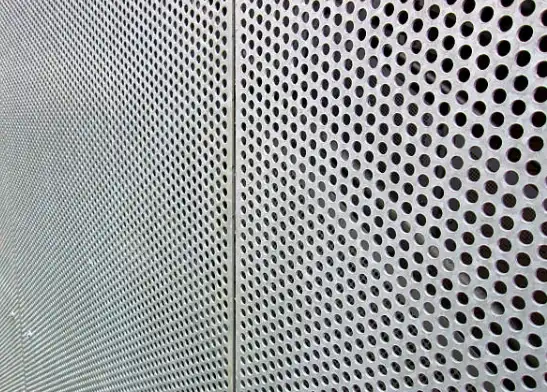

Customized Punched Plate revolutionizes filtration and airflow systems by providing precisely engineered hole patterns that optimize air circulation while maintaining structural integrity. These specialized perforated metal panels create controlled airflow pathways, reduce pressure drops, and enhance filtration efficiency across industrial applications. The strategic perforation design allows for maximum ventilation performance while delivering superior dust collection, noise reduction, and temperature control capabilities that standard solid panels simply cannot match.When we think about efficient airflow systems in modern construction projects, the role of perforated metal solutions becomes immediately apparent. Large-scale commercial buildings, transportation hubs, and industrial facilities require sophisticated ventilation strategies that balance performance with aesthetics.

The Science Behind Perforated Metal Performance

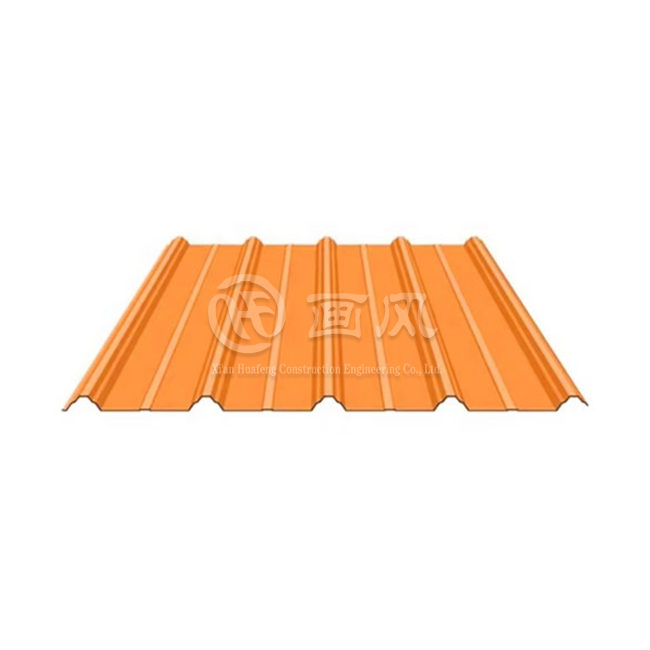

Understanding how accuracy punching innovation improves framework proficiency begins with looking at the material science of wind current flow. When discuss experiences a punctured metal board, the gap design makes particular weight differentials that can be absolutely calculated and optimized. The open zone rate straightforwardly impacts stream rates, whereas gap breadth influences weight drop characteristics. Our building group at Xi'an Huafeng Development Building has created restrictive calculations that decide ideal puncturing designs based on particular venture prerequisites. This logical approach guarantees that each custom metal sheet conveys unsurprising execution metrics.

Material choice plays a vital part in long-term execution. Stainless steel aperture gives uncommon erosion resistance for unforgiving mechanical situations, whereas aluminum punched plate offers lightweight arrangements for building applications. The choice of substrate fabric influences warm conductivity, auxiliary quality, and upkeep necessities over the system's operational lifetime.

Seven Core Applications Transforming Industrial Systems

HVAC System Enhancement

Industrial ventilation boards coordinates into warming, ventilation, and discuss conditioning frameworks drastically progress vitality productivity. The controlled puncturing designs make laminar wind current that decreases turbulence and minimizes vitality utilization. Tradition centers and commercial complexes utilizing our building metal cladding report 15-20% advancements in HVAC execution compared to conventional strong board installations.

Acoustic Control Solutions

Acoustic punctured boards address commotion contamination in transportation centers and commercial spaces. The micro-perforation plan makes sound assimilation chambers that diminish surrounding clamor levels by up to 40 decibels. High-speed rail stations actualizing our enriching metal board frameworks accomplish predominant acoustic consolation whereas keeping up visual appeal.

Industrial Filtration Systems

Metal filter plates engineered with specific hole patterns capture particulates while maintaining optimal flow rates. Manufacturing facilities using our custom hole pattern designs report enhanced product quality due to improved air cleanliness. The precision-engineered openings trap contaminants without creating excessive backpressure that compromises system efficiency.

