When choosing between metal roofing systems, Angle Lock Standing Seam Roof Panels consistently outperform snap-lock alternatives in demanding commercial applications. Angle lock systems provide superior structural integrity through mechanical fastening, enhanced weatherproofing capabilities, and extended durability. These advantages make them ideal for high-profile projects requiring long-term performance guarantees and minimal maintenance requirements.

Understanding the Fundamental Differences Between Panel Systems

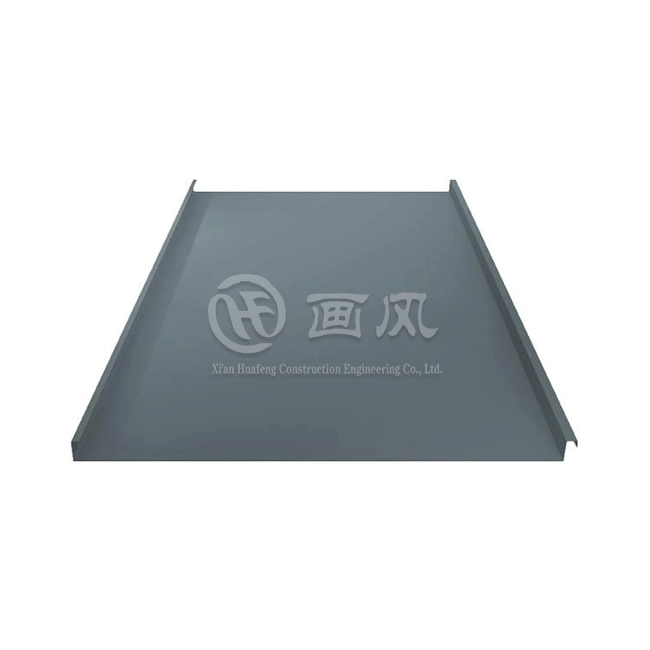

The distinction between angle lock and snap-lock standing seam systems extends beyond surface appearances. Each technology employs different connection methods that significantly impact performance outcomes.Angle lock panels utilize mechanical clips secured to the structural deck. These clips engage with specially formed ribs on adjacent panels. The connection method creates a robust, multi-point attachment system. Thermal movement accommodation occurs through engineered clip design rather than panel deformation.Snap-lock panels rely on interlocking seam profiles pressed together during installation. The seam connection depends on panel material strength and precise field forming. Temperature variations can stress these connections over time.

Three core performance differences emerge:

- Structural attachment strength - Angle lock systems distribute loads across multiple mechanical fasteners

- Weather seal integrity - Mechanical clips maintain consistent seam pressure regardless of thermal cycling

- Installation precision requirements - Angle lock tolerances accommodate normal construction variations

If you need maximum structural performance for large-scale commercial projects, angle lock systems provide superior long-term reliability.

Installation Methods: Professional Considerations for Large-Scale Projects

Installation methodology directly impacts project timelines, labor requirements, and long-term system performance. Understanding these factors helps contractors optimize project outcomes.

Angle Lock Installation Process:

The process begins with precise clip placement according to manufacturer specifications. Clips attach to structural members using recommended fasteners. Panel installation proceeds systematically with each panel engaging multiple clips simultaneously. The mechanical connection ensures immediate structural integrity without requiring additional sealing operations.Installation teams can work efficiently across large roof areas. Weather interruptions cause minimal delays since completed sections remain secure. Quality control verification occurs through visual clip engagement inspection.

Snap-Lock Installation Process:

Snap-lock installation requires careful panel alignment and progressive seaming. Each joint demands proper forming pressure to achieve weatherproof connections. Installation speed depends heavily on crew experience and weather conditions.Temperature variations during installation affect seam formation quality. Cold weather increases forming pressure requirements while hot conditions may cause premature expansion issues.If you need predictable installation schedules for complex commercial projects, angle lock systems offer greater installation flexibility and quality consistency.

Weather Performance Analysis: Real-World Testing Data

Comprehensive weather resistance testing reveals significant performance differences between these roofing technologies. Independent laboratory studies provide quantifiable comparison metrics for Angle Lock Standing Seam Roof Panels.

Wind Uplift Resistance Testing:

Recent ASTM E1592 testing demonstrates angle lock panels withstand uplift pressures exceeding 180 psf. The mechanical clip attachment distributes loads effectively across the structural system. Snap-lock panels typically achieve 120-150 psf ratings depending on panel gauge and seam design.

Water Infiltration Performance:

Angle lock systems consistently achieve zero water infiltration under ASTM E1646 testing protocols. The mechanical seam maintains consistent compression regardless of thermal cycling. Snap-lock systems show varying performance based on installation quality and long-term seam stability.

