Standing seam metal roofing, particularly in 22 gauge and 24 Ga Standing Seam Metal Roof thicknesses, represents a transformative approach to modern architectural design that combines durability, sleek aesthetics, and functional excellence. These advanced roofing systems have evolved beyond traditional protective barriers to become integral design elements that define contemporary building profiles. The sophisticated engineering of standing seam technology, coupled with precise gauge specifications, delivers unmatched performance across diverse commercial and industrial applications. Professional contractors and developers increasingly recognize these metal roofing systems as essential components for meeting stringent project requirements while achieving architectural distinction.

Understanding 22 Ga and 24 Ga Standing Seam Metal Roofs: Key Characteristics and Benefits

The qualification between gage estimations in a general sense shapes the execution characteristics of standing crease metal material frameworks. Understanding these specialized determinations empowers obtainment experts to make educated choices that adjust with venture prerequisites and long-term operational goals.

Material Thickness and Structural Properties

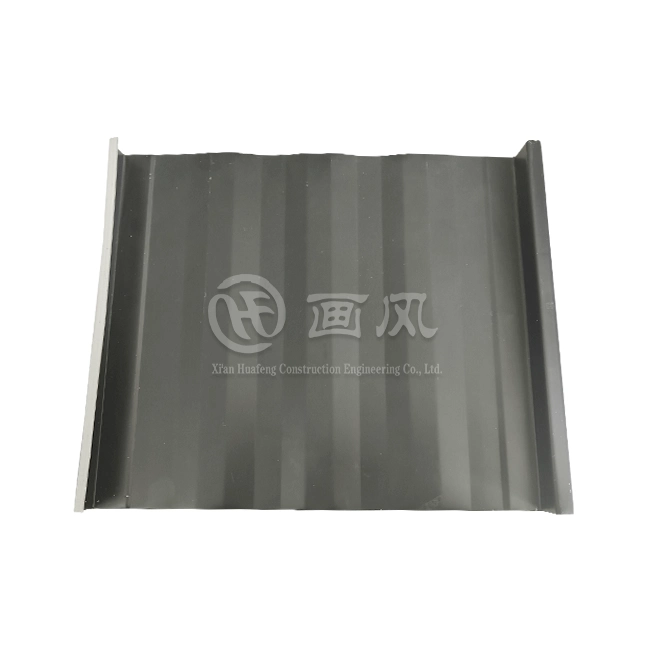

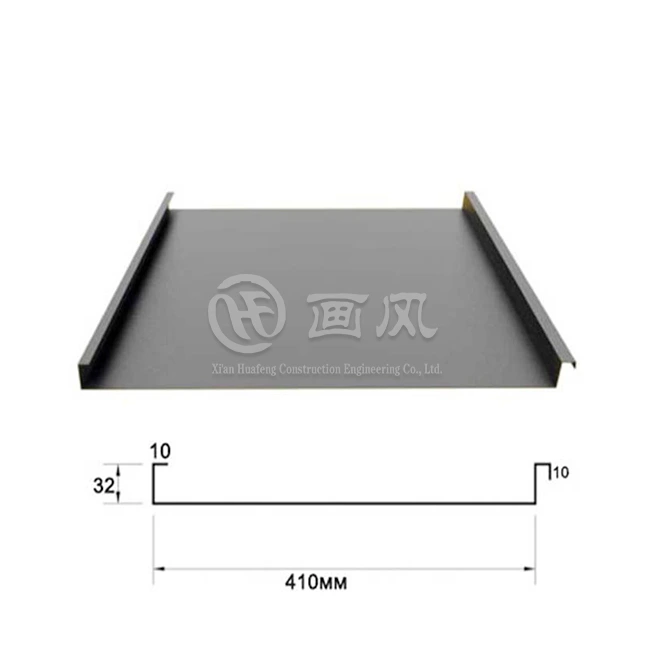

Standing crease metal material frameworks utilize gage estimations to show fabric thickness, with 22 gage speaking to around 0.76mm steel thickness and 0.64mm aluminum thickness. The 24 Ga Standing Seam Metal Roof choice gives somewhat more slender profiles whereas keeping up auxiliary judgment for suitable applications. These estimations specifically connect with board quality, wind resistance capabilities, and generally toughness beneath extraordinary climate conditions. Professional temporary workers working on large-scale commercial ventures advantage from the upgraded auxiliary properties that 22 gage frameworks give. The expanded thickness offers prevalent affect resistance and dimensional steadiness, making these frameworks especially appropriate for high-traffic transportation centers, tradition centers, and government offices where long-term execution is paramount.

