Picture this: your architectural vision demands a seamless, modern facade that balances aesthetic elegance with uncompromising weather resistance, but traditional cladding systems leave visible fasteners that disrupt the clean lines you envisioned. Flat Lock Metal Wall Sheets solve this critical challenge by delivering a flush, monolithic appearance with concealed attachment systems that create shadow lines and design flexibility impossible with conventional panels. This comprehensive guide explores the materials, surface finishes, and performance benefits that make flat lock metal wall panels the preferred choice for architects, contractors, and building owners seeking superior cladding solutions that combine form, function, and long-term value.

Understanding Flat Lock Metal Wall Sheets Architecture

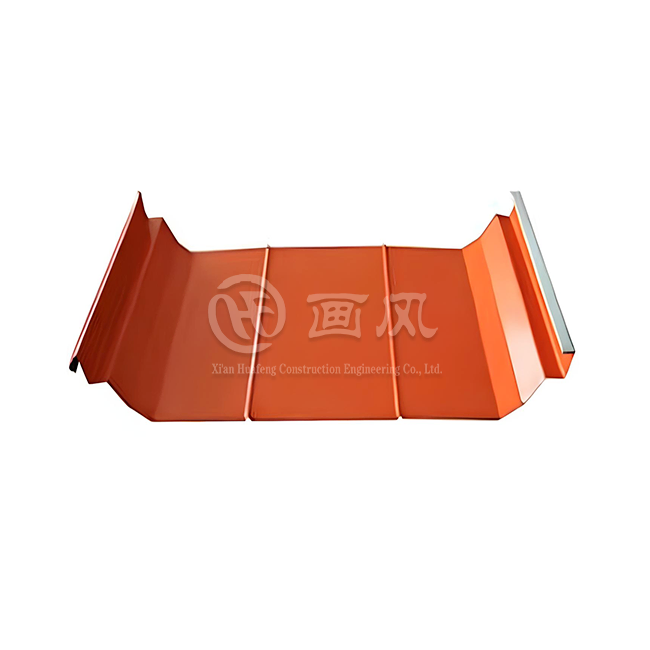

Flat lock metal wall panels represent an advanced architectural cladding system engineered to create seamless building envelopes with exceptional weather resistance and design versatility. Unlike traditional standing seam systems, these panels utilize interlocking fold mechanisms on all four sides, allowing installation in horizontal, vertical, or diagonal orientations to accommodate even the most geometrically complex building designs. The defining characteristic of flat lock metal wall panels is their ability to create a nearly flush surface appearance while maintaining structural integrity through concealed clip attachment systems that eliminate visible fasteners from the finished facade. The engineering sophistication behind Flat Lock Metal Wall Sheets lies in their hook seam construction, which creates wind-resistant connections while allowing for thermal expansion and contraction. Each panel integrates precisely fabricated edges that interlock with adjacent panels, forming continuous weather barriers that prevent water infiltration while accommodating building movement. This design methodology addresses a fundamental challenge in modern architecture: achieving monolithic visual aesthetics without compromising the functional performance required for building envelope systems. The panels' customizable dimensions, ranging from 100mm to 400mm in width with thicknesses between 0.4mm and 1.0mm, enable architects to scale the visual rhythm of the facade to match project-specific design intentions while maintaining consistent installation methodologies across varied building typologies.

