Picture this scenario: you've invested months planning your commercial building project, only to discover that your siding choice has already faded after just three years, forcing costly replacements and damaging your building's aesthetic appeal. This nightmare is more common than you think when builders and architects select inferior color and finish systems for aluminum corrugated siding panels. The right combination of color and finish technology doesn't just transform building aesthetics—it protects your investment for decades while maximizing property value and buyer appeal.

Understanding PVDF and HDP Coating Systems for Aluminum Corrugated Siding Panels

When specifying corrugated aluminum siding panels for architectural projects, the coating system you select determines both the longevity and visual performance of your building envelope. The finish isn't merely decorative—it serves as the primary defense mechanism against environmental degradation, ultraviolet radiation, and chemical exposure that can compromise panel integrity over time. PVDF coating technology represents the premium standard in protective finishes for aluminum corrugated siding panels. This fluoropolymer-based system contains approximately seventy percent polyvinylidene fluoride resin, creating a molecular structure that exhibits exceptional resistance to chalking, fading, and chemical attack. The carbon-fluorine bonds within PVDF coatings are among the strongest in organic chemistry, which explains why these finishes maintain their original appearance even after decades of exposure to harsh environmental conditions. Buildings clad with PVDF-coated corrugated aluminum siding panels consistently demonstrate superior color retention compared to alternative coating systems, with measurable color change values remaining within acceptable industry tolerances for twenty-five to thirty years.

HDP coating systems, also recognized as high-durability polyester formulations, provide an economically viable alternative while still delivering substantial performance benefits. These advanced polyester-based finishes incorporate specialized additives that enhance ultraviolet stability and improve resistance to atmospheric pollutants. While HDP coatings typically exhibit a service life of fifteen to twenty years before noticeable degradation occurs, they remain an excellent choice for projects where budget constraints require balanced performance and initial investment considerations. Both PVDF and HDP finishes available on our aluminum corrugated siding panels comply with rigorous international standards including ASTM, DIN, JIS, BS, and GB/T specifications, ensuring consistent quality across global project requirements. The application process for these premium coatings involves multiple layers applied through continuous coil coating technology. Our manufacturing facilities utilize seven dedicated color coating production lines that ensure uniform film thickness between 0.7 and 1.0 mils for standard applications. This precision coating process, combined with our incoming material inspection protocols that include adhesion testing, salt spray resistance evaluation, and accelerated weathering analysis, guarantees that every panel leaving our facility meets or exceeds specified performance criteria.

Color Selection Strategies That Enhance Market Appeal

Color psychology plays a critical role in architectural specification, particularly when aluminum corrugated siding panels serve as the primary visual element of building facades. Market research consistently demonstrates that certain color families generate stronger positive responses from prospective tenants, customers, and property evaluators. Neutral tones including various shades of gray, beige, and off-white dominate contemporary commercial architecture because these colors provide timeless appeal that transcends temporary design trends while offering excellent heat reflectivity properties that contribute to energy efficiency. Our corrugated aluminum siding panels are available in an extensive color palette that accommodates diverse architectural visions and regional preferences. Standard colors maintained in inventory include classic whites, sophisticated grays, earth tones, and blues that ship immediately upon order confirmation with no minimum quantity requirements. These readily available options streamline project timelines and eliminate the extended lead times associated with custom color matching. For projects requiring specific brand colors or unique aesthetic statements, our custom color development program can match virtually any RAL, Pantone, or proprietary color specification with a minimum order quantity of five hundred square meters.