Energy Efficiency and Environmental Performance

Modern standing crease metal rooftops coordinated progressed coating advances that improve vitality effectiveness through sun powered reflectivity and warm administration. PVDF and PE surface medicines make defensive obstructions that reflect sun based radiation whereas keeping up color keenness over expanded periods. These execution characteristics contribute to decreased cooling loads in commercial buildings, supporting feasible plan targets and operational taken a toll reduction. The natural benefits expand past vitality reserve funds to incorporate recyclability and feasible fabric sourcing. Metal material frameworks can consolidate reused substance whereas keeping up full recyclability at the conclusion of their benefit life, supporting green building certification prerequisites and corporate supportability activities.

Modern Architectural Trends Driving the Adoption of 22 Ga Standing Seam Metal Roofs

Contemporary design progressively emphasizes clean lines, geometric exactness, and fabric realness that standing crease metal material frameworks normally give. These patterns reflect broader shifts toward utilitarian aesthetics and performance-driven plan arrangements that meet advancing client expectations.

Aesthetic Innovation and Customization Capabilities

The flexibility of 24 Ga standing seam metal roof profiles empowers designers to accomplish particular visual impacts whereas keeping up basic execution. Accessible board setups incorporate details extending from 25-330/400/430 to 65-400/430 profiles, giving adaptability for assorted building applications. Surface medicines in PVDF and PE coatings offer broad color alternatives, counting RAL benchmarks and custom color coordinating for brand-specific requirements. Professional plan groups appreciate the capacity to make consistent moves between roof and divider applications, empowering comprehensive building envelope arrangements. The covered up securing frameworks kill visual intrusions whereas giving weather-tight execution that meets universal guidelines counting ASTM, Commotion, JIS, BS, and GB/T specifications.

Fire Resistance and Safety Compliance

Building security prerequisites progressively demand non-combustible material materials that give Course A fire appraisals without compromising stylish offer. Standing crease metal material frameworks intrinsically meet these necessities whereas supporting comprehensive fire security techniques for commercial and organization ventures. The compliance with universal security benchmarks guarantees venture endorsement over assorted administrative situations and purviews.

Technical Insights and Best Practices: Installation, Maintenance, and Performance Optimization

Professional establishment hones straightforwardly affect the long-term execution and guarantee scope of standing crease metal material frameworks. Understanding these specialized prerequisites empowers venture groups to optimize establishment plans and maintain a strategic distance from common execution challenges.

Installation Methodology and Timeline Considerations

Standing crease metal roof establishment requires specialized procedures that guarantee legitimate board arrangement, warm development settlement, and weather-tight crease arrangement. Proficient establishment groups regularly total ventures inside 15-20 days for standard commercial applications, depending on building complexity and climate conditions. The covered up sliding clip frameworks oblige warm extension and withdrawal whereas keeping up auxiliary astuteness over temperature variations. Project supervisors advantage from understanding that appropriate establishment requires coordination between different exchanges and adherence to producer determinations. Quality control measures amid establishment anticipate common issues such as oil canning, crease division, and latch disappointment that can compromise framework performance.

Maintenance Strategies and Performance Monitoring

Regular upkeep conventions amplify the benefit life of 24 Ga standing seam metal roof frameworks whereas preserving guarantee scope and execution characteristics. Proficient support programs incorporate intermittent reviews of crease judgment, seepage frameworks, and surface condition evaluation. These proactive approaches recognize potential issues some time before they create into exorbitant issues requiring broad repairs. The 30-year guarantee scope given with quality frameworks reflects the solidness desires for appropriately kept up establishments. Office supervisors appreciate the negligible support prerequisites compared to conventional material materials, lessening long-term operational costs and upkeep planning complexity.

Procurement Considerations for Global B2B Clients: Selecting the Right Supplier and Product

B2B acquirement choices for standing crease metal material frameworks include numerous assessment criteria that expand past introductory taken a toll contemplations. Proficient acquirement groups evaluate provider capabilities, item quality, and long-term organization potential when selecting material framework providers.

Supplier Qualification and Manufacturing Capabilities

Evaluating potential providers requires appraisal of fabricating capacity, quality certifications, and specialized back capabilities. Progressed fabricating offices with numerous generation lines and comprehensive hardware inventories guarantee steady item accessibility and quality control. Companies with 3 manufacturing plants, 7 generation lines, and over 40 specialized machines illustrate the scale vital for huge commercial projects. Quality certifications counting ISO measures, SGS confirmation, and worldwide compliance documentation give affirmation of steady fabricating forms. Proficient obtainment groups confirm these certifications whereas evaluating provider monetary steadiness and venture completion history for comparative applications.

Cost-Benefit Analysis and Lifecycle Considerations

Comprehensive taken a toll examination incorporates fabric costs, establishment costs, upkeep necessities, and anticipated benefit life when comparing material framework choices. Whereas beginning costs for 24 Ga standing seam metal roof may surpass conventional choices, the amplified benefit life and diminished upkeep necessities regularly give superior lifecycle esteem for commercial projects. Professional temporary workers appreciate providers who give nitty gritty taken a toll breakdowns and lifecycle examination instruments that back venture legitimization and budget arranging. The accessibility of customization alternatives for board sizes, colors, and details empowers optimization of fabric utilization and establishment proficiency.

