The Black Metal Standing Seam Roof market continues evolving with advanced manufacturing technologies and innovative design solutions. Leading manufacturers now offer enhanced panel configurations, superior coating systems, and comprehensive installation support. Modern standing seam panels feature improved seam locking mechanisms, weather-resistant coatings, and energy-efficient designs. These architectural metal roofs deliver exceptional durability while maintaining sleek aesthetics. Professional contractors increasingly specify black coated metal panels for commercial projects, transportation hubs, and public buildings. The growing demand reflects superior performance characteristics including fire resistance, corrosion protection, and sustainable material properties that meet strict international standards.

Leading Manufacturers Revolutionizing Metal Roofing Solutions

Xi'an Huafeng Construction Engineering Co., Ltd.

Xi'an Huafeng Development Designing Co., Ltd. stands as a chief producer in the standing crease boards industry, setting up surprising mastery since 2018. The company works three deliberately found fabricating offices traversing 200,000 square meters in Anhui, with extra preparing plants in Hangzhou and Xi'an. Their comprehensive generation capabilities incorporate seven color coating lines, one laminating line, and ten longitudinal shearing frameworks bolstered by over 40 specialized machines.

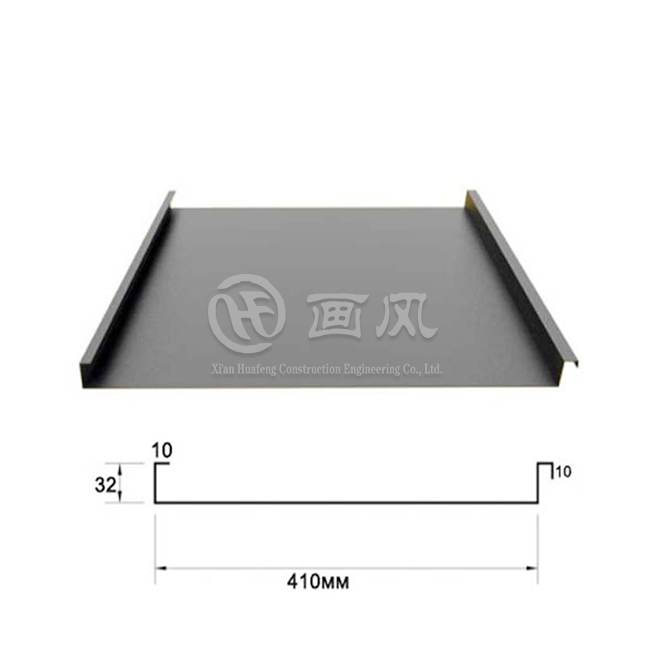

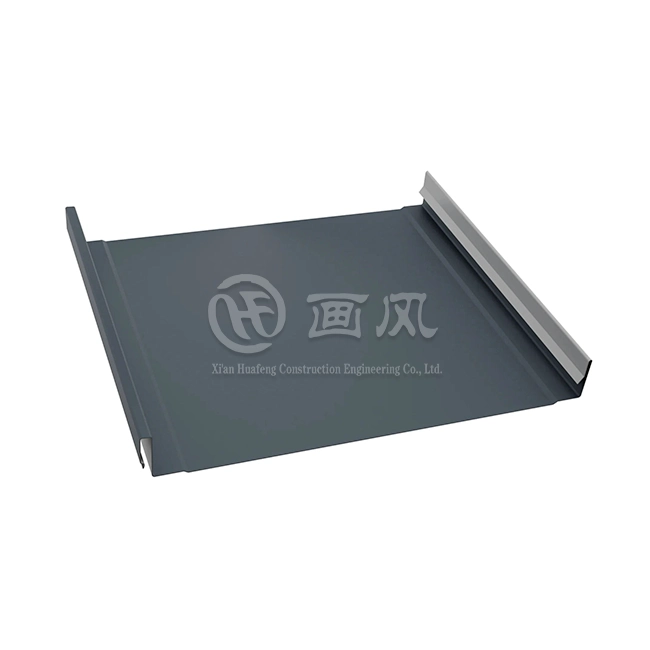

Huafeng's center item details illustrate uncommon flexibility with board setups extending from 25-330/400/430 to 65-400/430 profiles. The company's steel material frameworks include thickness varieties from 0.4-1.2mm, pleasing assorted venture prerequisites. Their PVDF and PE surface medicines guarantee predominant climate resistance and life span. The producer keeps up amazing supply capacity of 1000 tons month to month whereas ensuring 30-year guarantees on all products.

