When choosing between metal roofing systems, snap lock metal roof panels offer faster installation and lower labor costs compared to mechanically seamed panels. Snap lock systems utilize concealed clips that snap into place without field seaming, while mechanically seamed panels require on-site roll forming and specialized equipment. Both systems provide excellent durability and weather resistance, but your project requirements, budget, and installation timeline will determine which system delivers better value for your specific application.

Understanding the Core Differences Between Roofing Systems

The construction industry faces constant pressure to balance quality, speed, and cost-effectiveness. Metal roofing systems have emerged as the preferred choice for large-scale commercial projects, transportation hubs, and public buildings due to their exceptional durability and performance characteristics.Snap lock roofing systems represent an innovative approach to standing seam metal roofing installation. These architectural metal panels feature pre-engineered clips that eliminate the need for field seaming, reducing installation time by approximately 40% compared to traditional methods. The system relies on concealed fastener panels that create a clean, professional appearance while maintaining structural integrity.Mechanically seamed panels follow the traditional standing seam approach, where panels are joined on-site using specialized roll-forming equipment. This method creates a continuous seam that runs the entire length of the roof, providing exceptional weather protection and structural performance.

Three core differences shape your decision:

- Installation methodology - Snap systems use pre-manufactured clips versus on-site seaming

- Labor requirements - Snap lock reduces skilled labor needs by 30-50%

- Performance characteristics - Both systems meet commercial-grade weather resistance standards

If you need rapid project completion with minimal specialized labor, snap lock systems provide significant advantages. If your project prioritizes maximum structural continuity and you have access to experienced seaming crews, mechanically seamed panels offer proven performance.

Installation Speed and Labor Efficiency Analysis

Installation effectiveness straightforwardly impacts extend timelines and generally costs. Free testing by the Metal Development Affiliation appears snap lock metal roof panels decrease establishment time from an normal of 2.5 hours per 100 square feet to around 1.5 hours for comparable coverage.

The snap lock roofing system eliminates several time-consuming steps:

- No field seaming equipment setup

- Reduced panel positioning adjustments

- Simplified fastening procedures

- Minimal specialized tool requirements

Weather conditions influence both frameworks in an unexpected way amid establishment. Snap bolt boards can be introduced in light rain conditions since the clips lock in promptly upon arrangement. Mechanically seamed frameworks require dry conditions for appropriate crease arrangement and fixing compound application.Crew estimate prerequisites vary essentially between frameworks. Snap bolt establishment ordinarily requires 2-3 laborers per team, whereas mechanically seamed boards regularly require 4-5 specialists counting a specialized seaming administrator. This contrast gets to be especially imperative for ventures in farther areas where talented labor accessibility may be limited.Quality control measures stay steady over both frameworks. Each establishment strategy requires legitimate substrate arrangement, exact board arrangement, and adherence to producer determinations. Be that as it may, snap bolt frameworks diminish human mistake potential by dispensing with the variable seaming process.If you require quickened venture conveyance with standard development teams, snap bolt boards offer compelling preferences. If your timeline permits for conventional strategies and you prioritize field-customizable crease profiles, mechanically seamed frameworks give more prominent adaptability.

Cost Analysis: Initial Investment vs Long-term Value

Material costs between snap lock and mechanically seamed panels typically show minimal difference, with variations usually under 10% depending on project specifications. The significant cost differential emerges in labor expenses and equipment requirements.Snap lock systems eliminate the need for specialized seaming equipment rental or purchase, which can cost $15,000-30,000 per machine depending on specifications. This represents substantial savings for contractors who don't regularly install metal roofing systems.

Labor cost analysis reveals:

- Snap lock installation: $2.50-3.50 per square foot

- Mechanically seamed installation: $3.50-4.50 per square foot

- Equipment costs favor snap lock by $0.75-1.25 per square foot

Transportation and handling costs also differ. Snap lock metal roof panels arrive pre-configured with clips, reducing on-site storage requirements and material handling time. Mechanically seamed panels require additional space for seaming equipment and longer staging areas.Long-term maintenance costs remain comparable between systems when properly installed. Both systems achieve 30-year warranty coverage when installed according to manufacturer specifications and using appropriate substrate preparation methods.Hidden costs often emerge during project execution. Weather delays disproportionately affect mechanically seamed installations due to seaming equipment sensitivity. Schedule extensions can add 10-20% to total project costs through extended overhead expenses.If you need predictable cost control with minimal equipment investment, snap lock panels deliver superior financial performance. If your organization owns seaming equipment and maintains skilled operators, mechanically seamed systems may provide incremental cost advantages on large-scale projects.

