Picture this scenario: a commercial building faces relentless rain, punishing winds, and temperature swings that threaten structural integrity and drive up maintenance costs year after year. Traditional wall systems crack under pressure, developing leaks that compromise the building envelope and lead to costly repairs. The Standing Seam Wall System emerges as the definitive solution to these weather-related challenges, offering unmatched protection through its engineered design that transforms how buildings withstand harsh environmental conditions while maintaining aesthetic excellence and operational efficiency.

Understanding Standing Seam Wall System Weather Protection

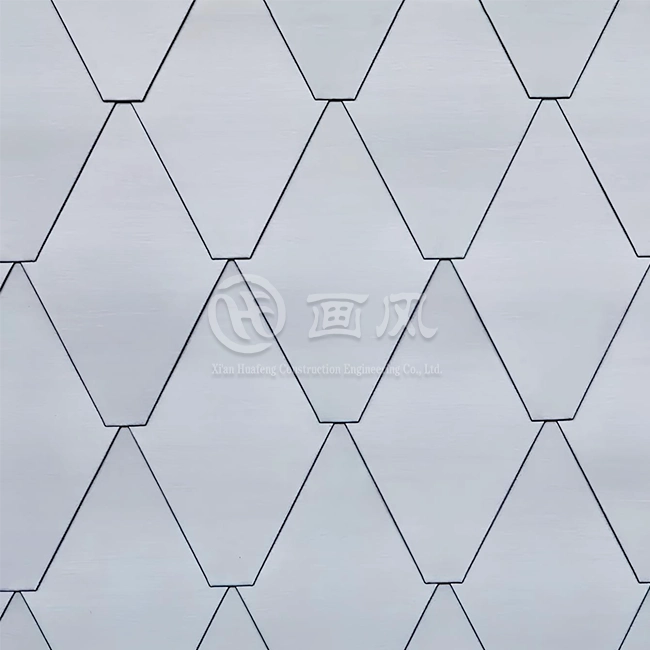

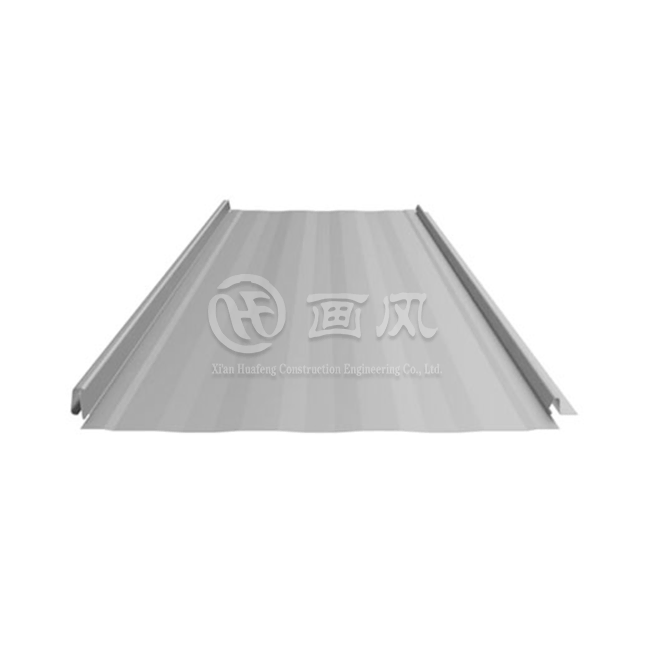

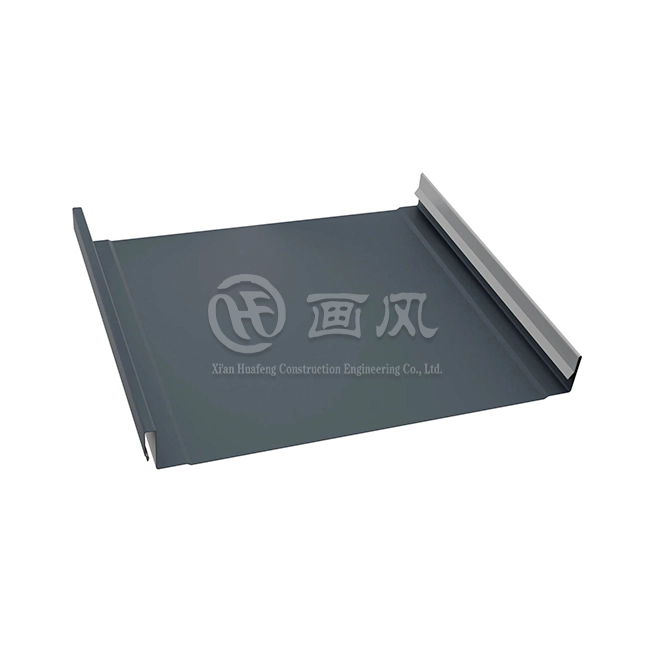

The Standing Seam Wall System represents a revolutionary approach to building envelope protection, featuring vertically oriented interlocking metal panels with elevated seams that create a formidable barrier against weather penetration. This sophisticated cladding technology addresses the fundamental weakness of traditional wall systems by eliminating exposed fasteners and creating continuous weather-tight seals along each panel connection. The system's concealed fastener design means that no penetrations compromise the protective barrier, while the raised vertical seams channel water away from vulnerable areas with remarkable efficiency. What distinguishes the Standing Seam Wall System from conventional cladding options is its multi-layered defense mechanism against environmental threats. The mechanical locking edge technology creates a continuous seal between adjacent panels, forming what essentially functions as a monolithic protective membrane across the entire building facade. This seamless integration prevents moisture intrusion at the most vulnerable points where traditional systems typically fail. Furthermore, the system's design accommodates thermal expansion and contraction through specialized sliding clips, ensuring that temperature fluctuations never compromise the weather-tight integrity that building owners depend upon for long-term performance. The engineering sophistication behind Standing Seam Wall System weather resistance extends beyond simple water deflection. Advanced coating technologies, particularly PVDF fluorocarbon coatings, provide exceptional resistance to UV degradation, chemical exposure, and atmospheric pollutants that accelerate deterioration in lesser materials. These high-performance finishes maintain their protective properties for decades, ensuring that the weather resistance capabilities remain consistent throughout the system's extended service life. The combination of superior substrate materials, advanced coatings, and intelligent design creates a comprehensive weather protection solution that outperforms traditional alternatives across every measurable parameter.