Material Selection for Optimal Performance

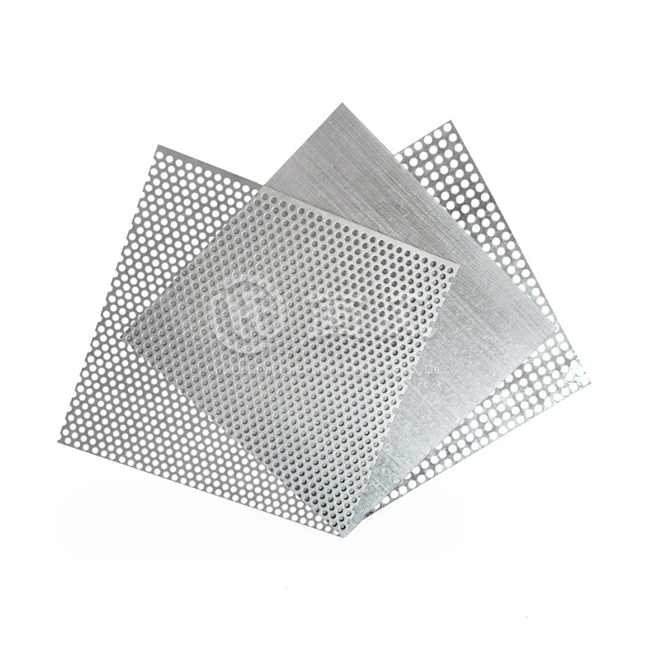

The material palette available for flat lock metal wall panels encompasses four primary categories, each offering distinct performance characteristics and aesthetic possibilities. Aluminum alloys, particularly 3003, 3004, and 5052 grades, provide exceptional corrosion resistance combined with lightweight properties that reduce structural loading requirements. These aluminum Flat Lock Metal Wall Sheets typically feature PVDF or anodized finishes that deliver superior UV resistance and color stability, making them ideal for projects requiring long-term appearance retention in harsh environmental conditions. The material's natural oxide layer provides inherent protection against atmospheric corrosion, while its thermal expansion coefficient requires careful detailing at panel connections to prevent stress concentration during temperature cycling. Stainless steel options, including 304 and 316 grades, offer unparalleled durability and strength for high-traffic applications or coastal environments where salt spray demands superior corrosion resistance. The material's higher modulus of elasticity compared to aluminum creates flatter panel surfaces with minimal oil-canning effects, particularly valuable for large-format installations where surface flatness critically impacts visual perception. Copper and titanium-zinc materials represent premium choices for projects prioritizing distinctive patina development and exceptional longevity. Copper flat lock metal wall panels naturally weather to characteristic green patinas, while titanium-zinc surfaces develop protective carbonate layers that self-heal minor surface damage. These materials command premium pricing but deliver service lives exceeding fifty years with minimal maintenance requirements, making them lifecycle cost-effective solutions for institutional and cultural facilities prioritizing architectural permanence.

Surface Finish Technologies and Visual Impact

Surface finish selection profoundly influences both the aesthetic character and long-term performance of Flat Lock Metal Wall Sheets installations. PVDF (polyvinylidene fluoride) coatings represent the industry standard for painted metal panels, delivering exceptional weatherability through resin chemistry that resists chalking, fading, and chemical degradation. These finishes maintain color integrity for decades while providing self-cleaning properties that minimize maintenance requirements in urban environments. The coating systems typically consist of primer layers for adhesion and corrosion protection, followed by topcoat applications that determine final color and gloss characteristics. Color selection from RAL, Pantone, or custom-matched specifications enables precise coordination with broader architectural color palettes, while metallic and mica-infused formulations create dynamic surface effects that shift appearance with changing light conditions. Anodized aluminum finishes offer an alternative approach that integrates color within the material's oxide layer rather than applying surface coatings. This electrochemical process creates exceptionally durable surfaces resistant to abrasion and UV degradation, making anodized flat lock metal wall panels particularly suitable for high-traffic areas where surface durability is paramount. Clear, bronze, and black anodized finishes provide distinct aesthetic characters, with brushed or directional grain patterns adding textural complexity to facade compositions. For projects emphasizing natural material expression, mill-finish stainless steel or pre-weathered zinc surfaces eliminate applied coatings entirely, allowing the inherent material characteristics to define aesthetic outcomes. These approaches align with contemporary design philosophies prioritizing material authenticity while requiring careful specification to ensure consistent surface appearance across panel production runs.

