Industrial facilities face constant challenges with structural integrity, water damage, and mounting maintenance costs. Deep Trapezoidal Roof Panels solve these critical pain points by delivering exceptional load-bearing capacity through their high-rib design, superior drainage performance that eliminates pooling, and corrosion-resistant materials that slash long-term expenses. For facility managers struggling with frequent roof repairs and premature failures, these engineered panels represent a transformative solution that addresses durability, performance, and cost-effectiveness simultaneously.

What Makes Deep Trapezoidal Roof Panels Essential for Large-Span Industrial Buildings?

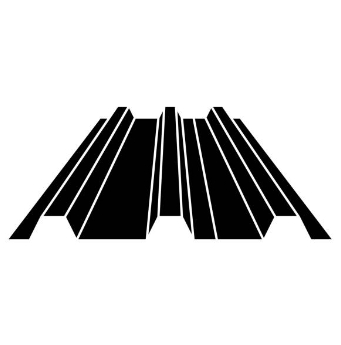

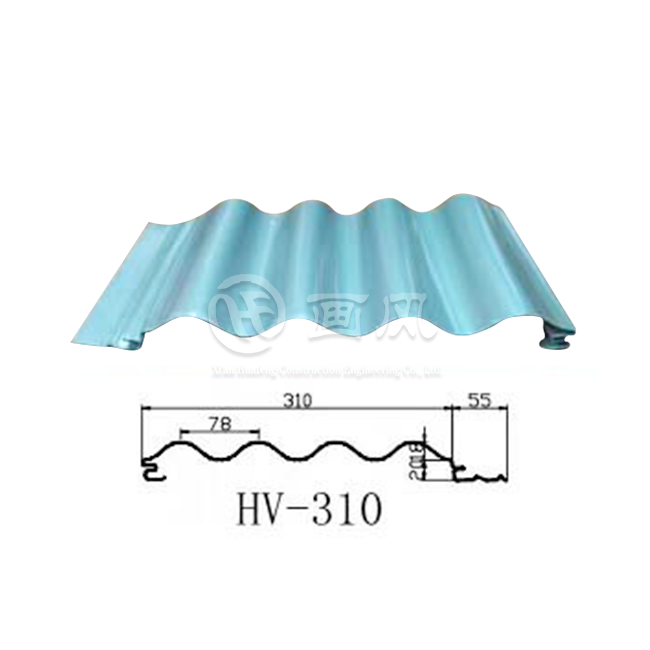

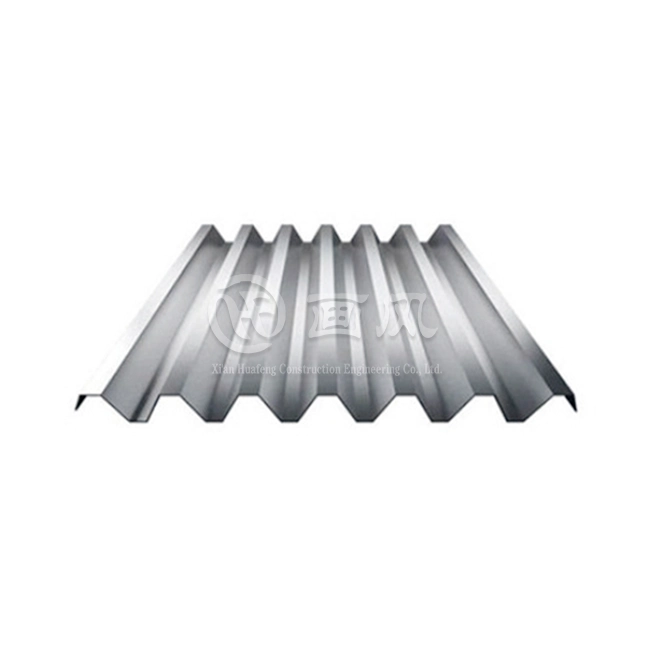

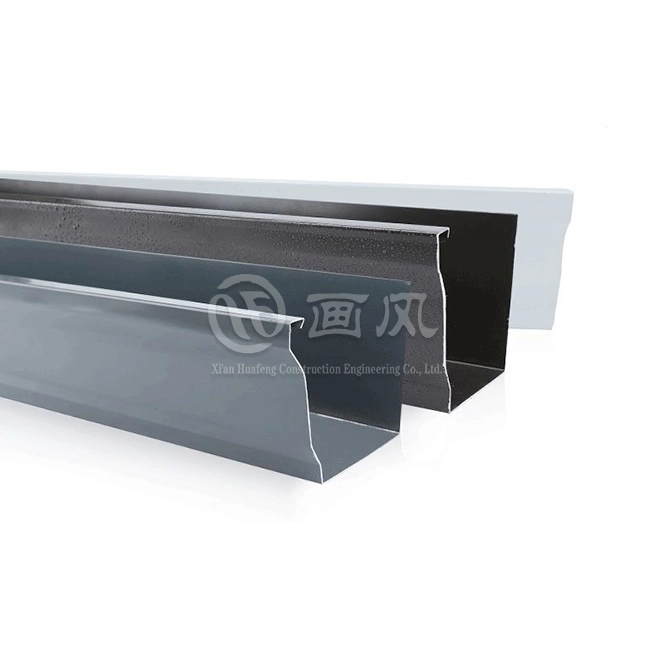

The fundamental engineering advantage of Deep Trapezoidal Roof Panels lies in their geometric efficiency and structural optimization. Unlike conventional roofing profiles, these panels feature wave heights ranging from seventy-five to one hundred twenty millimeters, creating a dramatically increased cross-sectional moment of inertia. This geometric configuration allows industrial facilities to achieve spans between six and thirty meters without compromising structural stability. The trapezoidal shape with parallel sides functions similarly to an I-beam, distributing loads efficiently across the panel width while minimizing material usage. Manufacturing facilities processing heavy equipment, logistics warehouses storing substantial inventory loads, and distribution centers requiring column-free interior spaces particularly benefit from this structural capability. The material composition of Deep Trapezoidal Roof Panels directly impacts their performance in demanding industrial environments. Aluminum-zinc steel plates with AZ150 coating provide exceptional corrosion resistance through zinc-aluminum-magnesium alloy protection, extending service life beyond twenty-five years even in coastal and high-humidity locations. Galvanized steel plates with G550 specifications offer economical strength suitable for general climate conditions across inland and