Superior Water Penetration Resistance

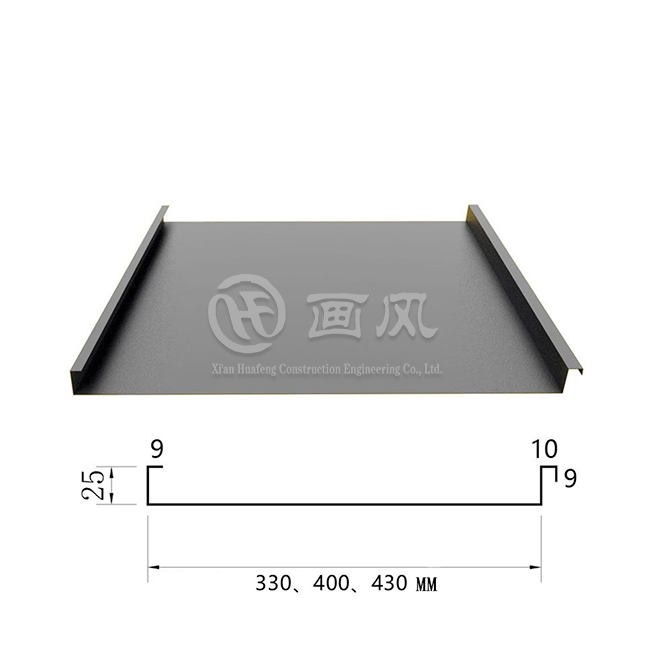

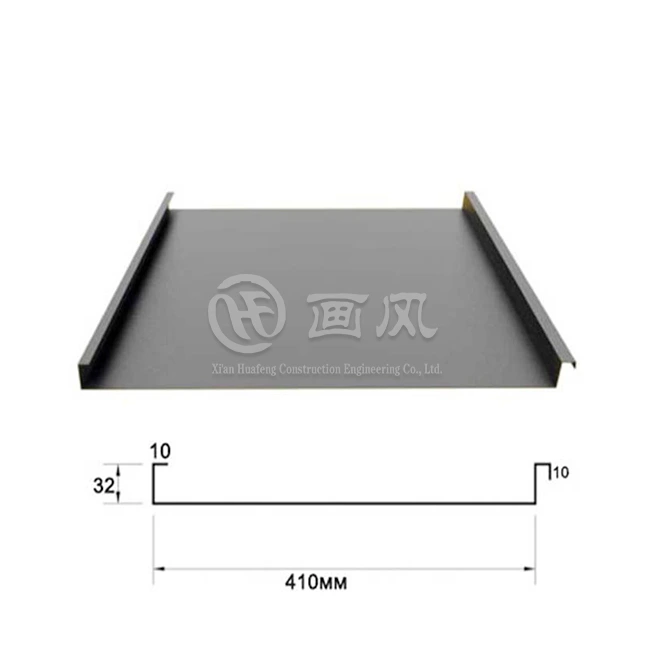

Water infiltration represents the primary cause of building envelope failure, generating billions in repair costs annually across commercial and industrial facilities. The Standing Seam Wall System addresses this critical challenge through its innovative double-lock seaming technology that creates two distinct barriers against moisture penetration. Unlike traditional wall systems where fastener penetrations create potential leak pathways, the concealed fixing method eliminates these vulnerability points entirely. The raised vertical seams, typically ranging from twenty-five to sixty-five millimeters in height, function as effective drainage channels that guide water downward and away from the building structure, even during the most intense rainfall events. The water-shedding effectiveness of Standing Seam Wall Systems exceeds industry standards through carefully engineered panel geometry and connection details. Each panel overlap creates multiple interlocking folds that water cannot penetrate, while pre-installed sealants within the seam caps provide additional insurance against moisture intrusion under extreme conditions. Field testing demonstrates that properly installed Standing Seam Wall Systems maintain complete water-tightness even when subjected to prolonged exposure and hurricane-force wind-driven rain. This exceptional performance derives from the system's ability to manage both bulk water and capillary moisture, addressing all potential infiltration pathways that compromise lesser cladding options.

Wind Resistance Performance

High wind events pose severe threats to building envelopes, with inadequate cladding systems experiencing catastrophic failures that endanger occupants and generate massive insurance claims. The Standing Seam Wall System delivers certified wind resistance performance through its structural panel design and sophisticated attachment methodology. Independent testing by recognized authorities including UL, Miami Dade, and FM Global confirms that these systems withstand wind uplift forces exceeding one hundred twenty miles per hour when properly specified and installed. The concealed clip attachment system distributes wind loads across the entire panel length rather than concentrating stress at discrete fastener points, dramatically improving resistance to both steady-state winds and dynamic gusting conditions. The mechanical