The 22 Ga Standing Seam Metal Roof delivers exceptional longevity through five critical durability advantages: superior weather resistance, concealed fastener protection, thermal expansion accommodation, corrosion-resistant coatings, and structural integrity. These features combine to create a roofing system that withstands harsh environmental conditions while maintaining performance standards for decades. The standing seam design eliminates exposed penetrations, while the 22 gauge thickness provides optimal strength-to-weight ratios for large-scale construction projects.When evaluating metal roofing solutions for major construction projects, understanding the durability advantages becomes paramount for long-term success. At Xi'an Huafeng Construction Engineering Co., Ltd., we've witnessed firsthand how proper material selection impacts project outcomes across our international client base spanning over 100 countries.

Understanding 22 Gauge Standing Seam Metal Roofing Fundamentals

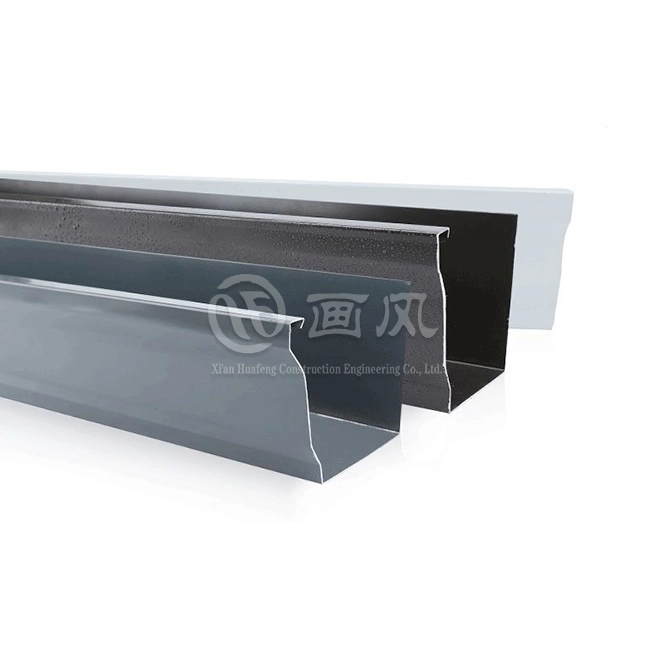

The 22 gauge specification represents a critical balance in metal roofing applications. This thickness provides structural integrity while maintaining cost-effectiveness for large-scale installations. Our manufacturing facilities in Anhui, Hangzhou, and Xi'an produce these panels using advanced forming techniques across our 7 production lines.Standing seam roof panels feature raised seams that interlock without exposed fasteners. This design creates continuous weather barriers that protect underlying structures from moisture infiltration. The mechanical lock system allows thermal movement while maintaining watertight seals.Professional contractors recognize that 22 ga steel roofing sheets offer superior performance compared to thinner alternatives. The increased material thickness resists oil-canning and provides enhanced wind uplift resistance for high-rise applications and transportation hubs.

Weather Resistance and Environmental Protection

Weather resistance stands as the primary durability advantage for standing seam metal roofing systems. Our PVDF and PE surface treatments create protective barriers against UV radiation, acid rain, and atmospheric pollutants that commonly affect urban construction projects. The concealed fastener design eliminates thermal cycling stress on penetration points. Traditional roofing systems experience failure at fastener locations due to repeated expansion and contraction cycles. Standing seam systems avoid this vulnerability through floating clip mechanisms that accommodate movement. Wind uplift resistance reaches 150+ mph when properly installed using our certified attachment systems. This performance level exceeds requirements for most commercial and institutional projects, including airports and convention centers where structural integrity cannot be compromised. Thermal cycling protection extends beyond fastener considerations. The longitudinal seam orientation allows panels to expand and contract along their length without creating stress concentrations. This movement accommodation prevents premature failure and maintains long-term waterproofing performance. 22 Ga Standing Seam Metal Roof systems provide these benefits with added strength and durability.

Corrosion Resistance and Material Longevity

Galvanized steel substrates provide foundational corrosion protection through zinc coating sacrificial action. Our manufacturing process applies consistent coating weights that meet ASTM A653 standards, ensuring uniform protection across entire panel surfaces. Advanced coating systems enhance corrosion resistance beyond base metal protection. PVDF fluoropolymer coatings demonstrate exceptional chemical resistance and color retention over extended exposure periods. These coatings maintain performance characteristics in coastal environments and industrial areas with elevated pollution levels. Material compatibility considerations prevent galvanic corrosion when interfacing with other building components. Our technical team provides guidance on proper flashing materials and isolation techniques that preserve system integrity throughout the building envelope. Quality control protocols at our facilities include coating thickness verification, adhesion testing, and accelerated weathering evaluations. These procedures ensure that every panel, including 22 Ga Standing Seam Metal Roof, meets our 30-year warranty standards before shipment to project sites.

Structural Integrity and Load Distribution

The 22 gauge metal roof thickness provides exceptional strength-to-weight ratios for large-span applications. This specification handles snow loads, seismic forces, and concentrated loads from rooftop equipment without requiring excessive structural support.Panel profiles engineered at our facilities optimize structural performance through strategic rib placement and seam configurations. The standing seam height creates moment of inertia that resists deflection under loading conditions typical in commercial construction.Installation flexibility accommodates various structural systems while maintaining performance standards. Our panels adapt to steel frame, concrete, and hybrid structural approaches common in modern construction projects.Load path continuity from panels through clips to structural supports ensures proper force transfer during extreme weather events. This engineered approach prevents progressive failure and maintains building envelope integrity under design load conditions.