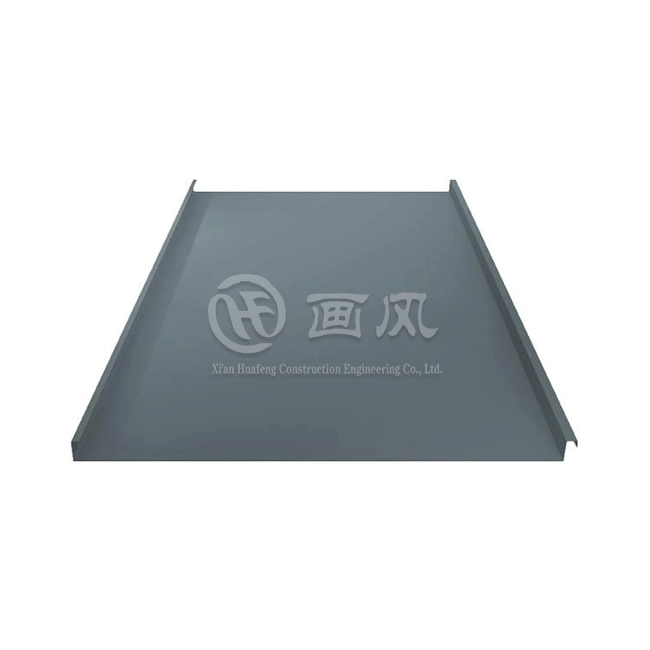

Dark colors on aluminum corrugated siding panels create dramatic visual impact and convey modern sophistication, making them increasingly popular for urban commercial developments and contemporary industrial facilities. However, darker hues absorb more solar radiation, which can result in higher surface temperatures and potential thermal expansion considerations. Our engineering team provides thermal movement calculations and appropriate fastening recommendations to accommodate the thermal behavior of dark-colored panels, ensuring long-term performance without buckling or distortion. Conversely, lighter colors reflect substantial portions of incident solar radiation, reducing cooling loads and contributing to sustainable building performance metrics that may qualify for green building certifications. The finish texture also influences perceived color intensity and visual character. Our standard smooth finish provides clean, modern aesthetics with maximum color clarity, while textured or embossed surface options can add dimensional interest and help minimize the visibility of minor surface imperfections that might occur during transportation or installation. The combination of color selection and finish texture should align with overall architectural intent, surrounding context, and long-term maintenance accessibility.

