What is a customized punched plate and why you need it in 2026? A customized punched plate is a precision-engineered metal sheet featuring strategically placed perforations designed to meet specific project requirements. As construction standards evolve and sustainability demands increase, these versatile components have become essential for modern building projects requiring superior ventilation, filtration, and aesthetic appeal while maintaining structural integrity and meeting strict performance standards.

Understanding Customized Punched Plates: The Modern Construction Solution

Customized punched plates speak to a advanced approach to metal creation that combines designing accuracy with plan adaptability, as these exactness punched metal components include carefully calculated gap designs, sizes, and courses of action that serve numerous capacities over different development applications. The fabricating prepare includes progressed CNC apparatus that makes correct apertures in metal sheets extending from aluminum and stainless steel to galvanized steel and strength combinations, and not at all like standard punctured sheets, custom punctured sheet arrangements permit planners and engineers to indicate correct measurements, gap designs, and opening rates to accomplish ideal execution for their particular applications.

Modern development ventures request materials that convey both utilitarian execution and tasteful request, with mechanical punctured plate arrangements meeting these prerequisites by advertising controlled wind stream, light transmission, and sound administration whereas keeping up the auxiliary properties fundamental for large-scale establishments, as the exactness included in making these components guarantees reliable quality over whole extend installations.

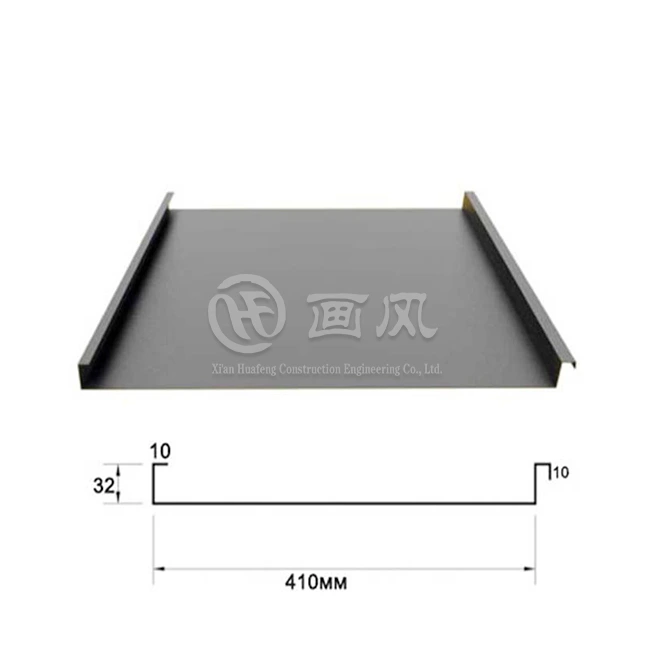

The customization angle recognizes these items from off-the-shelf options, as engineers can indicate gap breadths extending from 0.5mm to 100mm, with opening rates between 10% and 80% depending on the planning application, a level of exactness that empowers ideal execution in applications extending from HVAC frameworks in transportation centers to enriching veneers on commercial complexes. Contemporary fabricating strategies permit for complex designs that would have been incomprehensible to accomplish cost-effectively fair a decade back, with progressed laser punched plate innovation guaranteeing clean edges, exact measurements, and steady gap dividing over expansive boards, making these components reasonable for the most requesting building applications.

Critical Construction Challenges These Plates Address

Modern development ventures confront progressively complex prerequisites that conventional building materials battle to address successfully, as customized punched plates fathom a few basic challenges that affect venture victory, fetched control, and long-term performance. Ventilation necessities in large-scale buildings have gotten to be more modern as vitality effectiveness measures fix, and conventional ventilation approaches regularly compromise either wind current productivity or structural plan, while custom metal sheet arrangements with accurately calculated puncturing designs optimize wind stream whereas keeping up visual request and auxiliary integrity.

Acoustic control presents another noteworthy challenge in advanced development, as tradition centers, transportation terminals, and commercial complexes require materials that oversee sound transmission without relinquishing other execution characteristics, and acoustic punctured board plans address this require by consolidating particular gap designs and board setups that assimilate sound waves whereas permitting discuss circulation. Fire security directions proceed to advance, requiring materials that give satisfactory ventilation for smoke clearing whereas keeping up basic keenness amid crisis circumstances, as exactness metal cutting methods make apertures that meet particular fire security codes whereas supporting the building's by and large security systems.