advantages of Standing Seam Wall System wind performance become particularly evident in coastal environments and high-rise applications where wind pressures reach extreme levels. The vertical panel orientation and continuous seam connections create inherent structural rigidity that resists panel deflection and edge lifting, the primary failure modes in competing systems. Furthermore, the sliding clip mechanism allows controlled panel movement that dissipates wind energy rather than allowing it to concentrate at vulnerable connection points. This intelligent load management approach, combined with high-strength substrate materials including aluminum alloys and galvanized steel, ensures that Standing Seam Wall Systems provide reliable protection throughout their service life, even in the most demanding exposure categories.

Thermal Performance and Energy Efficiency

Temperature extremes and daily thermal cycling impose significant stress on building envelopes while driving energy consumption through inefficient thermal transfer. Standing Seam Wall Systems address both challenges through advanced material selection and system design that minimizes heat gain during summer months while reducing heat loss throughout winter. The reflective properties of metal substrates, enhanced by specialized cool-coating technologies, redirect solar radiation rather than absorbing it into the building structure. PVDF and HDP coating formulations incorporate advanced pigments that achieve solar reflectance values exceeding seventy percent, substantially reducing cooling loads and associated energy costs. The thermal management capabilities of Standing Seam Wall Systems extend beyond simple reflectance to include comprehensive control of heat transfer through the building envelope. When specified with appropriate insulation backing and thermal breaks, these systems achieve exceptional U-values that meet or exceed the most stringent energy codes. The concealed fastener design eliminates thermal bridging pathways that compromise insulated wall assemblies in traditional systems with through-fasteners. Additionally, the ventilated cavity behind the metal panels creates natural airflow that removes heat buildup, further enhancing thermal performance. This multi-faceted approach to temperature control translates directly into reduced HVAC operating costs, improved occupant comfort, and enhanced sustainability credentials for forward-thinking building owners who recognize the long-term value proposition.