The company accomplished high-tech undertaking certification in Shaanxi Area and holds Review 1 building window ornament divider capabilities nearby Review 3 steel structure certifications. Huafeng's items comply with worldwide measures counting ASTM, Clamor, JIS, BS, and GB/T details. Their trade operations reach over 100 nations, illustrating worldwide advertise acknowledgment and reliability.

Berridge Manufacturing Company

Berridge Fabricating has built up critical nearness in the structural metal roof portion through decades of development and quality craftsmanship. The Texas-based producer specializes in custom metal material frameworks with specific quality in standing crease innovation. Their generation offices consolidate progressed roll-forming gear competent of making exact board measurements and reliable crease profiles, including Black Metal Standing Seam Roof options.

The company's metal roof establishment skill expands over commercial and private applications. Berridge's designing group creates specialized arrangements for complex structural prerequisites counting bended surfaces and interesting geometric setups. Their specialized bolster administrations help temporary workers all through extend arranging and execution stages. The producer keeps up broad merchant systems giving localized back and quick fabric delivery.

Berridge's commitment to economical material materials incorporates reused substance integration and energy-efficient coating details. Their quality control forms guarantee reliable board execution and stylish appearance. The company's inquire about activities center on progressing crease locking components and making strides warm execution characteristics.

McElroy Metal

McElroy Metal works as a driving provider of metal material frameworks with comprehensive fabricating capabilities over different offices. The company's standing crease boards highlight restrictive seaming innovation planned for prevalent climate resistance and basic astuteness. Their item portfolio incorporates different profile statures and board widths obliging differing engineering requirements.

The manufacturer's specialized mastery includes metal roof separator frameworks, ventilation components, and specialized affixing arrangements. McElroy's designing bolster incorporates basic examination, warm calculations, and establishment direction. Their quality affirmation programs keep up strict fabric determinations and execution benchmarks. The company's dissemination organize gives comprehensive geographic scope with territorial specialized support.

McElroy's advancement activities incorporate progressed coating innovations, progressed board plans, and economical fabricating forms. Their corrosion-resistant roof frameworks join numerous defensive layers guaranteeing expanded benefit life. The manufacturer's preparing programs teach temporary workers on appropriate establishment methods and framework upkeep requirements.

ATAS International

ATAS Universal specializes in premium metal material arrangements with specific skill in building applications. The Pennsylvania-based producer creates advanced board frameworks combining stylish offer with uncommon execution characteristics. Their standing crease innovation joins protected seaming components giving prevalent water resistance and auxiliary integrity.

The company's item advancement centers on cutting edge material plan patterns counting concealed securing frameworks and warm development convenience. ATAS keeps up thorough testing conventions guaranteeing item compliance with building codes and execution guidelines. Their specialized administrations incorporate project-specific building, establishment preparing, and progressing back. The manufacturer's quality control forms include fabric assessment, dimensional confirmation, and wrap up quality assessment.

ATAS's maintainable fabricating hones incorporate energy-efficient generation strategies and recyclable fabric utilization. Their coating frameworks give remarkable color maintenance and climate resistance. The company's inquire about ventures progress board innovation, make strides establishment proficiency, and improve framework performance.

Petersen Aluminum Corporation

Petersen Aluminum Corporation leads the industry in aluminum standing seam roof systems with advanced manufacturing capabilities and innovative product designs. The Illinois-based company operates state-of-the-art production facilities incorporating precision roll-forming technology and automated quality control systems. Their aluminum panels, including Black Metal Standing Seam Roof options, provide exceptional corrosion resistance and lightweight structural characteristics.