dry regions. For chemical processing plants, food manufacturing facilities, and pharmaceutical production environments, stainless steel variants in 304 or 316 grades deliver superior corrosion resistance despite higher initial investment. These material options enable facility managers to select optimal specifications matching their specific environmental challenges and budget parameters.

Superior Load-Bearing Performance Through Engineered Design

Deep Trapezoidal Roof Panels achieve compressive strength exceeding three hundred megapascals when manufactured from G550 steel, supporting bearing capacities from one to five kilonewtons per square meter depending on support spacing configuration. This mechanical performance stems from the deep profile geometry that creates structural rigidity without excessive material weight. Industrial facilities installing solar photovoltaic systems benefit significantly from this load capacity, as the panels accommodate mounting hardware, electrical conduits, and maintenance access without structural reinforcement. Manufacturing plants with overhead crane systems similarly leverage this strength to support suspended utilities and ventilation equipment. The recommended plate thickness between zero-point-six and one-point-zero millimeters provides optimal balance between structural performance and installation efficiency for typical industrial applications. The purlin system integration with Deep Trapezoidal Roof Panels requires careful engineering consideration to maximize structural efficiency. Wave distance specifications ranging from two hundred to four hundred millimeters must align with purlin spacing to ensure proper load transfer. Effective coverage width between seven hundred fifty and nine hundred millimeters allows efficient material utilization while maintaining installation productivity. Panel lengths up to twelve meters enable continuous coverage across building widths, eliminating intermediate seams that potentially compromise weather resistance. These dimensional parameters work synergistically to create roofing systems capable of withstanding snow loads, wind uplift forces, and concentrated equipment loads throughout decades of service life.