Technical Specifications and Customization Capabilities

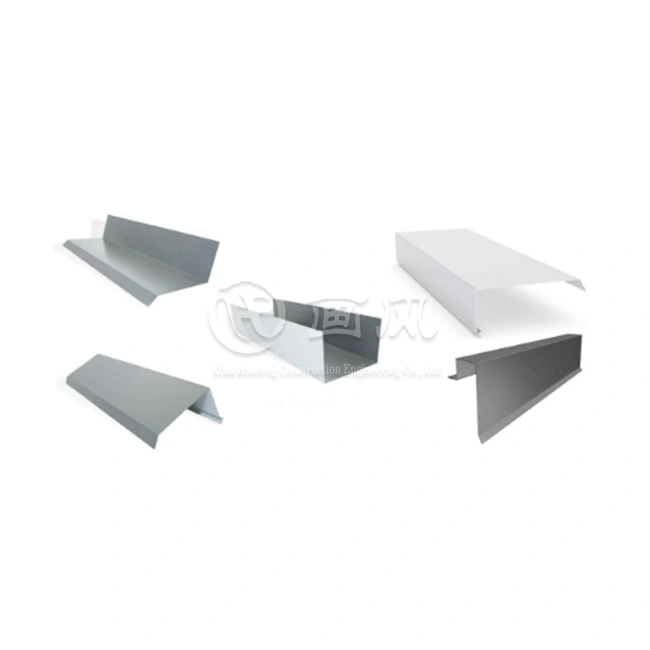

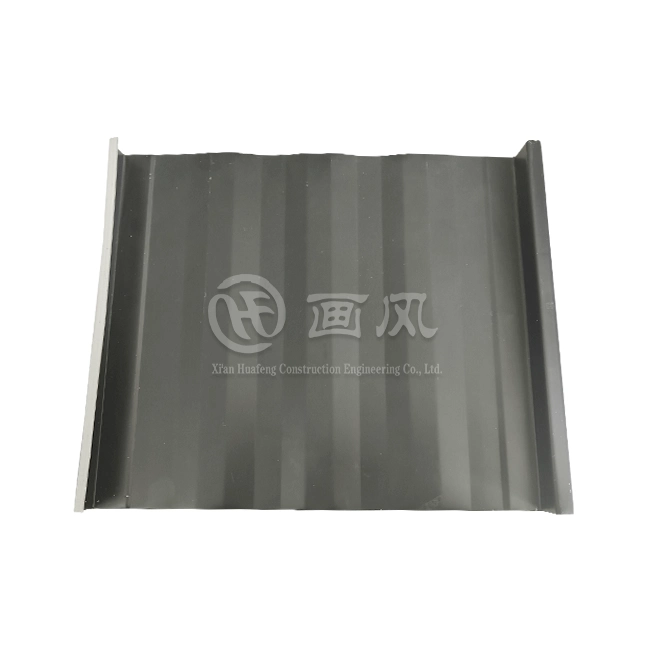

Manufacturing flexibility represents a crucial competitive advantage when sourcing aluminum corrugated siding panels for complex architectural applications. Our production infrastructure encompasses three specialized manufacturing facilities with combined monthly output capacity exceeding one thousand tons, supported by more than forty dedicated processing machines including shearing equipment, press brakes, and precision forming systems. This substantial manufacturing capability enables us to accommodate project schedules ranging from rapid design-build timelines to phased construction programs spanning multiple years. Panel width specifications for our corrugated aluminum siding panels range from six hundred to twelve hundred millimeters, with custom widths available upon request to optimize coverage efficiency for specific building geometries. Material thickness options span from 0.4 millimeters for interior applications or climate-controlled environments up to 1.2 millimeters for exterior cladding exposed to severe weather conditions or potential impact scenarios. The selection of appropriate thickness depends on multiple factors including span length between structural supports, local wind load requirements, and desired acoustic performance characteristics. The corrugated profile itself provides inherent structural advantages compared to flat panel systems. The alternating peaks and valleys create a geometry that significantly increases the moment of inertia perpendicular to the panel surface, allowing longer unsupported spans while maintaining structural adequacy. Our standard corrugation profiles include industry-common configurations with depths ranging from fifteen to fifty millimeters, with thirty-two millimeter profiles representing the most frequently specified option for general commercial and industrial applications. Custom corrugation patterns can be developed for signature projects requiring distinctive visual character or specific performance attributes.

Material Selection and Quality Assurance Protocols

The aluminum alloys utilized in our corrugated aluminum siding panels derive from carefully selected suppliers who maintain rigorous quality control programs and provide comprehensive material certifications. We primarily specify 3003 and 5052 series aluminum alloys, each offering distinct performance characteristics suitable for different application requirements. The 3003 alloy contains manganese as the primary alloying element, providing excellent formability and moderate strength properties ideal for architectural cladding applications. The 5052 alloy incorporates magnesium for enhanced strength and superior corrosion resistance, making it particularly appropriate for coastal environments or industrial settings with aggressive atmospheric conditions. Our procurement department maintains approved supplier lists that include recognized industry leaders such as Alucosuper, YATAI, and LIDAO for aluminum products, along with BAOSTEEL, GUANZHOU, and XINYU for steel components used in integrated building envelope systems. Every incoming material shipment undergoes comprehensive inspection procedures before release to production. These quality verification protocols include dimensional verification, surface quality assessment, and mechanical property confirmation through standardized testing methods. Material test reports from third-party laboratories accompany each delivery, providing independent verification of chemical composition and mechanical characteristics.

The incoming material inspection process extends beyond simple visual examination to include instrumental analysis of coating properties. Our quality assurance team performs salt spray testing per ASTM B117 standards to evaluate corrosion resistance, adhesion testing using both cross-hatch and pull-off methodologies, hardness measurements, impact resistance evaluation, and film thickness verification using calibrated coating thickness gauges. Color consistency is confirmed through spectrophotometric analysis that compares received materials against established color standards, ensuring that panel colors remain uniform across multiple production runs and material lots. This comprehensive quality framework, certified under ISO9001 and ISO14001 management systems, guarantees that corrugated aluminum siding panels consistently meet or exceed specified performance requirements.

Installation Considerations and Long-Term Performance

Proper installation methodology directly influences the service life and performance characteristics of aluminum corrugated siding panels. Our technical support team provides detailed installation guidance that addresses critical aspects including substrate preparation, fastener selection and placement, lap joint configuration, and thermal movement accommodation. The exposed fastener system utilized with corrugated profiles requires careful attention to fastener engagement and washer compression to ensure weather-tight penetrations while avoiding over-driving that could damage the panel coating or create localized stress concentrations. Panel installation typically begins at the lowest elevation and progresses upward, with each successive course overlapping the previous layer to direct water away from the building envelope. Side lap joints should be positioned to face away from prevailing wind directions, minimizing the potential for wind-driven moisture infiltration. Our engineering documentation specifies minimum overlap dimensions based on roof slope, exposure classification, and local climate conditions. For applications involving aluminum corrugated siding panels in high-wind coastal environments, additional fasteners or clip attachments may be recommended to ensure adequate load transfer and prevent panel uplift during severe weather events. The thirty-year warranty provided with our premium PVDF-coated corrugated aluminum siding panels reflects our confidence in long-term material performance. This comprehensive warranty coverage protects against excessive chalking, fading, peeling, cracking, or other coating degradation that might occur under normal exposure conditions. The warranty terms specify periodic inspection intervals and recommended maintenance procedures that help ensure optimal appearance retention throughout the panel service life. Simple maintenance requirements include periodic cleaning with mild detergent solutions to remove accumulated dirt, pollen, or atmospheric deposits that could otherwise detract from visual appeal. Unlike many alternative cladding materials, aluminum corrugated siding panels do not require periodic repainting, staining, or protective treatment application, resulting in substantially lower lifecycle maintenance costs.

