Choosing the wrong Corrugated Sheet Metal Wall Panels can lead to premature rusting, structural failures, costly replacements, and project delays that derail your budget and timeline. Whether you're constructing an industrial warehouse, upgrading a commercial facade, or renovating agricultural buildings, this comprehensive buyer's guide walks you through every critical decision point, from material selection and coating systems to gauge specifications and supplier verification, ensuring your investment delivers decades of reliable performance.

Understanding Corrugated Sheet Metal Wall Panel Fundamentals

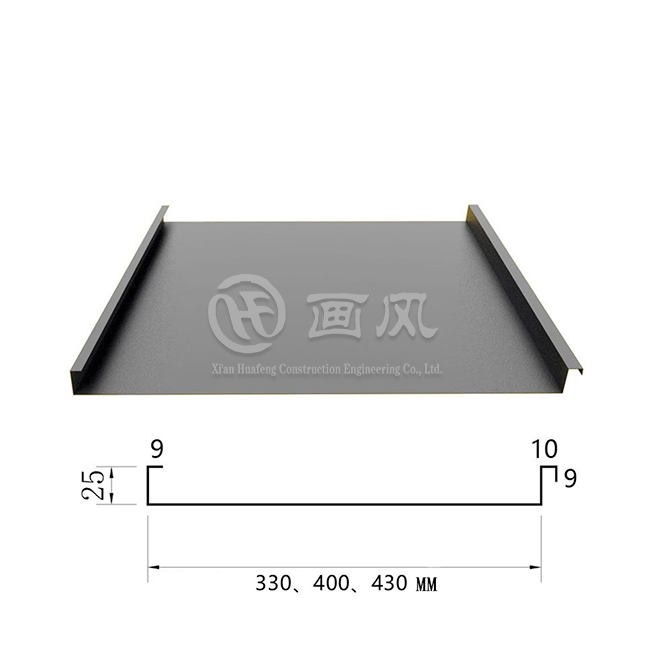

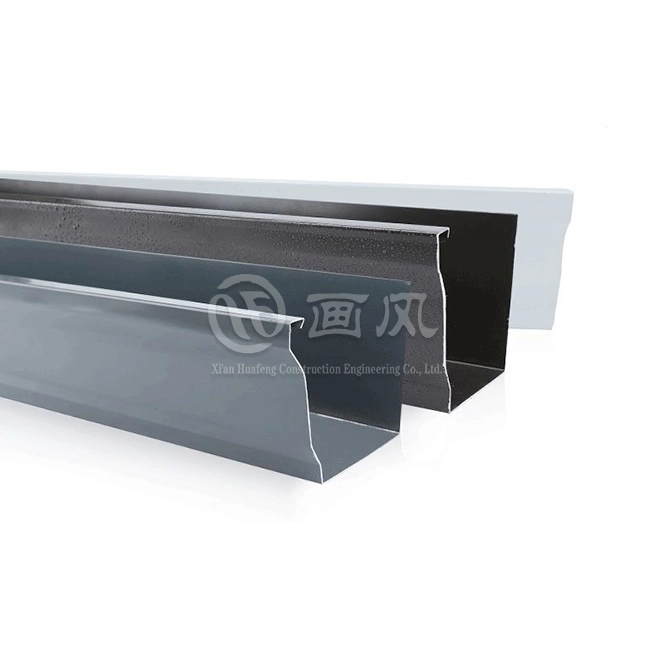

Corrugated Sheet Metal Wall Panels represent one of the most enduring and versatile building envelope solutions available in modern construction. The distinctive wavy profile that defines these panels is not merely aesthetic—it fundamentally enhances structural performance through geometric reinforcement. When flat metal is formed into repeating ridges and grooves, it creates a panel with significantly greater load-bearing capacity and spanning ability than flat sheets of equivalent thickness. This corrugated configuration distributes stress across the entire panel surface, allowing corrugated metal to resist wind loads, impact forces, and environmental pressures that would compromise lesser materials. The manufacturing process for Corrugated Sheet Metal Wall Panels involves cold-forming operations where metal coils are progressively shaped through precision rollers that create consistent wave patterns. This roll-forming technique produces panels with uniform dimensional tolerances while maintaining the metallurgical properties of the base material. Different corrugation profiles serve distinct architectural and structural purposes. Standard corrugations typically feature wave heights ranging from fifteen to thirty millimeters, with pitch distances designed to optimize strength-to-weight ratios. Box rib profiles offer deeper corrugations for applications requiring maximum structural depth, while tile profiles provide decorative options that blend industrial performance with traditional aesthetics.