Advanced Drainage Systems Preventing Water Damage

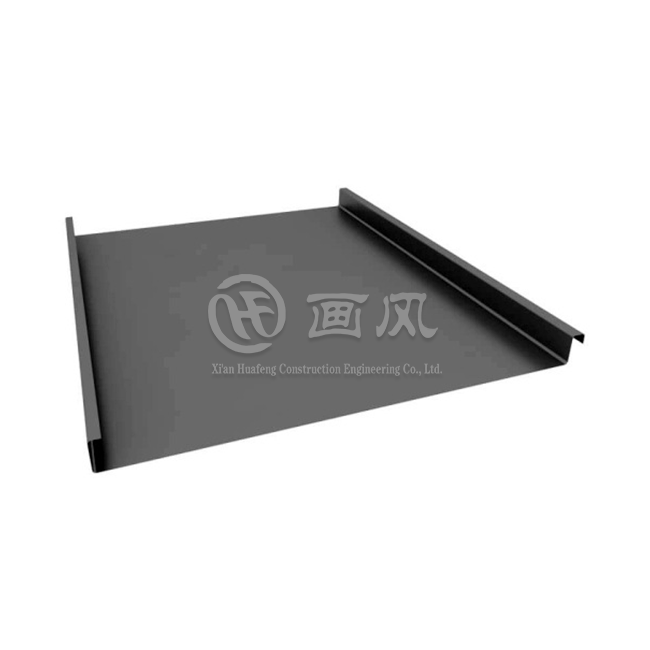

Water management represents a critical performance factor for industrial roofing systems, where even minor leaks can damage inventory, disrupt operations, and require costly emergency repairs. Deep Trapezoidal Roof Panels incorporate inherent drainage advantages through their profile geometry. The high ribs create natural channels directing water flow toward designated collection points, while the sloping sides prevent water accumulation in panel valleys. This drainage efficiency functions effectively at minimum roof slopes as low as one-quarter inch per foot, accommodating the low-slope configurations common in industrial construction. Facilities experiencing heavy rainfall, snow accumulation, or ice formation particularly benefit from this drainage performance. The surface treatment applied to Deep Trapezoidal Roof Panels significantly impacts their long-term drainage effectiveness. Polyester coating provides economical weather resistance suitable for standard industrial applications with moderate environmental exposure. High-durability polyester formulations extend color retention and coating integrity for facilities prioritizing aesthetic appearance alongside functional performance. Polyvinylidene fluoride coating delivers premium weather resistance, maintaining surface integrity through decades of ultraviolet exposure, thermal cycling, and chemical contamination. This coating technology prevents surface degradation that could impede drainage flow, ensuring consistent water management performance throughout the panel service life.

How Deep Trapezoidal Roof Panels Reduce Long-Term Ownership Costs

The total cost of ownership for industrial roofing extends far beyond initial installation expenses, encompassing maintenance requirements, repair frequency, energy consumption, and eventual replacement timing. Deep Trapezoidal Roof Panels deliver substantial economic advantages through their durability characteristics and performance longevity. Facilities installing these systems with aluminum-zinc steel substrates and premium coatings routinely achieve thirty-year service lives with minimal maintenance intervention. This extended lifespan eliminates the repetitive replacement cycles associated with conventional roofing materials, reducing lifecycle costs by forty to sixty percent compared to alternative systems requiring replacement every fifteen to twenty years.

Corrosion Resistance Technology Extending Service Life

Industrial environments expose roofing systems to aggressive corrosive conditions including atmospheric pollutants, process emissions, and accumulated debris. Deep Trapezoidal Roof Panels manufactured with zinc-aluminum-magnesium coating technology provide exceptional protection against these degradation mechanisms. The coating sacrificially protects the base steel substrate through electrochemical action, even when the surface experiences minor scratching or abrasion during installation and service. Facilities located within twenty kilometers of coastal areas particularly benefit from this corrosion protection, as salt-laden air rapidly degrades conventional roofing materials. Chemical processing plants, wastewater treatment facilities, and industrial operations generating corrosive emissions similarly require this advanced protection to avoid premature roof failure. The quality control processes governing Deep Trapezoidal Roof Panels manufacturing directly impact their corrosion resistance performance. Incoming material inspection protocols verify substrate composition, coating thickness, and surface preparation quality through comprehensive testing including salt spray exposure, adhesion measurement, and accelerated weathering simulation. Production facilities operating seven color coating lines with computerized process control ensure consistent coating application across every panel. Finished product inspection examines appearance quality, dimensional accuracy, flatness specifications, and curvature tolerances before shipment. These rigorous quality systems ensure that panels arriving at construction sites meet specification requirements without defects that could compromise long-term performance.