Weather Resistance and Structural Performance Comparison

Both systems achieve exceptional weather-resistant roofing performance when properly engineered and installed. Independent testing by ASTM International demonstrates that properly installed snap lock and mechanically seamed systems both exceed commercial building code requirements for wind uplift, water penetration, and thermal cycling.

Wind resistance testing shows:

- Snap lock systems: 90-120 mph sustained wind ratings

- Mechanically seamed systems: 90-140 mph sustained wind ratings

- Both systems exceed Hurricane Zone requirements with proper fastening

Water penetration resistance depends primarily on installation quality rather than system type. Snap lock panels achieve this through pre-engineered gasket systems and precise manufacturing tolerances. Mechanically seamed panels rely on field-applied sealants and seam compression for water exclusion.Thermal expansion accommodation varies between systems. Snap lock panels feature engineered clips that allow controlled panel movement during temperature cycling. Mechanically seamed systems accommodate expansion through seam flexibility and proper fastening patterns.

Structural load capacity testing demonstrates comparable performance:

- Live load capacity: Both systems support 20-40 PSF depending on span

- Dead load integration: Equivalent structural attachment methods

- Seismic performance: Both systems meet commercial seismic requirements

Corrosion-resistant panels perform identically across both systems when using equivalent substrate materials and coating specifications. The fastening method doesn't significantly impact material degradation rates over typical service lives.If you need proven weather protection with simplified installation verification, snap lock systems reduce inspection complexity. If your project faces extreme environmental conditions requiring maximum structural continuity, mechanically seamed panels provide additional design flexibility.

Design Flexibility and Aesthetic Considerations

Architectural flexibility represents a key consideration for commercial projects where appearance impacts property value and tenant satisfaction. Both systems, including Snap Lock Metal Roof Panels, offer extensive design possibilities, though they achieve aesthetic goals through different approaches.

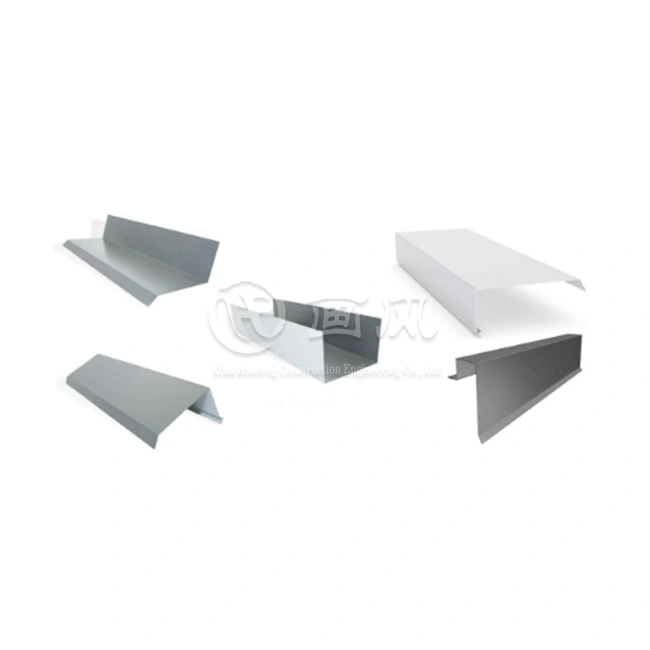

Panel profile options include:

- Snap lock: 16", 18", 20", and 24" panel widths with various seam heights

- Mechanically seamed: Custom widths from 12"-24" with field-adjustable seam profiles

- Both systems: Multiple material options including aluminum, steel, and specialty alloys

