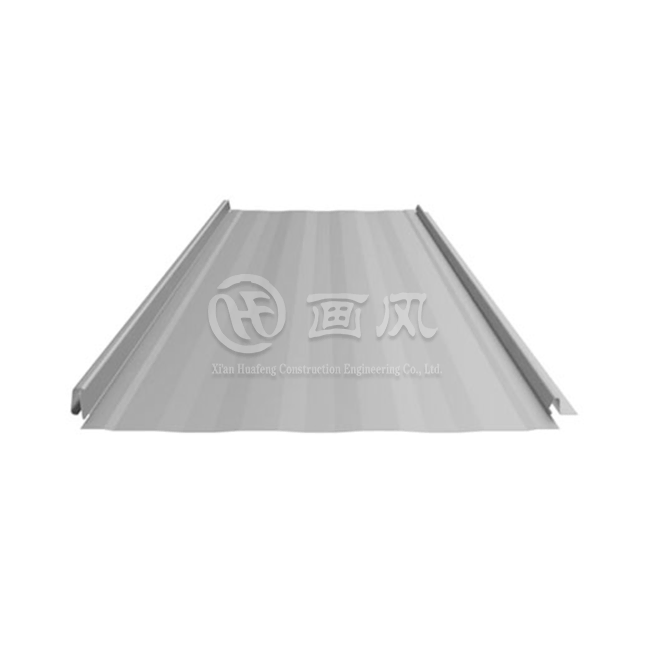

Modern construction projects demand roofing solutions that combine exceptional durability, aesthetic appeal, and installation efficiency. Snap Lock Metal Roof Panels represent the pinnacle of contemporary metal roofing technology, offering builders and contractors an interlocking system that eliminates exposed fasteners while providing superior weather protection. These engineered panels feature precision-crafted edges that seamlessly connect, creating continuous weatherproof barriers ideal for commercial, industrial, and residential applications. With their streamlined installation process and remarkable longevity, these panels have become the preferred choice for discerning builders seeking reliable performance.

What Are Snap Lock Metal Roof Panels and How Do They Work?

Understanding the essential mechanics of interlocking metal material frameworks is fundamental for development experts assessing cutting edge material choices. These boards utilize an imaginative edge-connection plan that makes secure joints without conventional uncovered securing methods.

Innovative Interlocking Design Technology

The snap bolt component works through accurately designed male and female edges that interconnect with an capable of being heard snap, affirming legitimate engagement. This association strategy disposes of the require for uncovered screws or bolts, making a clean stylish whereas upgrading climate resistance. The interlocking framework disperses auxiliary loads equally over the whole roof surface, moving forward generally basic astuteness compared to conventional affixed panels.

Superior Weather Sealing Performance

The ceaseless crease plan makes an continuous boundary against dampness penetration, wind elevate, and warm development. Each board association shapes a weatherproof seal that keeps up astuteness beneath extraordinary temperature changes and extreme climate conditions. This progressed fixing innovation altogether diminishes upkeep prerequisites whereas expanding the roof system's operational lifespan.

Simplified Installation Process

Professional installers appreciate the streamlined establishment strategy that diminishes labor time and specialized instrument prerequisites. The snap bolt framework permits for proficient board situating and association, quickening extend completion whereas keeping up accuracy arrangement. This establishment productivity deciphers specifically into taken a toll investment funds for temporary workers overseeing different ventures at the same time.

Benefits of Snap Lock Metal Roof Panels for Global B2B Projects

Large-scale commercial and mechanical ventures require material arrangements that provide reliable execution over assorted natural conditions and extend details. These metal material frameworks give various points of interest that address the complex prerequisites of worldwide development ventures.

