Modern architecture demands materials that combine aesthetic appeal with exceptional functionality. The Classic Rib Corrugated Panel has emerged as a versatile solution for contemporary construction projects worldwide. These ribbed metal panels offer architects and contractors a perfect balance of structural integrity, weather resistance, and visual appeal. Their distinctive corrugated profile not only enhances strength but also creates striking architectural features across residential, commercial, and industrial applications. Understanding these diverse applications helps construction professionals make informed decisions for their next project.

Industrial and Warehouse Facilities

Industrial buildings represent one of the most critical applications for Classic Rib Corrugated Panel systems. Manufacturing facilities, distribution centers, and warehouse complexes rely heavily on these durable siding solutions. The ribbed design provides exceptional structural strength while maintaining cost-effectiveness over large surface areas.Steel panels with folded profiles excel in industrial environments due to their ability to withstand heavy loads and extreme weather conditions. These lightweight panels reduce overall building weight, allowing for more economical foundation designs. The galvanized steel construction resists corrosion from industrial chemicals and moisture, ensuring decades of reliable performance.

Large-scale logistics centers particularly benefit from layered sheet installations. Amazon distribution centers, FedEx sorting facilities, and automobile manufacturing plants frequently utilize these metal panel systems. The panels accommodate thermal expansion and compression while maintaining weathertight seals. Installation teams can complete massive projects efficiently thanks to standardized panel dimensions and straightforward connection methods.Weather-resistant coatings further enhance industrial applications. PE and PVDF finishes protect against UV degradation and chemical exposure. These protective layers maintain color stability and surface integrity throughout the panel’s service life. Maintenance requirements remain minimal, reducing operational costs for facility owners.

Commercial Retail and Shopping Centers

Retail design progressively consolidates folded metal veneers to create cutting-edge, unmistakable appearances. Shopping centers, big-box stores, and mixed-use developments utilize these engineering boards to achieve modern aesthetics while controlling construction budgets.The flexibility of metal construction allows designers to create dynamic building envelopes. Even and vertical panel installations produce varied visual effects. Color choices range from traditional neutrals to bold complementary tones. Custom finishes can mimic wood grain or stone surfaces, expanding design possibilities without sacrificing durability.

Exterior panels on retail buildings must withstand constant foot traffic vibrations and frequent door operations. Folded profiles distribute stress effectively, preventing panel weakness and maintaining structural integrity. The ribbed configuration also conceals minor imperfections that may develop over time.Energy efficiency considerations drive many retail designs. Insulated panels combine foam cores between metal faces, significantly improving thermal performance. These building envelope systems reduce HVAC loads while maintaining the distinctive folded appearance. Reflective coatings further enhance energy savings by minimizing solar heat gain.

Transportation and Infrastructure Projects

Transportation hubs showcase Classic Rib Corrugated Panel applications in high-visibility public projects. Airport terminals, train stations, and bus transit facilities require materials that combine durability with architectural sophistication. These infrastructure projects often serve as architectural landmarks within their communities.Railway stations particularly benefit from corrugated roofing materials. The panels span long distances between structural supports while resisting wind uplift forces. Sound dampening properties help reduce noise transmission from passing trains. Fire-resistant treatments meet stringent building codes for public assembly spaces.Parking structures represent another significant transportation application. Multi-level garages expose metal facade systems to vehicle exhaust, de-icing chemicals, and temperature cycling. Galvanized substrates resist corrosion from these harsh conditions. Perforated panels provide ventilation while maintaining security and weather protection.Bridge enclosures and maintenance facilities utilize structural panels for equipment protection. These specialized applications require custom engineering to accommodate unique loading conditions. Panel installation must accommodate structural movement while maintaining weathertight performance.

Agricultural and Equestrian Buildings

Agricultural applications drive noteworthy request for cost-effective metal material arrangements. Dairy horse shelters, grain capacity offices, and animal buildings require materials that withstand country natural conditions while providing long-term value. Ventilation necessities in rural buildings make layered profiles especially appropriate. The ribbed plan allows normal wind current designs that help maintain proper indoor conditions. Edge ventilation frameworks are consistently coordinated with layered material materials. Cross-ventilation decreases dampness buildup and improves creature comfort.

