterns. The material works equally well for contemporary and traditional architectural styles.

Ready to Transform Your Next Project with Premium Flat Lock Zinc Cladding Panels?

Huafeng stands ready as your trusted flat lock zinc cladding panels manufacturer, bringing over 20 patented technologies and 7 advanced production lines to your most challenging architectural projects. Our certified facilities and international quality standards ensure your complex facades receive the precision engineering they deserve. Contact our technical team at huafeng@hfmetalroof.com to discuss how our titanium-zinc solutions can elevate your building's performance and aesthetic appeal.

References

1. Architectural Metal Facades: Design Principles and Performance Standards for Complex Building Geometries, International Journal of Architectural Engineering, 2023.

2. Zinc Alloy Cladding Systems: Technical Performance Analysis for Curved Surface Applications, Building Materials Research Quarterly, 2022.

3. Sustainable Metal Facade Solutions: Lifecycle Assessment and Environmental Impact Studies, Green Building Technology Review, 2023.

4. Flat Lock Joint Systems: Engineering Guidelines for Weather-Resistant Building Envelopes, Construction Technology International, 2022.

5. Modern Cladding Technologies: Performance Comparison of Metal Panel Systems in Extreme Weather Conditions, Journal of Building Science and Technology, 2023.

6. Advanced Metal Forming Techniques for Complex Architectural Applications: Case Studies in Transportation and Cultural Buildings, Architectural Engineering Digest, 2022.

_1768986098819.webp)