Installation Methodologies and System Performance

The installation methodology for flat lock metal wall panels fundamentally differs from conventional cladding systems, requiring specialized fabrication precision and field installation expertise. Each panel undergoes custom fabrication to project-specific dimensions, with CNC-controlled hemming equipment creating the interlocking edges that define the system's mechanical connection. The concealed clip attachment system isolates the panels from direct fastener penetration, allowing independent movement that accommodates thermal expansion while maintaining weather seal integrity. Installation sequencing typically begins at building corners or datum points, with subsequent panels interlocking in sequence to create continuous surfaces. The overlap configuration naturally directs water away from the building envelope, while the air cavity behind the panels provides drainage and ventilation paths that manage condensation and prevent moisture accumulation. Quality control during installation proves critical for achieving the flush surface appearance that defines successful Flat Lock Metal Wall Sheets projects. Panel alignment requires continuous monitoring to prevent cumulative tolerance stack-up that can create visible surface irregularities. Specialized tools including panel lifters, edge-locking machines, and precision measuring equipment ensure consistent installation quality while maintaining worker safety during facade construction. The system's inherent tolerance for minor substrate irregularities provides installation flexibility compared to face-fastened systems, but successful outcomes depend on maintaining plumb substrates and consistent clip spacing. Upon completion, the assembled facade should demonstrate uniform reveals, consistent shadow lines, and zero visible fasteners, creating the monolithic surface appearance that distinguishes flat lock systems from alternative cladding approaches.

Weather Resistance and Thermal Performance

The weather resistance characteristics of flat lock metal wall panels derive from multiple integrated design features working in concert to protect building envelopes. The overlapping panel configuration creates gravity-directed drainage paths that shed water away from vulnerable connection points, while the air cavity behind panels provides secondary drainage routes for any moisture that penetrates primary seals. This redundant weather protection aligns with rain-screen design principles, where the outer facade layer manages bulk water while allowing ventilation that dries incidental moisture before it reaches weather-resistant barriers. The metal substrate's inherent impermeability prevents water absorption that could lead to freeze-thaw damage in cold climates, while properly detailed transitions at penetrations, corners, and terminations maintain system integrity across the complete building envelope. Thermal performance considerations for Flat Lock Metal Wall Sheets installations extend beyond simple insulation values to encompass thermal bridging management and condensation control. The continuous metal panels create potential thermal bridges that can compromise wall assembly performance if not properly addressed through design detailing. Best practice installations incorporate thermal breaks at clip connections and utilize insulated substrates that minimize heat transfer through the facade assembly. The ventilated cavity behind panels provides additional thermal benefits by dissipating solar heat gain before it reaches the wall assembly, reducing cooling loads during summer months. In heating-dominated climates, careful vapor barrier placement and insulation continuity prevent condensation formation on cold panel surfaces during winter conditions. These thermal management strategies ensure that the visual benefits of flat lock metal wall panels do not compromise overall building energy performance.

Design Flexibility and Architectural Applications

The design flexibility inherent in flat lock metal wall panels stems from their modular construction methodology and material versatility, enabling architectural expressions ranging from traditional to contemporary. Panel dimensions can be customized to create specific visual rhythms, with rectangular formats producing orthogonal grid patterns, while diamond or hexagonal shapes generate dynamic geometric compositions. The ability to install panels in horizontal, vertical, or diagonal orientations multiplies design possibilities, allowing architects to emphasize building proportions or create visual movement across facade surfaces. Variable joint staggering patterns further enhance design flexibility, with running bond, stacked, or random arrangements creating distinct aesthetic characters while utilizing identical panel components. This geometric flexibility positions Flat Lock Metal Wall Sheets as solutions for both new construction and renovation projects, where existing building geometries may require adaptive cladding approaches.

Color and finish combinations provide additional design variables that expand the system's architectural potential. Monochromatic schemes emphasizing subtle tonal variations create sophisticated surfaces that reveal depth through shadow and reflection, while bold color contrasts between panel groups establish strong visual hierarchy. The integration of varied finishes within single facades—combining brushed, polished, and textured surfaces—adds tactile richness to visual compositions. Some contemporary projects incorporate perforated flat lock metal wall panels that balance opacity with transparency, creating dynamic surfaces that change appearance based on viewing angle and backlighting conditions. These perforated variations also serve functional roles in acoustic management and natural ventilation strategies, demonstrating how the system adapts to performance requirements beyond weather protection. The accumulation of these design variables positions flat lock systems as highly adaptable architectural tools capable of expressing diverse design intentions while maintaining consistent installation methodologies and performance standards.