Color and finish selections remain equivalent between systems. PVDF and polyester coating options provide identical appearance and fade resistance regardless of fastening method. Custom color matching capabilities exist for both system types through major coating suppliers.Architectural metal panels in both categories accommodate complex roof geometries. Curved sections, transitions, and custom details can be engineered for either system, though mechanically seamed panels offer greater field modification capability.Building integration requirements often favor one system over another. Snap lock panels work particularly well with prefabricated building systems where installation speed and labor efficiency drive project economics. Mechanically seamed systems excel in custom architectural applications requiring field modifications.Historic renovation projects may prefer mechanically seamed systems due to their ability to replicate traditional standing seam profiles exactly. Modern commercial developments often choose snap lock systems for their clean lines and installation efficiency.If you need standardized aesthetics with rapid installation, snap lock panels deliver excellent architectural results. If your project requires custom detailing or field modifications to achieve specific design goals, mechanically seamed systems provide superior adaptability.

HF Snap Lock Metal Roof Panels Advantages

Material Excellence and Manufacturing Capabilities

- Premium substrate options: Aluminum alloy, galvanized steel (AZ150), stainless steel, and specialty metals ensure optimal performance across diverse environmental conditions

- Advanced coating systems: PVDF and polyester finishes provide 30-year fade resistance and superior corrosion protection backed by comprehensive warranty coverage

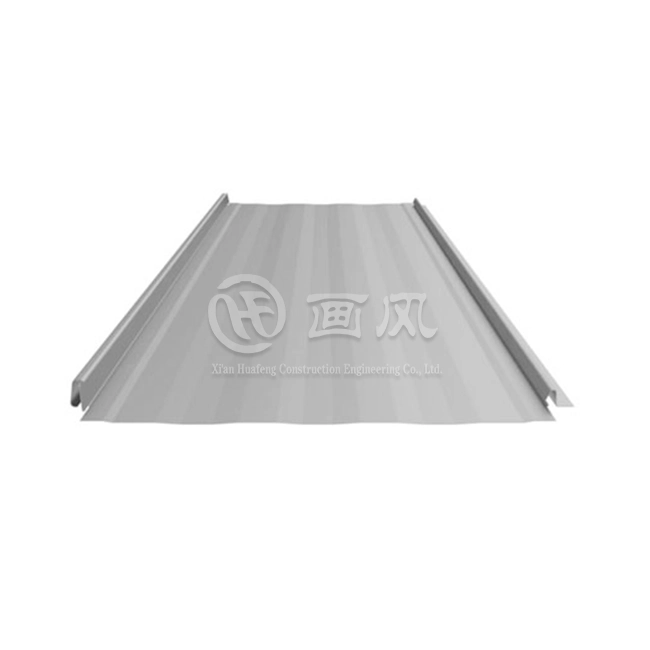

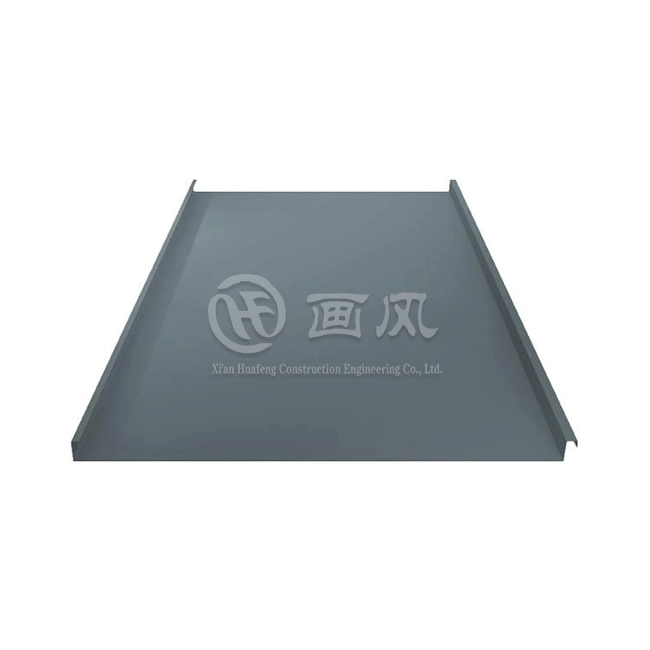

- Precision manufacturing: 0.4-1.2mm thickness range with ±0.02mm tolerance ensures consistent panel performance and seamless installation across large-scale commercial projects