Material composition profoundly influences panel performance characteristics. Galvanized steel panels receive a protective zinc coating through hot-dip galvanization, creating a sacrificial barrier that prevents corrosion from reaching the steel substrate. Galvalume represents an advanced coating technology combining fifty-five percent aluminum with forty-five percent zinc, delivering superior corrosion resistance in coastal and industrial environments where traditional galvanized finishes may prove inadequate. Aluminum Corrugated Sheet Metal Wall Panels offer exceptional corrosion resistance and lightweight properties, making them ideal for applications where weight considerations are paramount. Stainless steel variants provide the ultimate corrosion protection for harsh chemical environments, food processing facilities, and architectural applications where long-term appearance retention justifies premium investment.

Material Selection Criteria for Optimal Performance

Selecting the appropriate base material for your Corrugated Sheet Metal Wall Panels requires systematic evaluation of environmental exposure conditions, structural requirements, budget constraints, and aesthetic objectives. Galvanized steel dominates cost-effective applications where moderate corrosion protection suffices for agricultural buildings, storage facilities, and light industrial structures located in temperate climates with minimal salt air exposure. The zinc coating thickness significantly affects service life expectations, with G90 coatings providing 0.90 ounces of zinc per square foot of sheet surface representing the industry standard for general construction. Higher zinc weights such as G115 or G140 deliver enhanced protection for coastal proximity installations or environments with elevated humidity levels. Galvalume-coated steel panels have become the preferred specification for commercial and industrial buildings where extended service life justifies the moderate cost premium over galvanized alternatives. The aluminum-rich coating forms a dense oxide layer that self-heals minor scratches and provides exceptional resistance to atmospheric corrosion. Field performance studies document galvalume service life exceeding galvanized steel by two to four times in identical exposure conditions. This durability advantage translates directly to reduced lifecycle costs through extended replacement intervals and minimal maintenance requirements. Galvalume particularly excels in aggressive marine environments, industrial zones with airborne contaminants, and regions experiencing frequent freeze-thaw cycles that accelerate conventional coating degradation.

Aluminum Corrugated Sheet Metal Wall Panels deliver maximum corrosion resistance combined with weight reduction benefits approaching fifty percent compared to steel equivalents. The natural oxide layer that forms on aluminum surfaces provides inherent corrosion protection that continuously regenerates even when mechanically abraded. Aluminum panels prove indispensable for applications where structural loading limitations preclude heavier materials, such as retrofit installations on existing frameworks with limited load capacity. The material's excellent formability enables complex profile configurations and tight-radius bending operations impossible with higher-strength steel alloys. However, aluminum's lower tensile strength requires careful consideration of panel gauge selection to ensure adequate structural performance under anticipated load conditions. Stainless steel represents the premium material choice for Corrugated Sheet Metal Wall Panels in environments where corrosion protection and aesthetic longevity justify significant cost investment. Type 304 stainless steel provides excellent general-purpose corrosion resistance suitable for most architectural applications, food processing facilities, and commercial kitchens. Type 316 stainless steel incorporates molybdenum additions that dramatically enhance resistance to chloride-induced pitting corrosion, making it essential for coastal installations, chemical processing plants, and marine structures subjected to salt spray exposure. The bright metallic appearance of stainless steel Corrugated Sheet Metal Wall Panels maintains visual appeal throughout decades of service without requiring protective coatings or periodic refinishing.