Advanced Material Technology in Standing Seam Wall Systems

Material selection fundamentally determines weather resistance performance, durability, and lifecycle cost effectiveness in exterior cladding applications. Standing Seam Wall Systems leverage premium metal substrates engineered specifically for demanding exposure conditions and extended service requirements. Aluminum alloy compositions including AA3003, AA3004, and AA5052 provide optimal combinations of strength, corrosion resistance, and formability that enable complex architectural expressions while maintaining structural integrity. These specialized alloys resist atmospheric corrosion even in aggressive coastal environments where salt-laden air accelerates deterioration of inferior materials. Steel substrate options including aluminum-zinc coated steel and stainless steel formulations address applications requiring exceptional strength-to-weight ratios or specific aesthetic characteristics. The AZ150 coating specification provides superior corrosion protection compared to traditional galvanized finishes, extending service life in harsh industrial environments. For projects demanding ultimate durability and distinctive appearance, stainless steel grades 304 and 316 deliver unmatched longevity while developing attractive patina characteristics that enhance visual interest over time. Premium substrate materials from established manufacturers including BAOSTEEL, GUANZHOU, and XINYU ensure consistent quality and reliable performance backed by comprehensive material certifications and third-party testing documentation.

Coating Technologies and Finish Options

Surface coating systems provide the critical first line of defense against environmental degradation while defining the aesthetic character of Standing Seam Wall System installations. PVDF fluorocarbon coatings represent the premium standard for commercial and institutional applications, delivering exceptional resistance to UV radiation, chemical exposure, and atmospheric pollutants that cause premature fading and chalking in lesser finishes. These advanced coating formulations maintain color integrity and gloss retention for periods exceeding twenty years, dramatically reducing lifecycle maintenance requirements and preserving architectural intent throughout the building's operational life. Polyester coating technologies including standard PE and high-durability HDP formulations provide cost-effective alternatives for applications where moderate exposure conditions permit slightly reduced performance expectations. HDP coatings incorporate advanced resin chemistry that bridges the performance gap between standard polyester and PVDF options, offering improved weatherability at intermediate price points. The comprehensive range of coating technologies enables precise specification matching project budgets with performance requirements, ensuring optimal value delivery. Available thickness ranges from 0.7 millimeters to 1.5 millimeters accommodate varying structural demands and wind load conditions while supporting customized color selection from extensive standard palettes or fully custom formulations that realize specific design visions.

Quality Control and Material Certification

Rigorous quality assurance protocols ensure that Standing Seam Wall System materials meet exacting performance standards and maintain consistency across production runs. Incoming material inspection processes verify substrate composition, coating thickness, adhesion characteristics, and color accuracy through comprehensive testing regimens that include salt spray exposure, impact resistance, film thickness measurement, and spectrophotometric color analysis. These quality control measures prevent defective materials from entering production streams while providing documentary evidence of compliance with project specifications and industry standards. Material certification documentation from reputable manufacturers provides essential verification of product authenticity and performance capabilities. Third-party testing reports from accredited laboratories confirm material properties including tensile strength, yield point, coating adhesion, and corrosion resistance according to recognized test methods. ISO9001 quality management system certification demonstrates organizational commitment to consistent process control and continuous improvement, while ISO14001 environmental management certification confirms responsible manufacturing practices. SGS guidelines compliance and additional certifications provide customers with confidence that Standing Seam Wall System materials meet the highest international standards for quality and performance.