Equestrian offices require both functionality and appearance. Horse preparing fields, breeding offices, and boarding stables often serve both private and commercial purposes. Metal boards provide the strength needed for rural use while maintaining stylish appeal for property owners. Chemical resistance becomes significant in agrarian situations. Creature waste, fertilizers, and cleaning chemicals can accelerate erosion of inferior materials. Quality roof cladding frameworks combine protective coatings specifically designed for rural introduction conditions.

Residential and Architectural Accents

Contemporary residential design increasingly incorporates industrial materials for visual contrast and durability. Classic Rib Corrugated Panel systems appear in single-family homes, townhouse developments, and apartment complexes as both primary cladding and accent materials.Wall panels create striking feature walls that complement traditional siding materials. Architects combine corrugated metal with wood, brick, or stucco to achieve sophisticated mixed-material facades. The linear patterns add texture and visual interest while maintaining weather protection.Residential applications require careful attention to thermal bridging and condensation control. Insulated panel systems prevent temperature transfer through the building envelope. Vapor barriers and proper ventilation design eliminate moisture problems that could damage interior finishes.Custom color matching allows corrugated panels to complement existing architectural elements. Manufacturers offer extensive color palettes that coordinate with popular residential finishes. Special-order colors accommodate unique design requirements for high-end residential projects.

Sports and Recreation Facilities

Athletic facilities present unique challenges that corrugated metal systems handle effectively. Gymnasium buildings, sports complexes, and recreation centers require large clear spans with minimal interior columns. The strength-to-weight ratio of ribbed panels supports these architectural requirements.Swimming pool enclosures expose building materials to high humidity and chemical vapors. Specialized coatings resist chlorine corrosion while maintaining structural integrity. Proper ventilation design prevents condensation damage to interior components. Panel selection must consider thermal movement from temperature and humidity cycling.Outdoor recreation facilities like pavilions and covered courts utilize corrugated roofing for weather protection. These structures often incorporate natural ventilation strategies that take advantage of the ribbed panel profile. Acoustic considerations become important in sports applications where sound reflection affects performance.Community recreation centers frequently operate under tight budget constraints. The cost-effectiveness of corrugated panel systems allows municipalities to maximize building area within available funding. Low maintenance requirements reduce long-term operational costs for public facilities.

Educational and Institutional Buildings

Schools, universities, and public buildings increasingly specify corrugated metal systems for their combination of durability and design flexibility. These institutional projects require materials that withstand heavy use while maintaining attractive appearances over extended service lives.Laboratory and workshop buildings benefit from the chemical resistance of quality metal panels. Science facilities expose building materials to various chemicals and temperature extremes. Proper panel selection ensures long-term performance in these demanding environments. Easy cleaning and maintenance support sanitary requirements in educational settings.Dormitory and student housing projects utilize corrugated panels for cost-effective construction. The speed of panel installation helps meet tight project schedules common in educational construction. Energy-efficient panel systems support sustainability goals while controlling operational costs.Institutional projects often require compliance with specific architectural standards. Panel manufacturers provide technical documentation supporting LEED certification requirements. Fire resistance ratings and wind load calculations ensure code compliance for public buildings.

Conclusion

Classic Rib Corrugated Panel systems demonstrate remarkable versatility across modern architectural applications. From industrial facilities to residential accents, these durable materials provide cost-effective solutions that meet diverse performance requirements. Their combination of structural strength, weather resistance, and aesthetic flexibility makes them ideal for contemporary construction projects worldwide. Professional installation and quality materials ensure decades of reliable performance, making corrugated panels an excellent investment for building owners and contractors alike.

Frequently Asked Questions

What thickness options are available for Classic Rib Corrugated Panels?