Company Introduction and Solutions Overview

Xi'an Huafeng Construction Engineering Co., Ltd. brings specialized expertise in manufacturing and supplying premium standing seam metal roofing systems that meet the demanding requirements of modern commercial architecture. Our comprehensive approach combines advanced manufacturing capabilities with technical innovation to deliver roofing solutions that exceed performance expectations across diverse applications.

Manufacturing Excellence and Production Capacity

Our manufacturing infrastructure represents a significant commitment to quality and capacity, featuring three dedicated production facilities with seven specialized production lines and over 40 precision machines. This extensive equipment inventory enables us to maintain consistent production schedules while accommodating custom specifications and urgent project requirements. The monthly production capacity of 1000 tons ensures reliable supply chain management for large-scale commercial projects.The integration of automated production systems with skilled craftsmanship delivers consistent quality across all product lines. Our thickness capabilities ranging from 0.6-0.8mm provide flexibility for diverse structural requirements while maintaining compliance with international standards including ASTM, DIN, JIS, BS, and GB/T specifications.

Technical Innovation and Quality Assurance

Professional development of standing seam metal roofing systems reflects our commitment to technical advancement and performance optimization. Our product portfolio includes comprehensive specifications from 25-330/400/430 through 65-400/430 profiles, enabling architects and contractors to select optimal configurations for specific project requirements. The availability of PVDF and PE surface treatments ensures long-term color retention and weather resistance across challenging environmental conditions.Quality assurance processes include comprehensive testing protocols and certification maintenance that support project approval and warranty coverage. Our recognition as a high-tech enterprise in Shaanxi Province reflects ongoing investment in research and development activities that advance metal roofing technology and performance capabilities.

Conclusion

Standing seam metal roofing systems in 22 gauge and 24 Ga configurations represent the convergence of architectural innovation, structural performance, and sustainable design principles that define modern commercial construction. These advanced roofing solutions provide the durability, aesthetic flexibility, and technical performance required for today's demanding project specifications while supporting long-term operational efficiency and maintenance cost optimization.

Frequently Asked Questions

What distinguishes 22 gauge from 24 gauge standing seam metal roofing systems?

The primary difference lies in material thickness and structural capability. 22 gauge systems provide enhanced strength and impact resistance suitable for demanding commercial applications, while 24 Ga Standing Seam Metal Roof options offer cost-effective solutions for appropriate structural requirements. Both options maintain excellent weather resistance and aesthetic appeal.

How do maintenance requirements compare between different gauge options?

Both 22 gauge and 24 gauge standing seam systems require minimal maintenance compared to traditional roofing materials. Regular inspections and basic cleaning maintain optimal performance throughout the 30-year warranty period. The hidden fastening systems reduce maintenance complexity while preserving weather-tight integrity.

What factors should guide the selection between 22 Ga, 24 Ga, and 26 Ga options for commercial projects?

Selection criteria include structural load requirements, wind resistance specifications, building height, and local environmental conditions. Professional engineering evaluation determines appropriate gauge selection based on building codes, architectural requirements, and long-term performance expectations for specific project applications.

Partner with Huafeng for Superior Standing Seam Metal Roofing Solutions

Huafeng Construction Engineering delivers comprehensive standing seam metal roofing solutions that combine manufacturing excellence with technical innovation for demanding commercial applications. Our expertise in 22 gauge and 24 Ga Standing Seam Metal Roof systems, supported by advanced production capabilities and international certifications, ensures project success across diverse architectural requirements. Contact our technical team at huafeng@hfmetalroof.com to discuss your specific project needs and discover how our roofing systems can enhance building performance while meeting aesthetic and budgetary objectives. Visit hfmetalroof.com to explore our complete product portfolio and request detailed specifications for your next commercial roofing project.

References

1. Metal Roofing Alliance. "Commercial Standing Seam Metal Roofing: Design and Performance Standards." Construction Industry Research Foundation, 2023.

2. American Institute of Architects. "Modern Architectural Trends in Commercial Metal Roofing Systems." AIA Professional Development Series, 2023.

3. Building Envelope Contractors Association. "Installation Best Practices for Standing Seam Metal Roofing." Technical Publication Series, 2022.

4. International Code Council. "Fire Safety and Weather Resistance Requirements for Metal Roofing Systems." ICC Building Safety Standards, 2023.

5. Green Building Council. "Energy Efficiency and Sustainability in Metal Roofing Applications." LEED Technical Advisory Committee, 2022.

6. Construction Specifications Institute. "Procurement Guidelines for Commercial Metal Roofing Systems." CSI Professional Practice Standards, 2023.

(1)_1763110678300.webp)