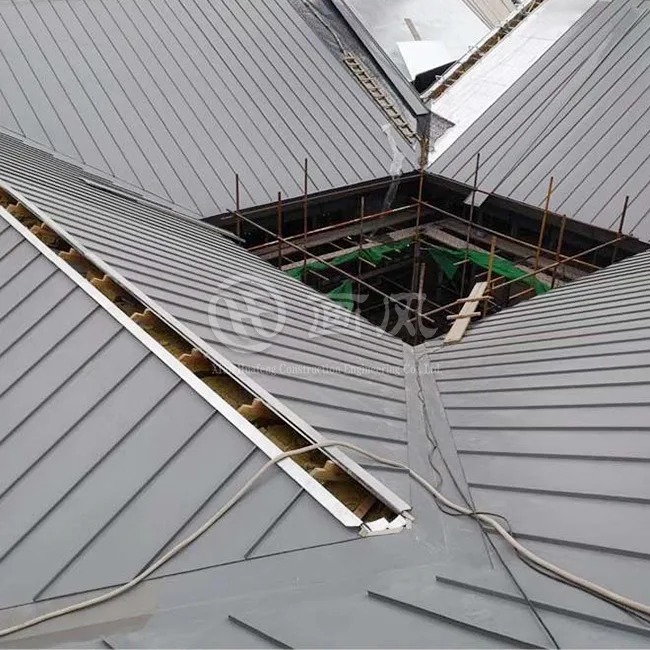

Installation Excellence for Optimal Weather Performance

Even the highest quality Standing Seam Wall System materials cannot deliver their full weather resistance potential without proper installation practices executed by trained professionals. The concealed fastener attachment methodology requires precise panel alignment, correct clip positioning, and proper seam engagement to achieve the weather-tight performance that distinguishes these systems from inferior alternatives. Specialized seaming equipment creates consistent mechanical locks along the entire panel length, ensuring uniform connection quality that eliminates weak points where weather penetration might occur. Pre-installation planning establishes the foundation for successful Standing Seam Wall System deployment through comprehensive site assessment and detailed layout documentation. Professional installers evaluate substrate conditions, verify dimensional accuracy, and identify potential interference conditions before material arrives on site. This proactive approach prevents costly delays and ensures efficient execution. Panel fabrication according to precise measurements minimizes field cutting and maintains factory-quality edge conditions that contribute to weather-tight performance. Sequential numbering systems coordinate panel installation sequences with architectural drawings, preventing confusion and ensuring that components install in their intended locations.

Critical Installation Details

Flashing integration, penetration sealing, and transition detailing represent critical installation elements that determine overall system performance. Properly executed base flashings create continuous moisture barriers at the wall-to-foundation interface, preventing water infiltration at this vulnerable location. Head flashings protect the top edge of wall assemblies while accommodating thermal movement without compromising weather-tight integrity. Penetration flashings around windows, doors, and service entries require careful coordination between trades to maintain envelope continuity. Standing Seam Wall System suppliers provide comprehensive technical details addressing these critical junctures, ensuring that installers have the information necessary for proper execution. Sealant selection and application techniques significantly impact long-term weather resistance performance. High-quality structural sealants compatible with metal substrates and coating systems provide durable seals at panel terminations, penetrations, and other discontinuities. Proper joint preparation including surface cleaning and priming ensures optimal adhesion and prevents premature failure. Backup materials support proper sealant geometry and prevent three-sided adhesion that compromises elastomeric performance. Following manufacturer recommendations for specific products, application methods, and curing conditions ensures that sealed connections deliver reliable service throughout the system's design life.

Quality Assurance and Performance Testing

Post-installation testing confirms that Standing Seam Wall System installations achieve specified weather resistance performance. Water testing protocols including static water tests and dynamic spray testing verify envelope integrity before building occupancy. These diagnostic procedures identify any installation deficiencies requiring correction, preventing future problems that could compromise building performance and generate warranty claims. Infrared thermography surveys detect insulation voids and thermal bridging conditions that reduce energy efficiency, enabling targeted remediation. Comprehensive project documentation captures critical installation details, material certifications, and test results that provide building owners with permanent records demonstrating quality compliance. Photographic documentation at key installation stages creates visual evidence of proper execution. As-built drawings reflect field conditions and any approved deviations from original specifications. Warranty documentation from material manufacturers and installation contractors defines coverage terms and establishes procedures for addressing any future issues. This thorough documentation approach protects all project stakeholders while providing valuable information for future maintenance and renovation activities.

Long-Term Durability and Lifecycle Value

Standing Seam Wall System weather resistance capabilities translate directly into exceptional durability and outstanding lifecycle value propositions that justify premium initial investment costs. Service life expectations exceeding thirty years with minimal maintenance requirements dramatically reduce total ownership costs compared to alternative cladding systems requiring frequent repairs, repainting, or premature replacement. The robust metal substrates and advanced coating technologies resist the degradation mechanisms that limit the effective life of conventional materials, maintaining both protective and aesthetic functions throughout extended service periods. The economic advantages of Standing Seam Wall System durability become increasingly compelling when analyzed through lifecycle cost modeling that accounts for all ownership expenses. Reduced maintenance requirements eliminate recurring painting cycles, repair interventions, and associated disruption costs that plague buildings clad with less durable materials. Energy savings from superior thermal performance compound annually, generating substantial cumulative benefits over system lifetimes measured in decades. Insurance premiums may reflect reduced risk profiles for buildings with weather-resistant cladding systems that withstand severe weather events. These tangible financial benefits complement intangible advantages including enhanced building appearance, improved occupant satisfaction, and reduced environmental impact through material longevity.