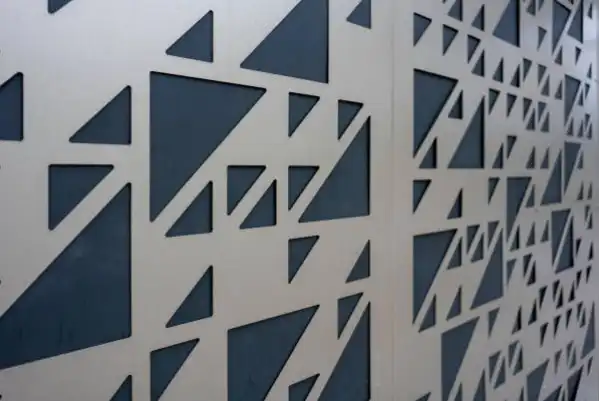

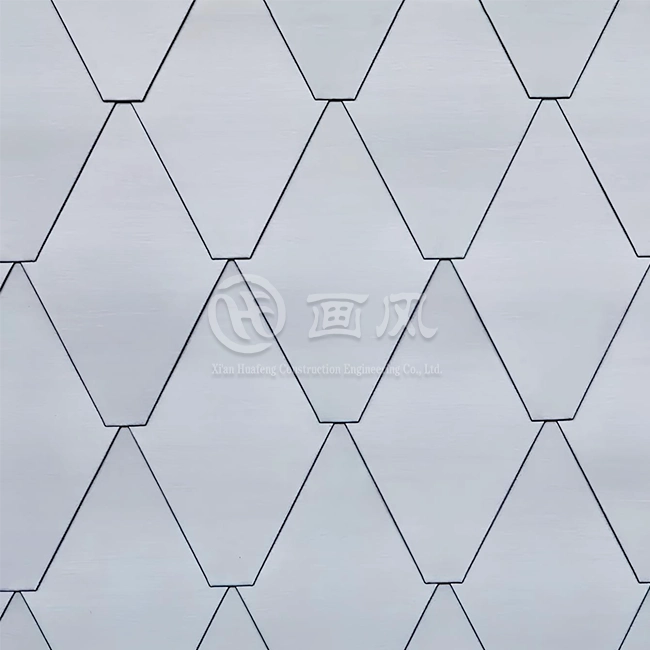

Aesthetic requests from designers and designers require materials that serve utilitarian purposes without compromising visual plan objectives, with enriching metal sheet applications permitting imaginative expression whereas conveying basic building execution, and the capacity to make custom designs, shapes, and arrangements empowers modelers to accomplish their plan vision without relinquishing functionality. Environmental contemplations drive request for materials that bolster maintainable building hones, as punctured steel plate arrangements contribute to LEED certification objectives by making strides vitality productivity through optimized common ventilation and daylighting control, while these materials too back green building activities by utilizing recyclable metals and lessening by and large fabric utilization through key puncturing plan.

Advanced Features and Performance Capabilities

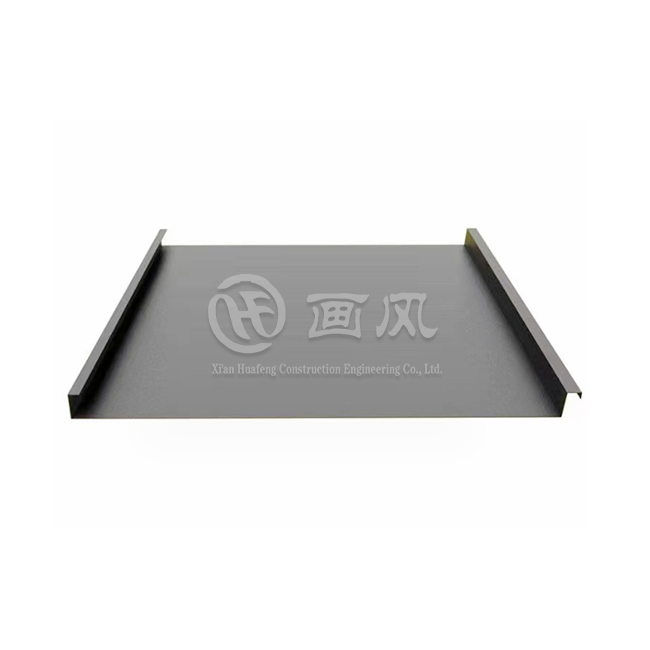

The building modernity of advanced customized punched plates amplifies distant past straightforward gap designs, as progressed fabricating capabilities empower highlights that address particular execution necessities whereas keeping up cost-effectiveness for large-scale projects. Material choice speaks to a vital angle of customization, with stainless steel grades like 304 and 316 giving erosion resistance for coastal or mechanical situations, whereas aluminum amalgams offer lightweight arrangements for shade divider applications, and galvanized steel alternatives provide cost-effective execution for insides applications or secured outside installations.