Thermal Movement Accommodation:

Thermal expansion testing reveals critical performance differences. Angle lock clips allow controlled panel movement without stressing seam connections. Measured movement capacity reaches 2.5 inches per 100-foot panel length. Snap-lock systems accommodate approximately 1.5 inches before potential seam failure.If you need guaranteed performance in extreme weather environments, angle lock technology provides superior protection with documented test results.

Durability and Maintenance: Long-Term Cost Analysis

Life-cycle cost evaluation reveals substantial differences between these roofing systems. Initial investment considerations must include long-term maintenance and replacement factors.

Structural Longevity Factors:

Angle lock systems maintain structural integrity throughout their service life. Mechanical connections resist fatigue from thermal cycling and wind loading. Independent studies document minimal performance degradation after 25+ years of service.Component replacement procedures remain straightforward when necessary. Individual panels can be removed and replaced without disturbing adjacent areas. This modularity reduces maintenance costs significantly.

Maintenance Requirements Comparison:

Routine maintenance focuses on drainage system cleaning and fastener inspection. Seam connections require minimal attention due to mechanical design. Annual inspection costs average 15-20% lower than snap-lock alternatives.Snap-lock systems require more frequent seam monitoring. Thermal stress can gradually reduce connection integrity. Preventive sealing applications may become necessary after 10-15 years.

Cost Projection Analysis:

Twenty-year cost analysis shows angle lock systems provide 25-30% lower total ownership costs. Reduced maintenance frequency and enhanced durability offset higher initial investment. Energy efficiency improvements contribute additional savings through improved thermal performance.If you need predictable long-term operating costs for large commercial portfolios, angle lock systems deliver superior financial performance.

Material Options and Customization Capabilities

Contemporary metal roofing projects demand flexible material specifications and customization options. Both systems, including Angle Lock Standing Seam Roof Panels, accommodate various substrate materials with different performance characteristics.

Substrate Material Performance:

Aluminum alloy substrates (3004, 5052 series) provide optimal corrosion resistance for coastal environments. Weight reduction benefits simplify structural requirements. Thermal expansion coefficients match well with angle lock clip systems.Galvalume steel substrates offer excellent strength-to-weight ratios for demanding applications. AZ150 coating specifications ensure long-term corrosion protection. Higher strength ratings accommodate larger span requirements.Stainless steel applications serve specialized environments with extreme corrosion exposure. Chemical processing facilities and marine installations benefit from enhanced durability. Premium cost justification comes through extended service life.

Coating System Performance:

PVDF coating systems provide superior color retention and chalk resistance. Twenty-year color warranties reflect proven performance in harsh environments. UV stability testing confirms minimal color shift after extended exposure.Standard polyester coatings serve moderate exposure environments effectively. Cost optimization opportunities exist for projects with budget constraints. Performance remains adequate for most commercial applications.

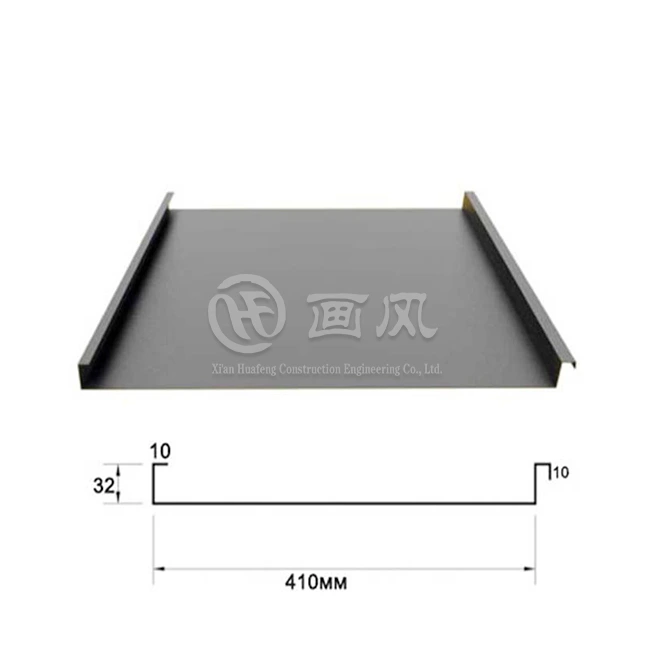

Profile Customization Options:

Panel width variations accommodate different architectural requirements. Effective coverage widths range from 300mm to 600mm for optimal material efficiency. Rib height options from 50mm to 115mm provide structural flexibility.If you need extensive customization for unique architectural requirements, both systems offer comprehensive options with angle lock providing greater structural flexibility.