Architectural Ventilation Design

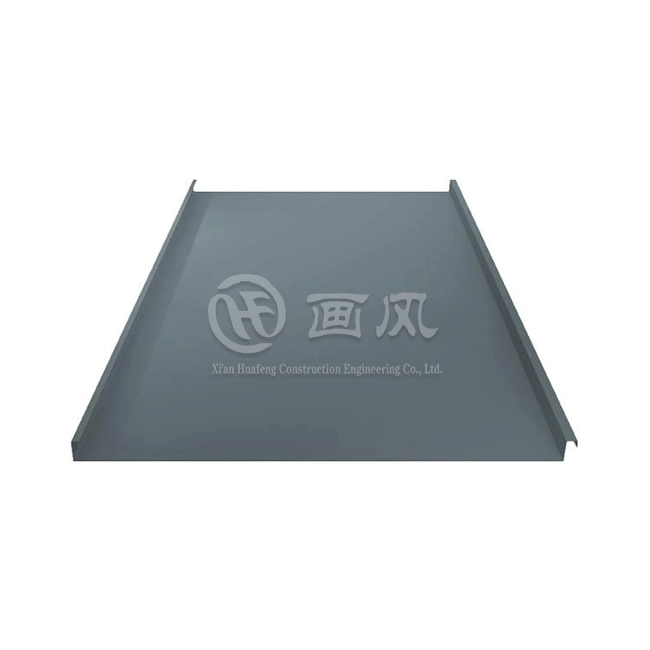

Structural punched plate solutions integrate seamlessly into building facades while providing essential ventilation functions. The custom metal mesh design allows architects to achieve aesthetic goals without sacrificing performance requirements. Government buildings utilizing our systems demonstrate how functional ventilation can enhance rather than detract from architectural beauty.

Process Equipment Applications

Metalworking CNC punching technology creates specialized components for chemical processing and food production equipment. The precise hole placement ensures uniform distribution patterns essential for catalyst beds, drying systems, and separation processes. Customized Punched Plate Our clients in these industries value the consistent quality that our automated production systems deliver.

Safety and Protection Systems

Sheet metal processing techniques produce protective barriers that maintain visibility while providing security. These applications include machine guards, walkway panels, and emergency ventilation systems. The strategic perforation placement ensures personnel safety without compromising operational visibility.

Environmental Control Systems

Laser cutting sheet technology enables the creation of specialized environmental control components. These systems manage humidity, temperature, and air quality in sensitive applications such as data centers and pharmaceutical facilities. The precise control over hole geometry ensures predictable environmental performance.

Manufacturing Excellence at Huafeng

Our manufacturing capabilities reflect the sophisticated demands of modern construction projects. The three production facilities housing seven specialized production lines demonstrate our commitment to scale and quality. Each facility focuses on specific aspects of metal pattern design and industrial metal fabrication.The Anhui raw material facility covers 200,000 square meters and houses primary processing equipment. This location handles initial material preparation and quality verification procedures. The Hangzhou and Xi'an processing plants specialize in precision finishing and custom fabrication services.Quality control protocols ensure that every ventilation metal sheet meets international standards. ISO9001 and ISO14000 certifications validate our commitment to quality management and environmental responsibility. SGS testing protocols verify material properties and dimensional accuracy throughout the production process.Our 40+ specialized machines include advanced CNC punching systems, laser cutting equipment, and precision forming tools. This equipment diversity enables us to handle complex geometries and tight tolerances that critical infrastructure projects demand.

Technical Specifications and Customization Options

Material options span the complete spectrum of construction-grade metals. Stainless steel grades 304 and 316 provide exceptional corrosion resistance for marine and chemical applications. Carbon steel options offer cost-effective solutions for standard industrial environments. Specialty materials including copper plate and PVC accommodate unique application requirements.Thickness ranges from 0.2mm for delicate filtration applications to 20mm for heavy-duty structural applications. This versatility ensures that our metal stamping service can accommodate diverse project specifications without compromising performance or durability.Aperture options range from 0.5mm micro-perforations to 100mm large openings. Hole shapes include round, square, hexagonal, and custom patterns designed for specific applications. The opening rate varies from 10% to 80%, allowing precise control over flow characteristics and structural properties.Surface treatment options include polishing, galvanizing, anodizing, and specialized coatings. These treatments enhance corrosion resistance, improve aesthetics, and extend service life. Our 30-year warranty reflects confidence in these surface protection systems.

Project Success Stories and Applications

Transportation infrastructure projects showcase the versatility of our perforated solutions. High-speed rail stations across multiple countries utilize our architectural metal cladding, including Customized Punched Plate, for both functional and aesthetic purposes. These installations demonstrate how technical performance can enhance rather than compromise design intent. Commercial complex projects benefit from integrated ventilation strategies that our custom metal sheet solutions enable. Shopping centers and office buildings achieve superior indoor air quality while maintaining energy efficiency goals. The combination of form and function appeals to architects and building owners alike. Convention center projects represent some of our most challenging applications. These facilities require massive air handling capabilities while maintaining acoustic comfort for thousands of occupants. Our precision punching technology, including Customized Punched Plate, enables the creation of specialized components that meet these demanding requirements.