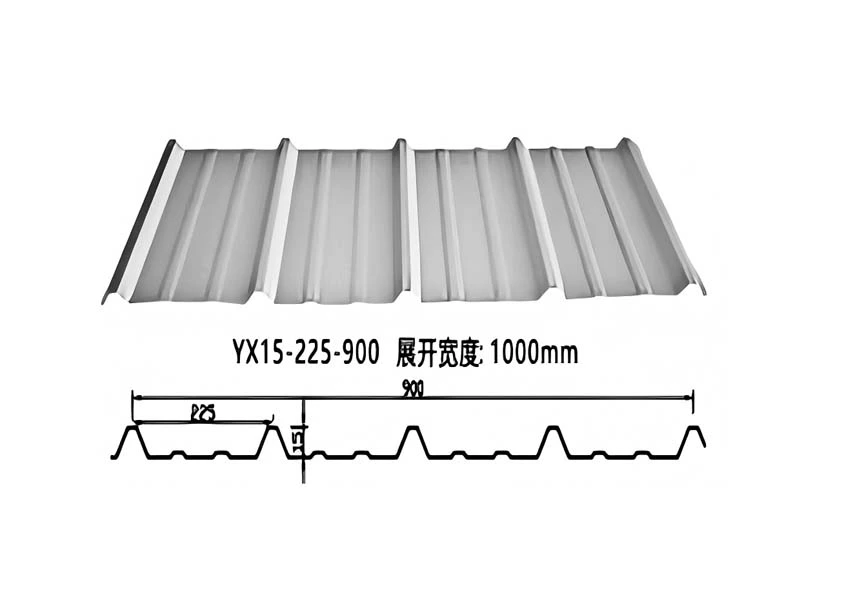

Standard thickness ranges from 0.3mm to 1.2mm for most applications. Thicker gauges provide increased strength for high-wind areas or heavy snow loads. Thinner materials offer cost savings for interior applications or mild climate conditions. Custom thickness specifications accommodate unique project requirements.

How do corrugated panels compare to standing seam systems?

Corrugated panels typically cost less than standing seam systems while providing excellent performance for many applications. The exposed fastener installation simplifies construction but requires proper sealing techniques. Standing seam systems offer concealed fasteners and enhanced weather resistance at higher cost.

What coating options provide the best longevity?

PVDF coatings offer superior weather resistance and color retention compared to PE finishes. These premium coatings justify their higher cost through extended service life and reduced maintenance requirements. HDP coatings provide intermediate performance levels suitable for most commercial applications.

Can corrugated panels accommodate curved architectural features?

Limited curving is possible with corrugated panels depending on the radius and panel orientation. Tight radius applications may require specialized forming techniques or alternative panel profiles. Manufacturers can provide guidance on feasible curvature limits for specific panel configurations.

What fire resistance ratings apply to metal corrugated panels?

Metal panels themselves are non-combustible but overall assembly ratings depend on substrate materials and construction details. Proper installation over approved sheathing systems achieves required fire resistance ratings. Building code requirements vary by occupancy type and construction classification.

How do environmental factors affect panel selection?

Coastal environments require enhanced corrosion protection through upgraded coatings or substrate materials. High-wind areas need thicker gauges and improved fastening systems. Snow load requirements influence structural design and panel thickness selection. Local climate data guides appropriate material specifications.

Upgrade Your Next Project with Professional Classic Rib Corrugated Panel Solutions

Huafeng Construction Engineering delivers industry-leading corrugated roofing solutions backed by three manufacturing facilities and over 40 specialized production machines. As a trusted Classic Rib Corrugated Panel supplier, we provide comprehensive design-to-installation services that ensure project success. Our 30-year warranty, international certifications, and 1000-ton monthly production capacity make us the preferred choice for contractors worldwide. Contact huafeng@hfmetalroof.com today to discuss your specific requirements and receive expert technical support.

References

1. Building Construction Illustrated by Francis D.K. Ching, 5th Edition, John Wiley & Sons, 2014

2. Metal Building Systems Manual by Metal Building Manufacturers Association, 3rd Edition, 2020

3. Architectural Metal Panels: Applications and Installation Guidelines by National Roofing Contractors Association, 2019

4. Sustainable Building Design: Principles and Practice in Metal Construction by Robert Hutchinson, Taylor & Francis, 2021

5. Modern Steel Construction: Design and Applications in Contemporary Architecture by James Patterson, McGraw-Hill Education, 2020

6. Weather-Resistant Building Design: Performance Standards for Metal Building Systems by International Building Code Council, 2022