Enhanced Durability and Weather Resistance

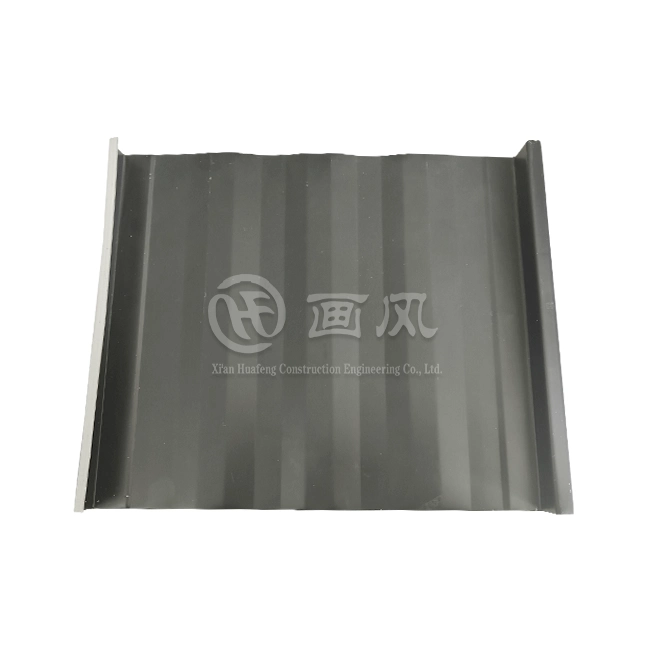

Xi'an Huafeng Development Designing Co., Ltd. fabricates these boards utilizing premium materials counting aluminum combination, galvanized steel, stainless steel, copper, and titanium zinc, with thickness alternatives extending from 0.4mm to 1.2mm. The PVDF and PE coating wraps up give uncommon erosion resistance and color maintenance, guaranteeing long-term tasteful request indeed in unforgiving coastal situations or mechanical zones with tall chemical exposure. These progressed coating frameworks experience thorough testing to meet universal measures counting ASTM, Clamor, JIS, BS, and GB/T details. The combination of high-quality base materials and premium wraps up empowers these boards to withstand extraordinary temperature varieties, UV radiation, and chemical presentation whereas keeping up auxiliary judgment all through their 30-year guarantee period, making Snap Lock Metal Roof Panels a durable and reliable option.

Energy Efficiency and Thermal Performance

Modern metal material frameworks contribute essentially to building vitality proficiency through their intelligent properties and warm administration capabilities. The 45mm board tallness makes ideal discuss circulation underneath the material surface, lessening warm exchange and making strides in general building warm execution. This improved separator capability underpins supportability activities whereas decreasing long-term operational costs for building owners.

Cost-Effective Installation and Maintenance

The streamlined establishment prepare decreases labor necessities and quickens extend timelines, giving quick fetched benefits for temporary workers overseeing tight plans. Also, the negligible upkeep necessities related with these material frameworks decrease lifecycle costs, making them especially alluring for large-scale commercial and mechanical applications where continuous upkeep get to may be challenging or expensive.

Comparing Snap Lock Metal Roof Panels with Other Roofing Types

Evaluating material choices requires cautious thought of execution characteristics, establishment prerequisites, and long-term esteem recommendations. This comprehensive comparison highlights the points of interest of snap bolt frameworks relative to elective material technologies.

Standing Seam vs. Snap Lock Systems

While standing crease frameworks offer great execution, they regularly require specialized establishment hardware and broad specialized ability. Snap bolt boards give comparable climate security and tasteful request whereas rearranging the establishment handle and diminishing gear necessities. The snap bolt association strategy dispenses with the require for complex seaming apparatus, making these frameworks more available for temporary workers with changing gear capabilities.

Traditional Fastened Panel Limitations

Conventional screw-down board frameworks depend on uncovered latches that make potential spill focuses and require standard support consideration. The Snap Lock Metal Roof Panels design kills these vulnerabilities by making nonstop weatherproof associations without uncovered infiltrations. This essential plan advantage altogether diminishes long-term support costs whereas moving forward by and large framework reliability.