Maintenance Requirements and Lifecycle Considerations

Long-term maintenance requirements for Flat Lock Metal Wall Sheets vary significantly based on material selection, finish type, and environmental exposure conditions. PVDF-coated aluminum and steel panels generally require only periodic washing to remove accumulated dirt and atmospheric pollutants, with cleaning frequencies ranging from annual to every five years depending on location. Urban environments with higher particulate concentrations typically demand more frequent maintenance compared to suburban or rural settings. The self-cleaning properties of modern PVDF coatings reduce maintenance intensity, as rainfall naturally washes away loosely adhered contaminants. For anodized aluminum surfaces, similar cleaning protocols apply, though the integral nature of anodized finishes provides enhanced abrasion resistance that may extend maintenance intervals. Cleaning methodologies should avoid abrasive materials or harsh chemicals that could damage finish integrity, instead utilizing low-pressure water and mild detergents.

Copper and zinc flat lock metal wall panels present unique maintenance considerations related to their natural patina development. While these materials require no protective finish maintenance, their appearance continuously evolves as patina layers develop and mature. Building owners must understand that this weathering process represents intended material behavior rather than deterioration requiring intervention. The characteristic green copper patina or gray zinc carbonate layer actually enhances corrosion protection over time, creating self-renewing surfaces that improve performance with age. Periodic inspection protocols should focus on mechanical connection integrity, sealant condition at terminations, and drainage path functionality rather than surface appearance. Panel replacement when necessary remains straightforward due to the interlocking design, allowing individual damaged panels to be removed and replaced without disturbing adjacent sections. This repairability, combined with material durability and finish longevity, positions flat lock metal wall panels as lifecycle cost-effective solutions that balance initial investment against decades of reliable service with minimal ongoing maintenance requirements.

Conclusion

Flat Lock Metal Wall Sheets deliver unmatched versatility combining seamless aesthetics, superior weather resistance, and exceptional design flexibility for modern architectural projects. Their concealed fastener systems, diverse material options, and customizable configurations make them ideal solutions for architects seeking monolithic facades that perform reliably across varied climatic conditions while expressing distinctive design visions.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

Partner with Xi'an Huafeng Construction Engineering Co., Ltd., a China Flat Lock Metal Wall Sheets manufacturer and China Flat Lock Metal Wall Sheets supplier recognized as a Shaanxi Province high-tech enterprise since 2020. Our three factories spanning 200,000 square meters in Anhui, with additional facilities in Hangzhou and Xi'an, operate 7 color coating production lines and over 40 precision machines delivering 1000 tons monthly production capacity. As a trusted China Flat Lock Metal Wall Sheets factory and China Flat Lock Metal Wall Sheets wholesale provider, we offer High Quality Flat Lock Metal Wall Sheets for sale with competitive Flat Lock Metal Wall Sheets price supported by ISO9001, ISO14001, SGS certifications and 20+ registered patents. Our one-stop service encompasses structural 3D modeling, custom fabrication of titanium-zinc, copper, aluminum, and stainless steel panels (0.4-1.0mm thickness, 100-400mm width), precision manufacturing with real-time quality control, and seamless on-site installation with 30-year warranties. Contact us at huafeng@hfmetalroof.com for customized solutions that integrate architecture, technology, and aesthetics while delivering measurable value for your project.

References

1 .American Architectural Manufacturers Association, "Metal Wall Panel Systems: Design and Installation Guidelines," AAMA TIR-A9-14, 2014

2. Metal Construction Association, "Architectural Metal Wall Panel Systems Manual," MCA Technical Bulletin, 2022

3. Smith, Robert J., "Modern Metal Facade Systems: Materials, Design, and Performance," Journal of Architectural Engineering, Vol. 28, No. 3, 2023

4. National Roofing Contractors Association, "The NRCA Metal Panel and SPF Roof Systems Manual," NRCA Publications, 2021

5. Wilson, Katherine M., "Sustainable Cladding Solutions: Life Cycle Assessment of Metal Panel Systems," Building and Environment Journal, Vol. 215, 2024

_1768552571575.jpg)