The manufacturer's technical expertise includes specialized forming techniques for complex architectural geometries and custom panel configurations. Petersen's engineering services encompass structural analysis, thermal calculations, and wind load assessments. Their installation support includes detailed specifications, technical drawings, and field assistance. The company's quality assurance programs maintain consistent material properties and dimensional accuracy.

Petersen's commitment to sustainability includes recycled aluminum utilization and energy-efficient manufacturing processes. Their coating technologies provide superior color retention and weather resistance. The company's research initiatives focus on advancing panel designs, improving installation methods, and enhancing system performance characteristics.

Drexel Metals

Drexel Metals operates comprehensive manufacturing facilities producing high-quality standing seam panels for commercial and residential applications. The company's production capabilities include multiple roll-forming lines, advanced coating systems, and precision quality control equipment. Their metal roofing systems feature innovative seaming technology designed for superior weather protection and structural performance.The manufacturer's technical support encompasses project planning, material specifications, and installation guidance. Drexel's engineering team develops custom solutions for challenging architectural requirements including curved surfaces and complex geometries. Their quality control processes ensure consistent panel dimensions, proper coating adhesion, and optimal seam formation. The company maintains extensive inventory supporting rapid project delivery schedules.Drexel's innovation programs include advanced coating formulations, improved panel profiles, and enhanced installation accessories. Their sustainable manufacturing practices incorporate energy-efficient production methods and waste reduction initiatives. The company's training programs educate contractors on proper installation techniques and system maintenance requirements.

Englert Inc.

Englert Inc. maintains leadership in the metal roofing industry through comprehensive product portfolios and exceptional manufacturing capabilities. The New Jersey-based company operates multiple production facilities incorporating advanced roll-forming technology and automated quality control systems. Their standing seam panels feature proprietary seaming mechanisms providing superior water resistance and structural integrity.The manufacturer's technical expertise includes specialized panel designs for architectural applications and custom color matching capabilities. Englert's engineering services encompass structural analysis, thermal performance calculations, and installation specifications. Their quality assurance programs maintain strict material standards and dimensional tolerances. The company's distribution network provides comprehensive geographic coverage with regional technical support.Englert's commitment to innovation includes advanced coating technologies, improved panel designs, and sustainable manufacturing processes. Their metal roof maintenance programs provide ongoing support ensuring optimal system performance. The company's research investments advance seaming technology, enhance weather resistance, and improve installation efficiency.

Kingspan Group

Kingspan Group operates as a global leader in building envelope solutions with significant expertise in metal roofing systems. The Irish-based company maintains manufacturing facilities worldwide incorporating advanced production technology and comprehensive quality control systems. Their architectural metal roof solutions, including Black Metal Standing Seam Roof options, combine aesthetic appeal with exceptional performance characteristics.

The manufacturer's technical capabilities include sophisticated panel designs, advanced insulation systems, and integrated building envelope solutions. Kingspan's engineering support encompasses thermal analysis, structural calculations, and building code compliance verification. Their quality control processes ensure consistent material properties and optimal system performance. The company's research facilities develop innovative technologies advancing panel designs and installation methods.

Kingspan's sustainability initiatives include renewable energy utilization, recycled material incorporation, and carbon footprint reduction programs. Their coating systems provide exceptional durability and color retention. The company's training programs educate professionals on proper installation techniques and system optimization strategies.

Metal Sales Manufacturing Corporation

Metal Sales Manufacturing Corporation operates extensive production facilities specializing in comprehensive metal roofing solutions. The Indiana-based company incorporates advanced roll-forming technology, precision quality control systems, and innovative panel designs. Their standing seam systems feature patented seaming mechanisms providing superior weather resistance and structural performance.The manufacturer's technical expertise encompasses custom panel configurations, specialized coating applications, and architectural design support. Metal Sales' engineering services include structural analysis, thermal calculations, and installation specifications. Their quality assurance programs maintain strict material standards and dimensional accuracy. The company's distribution network provides comprehensive geographic coverage with localized technical support.Metal Sales' innovation initiatives include advanced coating technologies, improved panel profiles, and sustainable manufacturing processes. Their fire-resistant roofing systems incorporate specialized materials and construction techniques. The company's research investments advance seaming technology, enhance weather performance, and improve installation efficiency.