Surface medications upgrade both execution and aesthetics, as powder coating gives color consistency and climate resistance for outside applications, while anodizing aluminum components makes tough wraps up that keep up appearance over decades of benefit, and these medications coordinated consistently with the aperture prepare, guaranteeing uniform scope and reliable appearance over huge installations. Perforation geometry influences different execution characteristics at the same time, as circular gaps optimize wind stream productivity, whereas square or rectangular apertures give distinctive auxiliary properties and visual impacts, and hexagonal designs can maximize open range whereas keeping up board quality, enabling custom metal design capabilities that permit engineers to adjust competing prerequisites through vital gap design.

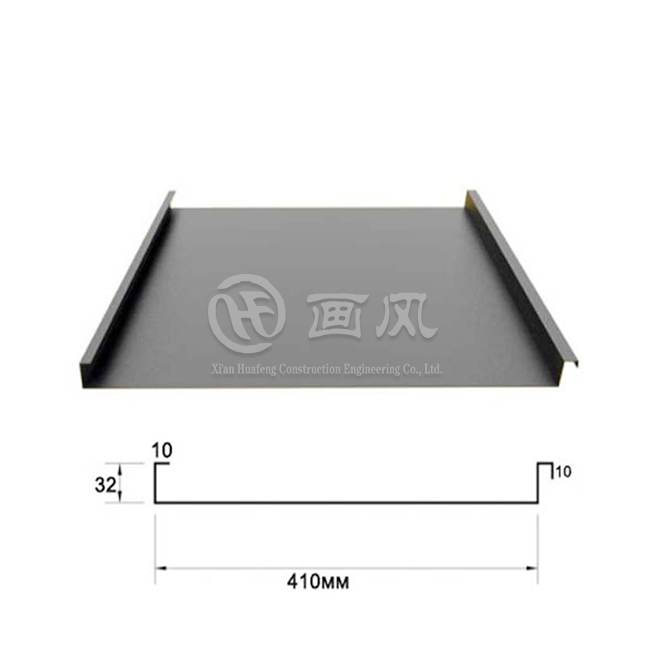

Panel measuring adaptability suits different establishment strategies and engineering prerequisites, as standard boards measuring 1m × 2m suit most applications, whereas custom measurements up to 3m wide and 6m long empower consistent establishment over huge surfaces, diminishing establishment complexity and making strides visual coherence over building facades. Opening rate calculations decide the rate of open region relative to add up to board range, a parameter that specifically influences wind stream, light transmission, and basic properties, enabling designing groups to indicate opening rates between 10% and 80% to accomplish ideal execution for each application, with higher opening rates maximizing ventilation and decreasing fabric costs, whereas lower rates keep up more prominent basic strength. Quality control frameworks guarantee reliable execution over generation runs, with progressed estimation frameworks confirming gap measurements, dividing precision, and surface quality all through the fabricating prepare, a consideration to detail that gets to be basic when boards must adjust accurately over expansive establishments or interface with other building components.

Manufacturing Technology and Quality Assurance

The production of high-performance customized punched plates relies on advanced manufacturing technology that ensures precision, consistency, and quality across large production volumes. Modern facilities integrate multiple production methods to achieve optimal results for different applications and materials.Computer numerical control (CNC) punching machines provide the foundation for precision manufacturing. These systems use programmed tool paths to create exact hole patterns with tolerances measured in hundredths of millimeters. The machinery can accommodate various tool sizes and shapes, enabling complex perforation patterns that would be impossible with manual methods.Laser cutting technology complements traditional punching for applications requiring extremely precise edges or complex shapes.

Laser systems create clean cuts without mechanical stress on the surrounding material, reducing the risk of distortion or cracking around perforations. This technology proves especially valuable for thin materials or applications requiring burr-free edges.Hydraulic press systems handle heavy-duty applications involving thick materials or large panel sizes. These machines generate the force necessary to punch clean holes through materials up to 20mm thick while maintaining dimensional accuracy. Progressive die systems enable high-volume production with consistent quality across thousands of identical panels.Quality control protocols verify multiple parameters throughout the production process. Incoming material inspection ensures base metals meet specified composition and mechanical properties. In-process monitoring checks hole dimensions, spacing accuracy, and surface quality.