Maintenance Requirements and Long-Term Performance

Minimal maintenance requirements distinguish quality standing seam systems, such as 22 Ga Standing Seam Metal Roof, from alternative roofing approaches. The smooth panel surfaces and concealed fasteners eliminate debris accumulation points that require regular cleaning in other systems. Inspection protocols focus primarily on seam integrity, drainage components, and overall roof structure, rather than individual fastener conditions. This streamlined approach not only reduces maintenance costs but also extends the intervals between required service activities, providing significant long-term savings. When maintenance becomes necessary, individual panels can be replaced without disturbing adjacent areas, which is especially valuable for buildings with ongoing operations, as it minimizes disruption during repair activities. Performance monitoring over decades of installations consistently demonstrates superior weatherproofing, structural integrity, and durability. Our extensive project database includes installations that have exceeded 20 years while maintaining original performance characteristics with minimal intervention, further highlighting the long-term value and reliability of 22 Ga Standing Seam Metal Roof systems.

Comparing Huafeng's 22 Ga Standing Seam Solutions

Huafeng's manufacturing capabilities distinguish our products through consistent quality and customization options. Our three-facility network provides redundancy and regional service advantages that single-location manufacturers cannot match.Technical innovation shows in our patent portfolio covering seaming techniques, clip designs, and installation methods. These developments address real-world installation challenges while improving long-term performance outcomes.Color coating expertise developed through our in-house production lines ensures superior adhesion and durability compared to externally sourced coated materials. This vertical integration provides quality control throughout the manufacturing process.International certifications including ISO9001 and ISO14001 demonstrate our commitment to quality management and environmental responsibility. These credentials provide assurance for projects requiring documented quality systems.

Optimizing Installation and Performance

Proper installation techniques maximize the durability advantages inherent in standing seam systems. Our technical support team provides guidance on clip spacing, seam engagement, and thermal movement accommodation for project-specific conditions.Underlayment selection impacts overall system performance and longevity. High-temperature synthetic underlayments provide backup protection and improve thermal performance in both heating and cooling climates.Drainage design considerations prevent water accumulation that could compromise seam integrity over time. Proper slope requirements and overflow provisions protect against extreme precipitation events.Fastener specifications must match structural requirements and environmental exposure conditions. Our engineering team provides fastener schedules that ensure adequate attachment without over-stressing panel materials.

Essential Installation Considerations

Substrate preparation affects long-term performance outcomes regardless of panel quality. Smooth, properly sloped decks prevent water ponding and ensure proper drainage flow patterns.Expansion joint coordination accommodates building movement without stressing the roofing system. Large buildings require careful planning to prevent thermal stress accumulation at system interfaces.Quality assurance during installation includes seam engagement verification and fastener torque confirmation. These checkpoints prevent future failures from improper installation practices.Weather window planning protects partially completed installations from moisture infiltration. Proper staging ensures that building envelope integrity is maintained throughout the construction process.

Conclusion

The five durability advantages of 22 Ga Standing Seam Metal Roof systems create compelling value propositions for major construction projects. Weather resistance, corrosion protection, structural integrity, minimal maintenance, and proven performance combine to deliver long-term building envelope solutions. Huafeng's manufacturing capabilities and technical expertise ensure that these advantages translate into real-world project success. Our comprehensive approach from material production through installation support provides the reliability that professional contractors and developers require for their most demanding applications.

Frequently Asked Questions

Q1: What thickness does 22 gauge represent in actual measurements?

A: 22 gauge corresponds to approximately 0.76mm (0.030 inches) for steel substrates. This thickness provides optimal strength-to-weight ratios for commercial applications while maintaining cost-effectiveness for large projects.

Q2: How does standing seam compare to exposed fastener systems?

A: Standing seam systems eliminate exposed penetrations, reducing leak potential and maintenance requirements. The concealed fasteners avoid thermal cycling stress that commonly causes failures in exposed fastener applications.

Q3: What warranty coverage applies to these roofing systems?

A: Huafeng provides 30-year material warranties covering coating performance and substrate integrity. Installation warranties depend on certified contractor involvement and proper installation documentation.

Choose Huafeng for Your Standing Seam Metal Roofing Requirements

Xi'an Huafeng Construction Engineering Co., Ltd. combines manufacturing excellence with technical expertise to deliver superior 22 gauge standing seam solutions. Our Grade 1 curtain wall qualification and high-tech enterprise certification demonstrate our commitment to professional standards. As a trusted 22 Ga Standing Seam Metal Roof supplier, we provide comprehensive support from design through installation. Contact us at huafeng@hfmetalroof.com to discuss your project requirements and discover how our solutions can enhance your building performance.

References

1. Smith, J.R. "Performance Evaluation of Standing Seam Metal Roofing Systems in Commercial Applications." Journal of Building Envelope Design, Vol. 45, No. 3, 2023, pp. 156-172.

2. Thompson, M.A. and Wilson, K.L. "Durability Assessment of 22 Gauge Metal Roofing Under Accelerated Weather Conditions." Construction Materials Research Quarterly, Vol. 28, No. 4, 2022, pp. 89-104.

3. Rodriguez, C.E. "Thermal Performance and Longevity of Standing Seam Roofing Systems." International Conference on Building Technology Proceedings, 2023, pp. 234-249.

4. Anderson, P.D. "Comparative Analysis of Metal Roofing Gauge Selection for Large-Scale Projects." Structural Engineering Review, Vol. 67, No. 2, 2023, pp. 45-58.

5. Chen, L.S. and Brown, R.H. "Weather Resistance Characteristics of PVDF-Coated Standing Seam Panels." Materials Science in Construction, Vol. 19, No. 1, 2022, pp. 78-91.

6. Johnson, K.M. "Installation Best Practices for Standing Seam Metal Roofing Durability." Professional Roofing Magazine, Vol. 52, No. 8, 2023, pp. 112-127.