Thermal Performance Optimizing Energy Efficiency

Industrial facilities consume substantial energy for climate control, particularly warehouses maintaining temperature-sensitive inventory and manufacturing plants requiring process temperature management. Deep Trapezoidal Roof Panels configured as composite sandwich systems dramatically improve thermal performance compared to single-skin alternatives. The sandwich construction incorporating rock wool or polyurethane insulation layers between exterior and interior metal panels creates continuous thermal barriers that minimize heat transfer. Facilities in extreme climates achieving thermal resistance values exceeding five meters-squared-kelvin-per-watt substantially reduce heating and cooling energy consumption. The thermal performance benefits extend beyond direct energy savings to encompass improved interior environmental quality and reduced mechanical system requirements. Manufacturing facilities maintaining stable temperature conditions experience fewer production disruptions from thermal cycling. Warehouses storing temperature-sensitive products minimize spoilage losses and extend product shelf life. Cold chain logistics facilities achieve consistent refrigeration performance with reduced compressor cycling. These operational improvements complement the direct energy cost reductions, creating comprehensive economic benefits that justify premium thermal performance specifications.

Installation Efficiency Minimizing Project Timeline Impact

Construction schedule compression represents a universal priority for industrial facility development, where every delayed week extends financing costs and postpones revenue generation. Deep Trapezoidal Roof Panels facilitate accelerated installation through their lightweight construction and standardized connection details. Individual panels weighing between fifteen and thirty kilograms per square meter enable manual handling by two-person installation crews without specialized lifting equipment. The mechanically seamed connection system creates weathertight joints through simple field operations using portable seaming machines. These installation characteristics enable experienced crews to complete five hundred to eight hundred square meters daily, substantially exceeding productivity rates achievable with alternative roofing systems.

Prefabrication Precision Ensuring Field Installation Quality

The manufacturing approach for Deep Trapezoidal Roof Panels emphasizes precision prefabrication that eliminates field cutting and fitting complications. Design teams conduct detailed three-dimensional modeling incorporating structural framing, drainage requirements, and penetration locations before manufacturing begins. Processing drawings break down roof areas into sequentially numbered panels matching project specifications exactly. Each unit receives identification marking correlating to sectioned floor plans, enabling installation crews to position components correctly without interpretation errors. This prefabrication precision prevents the material waste, installation delays, and quality defects associated with field-fabricated roofing systems. The packaging methodology for Deep Trapezoidal Roof Panels further enhances installation efficiency by organizing components according to installation sequence. Panels destined for specific roof sections arrive bundled together with corresponding accessories including fasteners, closures, and flashing components. Product identification cards attached to packaging clearly indicate section locations and component lists, enabling crews to stage materials adjacent to their installation areas. This logistical organization eliminates the searching, sorting, and material handling waste that typically consumes twenty to thirty percent of roofing installation labor hours.

On-Site Construction Support Ensuring Proper Implementation

Even the most carefully engineered Deep Trapezoidal Roof Panels require proper installation execution to achieve their performance potential. Comprehensive construction support services ensure that installation teams understand system details and execute work correctly. Installation technicians conduct pre-construction site visits verifying substrate conditions, reviewing tool requirements, and confirming accessory material completeness. Technical briefing meetings thoroughly review installation sequences, quality checkpoints, and safety protocols before work begins. This proactive preparation prevents the costly rework and schedule disruptions resulting from installation errors discovered after substantial work completion. The quality assurance protocols implemented during Deep Trapezoidal Roof Panels installation verify performance compliance through systematic inspection and testing. Seam integrity receives verification through visual examination and mechanical pull testing at representative locations. Fastener installation quality undergoes inspection confirming proper torque application and washer sealing. Upon installation completion, comprehensive water testing using calibrated spray equipment verifies zero leakage under simulated severe weather conditions. These validation procedures provide documented evidence of system performance, supporting warranty activation and providing facility owners confidence in their roofing investment.