Critical Thickness Specifications and Gauge Selection

Panel thickness represents a fundamental specification that directly governs structural performance, spanning capability, impact resistance, and overall system durability. Metal gauge designations follow an inverse numbering system where lower gauge numbers indicate thicker, heavier panels. Understanding this counterintuitive convention prevents specification errors that compromise project outcomes. Twenty-nine gauge corrugated panels measuring 0.36 millimeters thick serve light-duty applications such as interior accent walls, temporary structures, and decorative installations where structural demands remain minimal. These economical panels suit budget-conscious projects but require closer support spacing and exhibit greater susceptibility to impact damage. Twenty-six gauge Corrugated Sheet Metal Wall Panels at 0.48 millimeters thickness represent the entry point for serious exterior building envelope applications. This specification balances acceptable structural performance with cost efficiency for agricultural buildings, secondary structures, and light commercial installations in protected locations. However, twenty-six gauge panels approach their performance limits in high-wind regions or applications involving concentrated loading conditions. The moderate thickness provides reasonable dent resistance for normal handling and installation operations but remains vulnerable to damage from hail storms, falling debris, or accidental impact during construction activities.

Twenty-four gauge panels measuring 0.61 millimeters deliver substantially enhanced durability suitable for demanding commercial and industrial applications. This thickness specification has emerged as the industry standard for general-purpose building envelope installations where long-term performance justifies modest cost increments over thinner alternatives. The additional material thickness significantly improves impact resistance, reduces panel deflection under wind loading, and extends spanning capability between structural supports. Twenty-four gauge Corrugated Sheet Metal Wall Panels effectively resist damage during installation, withstand moderate hail impact, and maintain dimensional stability throughout decades of service exposure. Twenty-two gauge panels at 0.76 millimeters and twenty gauge panels at 0.91 millimeters address applications requiring maximum structural performance, extended spanning capability, or exposure to severe environmental conditions. These heavy-duty specifications prove essential for high-wind coastal regions, industrial facilities subjected to mechanical abuse, or architectural installations where panel flatness and appearance retention justify premium investment. The increased material thickness enables wider support spacing, reduces fastener quantity requirements, and delivers superior long-term appearance retention. Premium-gauge Corrugated Sheet Metal Wall Panels demonstrate exceptional resistance to oil canning distortion, thermal expansion stresses, and impact damage that would permanently deform lighter alternatives.

Coating Systems and Finish Options for Extended Service Life

Surface coating technology transforms basic metal substrates into complete building envelope systems engineered for specific environmental exposures and aesthetic requirements. The coating system selection process fundamentally shapes panel performance characteristics including corrosion resistance, color retention, chalking resistance, and maintenance requirements over multi-decade service lives. Understanding coating chemistry, application processes, and performance specifications enables informed decisions that align finish selection with project-specific durability expectations and budget parameters. Polyester coatings represent the economical foundation of the paint finish spectrum for Corrugated Sheet Metal Wall Panels. Standard polyester formulations deliver acceptable color retention and weather resistance for general-purpose applications in moderate climates with limited ultraviolet exposure intensity. These coatings typically carry warranties ranging from ten to fifteen years against excessive chalking and color change, making them appropriate for budget-conscious projects where appearance degradation within this timeframe proves acceptable. However, polyester coatings demonstrate accelerated performance degradation in intense sunlight regions, coastal environments, and industrial zones with atmospheric pollutants. The relatively soft coating surface remains susceptible to scratching during handling and installation, potentially exposing substrate material to corrosion initiation.

High-performance polyester formulations incorporate advanced resin technologies that significantly enhance durability compared to standard polyester systems. These modified polyester coatings achieve improved chalk resistance, reduced color fading, and better retention of gloss characteristics throughout extended service exposure. Premium polyester systems bridge the performance gap between economical standard polyester and premium fluoropolymer coatings while maintaining reasonable cost positioning. Typical warranty periods extend to twenty years for color change and chalking, making high-performance polyester an excellent value proposition for commercial projects where appearance retention matters but budget constraints preclude fluoropolymer specifications. Polyvinylidene fluoride coatings, commonly marketed under the Kynar 500 or Hylar 5000 trade names, represent the premium performance standard for architectural metal panel finishes. PVDF coating systems incorporate seventy percent fluoropolymer resins that deliver exceptional resistance to ultraviolet degradation, chemical attack, and environmental weathering. Field performance data spanning four decades demonstrates PVDF-coated Corrugated Sheet Metal Wall Panels maintain color integrity and surface gloss far exceeding alternative coating technologies. These fluoropolymer systems typically carry thirty-year warranties against excessive color change and chalking, with actual service life frequently extending well beyond warranty periods.