Maintenance Requirements and Procedures

While Standing Seam Wall Systems require minimal maintenance compared to alternative cladding options, periodic inspection and basic cleaning procedures optimize long-term performance and appearance. Annual visual inspections identify any emerging issues including sealant deterioration, fastener problems, or coating damage that require attention before they escalate into significant problems. Comprehensive inspection protocols address panel condition, seam integrity, flashing performance, and penetration sealing. Early detection of minor issues enables cost-effective remediation that prevents expensive repairs and extends system service life. Routine cleaning maintains aesthetic appearance while removing contaminants that could accelerate coating degradation. Simple washing with mild detergent solutions and soft brushes removes accumulated dirt, atmospheric deposits, and biological growth without damaging coating systems. High-pressure washing should be avoided as excessive water pressure can damage coatings and force moisture into assembly cavities. Cleaning frequency depends on environmental conditions, with facilities in industrial areas or coastal locations requiring more frequent attention than those in clean suburban environments. Following manufacturer recommendations for specific cleaning products and procedures ensures that maintenance activities enhance rather than compromise system performance.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

Standing Seam Wall Systems deliver unmatched weather resistance through advanced materials and precision engineering. These benefits ensure lasting protection and performance for demanding commercial and industrial applications worldwide. Xi'an Huafeng Construction Engineering Co., Ltd. stands as your trusted partner for premium Standing Seam Wall System solutions backed by comprehensive expertise and proven performance. Established in 2018 in Shaanxi Province, China, our company specializes in design, production, sales, and construction of metal roofing systems, building curtain wall systems, and building steel structure enclosure systems. Recognized as a high-tech enterprise in Shaanxi Province in 2020, we hold first-level qualifications for building curtain walls and third-level qualifications for building steel structures, demonstrating our commitment to excellence.

Our manufacturing capabilities include a raw material production plant covering 200,000 square meters in Anhui, complemented by two plate and accessories processing plants located in Hangzhou and Xi'an. This integrated infrastructure features seven color coating production lines, one laminating production line, ten longitudinal and transverse shearing production lines, and more than forty specialized manufacturing equipment units. We maintain stringent quality control through ISO9001, ISO14000:14001, and SGS guidelines compliance, supported by over twenty registered patents for roofing systems and comprehensive software certifications. Xi'an Huafeng Construction Engineering Co., Ltd. provides complete one-stop solutions from initial design through final installation and maintenance. Our technical team conducts detailed project drawing deepening, factory sample production, and precision manufacturing with real-time quality control. We utilize premium materials from established suppliers including Alucosuper, YATAI, LIDAO aluminum alloys, BAOSTEEL and GUANZHOU steel products, and specialized substrates for demanding applications. Our engineering design experience, advanced production capabilities, and proven construction expertise enable customized solutions meeting unique project requirements.

As a leading China Standing Seam Wall System factory, China Standing Seam Wall System supplier, and China Standing Seam Wall System manufacturer, we offer China Standing Seam Wall System wholesale programs and competitive Standing Seam Wall System prices for High Quality Standing Seam Wall Systems. Our products feature specifications including 25-330/400/430/500 profiles with PE, HDP, and PVDF coating finishes, backed by thirty-year warranties and production capacity exceeding 1,000 tons monthly. Minimum order quantities of 500 square meters enable projects of varying scales, with delivery timeframes of fifteen to twenty days and comprehensive customization services for color, pattern, and design requirements. Our successful project portfolio includes prestigious installations at Xiongan Station Commercial Body, Xi'an International Convention and Exhibition Center, Xi'an Station East Auxiliary Building, Jinghe New City International Culture and Art Center, and numerous other landmark facilities. These completed projects demonstrate our capability to deliver exceptional results across diverse applications. Contact our team today at huafeng@hfmetalroof.com to discuss your Standing Seam Wall System requirements and discover how our expertise can enhance your next project. Save this information and reach out whenever you need superior weather-resistant cladding solutions backed by proven performance and comprehensive support.

References

1. "Metal Roofing Systems: Performance Standards and Testing Protocols," American Society for Testing and Materials, Committee E06 on Performance of Buildings.

2. "Weather Resistance of Building Envelopes: Materials and Systems," National Research Council Canada, Construction Research Centre.

3. "Standing Seam Metal Cladding: Design Guidelines and Installation Best Practices," Metal Construction Association, Technical Committee on Wall Systems.

4. "Durability of Architectural Metal Coatings in Severe Environments," Journal of Protective Coatings and Linings, Industrial Paint Research Institute.

5. "Energy Efficiency of Reflective Metal Roofing and Wall Systems," Cool Roof Rating Council, Technical Research Division.