Design Integration and Aesthetic Versatility

The architectural flexibility inherent in aluminum corrugated siding panels enables creative design solutions that range from subtle background surfaces to bold visual statements. The distinctive corrugated profile adds texture and shadow lines that create visual interest without requiring complex detailing or expensive fabrication processes. This profile can be installed with corrugations oriented either horizontally or vertically, providing designers with options to emphasize different building proportions or align with adjacent architectural elements. Color blocking strategies that combine multiple colors of corrugated aluminum siding panels within a single facade composition can delineate functional zones, create visual rhythm, or reinforce corporate branding elements. Our project design support team collaborates with architects during the design development phase to evaluate color combinations, assess visual impact through digital renderings, and confirm technical feasibility of proposed panel arrangements. This collaborative approach ensures that aesthetic aspirations align with constructability requirements and budget parameters. The integration of corrugated aluminum siding panels with other building envelope components including windows, doors, and different cladding materials requires careful coordination of tolerances, thermal movement characteristics, and moisture management details. Our technical documentation includes standard details for common interface conditions, while our design team remains available to develop custom solutions for unique project requirements. This comprehensive support infrastructure, combined with our one-stop service model encompassing design assistance, precision manufacturing, and installation guidance, streamlines the specification and procurement process for architectural professionals and construction managers.

Conclusion

Strategic selection of color and finish systems for aluminum corrugated siding panels fundamentally determines project success, encompassing aesthetic satisfaction, lifecycle performance, and investment protection across decades of service.

Cooperate with Xi'an Huafeng Construction Engineering Co., Ltd.

Xi'an Huafeng Construction Engineering Co., Ltd. stands as a premier China Aluminum Corrugated Siding Panels manufacturer, recognized as a high-tech enterprise since 2020 with first-level building curtain wall qualifications and third-level building steel structure credentials. As a leading China Aluminum Corrugated Siding Panels supplier, our infrastructure includes a 200,000-square-meter raw material production facility in Anhui, plus processing plants in Hangzhou and Xi'an, operating seven color coating lines and over forty specialized machines. We provide High Quality Aluminum Corrugated Siding Panels backed by more than twenty registered patents and ISO9001, ISO14000, and SGS certifications. Our China Aluminum Corrugated Siding Panels wholesale program delivers monthly output exceeding 1,000 tons with competitive Aluminum Corrugated Siding Panels price structures. We offer comprehensive customization services covering color, pattern, and design specifications, with delivery within 15-20 days and a thirty-year warranty on all Aluminum Corrugated Siding Panels for sale. As experienced China Aluminum Corrugated Siding Panels factory partners to Fortune 500 companies, we provide complete one-stop solutions from design optimization and raw material testing through production and installation support. Contact us at huafeng@hfmetalroof.com to discuss your project requirements and discover how our engineering expertise and manufacturing excellence can elevate your building envelope performance.

References

1. Anderson, James M. "Advanced Coating Technologies for Architectural Metal Panels." Journal of Architectural Engineering, Volume 28, Issue 3, 2023.

2. Chen, Wei and Thompson, Sarah. "Color Stability and Weathering Performance of PVDF and Polyester Coatings on Aluminum Substrates." Materials Performance and Characterization, Volume 12, 2024.

3. International Building Code Council. "Metal Building Envelope Systems: Design, Specification and Installation Standards." Fourth Edition, 2024.

4. Rodriguez, Maria and Singh, Rajesh. "Lifecycle Cost Analysis of Premium vs. Standard Coating Systems for Commercial Cladding." Construction Economics Review, Volume 41, 2023.

5. Wilson, David et al. "Thermal Performance and Energy Efficiency Implications of Color Selection in Metal Building Facades." Building Science and Technology, Volume 39, Issue 2, 2024.