Color Selection and Custom Finishing Capabilities

Color specification for Corrugated Sheet Metal Wall Panels encompasses aesthetic objectives, thermal performance considerations, and practical maintenance requirements. Light-colored finishes reflect solar radiation more effectively than dark alternatives, reducing panel surface temperatures and minimizing thermal expansion stresses. This reflective property proves particularly valuable in warm climates where reduced cooling loads contribute to building energy efficiency. Conversely, darker colors absorb solar energy, potentially accelerating coating degradation in intense sunlight regions while creating dramatic architectural statements that align with contemporary design aesthetics. Standard color collections offered by major coil coating manufacturers provide immediate availability and economical pricing for projects with conventional appearance requirements. These industry-standard colors undergo extensive weathering validation and typically include neutral tones, earth colors, and primary architectural hues suitable for commercial and industrial applications. Custom color formulation services enable precise matching to corporate branding standards, historical restoration specifications, or unique architectural visions. However, custom colors typically require minimum order quantities, extended lead times for coil coating operations, and premium pricing that reflects specialized production requirements. Xi'an Huafeng Construction Engineering Co., Ltd. maintains extensive color sample libraries spanning standard collections and custom formulation capabilities. Our technical team provides color consultation services that consider viewing distance effects, surrounding material coordination, and long-term appearance retention expectations. We offer physical sample panels that enable accurate color evaluation under actual site lighting conditions, preventing the disappointment that results from selecting colors based solely on small swatch samples or digital representations. This commitment to color accuracy ensures your Corrugated Sheet Metal Wall Panels deliver the intended visual impact throughout their service life.

Technical Specifications and Performance Standards

Comprehensive technical specifications govern Corrugated Sheet Metal Wall Panel manufacturing, testing, and installation to ensure consistent quality and reliable performance across diverse applications and geographic regions. These industry standards establish minimum acceptable material properties, dimensional tolerances, coating thicknesses, and performance characteristics that protect buyers from substandard products while enabling valid comparisons between competing suppliers. Familiarity with relevant standards empowers informed purchasing decisions and facilitates clear communication of project requirements. American Society for Testing and Materials standards provide the foundation for metal panel specifications in North American markets. ASTM A653 governs steel sheet produced by hot-dip galvanizing processes, establishing coating weight designations, mechanical properties, and surface quality criteria. ASTM A792 addresses steel sheet coated with aluminum-zinc alloy through hot-dip processes, defining the coating composition and performance requirements for galvalume products. These material standards ensure consistent substrate quality regardless of manufacturer or geographic origin, enabling confident specification of Corrugated Sheet Metal Wall Panels for critical applications.

International Organization for Standardization standards harmonize technical requirements across global markets, facilitating international procurement and ensuring quality consistency for multinational projects. ISO 9001 certification demonstrates supplier commitment to comprehensive quality management systems encompassing design control, production processes, inspection protocols, and continuous improvement methodologies. This certification provides independent verification that manufacturing operations maintain documented procedures and consistent quality outputs. ISO 14001 environmental management certification indicates suppliers have implemented systematic approaches to minimize environmental impacts throughout their operations, addressing raw material consumption, energy efficiency, waste generation, and emissions control. Testing protocols validate that Corrugated Sheet Metal Wall Panels meet specified performance requirements before installation. Salt spray testing per ASTM B117 evaluates corrosion resistance by exposing coated specimens to concentrated salt fog environments that accelerate natural weathering processes. Coating adhesion testing using cross-hatch or pull-off methods confirms paint systems bond adequately to substrate surfaces and resist delamination under normal service conditions. Accelerated weathering testing subjects coated panels to intense ultraviolet radiation, moisture exposure, and temperature cycling that simulates years of outdoor exposure in condensed timeframes, enabling prediction of long-term color retention and chalk resistance characteristics.