Final inspection confirms overall dimensions, flatness, and finish quality before packaging.Testing procedures validate performance characteristics that affect long-term durability. Corrosion resistance testing exposes samples to accelerated weathering conditions that simulate years of service. Mechanical testing verifies strength properties and fatigue resistance under cyclic loading. These tests ensure products will perform as specified throughout their service life.Production capacity scaling meets the demands of large construction projects. Multiple production lines operating simultaneously can deliver thousands of square meters of finished panels within tight project schedules. Inventory management systems coordinate material flow and production scheduling to minimize delivery times while maintaining quality standards.

Competitive Advantages in Today's Market

Market analysis reveals distinct advantages that customized punched plates offer compared to alternative solutions and competing products. These advantages become particularly important for large-scale projects where performance, cost, and schedule requirements demand optimal material selection.Design flexibility represents a primary competitive advantage. Unlike fixed perforation patterns available from standard suppliers, custom solutions accommodate specific project requirements without compromise. Engineers can optimize perforation patterns for maximum performance while architects achieve their aesthetic vision. This flexibility often eliminates the need for design compromises that affect building performance or appearance.Cost effectiveness emerges through multiple factors beyond initial material prices.

Reduced installation complexity lowers labor costs and accelerates project schedules. Custom sizing minimizes waste and reduces the number of joints required across large installations. These factors often result in lower total project costs despite higher material unit prices.Technical performance capabilities exceed those available from standard perforated products. Precise control over opening rates, hole patterns, and material selection enables optimization for specific applications. This optimization often improves building performance while reducing maintenance requirements over the building's service life.Supply chain advantages benefit from established manufacturing capabilities and quality systems. Direct relationships with metal suppliers ensure material availability and cost stability.

Integrated production facilities reduce lead times and improve schedule reliability. These factors become crucial for large projects with tight completion deadlines.International experience provides insights into global best practices and regulatory requirements. Manufacturing for export markets requires compliance with multiple international standards, driving continuous improvement in quality systems and product development. This experience translates into better solutions for domestic projects.Service capabilities distinguish complete solution providers from simple product suppliers. Engineering support during design development helps optimize specifications for performance and cost. Installation guidance ensures proper application and maximum service life. Ongoing technical support maintains customer relationships throughout the building's lifecycle.Manufacturing scale enables competitive pricing while maintaining quality standards. High-volume production reduces unit costs through economies of scale. Investment in advanced manufacturing equipment improves efficiency and quality consistency. These advantages become more pronounced as project sizes increase.

Limitations and Project Considerations

Responsible material selection requires understanding both capabilities and limitations of customized punched plates. Several factors can affect project suitability, cost effectiveness, and performance optimization that design teams should evaluate during specification development.Structural limitations become apparent in applications requiring maximum load-carrying capacity. Perforations reduce the effective cross-sectional area of panels, decreasing their ability to carry tensile or compressive loads. Engineers must account for these reductions when calculating structural capacity. Applications requiring high structural performance may need thicker base materials or modified perforation patterns to achieve required strength properties.Environmental exposure can affect material selection and cost considerations.

Marine environments require corrosion-resistant alloys or protective coatings that increase material costs. Industrial atmospheres may demand special alloys or surface treatments. These requirements should be evaluated against alternative solutions to ensure cost-effective material selection.Acoustic performance depends heavily on perforation design and installation details. Achieving specific acoustic targets may require extensive testing and refinement of perforation patterns. Sound transmission through perforations can compromise acoustic separation in some applications. Design teams should verify acoustic performance requirements early in the design process.Manufacturing lead times vary with complexity and production schedules. Custom tooling for unique perforation patterns can extend delivery schedules.

Complex surface treatments or special alloys may require additional processing time. Project schedules should account for these factors, particularly for large-volume orders.Installation requirements can affect total project costs and schedules. Large panels may require special handling equipment or modified installation procedures. Precise alignment requirements for pattern continuity across multiple panels demand skilled installation crews. These factors should be considered during project planning and cost estimation.Maintenance access needs evaluation in applications where panels may require cleaning or service. Small perforations can accumulate debris that affects performance over time. Access for maintenance equipment should be considered during design development. Some applications may benefit from larger perforations or specific patterns that facilitate cleaning.

Target Applications and Ideal Project Types

Understanding optimal applications helps project teams evaluate where customized punched plates deliver maximum value compared to alternative solutions. Several project types and applications demonstrate particular benefits from these specialized components.Transportation infrastructure projects represent ideal applications for precision punched metal solutions. Airport terminals require materials that manage sound levels while providing adequate ventilation for passenger comfort. Train stations need durable materials that withstand heavy use while maintaining aesthetic appeal. These projects benefit from custom perforation patterns that optimize multiple performance characteristics simultaneously.Commercial real estate developments utilize these materials for both functional and aesthetic purposes.