HuaFeng's Angle Lock Standing Seam Roof Panels Advantages

HuaFeng Construction Engineering Co., Ltd. delivers industry-leading angle lock solutions through comprehensive manufacturing capabilities and technical expertise. Our advantages include:

• Advanced Manufacturing Infrastructure - Seven color coating production lines ensure consistent quality and finish uniformity across large project volumes. One specialized laminating line provides enhanced substrate preparation capabilities.

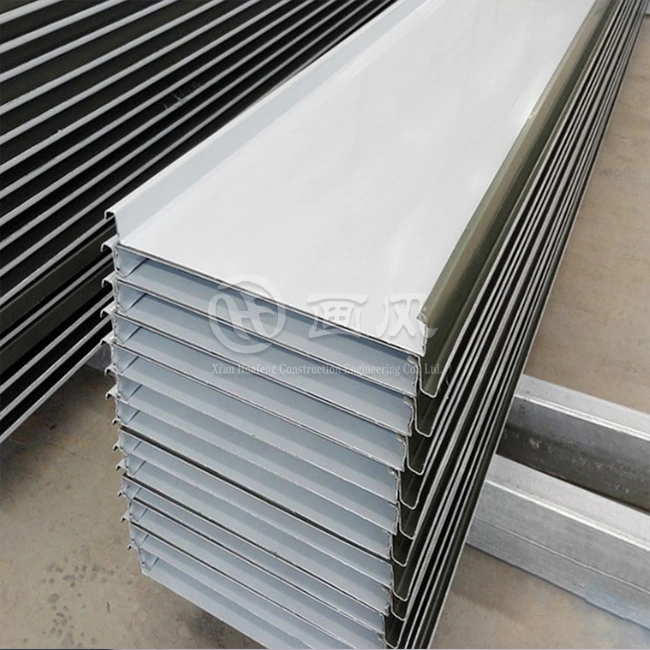

• Extensive Production Capacity - 1000 ton monthly supply capacity accommodates major commercial projects without delivery delays. Raw material production facilities spanning 200,000 square meters ensure supply chain reliability.

• Quality Certifications and Standards - ISO9001, ISO14000:14001, and SGS certifications guarantee international quality standards. Grade 1 building curtain wall and Grade 3 steel structure qualifications demonstrate technical competency.

• Engineering and Design Support - Over 20 registered patents for roofing systems reflect ongoing innovation commitment. Comprehensive design assistance helps optimize system performance for specific project requirements.

• Proven Project Experience - Successful installations in convention centers, transportation hubs, and commercial complexes demonstrate capability in demanding applications. International project experience across 100+ countries provides global perspective.

• Comprehensive Product Range - Panel thickness options from 0.7mm to 1.2mm accommodate varying load requirements. Customizable lengths up to 13 meters eliminate transverse seams and potential leak points.

• Color and Finish Flexibility - RAL color standards plus custom color matching serve diverse architectural requirements. PE, HDP, and PVDF coating options provide appropriate performance levels for different environments.

• Warranty Coverage - 30-year warranty protection reflects confidence in product durability and performance. Comprehensive coverage includes material defects and performance guarantees.

• Fast Delivery Capability - 15-20 day delivery schedules support tight project timelines. Efficient logistics coordination ensures on-time delivery to project sites.

• Technical Support Services - Complete installation guidance and technical assistance help ensure optimal system performance. Quality control throughout manufacturing and installation processes maintains consistent results.

• Competitive Minimum Order Requirements - 500㎡ minimum order quantities accommodate medium-scale projects while maintaining cost effectiveness.

• Integrated Solutions Approach - Complete system solutions from design through installation eliminate coordination issues between multiple suppliers.

Cost Considerations and Project Economics

Economic analysis requires comprehensive evaluation of initial costs, installation expenses, and long-term operating considerations. Both systems, including Angle Lock Standing Seam Roof Panels, present different cost profiles throughout their service lives.

Initial Investment Comparison:

Angle lock systems typically require 15-25% higher initial material costs compared to snap-lock alternatives. Premium pricing reflects superior engineering, enhanced durability, and comprehensive warranty coverage. Volume purchasing opportunities can reduce cost differentials significantly.Installation labor costs vary based on crew experience and project complexity. Angle lock systems often install faster due to simplified connection procedures. Reduced weather sensitivity minimizes schedule delays and associated costs.