Installation Methodologies and Fastening Systems

Proper installation techniques prove equally important as material selection for achieving satisfactory long-term performance from Corrugated Sheet Metal Wall Panels. The exposed fastener installation methodology commonly employed for corrugated profiles requires careful attention to fastener placement, drilling techniques, and sealing procedures. Fasteners must penetrate panel ridges rather than valleys to prevent water pooling around fastener penetrations that could compromise weather tightness. Self-drilling screws with integral neoprene washers provide efficient installation and reliable sealing, but proper drilling speed and applied pressure prevent washer damage or inadequate compression that would allow water infiltration. Horizontal installation orientations create traditional appearance profiles while facilitating natural water drainage across panel corrugations. This conventional approach suits most wall applications and simplifies flashing integration at openings and penetrations. Vertical installation orientations generate contemporary aesthetic effects while potentially reducing horizontal seam quantity depending on panel length availability and building height. Vertical orientations require careful attention to panel overlap sequencing and fastener patterns to prevent water intrusion at sidelaps between adjacent panels. Support structure spacing directly influences panel structural performance and overall system economy. Wider girt spacing reduces structural material costs but requires heavier panel gauges to maintain acceptable deflection limits under wind loading. Conversely, closer support spacing accommodates lighter, more economical panel gauges but increases structural framework costs. Engineering analysis optimizes this balance based on specific wind exposure classifications, panel profiles, and material specifications. Standard girt spacing for twenty-four gauge Corrugated Sheet Metal Wall Panels typically ranges from five to seven feet, providing adequate structural support while maintaining economical framework configurations.

Supplier Evaluation and Quality Assurance Protocols

Selecting qualified suppliers represents a critical success factor for projects involving Corrugated Sheet Metal Wall Panels. Comprehensive supplier evaluation encompasses manufacturing capabilities, quality control systems, technical support resources, and customer service responsiveness. Established manufacturers with extensive industry experience demonstrate deep understanding of material properties, coating technologies, and installation methodologies that newer market entrants may lack. This accumulated expertise translates to better problem-solving capabilities when project-specific challenges arise and more reliable product performance predictions based on decades of field installation feedback. Manufacturing infrastructure directly influences production capabilities, lead time consistency, and quality control effectiveness. Suppliers operating multiple production lines can accommodate varying project sizes from small renovations requiring several hundred square meters to massive industrial developments consuming thousands of tons of material. Integrated operations encompassing raw material production, coil coating, and panel roll-forming provide superior quality control through continuous monitoring of material properties throughout the manufacturing sequence. This vertical integration eliminates quality variations that can occur when multiple independent processors contribute to final product characteristics.

Xi'an Huafeng Construction Engineering Co., Ltd. operates three strategically located manufacturing facilities with seven dedicated production lines and more than forty specialized machines for Corrugated Sheet Metal Wall Panel fabrication. Our Anhui facility encompasses two hundred thousand square meters dedicated to raw material production, ensuring consistent substrate quality and eliminating dependence on external suppliers whose quality may fluctuate. Processing plants in Hangzhou and Xi'an provide convenient access for projects throughout Eastern and Central China while enabling rapid response to urgent delivery requirements. This manufacturing infrastructure supports monthly production capacity exceeding one thousand tons, accommodating projects of any scale without compromising delivery schedules.

Certification Verification and Compliance Documentation

Third-party certifications provide independent validation of manufacturing quality, product performance, and organizational capabilities. SGS certification confirms suppliers maintain rigorous quality control systems and product testing protocols verified through periodic independent audits. This certification demonstrates commitment to international quality standards and provides customers confidence that purchased materials will perform as specified. Construction projects requiring demonstrated compliance with building codes and insurance requirements benefit from comprehensive certification documentation that satisfies regulatory authorities and reduces approval delays. Testing laboratory reports document specific product performance characteristics including coating thickness measurements, adhesion test results, salt spray resistance duration, and accelerated weathering outcomes. These technical data sheets enable direct comparison between competing products and verification that specified materials meet project-specific performance requirements. Reputable suppliers willingly provide detailed testing documentation and maintain extensive libraries of performance data accumulated through decades of product development and field validation. Reluctance to share testing information or vague performance claims should raise concerns about product quality and supplier reliability. Patent portfolios indicate suppliers invest substantially in product innovation and process improvement rather than simply replicating established technologies. Xi'an Huafeng Construction Engineering Co., Ltd. holds more than twenty registered patents covering roofing system designs, installation methodologies, and specialized panel profiles. This intellectual property demonstrates our commitment to continuous innovation and provides customers access to advanced solutions unavailable from manufacturers offering only commodity products. Our engineering team actively develops new profiles, coating systems, and installation techniques that address emerging market requirements and solve challenging application problems.