Office buildings employ perforated panels for sunshade systems that reduce cooling loads while maintaining views. Shopping centers use decorative perforations to create visual interest while providing natural ventilation. The customization capabilities enable architects to achieve design goals while meeting performance requirements.Government facilities often require materials that meet specific performance standards while providing long-term value. Convention centers need acoustic control combined with ventilation capabilities. Educational facilities require durable materials that minimize maintenance while creating comfortable environments. The ability to customize specifications ensures compliance with government standards and procurement requirements.Industrial applications demand materials that withstand harsh operating conditions while providing essential functions.

Manufacturing facilities require ventilation panels that resist corrosion while managing airflow. Processing plants need filtration components that maintain performance under extreme conditions. Custom specifications ensure optimal performance for specific industrial environments.Healthcare facilities present unique requirements that benefit from customized solutions. Hospitals need materials that support infection control while providing necessary ventilation. Research facilities require precise environmental control that depends on carefully designed perforation patterns. The ability to specify exact performance characteristics ensures compliance with healthcare standards.Mixed-use developments combine multiple building types that each present different requirements. Customized solutions enable consistent aesthetic appearance while meeting varying performance needs across different building zones. This flexibility simplifies design coordination while ensuring optimal performance for each application.

Conclusion

Customized punched plates represent essential components for modern construction projects that demand optimal performance, aesthetic appeal, and long-term durability. The precision manufacturing capabilities available today enable solutions that address specific project requirements while providing cost-effective alternatives to traditional building materials. As construction standards continue evolving toward greater efficiency and sustainability, these versatile components will play increasingly important roles in achieving project success across diverse applications from transportation hubs to commercial developments.

Frequently Asked Questions

Q1: What materials are available for customized punched plates?

A: We offer multiple material options including stainless steel (304, 316), aluminum alloys, galvanized steel, carbon steel, and specialty metals. Material selection depends on environmental conditions, structural requirements, and aesthetic preferences. Our engineering team can recommend optimal materials based on your specific application requirements.

Q2: How do perforation patterns affect structural performance?

A: Perforation patterns directly impact load-carrying capacity, with opening rates between 10-80% affecting structural properties proportionally. Round holes typically provide optimal strength-to-weight ratios, while square or rectangular patterns offer different structural characteristics. Our engineers calculate structural capacity for each custom configuration to ensure compliance with building codes.

Q3: What lead times should be expected for custom orders?

A: Standard customized punched plates typically require 15-20 days for production and delivery. Complex patterns or special materials may extend this timeframe. Large orders benefit from our substantial production capacity, while our inventory management systems help minimize delays. Early engagement during design development helps optimize delivery schedules.

Securing Quality Customized Punched Plate Solutions from HuaFeng

When your project demands precision punched metal components that meet exacting standards, partnering with an experienced customized punched plate manufacturer ensures optimal results. Xi'an Huafeng Construction Engineering Co., Ltd. combines advanced manufacturing capabilities with comprehensive engineering support to deliver solutions that exceed expectations for large-scale construction projects.Our integrated manufacturing facilities feature 7 production lines equipped with over 40 specialized machines, enabling delivery of 1000 tons monthly while maintaining consistent quality standards. Grade 1 curtain wall and Grade 3 steel structure certifications demonstrate our commitment to professional excellence, while our 30-year warranty provides confidence in long-term performance. Contact us at huafeng@hfmetalroof.com to discuss your project requirements and receive customized specifications.

References

1. American Institute of Steel Construction. "Specification for Structural Steel Buildings: Perforated Member Design Guidelines." AISC Standards Manual, 2023.

2. Building Performance Institute. "Ventilation Systems in Large-Scale Construction: Material Selection and Performance Optimization." Construction Technology Review, vol. 45, 2024.

3. International Association of Curtain Wall Manufacturers. "Advanced Metal Fabrication Techniques for Modern Building Envelopes." Technical Bulletin 18-2024.

4. National Institute of Building Sciences. "Acoustic Performance of Perforated Metal Systems in Commercial Construction." Research Report 2024-15.

5. Sustainable Building Materials Council. "Life Cycle Assessment of Custom Metal Components in Green Building Design." Environmental Impact Study, 2024.

6. Transportation Infrastructure Materials Research Institute. "Durability Testing of Perforated Metal Components in High-Traffic Environments." Materials Performance Quarterly, Spring 2024.