Tile and Membrane System Comparisons

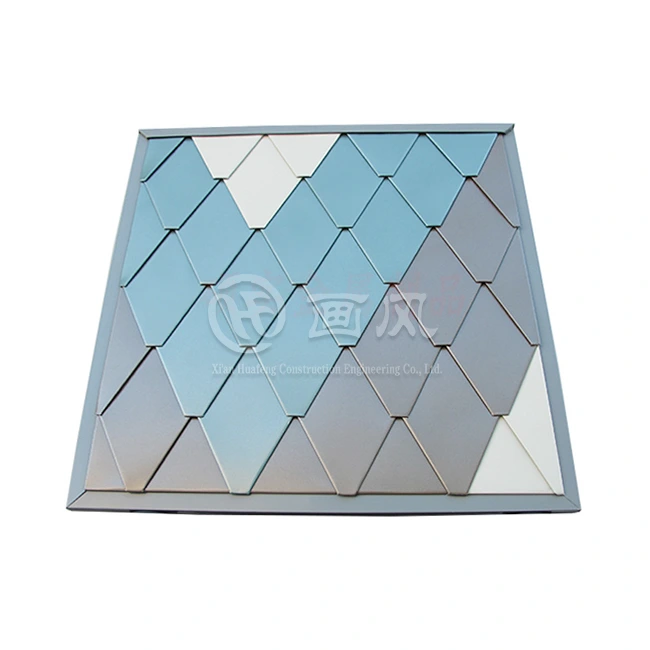

Traditional material materials like tiles and film frameworks frequently require broad auxiliary bolster and complex establishment strategies. Metal snap bolt frameworks give predominant strength-to-weight proportions, lessening basic stack necessities whereas advertising quicker establishment and upgraded strength. The Course A fire rating of metal boards gives extra security benefits compared to natural material materials.

Procuring Snap Lock Metal Roof Panels: What Buyers Need to Know

Strategic procurement of metal roofing systems requires understanding technical specifications, quality standards, and supply chain considerations that impact project success. Professional buyers must evaluate multiple factors to ensure optimal product selection and vendor relationships.

Material Quality and Specification Standards

Huafeng's manufacturing capabilities encompass three factories with seven production lines and more than 40 specialized machines, enabling consistent quality control and reliable production capacity. The company's 1000-ton monthly supply capacity ensures adequate inventory availability for large-scale projects, while the 15-20 day delivery timeframe supports tight construction schedules.Quality assurance protocols include comprehensive testing of base materials, coating adhesion, and dimensional accuracy to meet international standards. The availability of customized RAL colors and specialized finishes enables architects and designers to achieve specific aesthetic objectives while maintaining performance requirements.

Customization and Project-Specific Requirements

Professional procurement teams appreciate the extensive customization options available for panel dimensions, material selection, and finish specifications. The 500㎡/1T minimum order quantity accommodates medium to large-scale projects while providing economies of scale for bulk purchasing arrangements. Custom color matching and specialized coating options enable seamless integration with existing architectural elements and design specifications.

Vendor Qualification and Certification Requirements

Xi'an Huafeng Construction Engineering Co., Ltd. maintains Grade 1 building curtain wall qualifications and Grade 3 steel structure certifications, demonstrating compliance with industry standards and technical capabilities. The company's high-tech enterprise recognition reflects ongoing investment in research and development, ensuring access to innovative Snap Lock Metal Roof Panels technologies and manufacturing processes.

Installation and Maintenance Guide for Snap Lock Metal Roof Panels

Proper installation techniques and proactive maintenance protocols maximize the performance and longevity of metal roofing systems in demanding commercial and industrial environments. Understanding these requirements enables project managers to plan effectively and ensure optimal system performance.

Professional Installation Best Practices

Successful installation begins with accurate substrate preparation and precise panel alignment to ensure proper snap lock engagement. Installation crews must verify panel dimensions and spacing requirements before beginning installation to prevent alignment issues that could compromise system integrity. The snap lock connection requires specific engagement techniques to ensure complete sealing and structural connection.Temperature considerations during installation affect panel expansion characteristics and connection tolerances. Professional installers account for thermal movement by maintaining appropriate spacing and connection pressure throughout the installation process. This attention to detail prevents future performance issues related to thermal cycling and structural movement.