Customization Options and Project-Specific Solutions

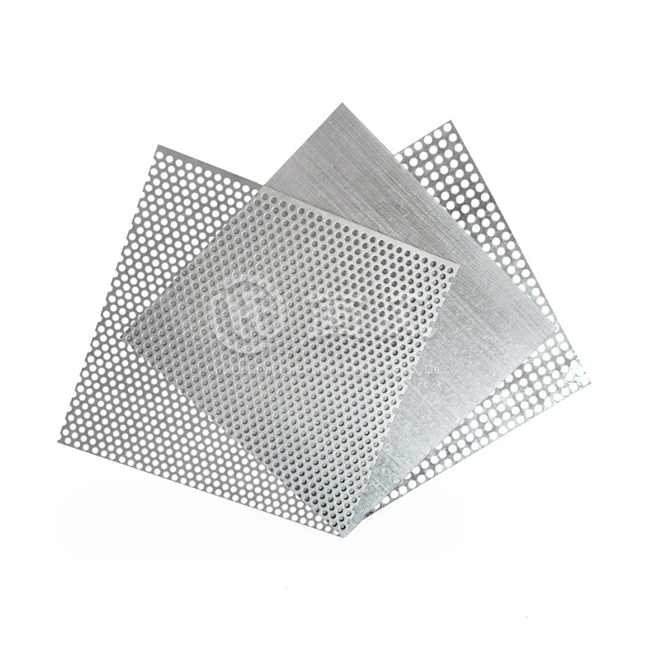

Standard Corrugated Sheet Metal Wall Panel configurations satisfy the majority of commercial and industrial building requirements, but certain projects demand customized solutions that address unique architectural visions, structural constraints, or performance specifications. Comprehensive manufacturers maintain flexibility to modify standard products or develop entirely new configurations that solve challenging application requirements. This customization capability proves particularly valuable for renovation projects involving existing buildings with non-standard dimensions, architectural installations requiring specific profile patterns, or industrial applications with specialized corrosion resistance needs. Panel width customization accommodates varying structural bay spacing and reduces waste from trimming standard widths to fit specific building dimensions. Custom width production requires minimum order quantities that justify roll-forming die adjustments and production setup time, but the resulting material efficiency and improved appearance often justify this investment for large-scale projects. Panel lengths can extend up to twelve meters depending on handling and transportation constraints, enabling single-piece coverage of tall building walls without horizontal seams that interrupt appearance continuity and create potential water infiltration paths. Specialized corrugation profiles serve aesthetic objectives or functional requirements beyond standard wave patterns. Deeper corrugations provide enhanced structural capacity for applications requiring extended spanning distances between supports or resistance to extreme wind loading. Asymmetric corrugation patterns create distinctive visual effects that differentiate buildings from conventional industrial aesthetics. Custom perforation patterns integrated into corrugated profiles enable ventilation for agricultural buildings, sound absorption for noise-sensitive installations, or decorative screening applications.