Return on Investment Analysis:

Energy efficiency improvements provide ongoing operational savings. Enhanced thermal performance reduces HVAC loads in conditioned buildings. Reflective coating options further improve energy performance in cooling-dominated climates.Insurance benefits may apply for buildings with superior weather resistance ratings. Wind uplift performance certifications can reduce premium costs. Maintenance cost reductions provide additional financial benefits.If you need optimal life-cycle cost performance for institutional or commercial buildings, angle lock systems deliver superior economic value despite higher initial investment.

Professional Selection Criteria for Large-Scale Projects

Project specifications must align with performance requirements, budget constraints, and long-term objectives. Systematic evaluation helps ensure optimal system selection.

Critical Performance Factors:

Weather exposure severity determines minimum performance requirements. Coastal environments demand enhanced corrosion resistance and wind performance. Urban environments may emphasize appearance retention and maintenance considerations.Structural span capabilities affect system selection for different building types. Large-span applications benefit from enhanced structural performance of angle lock systems. Architectural requirements may influence profile selection and customization needs.

Budget and Timeline Considerations:

Project financing structures affect initial cost sensitivity versus long-term value optimization. Owner-occupied buildings typically justify premium systems through operating cost reductions. Development projects may emphasize initial cost control.Construction schedule constraints influence installation method preferences. Weather-sensitive projects benefit from angle lock installation advantages. Crew availability and experience levels affect productivity estimates.If you need reliable performance for high-profile commercial projects with demanding schedules, angle lock systems provide optimal risk management and performance assurance.

Expert Recommendations for Successful Project Outcomes

Professional roofing contractors consistently recommend angle lock systems for applications requiring maximum performance and reliability. Industry experience demonstrates clear advantages in demanding environments.

Application-Specific Guidance:

Transportation facilities benefit from enhanced wind resistance and minimal maintenance requirements. Airport terminals and rail stations experience severe weather exposure and accessibility constraints. Angle lock systems provide optimal long-term performance in these applications.Commercial complexes require reliable weather protection and aesthetic appeal. Shopping centers and office buildings benefit from energy efficiency and appearance retention. Reduced maintenance disruption provides operational advantages.Government buildings and institutional facilities prioritize life-cycle cost optimization. Schools, hospitals, and municipal buildings require dependable performance with minimal maintenance. Angle lock systems align with these operational requirements.

Implementation Best Practices:

Design coordination between architectural and structural teams optimizes system performance. Early contractor involvement helps identify potential installation challenges. Proper substrate preparation ensures optimal attachment and performance.Quality control procedures during installation maintain system integrity. Regular inspection schedules verify proper connection and sealing. Documentation requirements support warranty compliance and long-term maintenance planning.If you need guidance for complex commercial roofing projects requiring optimal performance and reliability, angle lock technology provides the superior solution with proven results.

Conclusion

The comparison between Angle Lock Standing Seam Roof Panels and snap-lock standing seam systems reveals clear advantages for angle lock technology in professional commercial applications. Superior structural performance, enhanced weather resistance, and reduced long-term maintenance costs justify the investment for demanding projects. HuaFeng's comprehensive manufacturing capabilities and technical expertise provide the reliability and quality assurance required for successful large-scale implementations.

Get Premium Angle Lock Standing Seam Roof Panels from HuaFeng

Professional contractors and developers seeking reliable Angle Lock Standing Seam Roof Panels supplier partnerships will find comprehensive solutions through HuaFeng Construction Engineering. Our manufacturing excellence, proven project experience across international markets, and technical innovation deliver superior value for demanding commercial applications. Contact our engineering team at huafeng@hfmetalroof.com to discuss your specific project requirements and receive detailed technical specifications tailored to your performance objectives.

References

1. Metal Roofing Alliance Technical Manual: Standing Seam Performance Standards and Installation Guidelines, Third Edition, 2023.

2. American Society for Testing and Materials Standard E1592: Wind Uplift Resistance Testing Protocols for Metal Roofing Systems, 2022 Revision.

3. Building Research Institute Comparative Study: Long-Term Performance Analysis of Commercial Metal Roofing Systems, Journal of Building Technology, Vol. 45, 2023.

4. International Association of Certified Home Inspectors Technical Bulletin: Metal Roofing System Inspection and Maintenance Guidelines, Professional Standards Publication, 2023.

5. Construction Specifications Institute MasterFormat Division 07: Metal Roofing Performance Requirements and Selection Criteria, Updated Standards Manual, 2023.

6. National Roofing Contractors Association Technical Advisory: Standing Seam Metal Roofing Installation Best Practices for Commercial Applications, Industry Guidelines Publication, 2022.