Preventive Maintenance Protocols

Regular inspection schedules should include verification of panel connections, drainage system functionality, and coating condition assessment. The 30-year warranty period reflects the expected service life under normal maintenance conditions, but proactive care can extend performance well beyond warranty periods. Cleaning protocols should utilize appropriate materials and techniques to preserve coating integrity while removing environmental contaminants.

Troubleshooting Common Issues

Panel warping typically results from improper installation techniques or inadequate thermal movement accommodation. Connection loosening may indicate foundation settlement or thermal stress concentration requiring professional evaluation. Weather seal degradation usually occurs gradually and can be addressed through targeted maintenance rather than complete system replacement.

Conclusion

The construction industry continues to demand roofing solutions that deliver exceptional performance, aesthetic appeal, and installation efficiency. Snap Lock Metal Roof Panels successfully address these requirements through innovative design, premium materials, and streamlined installation processes. These systems provide contractors and building owners with reliable, long-term roofing solutions that minimize maintenance requirements while maximizing performance value. The combination of advanced materials, precision manufacturing, and comprehensive support services makes these panels an excellent choice for discerning construction professionals.

FAQ

What makes snap lock panels suitable for extreme weather conditions?

The interlocking design creates continuous weatherproof seams that resist moisture penetration, wind uplift, and thermal expansion. Premium materials like aluminum alloy and stainless steel provide excellent corrosion resistance in coastal environments, while PVDF coatings maintain color stability under intense UV exposure. The 45mm panel height enhances structural strength against snow loads and high winds.

How long do these metal roofing systems typically last?

Huafeng provides a 30-year warranty on their snap lock panels, reflecting confidence in material quality and manufacturing processes. With proper installation and routine maintenance, these systems often exceed warranty periods significantly. The combination of premium base materials and advanced coating systems ensures long-term performance in diverse environmental conditions.

What customization options are available for specific projects?

Material options include aluminum alloy, galvanized steel, stainless steel, copper, and titanium zinc in thicknesses from 0.4mm to 1.2mm. Custom RAL colors and specialized finishes enable precise color matching for architectural requirements. Panel dimensions can be customized to accommodate specific design requirements while maintaining structural performance standards.

Partner with Huafeng for Premium Snap Lock Metal Roof Panel Solutions

Huafeng's extensive manufacturing capabilities and commitment to quality excellence make us the ideal snap lock metal roof panels supplier for your next project. Our three factories and seven production lines ensure reliable delivery of premium roofing systems that meet the most demanding project specifications. Contact huafeng@hfmetalroof.com today to discuss your requirements and discover how our expertise can enhance your construction projects. Visit hfmetalroof.com to explore our complete product portfolio and request customized quotations that optimize your procurement budget while delivering exceptional performance value.

References

1. National Roofing Contractors Association. "Metal Roofing Systems: Design and Installation Guidelines for Commercial Applications." NRCA Technical Manual, 2023.

2. American Institute of Steel Construction. "Specification for Structural Steel Buildings: Metal Roof Panel Systems and Connection Requirements." AISC 360-22 Standards.

3. Metal Construction Association. "Guidelines for Snap Lock Seam Metal Roofing Installation and Performance Standards." MCA Technical Bulletin 15-2023.

4. International Code Council. "International Building Code: Metal Roof Panel Systems and Weather Resistance Requirements." ICC Building Standards 2024.

5. Steel Construction Institute. "Metal Roofing Design Guide: Interlocking Panel Systems for Commercial and Industrial Applications." SCI Publication P432.

6. Construction Specifications Institute. "MasterFormat Specification: Metal Roof Panel Systems Installation and Quality Assurance." CSI Division 07 41 13.

_1768986098819.webp)