Color Matching and Surface Texture Variations

Precise color matching capabilities enable Corrugated Sheet Metal Wall Panels to coordinate with existing building elements, corporate branding standards, or architect-specified palettes. Advanced spectrophotometric analysis equipment measures color values from physical samples with precision sufficient to formulate matching paint systems. This technology proves invaluable for renovation projects requiring seamless integration with weathered existing panels or matching specific architectural materials like masonry, concrete, or glazing systems. Custom color formulation services typically require lead times of several weeks for coil coating operations plus minimum order quantities reflecting specialized production runs. Surface texture variations enhance visual interest and modify light reflection characteristics. Smooth finishes provide contemporary appearance with high gloss potential, maximizing color vibrancy and creating striking architectural statements. Embossed or stucco textures reduce glare from direct sunlight while creating subtle visual depth that softens industrial aesthetics. Textured finishes also help conceal minor surface imperfections and reduce visibility of dirt accumulation between cleaning cycles. The texture selection influences coating performance characteristics, with smooth surfaces generally demonstrating superior chalk resistance and color retention compared to heavily textured alternatives. Xi'an Huafeng Construction Engineering Co., Ltd. provides comprehensive customization services encompassing color formulation, pattern design, and dimensional modifications. Our technical team collaborates directly with architects and project owners to translate design concepts into manufacturable specifications that balance aesthetic objectives with performance requirements and budget constraints. Sample production capabilities enable physical mockups that validate appearance expectations and installation details before committing to full production runs. This consultative approach minimizes costly specification errors and ensures delivered products precisely match project requirements.

Conclusion

Selecting appropriate Corrugated Sheet Metal Wall Panels demands systematic evaluation of material properties, coating systems, gauge specifications, supplier capabilities, and project-specific requirements to ensure decades of reliable performance and satisfactory appearance.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

Xi'an Huafeng Construction Engineering Co., Ltd., established in 2018 and recognized as a Shaanxi Province high-tech enterprise, specializes in comprehensive metal roofing and wall system solutions with first-level curtain wall qualifications and third-level steel structure certifications. Our integrated manufacturing infrastructure spans three facilities including a two-hundred-thousand-square-meter raw material production plant in Anhui and processing operations in Hangzhou and Xi'an, housing seven color coating lines, ten shearing production lines, and over forty specialized machines supporting monthly output exceeding one thousand tons. We maintain more than twenty registered patents and comprehensive ISO9001, ISO14001, and SGS certifications while serving Fortune 500 clients with customized Corrugated Sheet Metal Wall Panels featuring thickness ranges from 0.3 to 1.2 millimeters, widths from 600 to 1200 millimeters, premium HDP and PVDF coatings, and thirty-year warranties.

As a leading China Corrugated Sheet Metal Wall Panels factory, China Corrugated Sheet Metal Wall Panels supplier, and China Corrugated Sheet Metal Wall Panels manufacturer offering China Corrugated Sheet Metal Wall Panels wholesale, we provide competitively priced Corrugated Sheet Metal Wall Panels for sale with transparent Corrugated Sheet Metal Wall Panels price structures and guaranteed High Quality Corrugated Sheet Metal Wall Panels backed by rapid fifteen-to-twenty-day delivery timelines and flexible 500-square-meter minimum order quantities. Our comprehensive one-stop service encompasses project drawing deepening, structural analysis, drainage simulation, material procurement from premium brands including Baosteel and Alucosuper, rigorous incoming material inspection with salt spray testing and adhesion verification, precision production with real-time quality control, detailed finished product packaging with sectional identification systems, on-site construction guidance, and complete acceptance procedures with maintenance support. Contact our technical team at huafeng@hfmetalroof.com to discuss your specific requirements, request detailed product samples, obtain project-specific quotations, or schedule facility tours demonstrating our manufacturing capabilities and quality assurance protocols.

References

1. Metal Construction Association. "Design Guide for Corrugated Metal Wall and Roof Systems." Technical Publication Series, 2023. Authors: James Patterson, Robert Chen, Sarah Williams.

2. American Society of Civil Engineers. "Minimum Design Loads and Associated Criteria for Buildings and Other Structures: ASCE/SEI 7-22." Structural Engineering Institute, 2022. Authors: Lawrence Novak, Thomas Sabol, Committee Members.

3. Sheet Metal and Air Conditioning Contractors' National Association. "Architectural Sheet Metal Manual." 8th Edition, 2022. Authors: SMACNA Technical Committee, Editor Michael Thompson.

4. National Coil Coating Association. "Guide to High-Performance Architectural Coatings for Metal Building Products." Industry Standards Document, 2023. Authors: David Martinez, Jennifer Lee, Technical Advisory Panel.

5. Steel Framing Industry Association. "Installation Guidelines for Corrugated Metal Panels in Commercial Construction." Technical Bulletin No. 24, 2023. Autho

_1768986098819.webp)