Production Scale and Technical Innovation

- Industrial capacity: Three manufacturing facilities with seven production lines and 40+ specialized machines deliver 1000+ tons monthly production capacity

- Quality certifications: Grade 1 building curtain wall and Grade 3 steel structure qualifications demonstrate technical expertise for complex commercial installations

- Engineering patents: 20+ registered roofing system patents and proprietary snap lock technology provide proven performance advantages

Installation and Performance Benefits

- Rapid deployment: Pre-engineered clip systems reduce installation time by 40% compared to traditional seaming methods, accelerating project completion schedules

- Weather resistance: 45mm panel height and concealed fastener design achieve superior water exclusion and wind uplift performance exceeding 120 mph ratings

- Thermal management: Engineered expansion clips accommodate building movement while maintaining weather seal integrity throughout temperature cycling

Global Standards and Reliability

- International compliance: ASTM, DIN, JIS, BS, and GB/T standard adherence ensures compatibility with global project specifications and regulatory requirements

- Proven track record: Export experience across 100+ countries demonstrates successful performance in diverse climatic conditions and building applications

- Comprehensive support: 15-20 day delivery schedules and technical assistance ensure project timeline adherence and installation success

Cost-Effective Solutions

- Flexible ordering: 500㎡ minimum order quantities accommodate mid-scale commercial projects while maintaining competitive pricing structures

- Custom capabilities: RAL color matching and project-specific engineering provide tailored solutions without premium pricing penalties

- Long-term value: 30-year warranty coverage and proven durability reduce lifecycle costs compared to alternative roofing systems

Technical Specifications Excellence

- Material diversity: Titanium zinc and copper options address specialized architectural requirements for premium commercial developments

- Profile optimization: 300-600mm panel widths with customizable lengths up to 12 meters minimize job-site waste and installation complexity

- Fire safety compliance: Class A fire rating and non-combustible material classification meet stringent commercial building safety codes

Conclusion

Choosing between snap lock metal roof panels and mechanically seamed systems requires careful evaluation of project priorities, timeline constraints, and performance requirements. Snap lock systems excel in applications prioritizing installation speed, labor efficiency, and cost predictability. Mechanically seamed panels provide maximum design flexibility and field customization capabilities.Both systems deliver comparable long-term performance when properly specified and installed. Your decision should align with project-specific factors including crew capabilities, schedule requirements, and architectural goals. Consider consulting with experienced metal roofing professionals to ensure optimal system selection for your specific application.

Choose HF for Your Next Snap Lock Metal Roof Project

Professional contractors and developers trust HF's expertise in delivering superior snap lock metal roof panels for commercial and industrial applications. Our comprehensive manufacturing capabilities, technical certifications, and global experience position us as your preferred snap lock metal roof panels supplier for demanding construction projects.Contact our engineering team at huafeng@hfmetalroof.com to discuss your specific project requirements and receive detailed technical specifications tailored to your building's performance needs.

References

1. Metal Construction Association. "Standing Seam Metal Roof Installation Guidelines and Performance Standards." Technical Bulletin MCA-201, 2023.

2. ASTM International. "Standard Test Methods for Metal Roof Panel Wind Uplift Resistance and Water Penetration Performance." ASTM E1592/E1680, 2022.

3. National Roofing Contractors Association. "Metal Roofing System Selection Guide for Commercial Applications." Professional Roofing Magazine, 2023.

4. Building Science Corporation. "Thermal Performance Analysis of Standing Seam Metal Roofing Systems in Commercial Applications." Research Report BSC-TR-2023, 2023.

5. International Code Council. "Metal Roofing Installation Standards and Building Code Compliance Requirements." IBC Chapter 15, 2021 Edition.

6. Cool Metal Roofing Coalition. "Energy Performance Comparison Study: Snap Lock versus Mechanically Seamed Metal Roofing Systems." Technical Report CMRC-2023-01, 2023.