Customization Flexibility Meeting Diverse Industrial Requirements

Industrial facilities encompass extraordinary diversity in building configurations, operational requirements, and aesthetic preferences. Deep Trapezoidal Roof Panels accommodate this variability through extensive customization capabilities spanning dimensional specifications, material selections, and surface finishes. Width specifications ranging from seven hundred fifty to fifteen hundred millimeters enable optimization for specific building geometries and structural framing layouts. Thickness options from zero-point-four to one-point-two millimeters allow performance tuning matching load requirements and span conditions. This dimensional flexibility ensures optimal material efficiency without compromising structural performance or weather resistance.

Color and Finish Options Supporting Brand Identity

The visual appearance of industrial facilities increasingly reflects corporate branding and community integration priorities. Deep Trapezoidal Roof Panels offer comprehensive color selection spanning neutral tones suitable for conservative industrial aesthetics through vibrant hues supporting distinctive brand identity. Standard color libraries include polar white, slate gray, and medium bronze finishes meeting conventional preferences. Custom color matching services enable precise coordination with existing facility elements or corporate color specifications. The coating technologies available ensure color retention throughout decades of service, maintaining aesthetic appearance without periodic repainting requirements. Surface texture options for Deep Trapezoidal Roof Panels extend beyond simple color selection to encompass varied visual effects. Smooth finish surfaces provide clean contemporary appearance suitable for high-visibility facilities adjacent to residential areas or commercial districts. Embossed textures create visual interest while masking minor surface imperfections that might appear during manufacturing or installation. These finish options enable facility designers to balance functional performance requirements with architectural objectives, creating industrial buildings that contribute positively to their surrounding environments rather than appearing purely utilitarian.

Conclusion

Deep Trapezoidal Roof Panels transform industrial roofing through superior structural performance, extended service life, and installation efficiency. Their high-rib geometry, corrosion-resistant materials, and thermal performance capabilities address the critical challenges facing facility managers while delivering substantial lifecycle cost advantages over conventional alternatives.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

Xi'an Huafeng Construction Engineering Co., Ltd. stands as a leading China Deep Trapezoidal Roof Panels manufacturer with comprehensive capabilities spanning design, production, and construction services. Our three manufacturing facilities covering two hundred thousand square meters in Anhui plus processing plants in Hangzhou and Xi'an operate seven color coating production lines and forty specialized machines producing one thousand tons monthly. As a recognized Shaanxi Province high-tech enterprise holding first-level curtain wall and third-level steel structure qualifications, we deliver China Deep Trapezoidal Roof Panels wholesale solutions meeting international standards including ASTM, DIN, JIS, BS, and GB/T specifications. Our China Deep Trapezoidal Roof Panels supplier services provide High Quality Deep Trapezoidal Roof Panels featuring thirty-year warranties, fifteen to twenty day delivery, and Deep Trapezoidal Roof Panels for sale with competitive Deep Trapezoidal Roof Panels price structures. With over twenty registered patents, ISO9001, ISO14001, SGS certifications, and successful projects including Xiongan Station and Xi'an International Convention Center, we provide China Deep Trapezoidal Roof Panels factory direct solutions. Contact huafeng@hfmetalroof.com for customized specifications, technical consultation, and project quotations.

References

1. American Society of Civil Engineers. "Minimum Design Loads and Associated Criteria for Buildings and Other Structures (ASCE/SEI 7-22)." Standards Committee on Loads and Load Combinations, 2022.

2. National Roofing Contractors Association. "The NRCA Roofing Manual: Metal Panel and SPF Roof Systems." NRCA Technical Operations Department, 2023.

3. Metal Construction Association. "Technical Bulletin: Design and Installation of Metal Roof and Wall Panels." MCA Engineering Committee, 2024.

4. International Code Council. "International Building Code (IBC): Chapter 15 Roof Assemblies and Rooftop Structures." ICC Board of Directors, 2024.

5. Steel Construction Institute. "Design Guide for Cold-Formed Steel Purlins and Side Rails." SCI Publication P419, Structural Engineering Research Institute, 2023.