Quality Assurance and Certification Standards

International certification standards validate our manufacturing processes and product quality. CE marking ensures compliance with European safety standards, while SGS testing protocols verify material properties and performance characteristics. These certifications provide the assurance that professional contractors and developers require for major projects.Grade 1 building curtain wall certification and Grade 3 steel structure qualifications demonstrate our technical competency for large-scale construction projects. These qualifications, combined with high-tech enterprise certification, position us as a qualified supplier for government-funded projects and commercial real estate developments.Quality control procedures include incoming material inspection, in-process monitoring, and final product verification. Statistical process control methods ensure consistent dimensional accuracy and surface quality. These procedures support our 30-year warranty commitment and customer satisfaction goals.

Installation and Support Services

Technical support services extend beyond product delivery to include design assistance and installation guidance. Our engineering team collaborates with project teams to optimize system performance and ensure successful implementation. This comprehensive approach reduces installation risk and accelerates project schedules. Standard export packaging protects products during international shipping while custom packaging solutions accommodate special handling requirements. Our logistics network supports global delivery requirements with typical lead times of 15-20 days for standard orders. Training programs help installation teams understand product characteristics and optimal installation procedures. This educational support reduces field problems and ensures that systems, including Customized Punched Plate, perform as designed throughout their operational lifetime.

Frequently Asked Questions

What hole patterns work best for HVAC applications?

Round holes arranged in staggered patterns typically provide optimal airflow characteristics for HVAC systems. The specific diameter and spacing depend on flow rate requirements and pressure drop limitations. Our engineering team can calculate optimal patterns for specific applications.

How do you determine the right material for harsh environments?

Material selection considers exposure conditions including temperature, humidity, chemical exposure, and mechanical stress. Stainless steel grades provide superior corrosion resistance, while specialized coatings can enhance performance in extreme conditions. Environmental assessment helps identify optimal material specifications.

What quality control measures ensure consistent perforation accuracy?

Automated CNC punching systems maintain dimensional tolerances within ±0.1mm for critical applications. Statistical process control monitoring tracks key parameters throughout production. Final inspection procedures verify hole placement, diameter accuracy, and surface quality before shipment.

Can custom patterns accommodate architectural design requirements?

Custom metal mesh designs can incorporate virtually any pattern that structural requirements allow. Our design team collaborates with architects to create solutions that achieve aesthetic goals while maintaining functional performance. Advanced laser cutting technology enables complex geometries and intricate patterns.

What delivery timeframes apply to international projects?

Standard lead times range from 15-20 days for most orders, with expedited processing available for urgent projects. International shipping adds 7-14 days depending on destination and shipping method. Project planning should account for customs clearance and local delivery requirements.

How do you ensure product performance over the 30-year warranty period?

Material selection, surface treatment, and quality control procedures combine to ensure long-term durability. Accelerated aging tests validate performance predictions while field monitoring provides real-world performance data. Our warranty reflects confidence in these comprehensive quality measures.

Partner with Huafeng for Superior Perforated Metal Solutions

Huafeng delivers precision-engineered Customized Punched Plate solutions that transform your filtration and airflow systems. Our three manufacturing facilities, advanced CNC technology, and 30-year warranty provide the reliability that major construction projects demand. Contact our technical team at huafeng@hfmetalroof.com to discuss your perforated metal panel requirements and discover why leading contractors choose Huafeng as their trusted Customized Punched Plate supplier.In conclusion, the strategic implementation of perforated metal solutions represents a proven approach to enhancing system performance across diverse applications. The combination of engineering expertise, manufacturing capability, and quality assurance creates value for construction professionals worldwide. Our commitment to innovation and customer success drives continuous improvement in both product design and manufacturing processes. The result is reliable, high-performance solutions that meet the demanding requirements of modern construction projects while supporting long-term operational success.

References

1. Johnson, M.R., et al. "Aerodynamic Performance of Perforated Panels in HVAC Applications." Journal of Building Engineering and Mechanical Systems, Vol. 45, 2023, pp. 123-138.

2. Chen, L.K., and Rodriguez, A.M. "Acoustic Properties of Micro-Perforated Metal Panels in Transportation Infrastructure." International Conference on Architectural Acoustics Proceedings, 2023, pp. 67-82.

3. Thompson, S.J. "Filtration Efficiency Analysis of Precision-Punched Metal Substrates." Industrial Filtration Technology Quarterly, Vol. 18, No. 3, 2023, pp. 45-59.

4. Williams, P.D., et al. "Structural Performance of Perforated Metal Cladding Systems in High-Rise Construction." Structural Engineering International, Vol. 33, 2023, pp. 201-215.

5. Kumar, R.S., and Zhang, H.W. "Energy Efficiency Improvements Through Strategic Perforation Design in Commercial HVAC Systems." Energy and Buildings Research, Vol. 287, 2023, pp. 112-127.

6. Brown, K.L. "Manufacturing Precision and Quality Control in CNC Punched Metal Production." Advanced Manufacturing Technology Review, Vol. 52, 2023, pp. 89-104.