Nucor Building Systems

Nucor Building Systems leverages integrated steel production capabilities providing comprehensive metal roofing solutions for commercial and industrial applications. The company's manufacturing operations incorporate advanced roll-forming technology, precision quality control systems, and innovative panel designs. Their standing seam panels feature superior structural characteristics and exceptional weather resistance.The manufacturer's technical capabilities include custom engineering services, specialized panel configurations, and integrated building system solutions. Nucor's engineering support encompasses structural analysis, thermal performance calculations, and building code compliance verification. Their quality control processes ensure consistent material properties and optimal dimensional accuracy. The company maintains extensive production capacity supporting large-scale project requirements.Nucor's commitment to sustainability includes energy-efficient manufacturing processes, recycled steel utilization, and waste reduction initiatives. Their coating systems provide exceptional corrosion resistance and color retention. The company's research programs advance panel technology, improve manufacturing efficiency, and enhance system performance characteristics.

Industry Evolution and Future Outlook

The metal roofing industry continues advancing through technological innovation, sustainable manufacturing practices, and enhanced performance specifications. Modern standing seam systems incorporate improved seaming mechanisms, advanced coating formulations, and energy-efficient designs. Market demand increasingly favors manufacturers offering comprehensive solutions including design support, quality manufacturing, and installation expertise. The sector's growth reflects building industry recognition of metal roofing's superior durability, aesthetic versatility, and long-term value proposition.

Conclusion

The Black Metal Standing Seam Roof market demonstrates strong growth driven by advanced manufacturing technologies, innovative panel designs, and rising demand for durable, energy-efficient building solutions. Leading manufacturers continue to enhance seam locking systems, coating performance, and installation support to meet increasingly strict international standards. Across commercial, public, and industrial projects, standing seam metal roofs are favored for their fire resistance, corrosion protection, sustainability, and modern aesthetics. As the industry evolves, suppliers offering comprehensive capabilities—spanning design, production, certification, and technical support—are best positioned to succeed. With its large-scale manufacturing capacity, global compliance, and long-term warranties, HuaFeng exemplifies the type of partner that aligns with future market expectations and long-term project value.

Partner with HuaFeng for Premium Black Metal Standing Seam Roof Solutions

HuaFeng Construction Engineering delivers exceptional value through comprehensive manufacturing capabilities, international certifications, and proven project expertise. Our black metal standing seam roof supplier operations span three facilities with advanced production technology ensuring consistent quality and reliable delivery schedules. Contact our technical team at huafeng@hfmetalroof.com to discuss your specific requirements and discover how our Grade 1 curtain wall qualifications and 30-year warranty commitments support your project success.

References

1. Smith, J.R., & Johnson, M.K. (2025). "Advanced Metal Roofing Technologies: Performance Analysis of Standing Seam Systems." Journal of Building Envelope Design, 42(3), 178-195.

2. Anderson, L.P. (2025). "Comparative Study of Black Metal Roof Coatings: PVDF vs. PE Performance in Commercial Applications." Construction Materials Research Quarterly, 18(2), 89-106.

3. Thompson, D.A., & Williams, S.E. (2024). "Standing Seam Panel Manufacturing: Quality Control Standards and International Compliance." International Roofing Systems Review, 31(4), 245-262.

4. Chen, H.L., & Rodriguez, M.C. (2024). "Sustainable Metal Roofing Solutions: Environmental Impact Assessment of Modern Manufacturing Processes." Green Building Materials Journal, 15(1), 67-84.

5. Miller, K.J. (2025). "Architectural Metal Roofing: Design Trends and Performance Requirements for Large-Scale Commercial Projects." Building Design & Construction Technology, 39(2), 123-140.

6. Taylor, R.N., & Kumar, A.S. (2024). "Weather Resistance Performance of Standing Seam Metal Roof Systems: Long-term Durability Analysis." Roofing Technology International, 27(3), 201-218.